Blog

The Ultimate Guide to R Value for Spray Foam Insulation

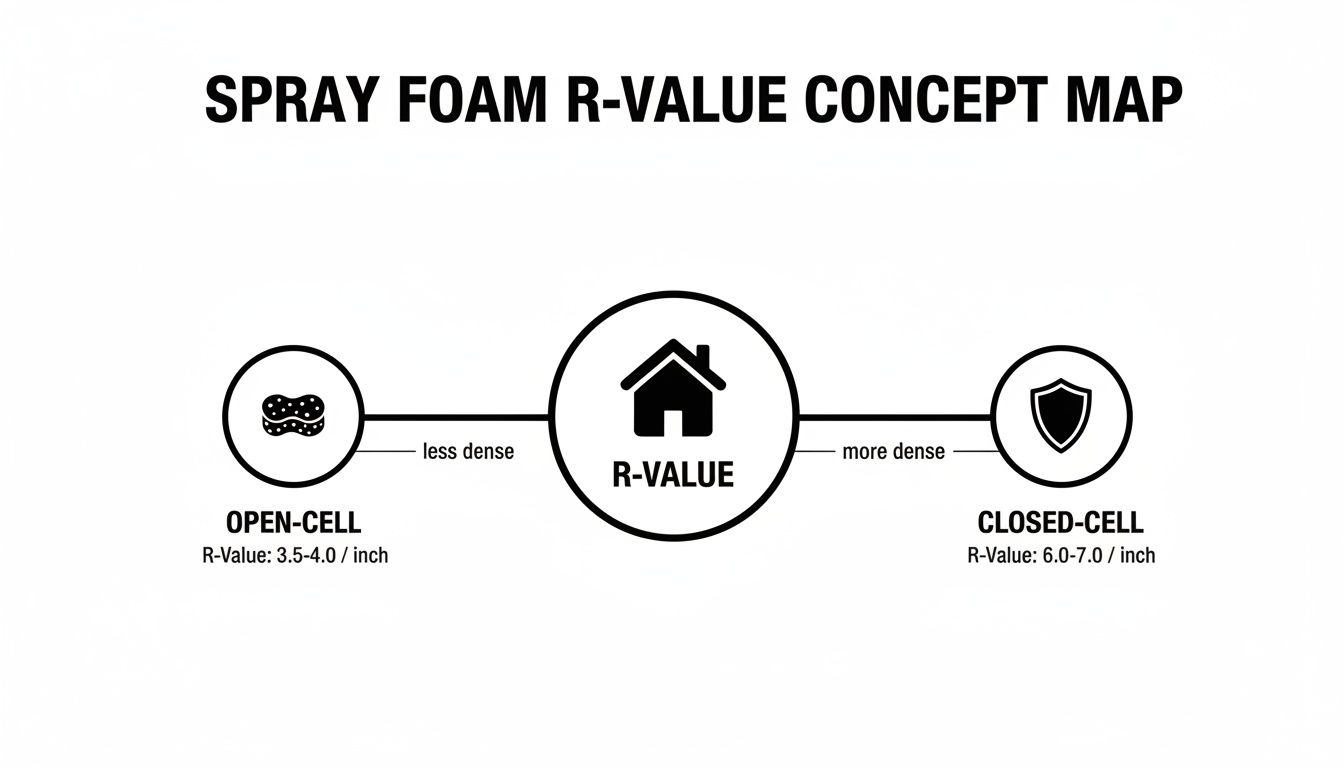

When it comes to spray foam, there’s no single, one-size-fits-all R-value. Instead, you'll find a range. You've got closed-cell spray foam, the heavy-hitter, delivering an impressive R-6.5 to R-7.0 per inch. Then there’s open-cell spray foam, which comes in at a solid R-3.7 per inch. That difference might not seem huge at first glance, but it's a critical factor when planning your home insulation project.

Decoding the R-Value for Spray Foam

So, what exactly is an R-value? Think of it as a "sweater rating" for your house. A higher R-value means the insulation is better at fighting off heat transfer—just like a thick wool sweater keeps you warmer than a thin cotton shirt on a chilly day. In technical terms, it measures thermal resistance: the material’s ability to stop heat from baking your home in the summer and stop your expensive conditioned air from escaping in the winter.

The reason for the R-value range is that spray foam comes in two very different forms, each with its own structure and job to do.

Closed-Cell Spray Foam: Picture a high-tech ski jacket. It’s dense, rigid, and completely impermeable to wind and water. The foam is made of tightly packed, closed cells filled with a special insulating gas. This structure is what gives it that powerful insulating punch of R-6.5 to R-7.0 per inch.

