Blog

Spray Foam Insulation Installation Cost: How Much to Budget

When you start looking at spray foam insulation installation costs, you'll typically see numbers falling somewhere between $1,453 and $4,333 for an average home project. While that might seem like a wide range, it’s a smart investment in a high-performance thermal barrier that seriously improves your home’s energy efficiency and comfort, especially in our tough South Florida climate.

Breaking Down Your Initial Investment

Getting a handle on the numbers in a spray foam quote is the first step toward making a great decision for your home. Unlike traditional insulation that comes in pre-cut batts, spray foam is a liquid applied on-site. It expands on contact, creating a completely seamless and airtight seal. This custom application is a big reason for the higher upfront cost, but it's also where all the performance benefits come from.

Think of it this way: you could buy a generic, off-the-rack jacket, or you could get a winter coat tailored to fit you perfectly. Both keep you warm, but only the tailored one leaves zero gaps for cold air to sneak in. Spray foam does the exact same thing for your home, sealing all the tiny cracks and crevices that let your cool, conditioned air escape and our hot, humid air creep inside.

Average Project Costs in South Florida

For most homeowners around here, a professional spray foam installation lands at about $2,886, which covers both materials and the crew's labor. The pricing is usually broken down per board foot—a 12" x 12" x 1" area—with rates typically between $0.60 and $3.10. This price reflects the premium nature of the material and its proven ability to deliver big energy savings over time. You can read more about these average insulation costs and see how they can dramatically improve your home.

This initial investment isn't just for the foam itself. You're also paying for the expertise needed to apply it safely and correctly. A professional installer makes sure the right thickness is used to hit the target R-value, all while following strict safety protocols.

A well-executed spray foam project is more than just an expense; it’s an upgrade to your home's entire building envelope, directly impacting your comfort and monthly energy bills for years to come.

To give you a clearer picture, here’s a quick look at typical project costs you can expect here in South Florida.

Estimated Spray Foam Insulation Costs in South Florida

This table gives a general idea of what to budget for insulating different parts of your home. It's a great starting point for planning your project.

| Project Area | Typical Cost Range | Best For |

|---|---|---|

| Attic Insulation | $2,000 – $6,000 | Preventing heat gain, reducing HVAC strain, and lowering bills. |

| Wall Insulation | $2,500 – $7,500+ | New construction or major renovations for maximum air sealing. |

| Garage Insulation | $1,500 – $4,000 | Climate control for workshops or protecting stored items. |

Keep in mind, these are just ballpark figures. The final price tag will always depend on your home's specific needs, the type of foam you choose, and the complexity of the job.

Decoding the Key Factors That Drive Your Project Cost

No two spray foam insulation quotes are ever the same, and that's a good thing. The final price is a blend of several crucial variables that tell the story of your specific project. Understanding what goes into a quote helps you see the real value behind each line item, not just the bottom-line number.

The biggest driver of your cost? The type of foam you choose. This is the foundation of the entire project, determining the material's density, how it performs, and its price per board foot.

Open-Cell vs. Closed-Cell Foam

Think of it this way: you have two main options, and they behave very differently.

Open-cell foam is like a dense sponge. Its structure is made of tiny, interconnected cells that aren't completely sealed. This makes it light, soft, and flexible—great for dampening sound between floors or in home theaters. It’s the less expensive option, but it has a lower R-value (insulating power) per inch and can hold onto moisture if exposed to it.

Closed-cell foam, on the other hand, is like a solid block of hard rubber. Its cells are packed tightly together and completely sealed off from one another. This creates an incredibly dense, rigid material that acts as a powerful barrier against both air and moisture. Because of this superior performance, it's the more expensive of the two.

The choice between open-cell and closed-cell directly shapes your material costs. Expect closed-cell foam to cost 30% to 50% more because of its density and incredible moisture-blocking power—an absolute must-have feature for battling South Florida's humidity.

Insulation Thickness and R-Value

Next up is thickness. How much foam do we need to apply? That all comes down to the R-value your project requires.

R-value is simply a measure of thermal resistance. The higher the R-value, the better the insulation is at stopping heat from moving in or out of your home. Florida building codes have specific minimums for different parts of a house, like requiring R-30 or more for attics.

