Blog

Insulate Metal Building: How to insulate metal building in South Florida

To properly insulate a metal building in South Florida, you have to get a handle on two things: relentless heat transfer and the condensation that comes with our extreme humidity. The best solutions, like closed-cell spray foam, do both. They create an airtight seal that manages temperature and moisture, which is key to preventing rust, mold, and insane energy bills.

This guide will walk you through the smartest options to protect your structure for the long haul.

Why You Must Insulate a Metal Building in Florida

Think of an uninsulated metal building in Florida like a cold can of soda on a hot August afternoon. The sun absolutely bakes the metal roof and walls, turning the inside into an oven. At the same time, all that humid air hits the cooler interior metal surfaces and causes them to "sweat" constantly.

This process is called condensation, and it's the number one enemy of any steel structure in our climate.

This isn't just a little bit of moisture. It's a non-stop cycle that creates a perfect storm for serious problems that go way beyond just feeling uncomfortable. Without the right insulation, you’re basically inviting costly, damaging issues that will eat away at your building's integrity and value.

The Science of Steel and Sweat

Metal is a fantastic conductor of heat. That's great for a frying pan, but terrible for a building. It means thermal energy moves through it incredibly fast.

When our hot, moisture-packed Florida air makes contact with the cooler surface of your building’s interior metal panels, that air cools down in a hurry. As it cools, it can't hold onto its moisture anymore. The excess water vapor has nowhere to go, so it condenses into liquid droplets right there on your walls and ceiling.

Over time, this condensation leads to rust and corrosion, which can weaken the structural panels and fasteners holding your building together. It also creates a damp environment where mold and mildew thrive, tanking your indoor air quality.

The Consequences of Neglecting Insulation

Ignoring the need for proper insulation in a South Florida metal building leads to predictable and expensive headaches. We see it all the time with business owners and homeowners from Jupiter to Wellington who face a nasty combination of these challenges:

- Extreme Indoor Temperatures: The interior can get dangerously hot, making it useless for work or storage. It also puts an incredible strain on any air conditioning you try to run.

- Destructive Moisture Damage: That constant dripping from condensation ruins equipment, inventory, and anything else you have stored. It causes rust, water spots, and irreversible damage.

- Skyrocketing Energy Bills: Trying to cool the space is a losing battle. Your HVAC unit will run constantly, fighting against endless heat gain and air leaks, and your utility bills will go through the roof.

- Structural Decay: Year after year, unchecked corrosion silently weakens your building. What starts as a small rust spot can eventually lead to expensive structural repairs.

These issues make it clear why a proactive approach is so critical. Choosing the right insulation isn’t just about comfort—it’s about protecting your investment. Understanding the crucial role of a proper vapor barrier and insulation system is the first step toward a durable, efficient, and long-lasting building.

Comparing The Best Insulation For Metal Buildings

Picking the right insulation for a metal building here in Florida is a critical decision. It’s not just about temperature; it’s about fighting a constant battle against oppressive heat and relentless humidity. Using the wrong material is like trying to patch a leaky boat with a screen door—it just won’t work.

You have to know what you’re up against. Let’s break down how the most common insulation types stack up in our unique climate.