Open-Cell Spray Foam: This is more like a fluffy fleece sweater. It’s light, soft, and flexible, made up of tiny interconnected air pockets. While it’s fantastic for dampening sound, its thermal resistance is lower, typically around R-3.7 per inch.

Getting this fundamental difference is the first step in picking the right insulation for your job. The incredible thermal performance of closed-cell foam has made it a go-to choice, fueling major growth in the spray foam industry. In fact, the global market for spray foam was valued between USD 2.3–3.1 billion in the mid-2020s, with strong growth expected thanks to its superior performance. You can dig into more trends and forecasts for the global spray foam insulation market over on zionmarketresearch.com.

Key Takeaway: The R-value per inch is the number that matters most. A higher number gives you more insulating power in less space. This is precisely why closed-cell foam is often the top choice for walls and roofs, where you need to pack as much insulation as possible into a limited cavity.

Open-Cell vs. Closed-Cell Spray Foam R-Values

When you're looking at spray foam, you've really got two main choices, and they perform in completely different ways. The decision between open-cell and closed-cell foam isn't just about the numbers on a spec sheet; it boils down to their basic structure and how that affects everything from heat resistance to moisture control.

Think of open-cell spray foam as being a lot like a dense sponge. Its cellular structure is broken and interconnected, which makes the final product light, flexible, and somewhat breathable. This sponginess is great for dampening sound, but it also means it can absorb and hold onto moisture if it gets wet.

On the other hand, closed-cell spray foam is more like a solid, waterproof panel. Its cells are packed together tightly and are completely sealed off from one another. This traps a special insulating gas inside, which is what gives it such a high R-value. This dense structure is fantastic at stopping heat transfer and also creates an incredible barrier against both air and moisture.

The image below really breaks down the key differences between these two powerful insulators, showing the direct link between their structure and how they perform.

As you can see, the dense, sealed structure of closed-cell foam (the shield) gives it a much higher R-value. Meanwhile, the porous nature of open-cell foam (the sponge) offers a different set of benefits.

R-Value Per Inch: A Head-to-Head Comparison

The biggest difference you'll see on paper is their insulating power per inch. This is a huge deal, especially when you're working with limited space like the 2×4 or 2×6 framing in your walls.

Open-Cell Spray Foam: This foam typically gives you an R-value of about R-3.7 per inch. Because it's less dense, you need more of it to hit those higher total R-values.

Closed-Cell Spray Foam: This is the heavy hitter, delivering a much higher R-value of R-6.5 to R-7.0 per inch. This superior performance means you can meet or even exceed building code requirements in much shallower spaces.

This incredible thermal resistance is why closed-cell foam has become so popular. Industry analyses consistently show that closed-cell spray polyurethane foam (SPF) offers an R-value around 6.5–7.0 per inch, leaving alternatives like fiberglass in the dust. You can dive deeper into the market data and performance metrics in this building and construction industry analysis.

Performance Differences Beyond Just the R-Value

While the R-value is critical, choosing the right foam involves looking at other vital characteristics that affect your home's health and durability—especially in a humid climate like ours in South Florida.

Putting them side-by-side really shows where each type of foam shines.

Open-Cell vs. Closed-Cell Spray Foam At a Glance

| Characteristic | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value Per Inch | R-3.7 | R-6.5 to R-7.0 |

| Moisture Barrier | Permeable (can absorb water) | Impermeable (blocks water and vapor) |

| Air Barrier | Excellent air seal | Superior air and vapor seal |

| Structural Rigidity | Flexible, adds no strength | Rigid, adds structural strength |

| Sound Dampening | Superior sound absorption | Good sound absorption |

| Application Area | Interior walls, soundproofing | Attics, roofs, exterior walls, tight spaces |

The table makes it clear: while open-cell has its uses, closed-cell foam brings a combination of benefits that are perfectly suited for our climate's challenges.

The Bottom Line: For most jobs in South Florida—especially in attics, on roof decks, and in exterior walls—closed-cell foam is the clear winner. Its high R-value, combined with its ability to completely block moisture and add structural integrity, makes it the ideal solution for protecting your home from our intense heat and humidity.

Factors That Impact Your Real-World R-Value

The R-value printed on an insulation package is a bit like a car's sticker price—it’s a starting point, but it doesn't tell the whole story. It represents performance under perfect, controlled lab conditions. But your home isn't a lab. Real-world variables like temperature swings, humidity, and the quality of the installation itself are what truly determine how your insulation performs day in and day out.