- Higher R-Value Needs: To hit a higher number like R-30, we have to spray a thicker layer of foam. This naturally uses more material and takes more time.

- Foam Type Matters: This is where the foam choice becomes critical. Closed-cell foam packs a bigger punch, with an R-value of around R-6.5 to R-7 per inch. Open-cell foam comes in at about R-3.5 to R-4 per inch. This means you need a much thinner layer of closed-cell to reach your target R-value.

This difference in performance is a big reason why it’s so important to compare materials properly. If you want to see a full breakdown, check out our guide on spray foam vs blown-in insulation to see how they stack up.

Project Size and Complexity

Of course, the total square footage we're insulating plays a huge role. A 2,500 sq. ft. attic will cost more than a 1,000 sq. ft. one—that's a given. But sometimes, the complexity of the job is just as important as the size.

A straightforward, wide-open space is one thing. But costs can increase when we run into things like:

- Tight Spaces: Working in cramped attics with low rooflines, tight crawl spaces, or hard-to-reach corners demands more time and precision from the crew.

- Numerous Obstructions: Spraying around a maze of trusses, ductwork, plumbing lines, and electrical wiring is far more detailed work than spraying clean, empty wall cavities.

- Site Accessibility: If our truck and equipment can't get close to the work area, it adds to the setup time and labor. Our gear, like the Graco Contractor PC Gun Hose Kit, needs clear access to run efficiently and safely.

Necessary Prep Work

Finally, we have to consider what needs to be done before a single drop of foam is sprayed. If you have old, sagging, or contaminated insulation in the space, it has to go. That removal and disposal is a separate, specialized job that adds to the project total.

More importantly, any moisture problems like roof leaks or existing mold must be completely fixed first. Spray foam needs a clean, dry surface to bond to. Sealing over an unresolved moisture issue is just asking for trouble down the road.

Choosing Between Open-Cell and Closed-Cell Foam

Picking the right type of spray foam is one of the biggest decisions you'll make, and it has a massive impact on both the initial spray foam insulation installation cost and how well it performs for years to come. You’ve got two main players: open-cell and closed-cell. They have totally different structures at a microscopic level, which gives them unique strengths and weaknesses.

Think of it like this: you could fill a gap with either a sponge or a solid rubber block. Both fill the space, right? But they behave very differently when it comes to stopping air and water. That choice is especially crucial here in South Florida, where our relentless humidity means your insulation has to do more than just keep you cool. It has to act as a serious moisture barrier to protect your home from rot and mold.

Open-Cell Foam: The Softer, More Affordable Option

Open-cell foam has a soft, almost spongy texture. The tiny cells inside aren't completely sealed off from each other, which allows the material to "breathe." This structure makes it a fantastic sound-dampening material. We often use it for interior walls or between floors when clients want to cut down on noise traveling through the house.

From a budget standpoint, open-cell is the friendlier choice. It’s less dense, meaning it takes less raw material to make, and that savings gets passed on to you. However, that sponge-like quality is also its biggest weakness in our climate—it can absorb and hold onto water. That makes it a no-go for areas with potential moisture issues, like crawl spaces or basements. You can learn more about the best uses for open-cell spray foam insulation in Palm Beach to see where it really shines.