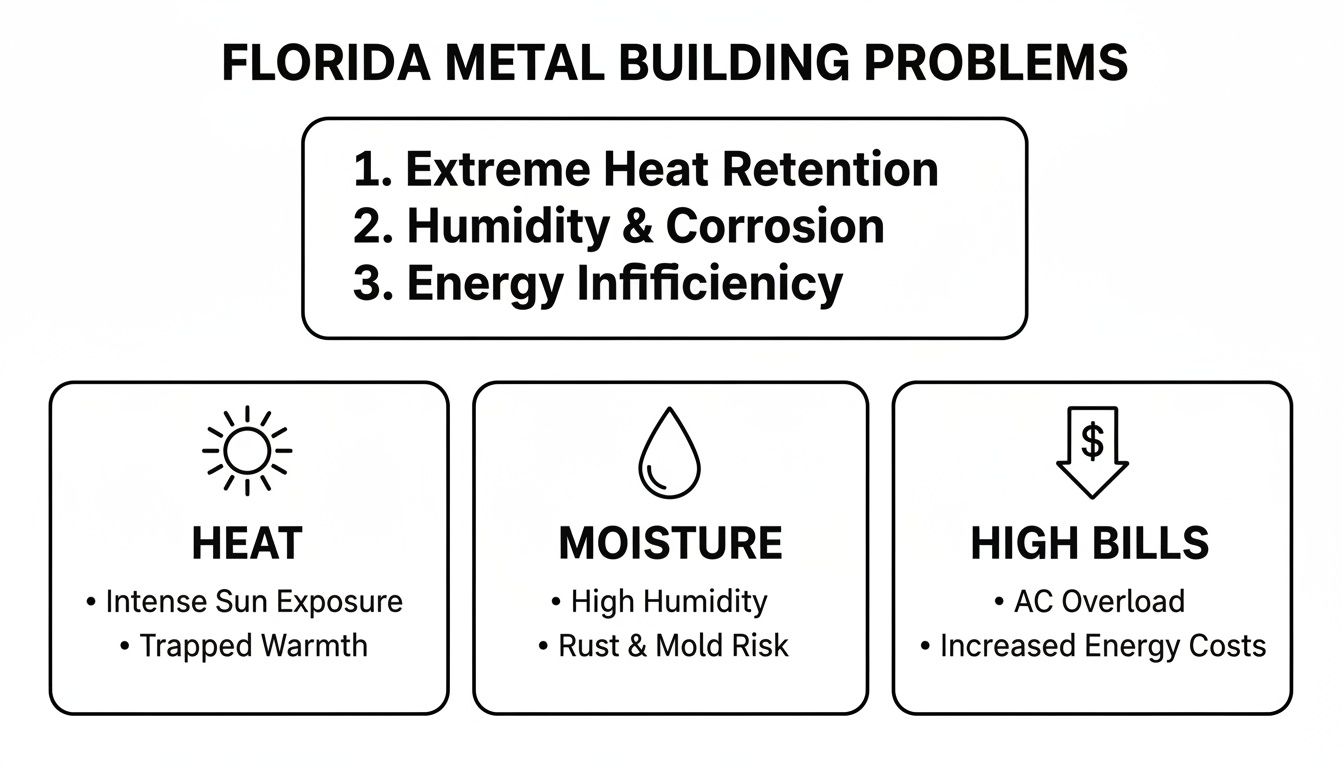

As you can see, the fight is on three fronts: punishing solar heat gain, invasive moisture, and the sky-high energy bills that come from trying to keep things cool and dry.

Radiant Barriers: A Reflective Shield

A radiant barrier is probably the most basic option. Think of it like the sunshade you put in your car's windshield. It doesn't actually cool the car, but it reflects the sun's direct rays, which makes a big difference. Made of a highly reflective material, its only job is to bounce radiant heat away from the building.

This makes it a popular budget-friendly choice for spaces where precise climate control isn't the main goal, like a barn or a simple workshop. But here's the catch: it provides almost zero R-value, which measures thermal resistance. It reflects heat, but it does very little to stop heat that moves through conduction or convection.

Fiberglass Batts: The Traditional Choice

When most people hear "insulation," they picture the fluffy pink or yellow rolls of fiberglass batt. It's affordable and has been the standard for years in traditional wood-framed homes, working by trapping air pockets to slow heat transfer.

But in a metal building, especially in Florida, fiberglass has a fatal flaw: moisture. When condensation forms on the cool metal panels (which it absolutely will), the fiberglass gets damp, compresses, and loses its insulating power. Even worse, it holds that moisture against the steel, creating a perfect recipe for rust and mold growth.

Rigid Foam Board: A Sturdy Panel Solution

Rigid foam board is a definite step up. These solid panels, made from materials like polystyrene, offer a consistent R-value and are far more resistant to moisture than fiberglass. They won’t turn into a soggy, useless mess when the humidity kicks in.

The downside is the installation. Every single board has to be painstakingly cut to fit perfectly between the building's steel frame, and every seam must be meticulously sealed with special tape. It’s a labor-intensive process, and any tiny gap becomes a superhighway for air and moisture to get in. And when you're sealing the building envelope, don't forget the largest openings—upgrading to insulated overhead doors is a must for achieving true energy efficiency.

Spray Foam Insulation: The Airtight Champion

This is where the game really changes. Spray polyurethane foam (SPF) isn't just installed; it's created on-site. Applied as a liquid, it expands instantly to fill every single crack, gap, and irregular space, forming a seamless, monolithic barrier. It's less like adding a layer of insulation and more like creating a custom-molded, protective shell for your entire building.