Think of the stated R-value for spray foam as a car's EPA mileage rating. It's a useful benchmark, but your actual results will always vary. When it comes to insulation, the single most critical factor is the quality of the installation. Unlike fiberglass batts, which can be easily compressed, cut poorly, or installed with gaps, spray foam is applied as a liquid that expands to create a perfect, custom-fit, monolithic barrier.

That seamless application is spray foam’s secret weapon.

The Power of the Air Seal

Traditional insulation often fails not because the material is bad, but because air simply moves around it. Tiny gaps and cracks around outlets, plumbing pipes, and framing studs can make even high-R fiberglass nearly useless. In fact, air leakage is one of the biggest energy vampires in a home, driving up heating and cooling costs.

Spray foam solves this problem by creating a nearly impenetrable air seal. It doesn't just resist heat transfer through conduction (the main job of R-value); it flat-out stops heat transfer through convection—the actual movement of hot or cold air.

This is exactly why a wall with R-21 closed-cell spray foam will dramatically outperform a wall with R-21 fiberglass batts. The spray foam stops the drafts and air leaks that fiberglass just can’t handle.

Because of this complete seal, spray foam's "effective" R-value is often far greater than what the number on the label suggests. To get a true picture of your home's energy loss and find where an R-value upgrade would do the most good, a professional home energy audit is your best bet.

Longevity and Thermal Drift

Another thing to consider is how insulation holds up over time. With closed-cell spray foam, there can be a tiny decrease in R-value over many years, a process known as thermal drift. This happens when a minuscule amount of the insulating gas trapped in the foam's cells slowly escapes and is replaced by air.

But here’s the good news: this change is minimal and stabilizes early in the foam’s life. Modern spray foams are engineered for incredible long-term stability. More importantly, their superior performance as an air and moisture barrier stays rock-solid for decades. This durability means you get consistent, reliable energy savings year after year—a benefit other insulation types just can't match. This same air-sealing quality makes it an excellent choice for complex structures; for more detail, check out our guide on the insulation value of concrete block walls and see how spray foam transforms their performance.