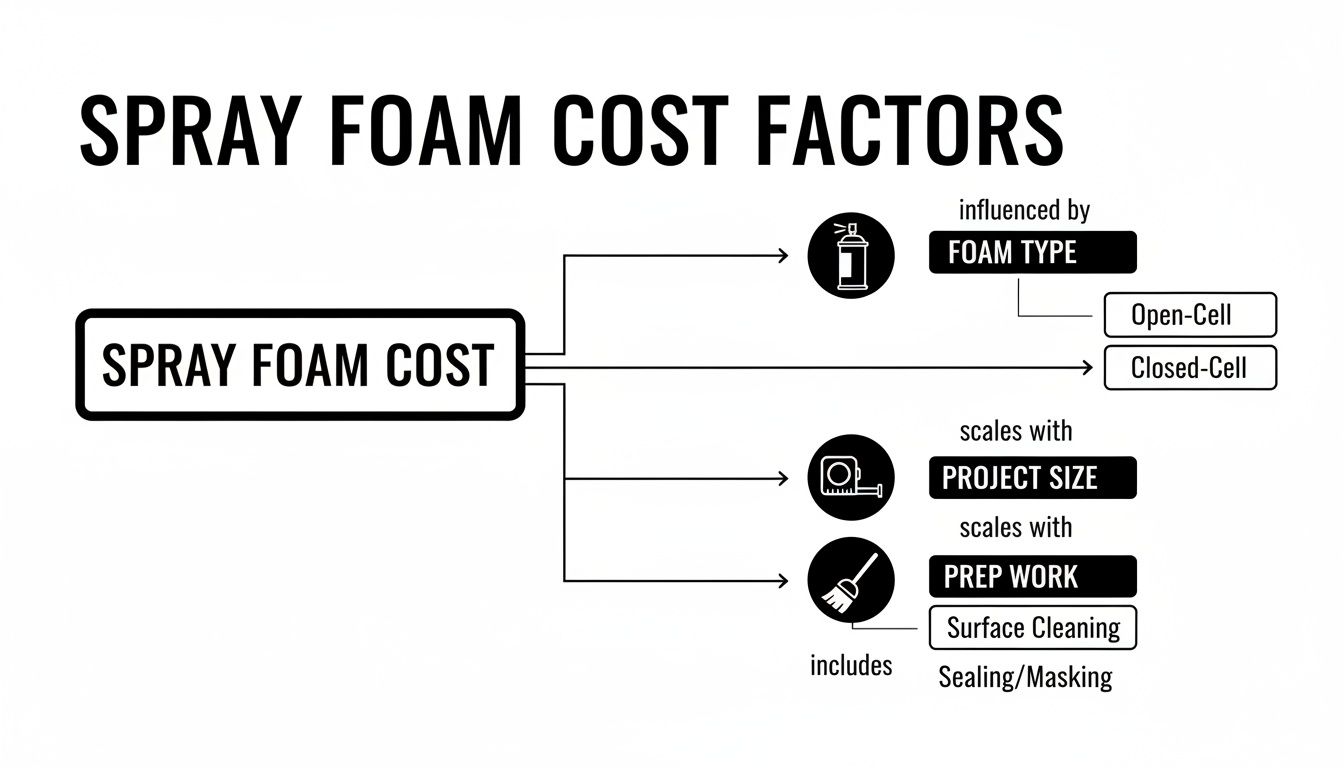

The diagram below breaks down the key factors that go into a quote, with the type of foam you choose being a major piece of the puzzle.

As you can see, the foam type, the size of your project, and the prep work involved are the three pillars that determine your final cost.

Closed-Cell Foam: The High-Performance Barrier

Now, closed-cell foam is a completely different animal. It’s dense, rigid, and incredibly strong. Its cells are totally sealed, creating an impermeable barrier that stops both air and moisture dead in their tracks. It’s an all-in-one insulator, air sealant, and vapor barrier.

That high-performance structure does come with a higher price tag. The spray foam insulation installation cost for closed-cell can be 30-50% more than open-cell because it’s denser and just plain does more. It also packs a much bigger punch in terms of R-value, typically hitting R-6.5 to R-7 per inch, while open-cell is around R-3.5 to R-4. This means you can get the same insulation power with a thinner layer—a huge benefit in walls or tight spots where every inch counts.

For South Florida homes, I almost always recommend closed-cell foam. Its ability to completely block moisture is non-negotiable for preventing the mold, mildew, and structural rot that thrive in our humid air.

This table gives you a quick side-by-side look at the two options to help you see the differences clearly.