This complete air seal is spray foam's superpower. By stopping all air movement, it effectively eliminates condensation on metal surfaces and provides an exceptional thermal barrier in a single application.

There are two main types of spray foam you’ll encounter:

- Open-Cell Spray Foam: This version is lighter, with a flexible, spongy texture. It’s a fantastic air sealer and does a great job of dampening sound. However, its open cells can absorb water if exposed directly, so it isn't the right fit for every situation.

- Closed-Cell Spray Foam: This is the high-performance workhorse. Its dense, rigid structure makes it a true vapor barrier, completely shutting out moisture. It boasts a much higher R-value per inch (typically R-6 to R-7) and even adds structural strength to the building itself.

For the unique challenges a South Florida metal building faces, closed-cell spray foam is the clear winner. It solves all three major problems—heat, moisture, and high energy bills—in one powerful, comprehensive solution.

Metal Building Insulation Performance Comparison

To make sense of these options, it helps to see them side-by-side. This table breaks down how each insulation type performs against the key challenges in our climate.

| Insulation Type | R-Value Per Inch | Moisture & Humidity Control | Air Sealing Ability | Best Use Case in Metal Buildings |

|---|---|---|---|---|

| Radiant Barrier | Negligible (~R-1) | None. Can trap moisture behind it. | None | Basic heat reflection in non-conditioned spaces (e.g., barns, open-air storage). |

| Fiberglass Batt | R-3.1 to R-3.7 | Poor. Absorbs moisture, loses R-value, and promotes mold/rust. | Poor. Air gaps are common. | Not recommended for South Florida metal buildings due to humidity issues. |

| Rigid Foam Board | R-3.8 to R-6.5 | Good. Resists moisture but relies on perfect seam sealing. | Fair. Seams must be meticulously taped to prevent leaks. | DIY projects or where spray foam isn't feasible, but requires careful installation. |

| Open-Cell Foam | R-3.5 to R-3.8 | Fair. Stops air but can absorb moisture if directly exposed. | Excellent | Interior walls, soundproofing. Not ideal for exterior walls/roof without a vapor barrier. |

| Closed-Cell Foam | R-6.0 to R-7.0 | Excellent. Acts as a complete air and vapor barrier. | Excellent. Creates a monolithic, airtight seal. | The ideal solution for all applications; provides the best protection against heat, air, and moisture. |

As the comparison shows, while other options have their niche uses, closed-cell spray foam is the only one that truly checks every box for protecting a metal building in South Florida's demanding environment.

Why Spray Foam Excels in Florida's Climate

While traditional insulation types like fiberglass and rigid board have their place, Florida's brutal combination of intense sun and suffocating humidity calls for something more. You don't just need to slow down heat; you need a solution that stops both heat and moisture dead in their tracks.

This is exactly where spray foam insulation, especially closed-cell, leaves everything else behind for metal buildings in our area.

Unlike fiberglass batts that are just stuffed into cavities or rigid boards laid against the metal, spray foam creates a powerful, permanent bond. We apply it as a liquid that expands in seconds, filling every single gap and creating one solid, unbroken barrier. It's the difference between throwing a blanket over a frame versus molding a custom-fit shell that seals every last seam and imperfection.

That seamless seal is the whole ballgame. It puts a stop to the air gaps that let hot, humid outdoor air collide with cooler interior metal surfaces—the exact recipe for condensation and rust. By creating a truly airtight envelope, spray foam prevents moisture problems before they even have a chance to start.

The Unbeatable Air and Vapor Barrier

Here in South Florida, keeping moisture out is just as critical as keeping the heat out. Closed-cell spray foam is an all-in-one solution: it’s your insulation, your air barrier, and your vapor barrier, all in a single application. This is a game-changer compared to other materials that need separate, multi-step installations of vapor retarders that can easily fail.

With traditional methods, one little tear, an un-taped seam, or a gap in the vapor barrier is all it takes for moisture to sneak in and get trapped against the steel. That trapped moisture is a ticking time bomb for corrosion and mold. Spray foam completely sidesteps this risk because the vapor barrier is built right into its dense, closed-cell structure.