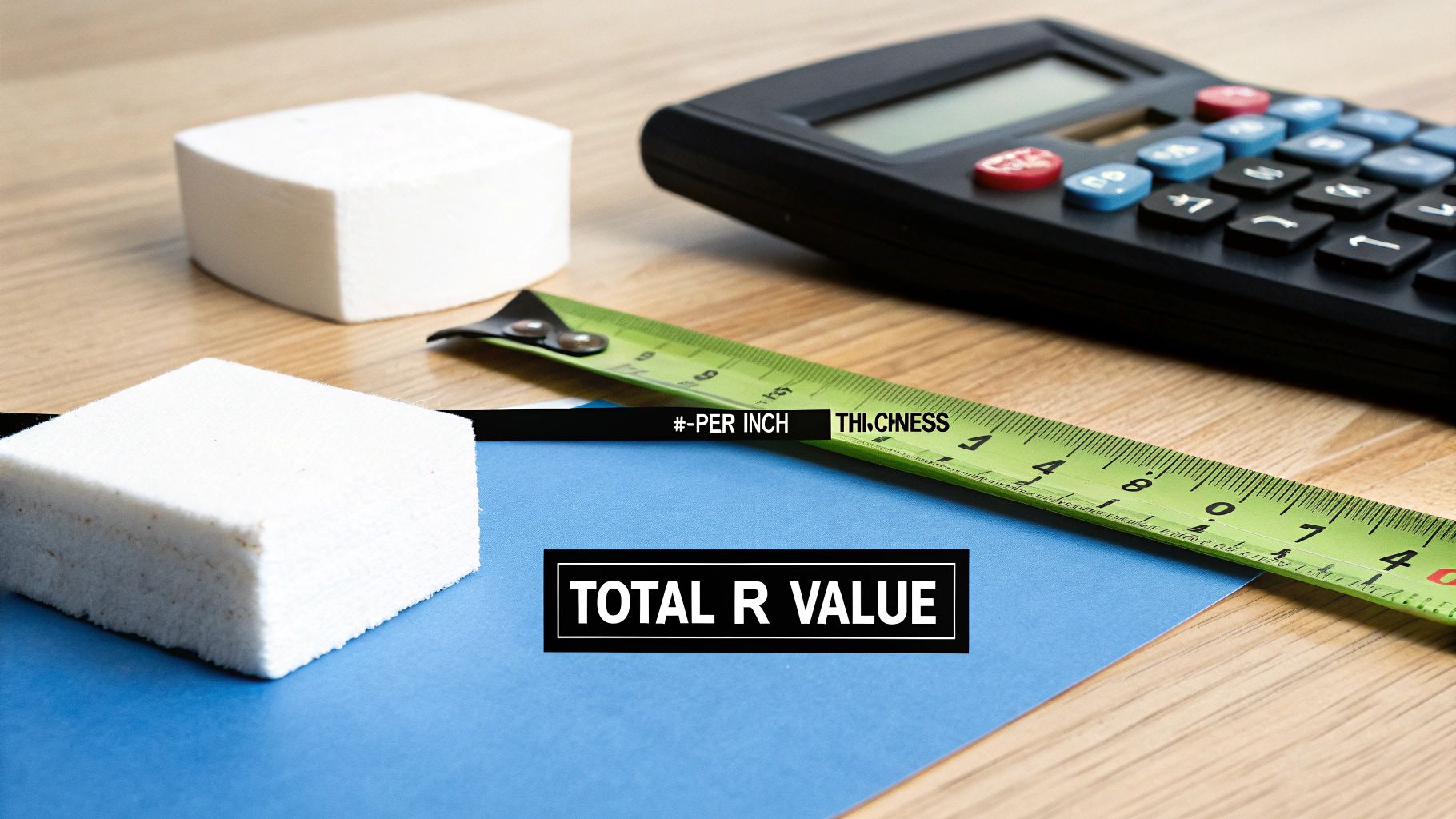

How to Calculate the Total R-Value You Need

Knowing the R-value per inch is a great start, but the real magic happens when you see how that number plays out in your actual project. Figuring out the total thermal resistance you’ll end up with is surprisingly simple, and it’s the key to understanding how just a few inches of spray foam can completely change your home's comfort and energy use. For any project, getting this number right is a must if you want to properly estimate project costs without any guesswork.

The formula is just basic multiplication. You take the foam's R-value per inch and multiply it by how thick you plan to spray it.

(R-Value per Inch) x (Thickness in Inches) = Total R-Value

This little equation removes all the mystery from insulation planning. It turns abstract ratings into a solid target for your walls, attic, or roofline, ensuring your project doesn’t just meet building codes but actually delivers the comfort you're paying for.

Putting the Formula into Practice

Let's run through a quick, real-world scenario to see how this works. Say you're insulating a standard 2×6 exterior wall, which leaves you about 5.5 inches of space to fill. Your main goal is to block out that intense South Florida heat.

- Foam Type: You’ve decided on closed-cell spray foam for its best-in-class thermal performance.

- R-Value Per Inch: We’ll use a solid R-6.5 per inch.

- Calculation: 6.5 (R-Value/Inch) x 5.5 (Inches) = R-35.75

And just like that, you know that filling a 2×6 wall cavity with closed-cell foam gives you an incredible total R-value of nearly R-36. That’s way beyond what traditional insulation can offer in the same space and shows you the raw power of a high r value for spray foam.

Quick Reference for Total R-Values

To help you plan, we put together a simple table showing the total R-value you can expect from different thicknesses of both open-cell and closed-cell spray foam. It's a handy tool for comparing your options on the fly.

Example Total R-Value Calculations for Spray Foam

This table shows the total R-value achieved at different thicknesses for both open-cell and closed-cell spray foam, helping homeowners plan their insulation projects.

| Insulation Thickness (Inches) | Total R-Value (Open-Cell @ R-3.7/inch) | Total R-Value (Closed-Cell @ R-6.5/inch) |

|---|---|---|

| 2 inches | R-7.4 | R-13.0 |

| 3 inches | R-11.1 | R-19.5 |

| 4 inches | R-14.8 | R-26.0 |

| 5 inches | R-18.5 | R-32.5 |

| 6 inches | R-22.2 | R-39.0 |

| 7 inches | R-25.9 | R-45.5 |

Whether you're working with a shallow roof deck or a deep attic floor, this chart makes it easy to figure out exactly how much insulation you'll need to hit your performance goals.

Recommended R-Values for South Florida Climate

Insulating a home in South Florida is a whole different ballgame. Up north, you're trying to keep heat in. Down here, our job is to lock the relentless, humid heat out. Getting the R-value right isn't just about meeting a code; it's your home's primary defense against sky-high cooling bills and our oppressive climate.

Our building codes are designed with one thing in mind: managing heat gain. That's the constant flow of outdoor heat trying to sneak into your nice, cool, air-conditioned space. The attic is the main battlefield, where the sun beats down on your roof all day long, turning it into an oven.

Code Requirements and Performance Targets

Local building codes are there for a reason. They reflect the tough demands of our hot and humid environment and set the minimum standard for an energy-efficient home that can actually stand up to a Florida summer.