Comparing Open-Cell and Closed-Cell Spray Foam

| Feature | Open-Cell Foam | Closed-Cell Foam |

|---|---|---|

| Density & Structure | Soft, flexible, and spongy | Rigid, dense, and strong |

| R-Value (per inch) | R-3.5 to R-4 | R-6.5 to R-7 |

| Moisture Permeability | Permeable (can absorb water) | Impermeable (acts as a vapor barrier) |

| Air Seal | Good | Excellent (creates a true air barrier) |

| Sound Dampening | Excellent | Good |

| Structural Strength | Does not add structural rigidity | Adds significant racking strength to walls |

| Cost | $0.44 to $0.65 per board foot | $1.00 to $2.00 per board foot |

| Best For | Interior walls, soundproofing rooms, budget-conscious projects in dry areas | Attics, exterior walls, roofs, metal buildings, any area needing moisture control |

Ultimately, while open-cell has its place, closed-cell foam is the clear winner for most applications here in South Florida, offering the robust protection our homes need to stand up to the climate.

Putting the Numbers to Work: Real-World Cost Scenarios

The price ranges are a great starting point, but let's be honest—it’s tough to visualize what they mean for your project. The best way to understand the real spray foam insulation installation cost is to walk through a few jobs we see every day here in South Florida.

These scenarios show how the final quote comes together based on the size of the space, the type of foam we use, and any prep work needed. Each one is a classic example of the challenges local homeowners and business owners face in our climate.

Scenario 1: The Leaky, Overheated Attic

First up is a problem we solve all the time: a 1,500 sq. ft. attic in a single-family home that was basically an oven in the summer. The old fiberglass insulation was matted down, full of gaps, and wasn't doing a thing to stop the heat and humid air from pouring in.

The goal was simple: make the upstairs rooms comfortable again and get those FPL bills under control. In our climate, closed-cell foam is the only way to go for an attic, as it's a rock-solid barrier against both air and moisture.

Here’s how the numbers broke down for this game-changing upgrade:

- The Job: Insulate the entire 1,500 sq. ft. attic roof deck.

- The Foam: We used 2 inches of closed-cell foam. This delivers an R-value of about R-14 and, more importantly, creates an airtight vapor barrier.

- Prep Work: Our crew had to remove and haul away all the old, useless fiberglass insulation.

- Final Cost: The project landed in the $4,500 – $6,500 range. That includes everything from prep and disposal to the final spray, giving the homeowners a fully sealed and protected attic.

You can learn more about why this is such a critical upgrade in our guide to attic spray foam insulation in Palm Beach County.

Scenario 2: Getting It Right in a New Construction Home

Next, let's look at a new build—a 2,200 sq. ft. custom home. Here, the builder wanted to create a seriously energy-efficient home right from the start, which is a fantastic move that pays off for decades.

The best time to insulate walls is before the drywall goes up, when we can create a perfect, seamless seal. The choice of foam here is about more than just temperature control; it’s about the home's long-term strength.

In new construction, closed-cell foam does double duty. It not only provides exceptional insulation but also adds significant racking strength to the wall structure, making the entire home more resilient.

Here's what it costs to build it right the first time:

- The Job: Insulate all exterior wall cavities in a 2,200 sq. ft. home.

- The Foam: We applied 3 inches of closed-cell spray foam for maximum R-value and structural reinforcement.

- Prep Work: Almost none. The wall cavities were open, clean, and ready to go.

- Final Cost: The total came to $7,800 – $10,500. It's a key investment, but it's baked into the home's value and sets the stage for a lifetime of lower energy bills.

Scenario 3: Taming a Metal Workshop

Our last example is a 2,000 sq. ft. metal workshop. Anyone who has one knows they become scorching hotboxes in the summer and are prone to "sweating" with condensation when the temperature drops. The owner needed to protect his tools from rust and make the space usable year-round.

For metal buildings, spray foam isn't just the best choice—it's the only real solution. It sticks directly to the metal panels, stopping condensation in its tracks and creating a thermal break that no other insulation can replicate.

Project Breakdown

| Detail | Specification |

|---|---|

| The Job | Insulate the roof and walls of a 2,000 sq. ft. metal building. |

| The Foam | 2 inches of closed-cell spray foam to stop condensation and insulate. |

| Prep Work | We cleaned the metal surfaces and masked off all windows and doors to prevent overspray. |

| Final Cost | $6,000 – $8,500 |

This one-time cost transformed a barely usable shed into a fully functional, climate-controlled workspace, protecting the owner's investment and adding massive value to the property. As you can see, every final price is a direct reflection of the project's unique needs and goals.