By forming a monolithic seal, closed-cell spray foam makes the building airtight. This not only stops condensation cold but also plugs the massive energy leaks that can account for up to 40% of a building's heating and cooling costs.

This kind of comprehensive protection is quickly becoming the new standard. The global market for metal structural insulation panels is expected to jump from $43.7 billion in 2021 to $68.3 billion by 2031, a clear signal that building owners are moving toward superior, integrated insulation systems. You can dig into the numbers in this in-depth market analysis on AlliedMarketResearch.com.

Adding Structural Integrity

Beyond stopping heat and moisture, closed-cell spray foam delivers another powerful benefit you just don't get from other materials: it actually makes the building stronger. Once it cures, the dense, rigid foam acts like an industrial-strength adhesive, literally gluing the metal panels to the building’s frame.

This added rigidity helps the entire structure resist the racking and flexing caused by high winds—a serious advantage during Florida's hurricane season. You're essentially reinforcing the whole building envelope, adding a layer of resilience that no other insulation can match. You can learn more about how spray foam insulation works to deliver these unique benefits in our detailed guide.

For facility managers and business owners from Jupiter to Wellington, this structural boost provides real peace of mind, knowing their investment is better fortified against severe weather. The decision to insulate a metal building with spray foam pays dividends far beyond just temperature control.

Here’s a quick rundown of why it's the right choice for our climate:

- Complete Condensation Control: The airtight seal prevents warm, moist air from hitting cool metal, cutting off "building sweat" at the source.

- Superior Thermal Performance: Closed-cell foam delivers an impressive R-value of up to R-7 per inch, giving you maximum insulation power without eating up a ton of space.

- Built-In Vapor Barrier: Its closed-cell structure is impermeable to moisture, eliminating the need for a separate (and often problematic) vapor retarder.

- Enhanced Structural Strength: It bonds panels directly to the frame, making the whole building more rigid and resistant to wind uplift.

At the end of the day, spray foam offers a tough, multi-layered defense against the unique challenges of South Florida's climate, ensuring your metal building stays dry, efficient, and structurally solid for decades to come.

What to Expect During a Professional Spray Foam Installation

Choosing spray foam for your metal building isn't like picking up a few rolls of insulation from the hardware store. It's an investment in a highly technical, on-site manufacturing process. Unlike other materials that are just cut and fit, spray foam is literally created the moment it's applied. This is precisely why professional expertise is non-negotiable.

Trying to DIY this is a recipe for a costly mess. Understanding how a real pro team handles the job will give you confidence that you're getting what you paid for: a perfect, long-lasting thermal and moisture barrier. A reputable company like Airtight Spray Foam Insulation follows a meticulous process from start to finish, ensuring safety, quality, and performance.

The Initial Site Assessment

Before a single hose is unrolled, the first step is always a thorough site assessment. The project manager or lead technician will walk the property with you, confirming the scope of work and spotting any potential hiccups before they become problems. This isn't just a quick glance—it's a critical planning session.

During this walkthrough, the team will:

- Verify Measurements: They'll double-check the square footage and confirm every surface that's getting insulated.

- Inspect Surfaces: The crew will examine the condition of the metal panels, looking for any issues that could interfere with a strong bond.

- Plan for Access: They’ll map out the best entry points for hoses and equipment to make the workflow smooth and efficient.

- Review Safety Protocols: They will identify ventilation requirements and establish a clear, safe work zone for everyone's protection.

Preparing the Building for Application

Proper prep work is everything in a spray foam job. This stuff adheres permanently to whatever it touches, so protecting what shouldn't be sprayed is paramount. This meticulous masking and covering is often the most time-consuming part of the process, but it’s what separates a professional job from an absolute disaster.

A professional crew spends a huge chunk of their time on prep. They'll meticulously cover windows, doors, floors, and any equipment with heavy plastic sheeting to shield everything from overspray. It's this painstaking attention to detail that guarantees a clean, precise finish.

The metal surfaces themselves also have to be spotless. Technicians will make sure the panels are clean, dry, and totally free of oil, dust, or rust. Anything that could compromise the foam's grip has to go. This step is what ensures the foam creates that powerful, airtight seal we're after.

The Technical Application Process

With the site fully prepped and secured, the real action begins. The crew suits up in full personal protective equipment (PPE), including respirators and coveralls, and fires up the specialized spray rig. This rig is a mobile factory, heating and pumping two separate liquid components through hoses to a mixing gun.