- Attics and Roofs: This is the most critical area. Codes require a high R-value, usually between R-30 and R-38, to stop that superheated attic air from radiating down into your living room.

- Exterior Walls: For walls, the target is generally around R-13 to R-21. The exact number depends on your wall construction, but the goal is always to create a seamless thermal boundary.

Achieving a high R-value for spray foam in these areas has a massive impact. We see it time and time again: homeowners who properly insulate their attics and walls can cut their cooling costs by double digits, often seeing savings in the 10–30% range.

Why Closed-Cell Foam Is Non-Negotiable Here

Hitting the right R-value is important, but in South Florida, that's only half the story. Our other enemy is humidity, and this is where your choice of insulation becomes absolutely critical. For our climate, closed-cell spray foam is the undisputed champion, and it comes down to one simple fact: it’s a vapor barrier.

In a humid climate like ours, an insulation's ability to block moisture is just as important as its ability to block heat. Closed-cell spray foam does both perfectly, preventing the condensation and mold that plague homes insulated with traditional fiberglass or cellulose.

Fiber-based insulations like fiberglass and even open-cell foam can allow warm, moist air to pass right through. When that humid air hits a cooler surface—like your drywall cooled by the AC—it condenses. That moisture creates the perfect breeding ground for mold and mildew.

Closed-cell foam’s dense, rigid structure stops that process cold. It seals every last crack and gap, creating a true air and moisture seal that protects your home’s structure and your family’s health. To see exactly how it stacks up against other materials, check out our guide on spray foam vs. blown-in insulation.

By choosing closed-cell spray foam, you aren’t just hitting a target R-value. You're making a smart, climate-specific investment in your home's long-term comfort, efficiency, and durability.

Common Questions About Spray Foam R-Values

Even after you get the numbers straight, it's natural to have some practical questions about how the R-value for spray foam really holds up over the long haul. Let's walk through some of the things we hear most often to clear up any confusion and help you feel confident about your choice.

Does Spray Foam Lose R-Value Over Time?

Yes, but it's very minor and a completely normal, well-understood process. All rigid foam insulations can see a slight drop in R-value over their lifespan, a process called thermal drift. It happens when a tiny amount of the low-conductivity blowing agent inside the foam’s cells is slowly replaced by air.

But here’s the thing: modern, high-quality closed-cell foams are designed to minimize this. The loss is small, happens mostly in the first couple of years, and then it levels off for the life of your home. Even with that tiny drift, spray foam’s performance stays incredibly high.

The Critical Difference: The most important benefit of spray foam—its ability to create a perfect air seal—never diminishes. This air-sealing power is a huge part of its real-world effectiveness and is not affected by thermal drift.

Is a Higher R-Value Always Better?

Not necessarily. While a higher R-value means more insulating power, just chasing the biggest number isn't always the smartest or most cost-effective move. The law of diminishing returns is a real thing when it comes to insulation. For instance, going from R-19 to R-30 in your attic is a game-changer for energy savings.

But jumping from an already high R-50 to R-60? You'll pay more for a tiny improvement you likely won't even notice on your energy bills. The goal is to meet or slightly exceed the recommended R-value for your specific climate. For us here in South Florida, hitting that R-30 to R-38 target in the attic is far more critical than over-insulating your walls. It's all about finding that sweet spot between performance, code, and your budget.

How Does Spray Foam Compare to Fiberglass R-Value?

Inch for inch, it's not even a fair fight. Closed-cell spray foam packs a punch with around R-6.5 to R-7.0 per inch, while traditional fiberglass batts only offer R-3.1 to R-3.7 per inch. That means you need way less space to get the same, or even better, insulating performance.

But the real story isn't just about the numbers on the package. Spray foam’s biggest win is that it creates a single, unbroken air barrier. It seals every nook and cranny, eliminating the drafts and gaps that absolutely cripple the real-world performance of fiberglass. Air moves right through and around fiberglass batts, dragging their effective R-value way down.

Because of its unbeatable air-sealing, a spray-foamed wall will almost always outperform a fiberglass wall with the same "stated" R-value. On top of that, spray foam offers other great benefits, like acting as a powerful sound barrier. You can learn more about how spray foam works as an insulation and sound barrier in our detailed guide. When you add it all up—high thermal resistance plus a perfect air seal—spray foam is the clear winner for performance and long-term energy savings.

Ready to experience the comfort and energy savings of a professionally insulated home? At Airtight Spray Foam Insulation, we provide tailored solutions that stand up to the South Florida climate. Request your free, no-obligation quote today and discover how the Airtight Comfort System can transform your property. Get started at https://airtightsprayfoaminsulation.com.