Calculating Your Long-Term Return on Investment

It's easy to get focused on the upfront spray foam insulation installation cost, but that's really just the beginning of the story. Once you start looking at the long-term value, the whole conversation changes. Spray foam stops being just another line item on a budget and becomes one of the smartest investments you can make for your home's performance and comfort. This isn't a temporary fix; it's a permanent upgrade to your home's core structure.

Think of it this way: traditional insulation is like laying a blanket over your house. It helps, but there are always gaps. Spray foam is different. It’s like encasing your home in a seamless, protective shell. This airtight seal is the secret sauce behind its incredible performance, especially here in South Florida. It locks in your expensive, conditioned air and, just as importantly, stops our thick, humid air from forcing its way inside.

Slashing Your Monthly Energy Bills

The first, and most satisfying, return you'll see is on your monthly FPL bill. By creating that perfect air seal, your HVAC system can finally stop running a marathon just to keep up. It's no longer fighting a losing battle against the relentless Florida heat, so it can cool your home efficiently and maintain a steady temperature without working overtime.

For most homeowners in our area, this translates into some serious energy savings—often between 20% and 50%. On a blistering summer month, that kind of a drop can make a real difference in your budget. While the initial cost is a factor, spray foam's ability to drive down energy use is a huge benefit. For a deeper dive, you can explore other strategies to reduce utility bills to make your home even more efficient.

This push for efficiency isn't just a local trend. Globally, the spray foam insulation market hit $2.4 billion in 2023 and is only expected to grow as energy prices rise and building codes get stricter. This is especially true in places like South Florida, where high cooling costs are a constant headache for homeowners and commercial property managers alike.

More Than Just Energy Savings

Lowering your bills is a huge win, but the real value of spray foam goes much deeper and unfolds over many years.

- Longer HVAC Lifespan: An overworked air conditioner is a stressed-out air conditioner. When you lighten its daily load, you can seriously extend the life of your expensive HVAC equipment, saving you thousands on a premature replacement.

- Added Structural Strength: When you go with closed-cell foam, you're getting more than just insulation. Its dense, rigid structure bonds directly to studs and sheathing, adding significant racking strength to your walls and roof. This makes your entire home more resilient, especially against high winds.

- Higher Property Value: An energy-efficient home is a hot commodity on the real estate market. When it's time to sell, having professionally installed spray foam is a major selling point that can boost your property's value.

A home with spray foam isn't just cheaper to run—it's also quieter, healthier, and structurally stronger. That combination of benefits makes it a powerful long-term asset that pays you back every single day.

How to Get a Truly Accurate Insulation Quote

Figuring out the real spray foam insulation installation cost shouldn't be a guessing game. If you're getting vague numbers over the phone, that's your first red flag. Any seasoned pro will tell you they need to see the space in person before they can give you a firm price—it's the only way to know what they're truly up against.

Think of it like a doctor’s diagnosis. You wouldn't want a treatment plan based on a phone call, and you shouldn't accept an insulation quote that way either. This in-person visit is where an expert puts their eyes on all the variables we've been talking about, from how tricky it is to access the area to the condition of the existing structure. They'll measure everything precisely, see if old insulation needs to be hauled out, and hunt for hidden air leaks or moisture problems that have to be fixed first.

The On-Site Inspection Is Non-Negotiable

A detailed, on-site inspection is just as much for your protection as it is for the contractor's. It's what ensures the price you're quoted is the price you'll actually pay, wiping out the risk of surprise charges popping up halfway through the job. It also gives the installer the intel they need to create a solid plan, so they show up with the right crew, the right gear, and the right amount of material to get it done right the first time.

During this visit, the contractor will dial in the specifics for your project. They’ll figure out the best type of foam for each area—whether it’s open-cell or closed-cell—and calculate the exact thickness needed to hit Florida's building codes and deliver on those energy savings you're after. This is what turns a ballpark guess into a reliable, tailor-made proposal.

An on-site quote isn't just a formality; it's a mark of a professional, transparent contractor. It shows they're committed to understanding the job completely and giving you a price based on facts, not fiction.