The magic happens right at the nozzle. As the two liquids combine and hit the metal, they trigger an immediate chemical reaction, expanding up to 30-60 times their original volume in just a few seconds. This incredible expansion is what allows the foam to force its way into every tiny crack, seam, and gap, creating a single, seamless, airtight barrier.

The technicians apply the foam in smooth, even passes called "lifts" to build up to the specified thickness and R-value. Their skill is on full display here—applying too much too fast can mess with the chemical cure, while applying too little leaves you with an inconsistent thermal shield.

Curing, Trimming, and Final Inspection

After the spraying is done, the foam needs a moment to fully cure and harden. Most closed-cell foams become tack-free within minutes. The crew will then go back and trim any excess overspray, especially around framing, to give the job a neat, professional appearance.

The last step is a full cleanup and a final inspection. The team removes all the plastic sheeting and their equipment, leaving your property just as they found it. Then, they'll do a final walkthrough with you to inspect the work, show you the complete coverage, and make sure you are 100% satisfied. This multi-stage, professional process is the only way to guarantee your metal building gets the tough, airtight protection it needs to stand up to the Florida climate.

Understanding Insulation Costs and ROI

When you decide to insulate a metal building, you're not just buying a product; you’re making a serious investment in your property's future. The upfront cost is always a big question, but the real story is in the long-term return on that investment (ROI). It's tempting to look at materials like fiberglass batts or rigid foam board because they seem cheaper on paper, but they often just can't handle the unique demands of South Florida.

Spray foam insulation, especially the closed-cell kind, does come with a higher price tag. That cost covers both the advanced material and the professional skill needed to get the application perfect. But thinking of it as just an expense is a mistake. This is a capital improvement that starts paying you back from day one through lower bills and protecting your building from the elements.

Breaking Down the Cost Factors

There's no one-size-fits-all price for insulating a metal building. A professional quote will always dig into the specific details of your structure to give you an accurate number.

Here’s what we look at:

- Total Square Footage: It’s simple—the more wall and roof space you have, the more material and time it takes.

- Type of Spray Foam: Closed-cell foam is denser and gives you a higher R-value, so it costs more than open-cell. But for our humid climate, its superior moisture protection is non-negotiable.

- Desired Thickness (R-Value): How you plan to use the building and our local climate will determine the R-value you need, which in turn dictates how thick the foam needs to be.

- Building Complexity and Prep Work: A simple, wide-open barn is different from a building with complex framing or hard-to-reach spots. The amount of prep work needed can also add to the labor costs.

You can dive deeper into the numbers in our complete guide to the cost of spray foam insulation.

Calculating Your Long-Term Return

That higher initial cost for spray foam is quickly balanced out by its powerful, long-term financial wins. The ROI comes from three main places: massive energy savings, avoiding expensive repairs, and a higher property value.

A properly insulated metal building can slash energy costs by 30-50%. By creating a complete air seal, spray foam stops your conditioned air from pouring out, which means your HVAC system isn’t running non-stop just to keep up with the Florida heat.

This kind of efficiency is exactly why the global insulation market is booming. The building thermal insulation market hit $35.51 billion in 2025 and is set to keep growing, showing a worldwide move toward high-performance buildings. Here in South Florida, smart property managers and contractors are leading the charge because they know better insulation directly boosts their bottom line.

A Practical ROI Example

Let's imagine a 5,000-square-foot commercial warehouse right here in Palm Beach County. Before insulation, the owner is getting hit with a $1,500 electric bill every summer. His two big HVAC units are fighting a losing battle against the heat and humidity.

After we come in and install closed-cell spray foam, the building is now completely airtight.

The HVAC units run far less often, and the monthly bill drops to $850. That’s a savings of $650 every single month. Over a year, he's saved $7,800. At that rate, the initial investment pays for itself in just a few years.

But the savings don't stop there. The owner is also avoiding thousands in potential future headaches—rust repair, mold remediation, and replacing inventory ruined by moisture. On top of that, a climate-controlled, energy-efficient building is way more valuable and much easier to lease or sell. Before making a big insulation investment, it can be a smart move to look into conducting a home energy audit to pinpoint exactly where you're losing money.