Your Contractor Consultation Checklist

When the estimator walks your property, it's your chance to see what they're made of. Coming prepared with the right questions helps you gauge their expertise and find a partner you can trust. This isn't just about chasing the lowest price; it's about investing in quality work that's going to perform for decades.

Use this checklist during your consultation to make sure you cover all your bases. A confident, experienced contractor won't hesitate to give you clear, straight answers.

Questions to Ask Your Insulation Contractor:

- Experience and Licensing: How long have you been installing spray foam in South Florida? Can I see your license and insurance?

- Materials Used: What brand of foam do you use, and why do you prefer it? Can you provide the material safety data sheets (MSDS)?

- Safety Protocols: What's your plan for protecting my home and family during and after the job, especially regarding ventilation?

- Team and Training: Are your installers certified? Are they your employees or do you use subcontractors?

- Warranty Details: What kind of warranty do you offer on the material and the workmanship? Does it transfer to a new owner if I sell?

- Quoting Process: Is this quote all-inclusive? Does it cover all the prep, cleanup, and disposal of old insulation?

- Timeline and Cleanup: How long will the entire project take? What does your cleanup process look like when you're done?

Asking these questions moves you from someone who's just curious to a truly educated buyer. When you get detailed, transparent quotes from a few pros, you can feel confident you're choosing the right team to make your home more comfortable and efficient.

Of course. Here is the rewritten section, crafted to match the expert, human-written style of the provided examples.

Final Questions Before You Commit

It’s completely normal to have a few last questions before moving forward with a big home improvement project. Let's tackle some of the most common things homeowners ask about the spray foam insulation installation cost and its real-world value, so you can feel confident you’re making the right move for your home in South Florida.

Is Spray Foam Really Worth the Higher Price Tag?

Absolutely. The answer boils down to long-term performance versus a cheap, short-term fix.

Think of it like this: choosing fiberglass is like buying a clunky, inefficient window AC unit. Sure, it’s cheaper today, but you'll pay for it over and over again on your FPL bill. Those initial savings get eaten up fast.

Fiberglass batts are notorious for sagging, getting compressed, and leaving small gaps around wiring and pipes. Every one of those gaps is a tiny leak where your conditioned air escapes and humid air gets in. Your HVAC system has to run constantly just to keep up.

Spray foam is different. It creates a solid, seamless air barrier that becomes part of your home’s structure.

The higher upfront cost of spray foam isn't just a purchase; it's an investment that starts paying you back from the very first month. You aren’t just buying insulation—you’re buying decades of lower energy bills, better air quality, and a much more comfortable home.

How Long Does This Stuff Actually Last?

One of spray foam's biggest selling points is its incredible lifespan. Unlike traditional insulation that breaks down, gets moldy, or needs to be replaced after a few years, spray foam is an inert polymer.

Once it’s professionally installed and cured, it doesn't degrade, shrink, or lose its insulating power (R-value). It just stays put and does its job.

As long as your house is standing and you don't have a catastrophic event like a major roof leak that damages the structure itself, the foam will last for the life of your home. It’s a true “set it and forget it” solution.

Are There Any Tax Credits or Rebates I Can Get?

Yes, and you should definitely take advantage of them. Government incentives can help bring down the net spray foam insulation installation cost. The main one to look into is the Federal Energy Efficient Home Improvement Credit.

This program is designed to reward homeowners for making smart, energy-saving upgrades. Here’s what you need to know:

- Credit Amount: You could be eligible to claim a tax credit of up to $1,200 per year.

- How to Qualify: The insulation product and project must meet specific energy efficiency requirements.

- Documentation: Make sure you keep all your receipts and paperwork. It's always a good idea to chat with a tax professional to make sure you file everything correctly.

By using these incentives, you can make a smart investment even smarter. It shortens the time it takes for the project to pay for itself and gets you a more efficient, comfortable home for less out-of-pocket.

Ready to see what a difference a truly professional installation can make? The team at Airtight Spray Foam Insulation has the hands-on experience to get the job done right, ensuring your home is comfortable and efficient for years to come. Request your free, no-obligation quote today!