Common Mistakes to Avoid When Insulating Metal Buildings

When you decide to insulate a metal building, the goal is simple: create a space that’s durable, dry, and doesn't cost a fortune to keep comfortable. But even with the best intentions, a few common slip-ups can completely derail the project. You can end up with wasted money, serious moisture damage, and an insulation system that just doesn't perform.

Getting it right means sidestepping these key pitfalls from the very beginning.

The single most common mistake we see is improper surface preparation. Think of it like painting your car—you wouldn't just spray new paint over dirt and rust, right? Insulation is no different. Applying spray foam over a dirty, oily, or rusty surface means it can't get a good grip, leading to delamination and leaving huge gaps in your building's thermal shield.

Overlooking the Importance of an Air Seal

Another huge misstep is focusing only on R-value while forgetting about the air seal. In Florida's soupy humidity, uncontrolled air leakage is the real enemy of any metal building. This is where traditional materials like fiberglass batts just can't keep up.

Even tiny gaps around steel framing or the seams of rigid boards are like open doors for warm, moist air. When that humid air sneaks in and hits the cool interior metal panels, you get condensation. That condensation quickly turns into much bigger problems:

- Corrosion: Trapped moisture is the arch-nemesis of steel. It will eat away at your panels and fasteners over time.

- Mold Growth: Damp, dark, and enclosed spaces are a five-star resort for mold.

- Reduced R-Value: Once insulation gets damp, its ability to resist heat transfer plummets.

A true air barrier isn't a luxury; it's non-negotiable in a metal building. Without one, you’re basically installing a system that's designed to fail, creating the very moisture issues you were trying to solve in the first place.

Choosing the Wrong Insulation for the Climate

Let's be blunt: not all insulation is created equal, especially not for a place like South Florida. Picking an insulation that can't handle our relentless humidity is a recipe for disaster. For instance, putting in fiberglass without a perfectly installed, 100% seamless vapor barrier is a huge gamble, as that material soaks up and holds onto moisture like a sponge.

To protect your investment and your building, make sure to avoid these classic blunders:

- Skipping a Vapor Barrier: Never assume your insulation will just stay dry. A robust vapor barrier is crucial unless you're using a material like closed-cell spray foam, which has one built right in.

- Neglecting Ventilation: An airtight building is great for efficiency, but it still needs to breathe. Proper ventilation is essential for good indoor air quality and managing any moisture created inside.

- Ignoring Air Leaks: Don't forget to seal everything—doors, windows, and any pipe or wire penetrations. Every unsealed gap is an open invitation for heat and humidity to come right back in.

By dodging these common mistakes, you can ensure your project to insulate a metal building actually delivers the long-term protection and energy savings you're paying for.

Got Questions About Insulating Your Metal Building? We've Got Answers.

Even after you’ve done your homework, some questions always pop up when it's time to insulate a metal building. Here are some straightforward answers to the things we hear most often from property owners here in South Florida.

Can You Insulate An Existing Metal Building?

Absolutely. In fact, adding insulation to an existing structure is one of the smartest upgrades you can make. The process is pretty direct: we prep the interior surfaces—making sure they’re clean and completely dry—and then apply the insulation.

Spray foam is a perfect fit for this kind of retrofit job. It bonds right to the existing metal panels and framing, creating a complete seal without needing to tear anything apart or make big structural changes.

Does Spray Foam Stop Roof Leaks?

While spray foam isn’t a roofing product, its seamless and waterproof nature is fantastic at sealing up minor leaks. When closed-cell spray foam is applied, it expands to cover small cracks, gaps around fasteners, or tiny openings in the seams, forming one solid barrier that water just can't get through.

But it’s important to be clear: if you have serious roof damage, that needs to be fixed first.

Think of spray foam as a powerful second line of defense against water. It’s not a substitute for proper roof repair, so always get the main problem sorted out before we start spraying.

How Long Does Spray Foam Insulation Last?

Spray foam is a one-and-done solution. It’s incredibly durable and built for the long haul. Once it’s installed by a pro, it won’t sag, break down, or lose its effectiveness over time like fiberglass batts can.

It forms a permanent, rigid bond with the building itself, locking in its R-value and air-sealing power for the life of the structure. You can honestly expect it to perform for decades without ever needing to think about it again.

Ready to protect your investment with a solution that can actually handle Florida's heat and humidity? The team at Airtight Spray Foam Insulation has spent years getting this right. Request a free, no-obligation quote today and let's talk about your project.