Blog

Existing Wall Spray Foam Insulation A Florida Homeowners Guide

When you live in South Florida, fighting the heat and humidity can feel like a full-time job. Your AC runs nonstop, but the house never quite feels comfortable, and your energy bills just keep climbing. If this sounds familiar, it's time to look at your walls. Retrofitting them with existing wall spray foam insulation isn't just an upgrade; it's a permanent solution to an ongoing battle.

Is Spray Foam Insulation Worth It For Your Existing Walls?

Unlike traditional insulation that comes in rolls or batts, injection spray foam is a liquid that's pumped into your enclosed wall cavities. From there, it expands to fill every single nook, cranny, and air leak. This process creates a solid, airtight barrier that transforms your home’s performance without any major demolition.

Think about it: your home's walls are full of thousands of tiny, unseen gaps. Every little crack around pipes, outlets, and window frames acts like a miniature open door, letting your expensive cool air escape while welcoming in hot, muggy outdoor air. This constant air exchange is what forces your HVAC system into overdrive.

Sealing Your Home From the Inside Out

Injection foam insulation stops this problem right at the source. By expanding to create a seamless, monolithic barrier inside your walls, it accomplishes three critical jobs all at once:

- It Creates an Air Barrier: This is the big one. It stops uncontrolled air leakage, which is often the biggest energy waster in a home.

- It Provides a Moisture Barrier: By blocking humid air from seeping into your wall cavities, it dramatically cuts down the risk of mold and mildew growth—a huge concern here in Florida.

- It Boosts Thermal Performance: Spray foam has a high R-value, meaning it’s incredibly effective at slowing down heat transfer, keeping the sun’s blistering heat outside where it belongs.

We're not just stuffing insulation into a wall; we're fundamentally changing how your home breathes. By creating a truly sealed building envelope, spray foam addresses the root causes of discomfort and high energy bills in our climate. It’s about achieving a consistently cool and dry indoor environment.

The benefits don't stop at temperature and moisture control. The dense, solid barrier created by the foam is also fantastic for sound dampening, making your home a quieter, more peaceful place. You can learn more about how insulation serves as an effective sound barrier in our detailed guide on the topic.

A Proven Solution for Energy Savings

The numbers don't lie. Energy studies have shown that air leakage alone can account for 25–40% of a home's cooling and heating costs. That's a massive amount of wasted money.

For homes in hot, humid climates like ours, retrofitting walls with spray foam can lead to whole-house energy savings of 15–30% or more compared to old, inefficient insulation. It's a smart investment in your home's immediate comfort, its long-term value, and its overall efficiency.

Choosing Between Open-Cell and Closed-Cell Foam

When we talk about retrofitting existing walls with spray foam, it’s not a one-size-fits-all conversation. The biggest decision you'll make is between open-cell and closed-cell foam. They might sound similar, but they perform very differently, especially here in Florida’s brutal climate.

Think of open-cell spray foam like a dense, high-quality sponge. Its cells are left open, which makes the foam soft, flexible, and lightweight. This structure is fantastic at trapping and deadening sound waves, making it a go-to for interior walls or home theaters where quiet is the goal.

On the other hand, closed-cell spray foam is like a solid panel made of countless tiny, airtight plastic bubbles. This creates an incredibly dense and rigid material. That fundamental difference in structure is what dictates where each type of foam truly shines.

R-Value and Holding Back the Humidity

Every insulation material has an R-value, which is simply a measure of how well it resists heat flow. Higher R-value means better insulation.

- Open-Cell Foam: This will typically give you an R-value around R-3.5 to R-4.0 per inch. While it insulates well, it's also vapor-permeable. Just like a sponge, moisture can eventually pass through it.

- Closed-Cell Foam: This is the heavy hitter, delivering a much higher R-value between R-6.0 and R-7.0 per inch. Its sealed-cell structure is the key—it acts as a true vapor barrier, completely blocking moisture from getting into your wall cavity.

For any existing wall spray foam insulation project in South Florida, that distinction is everything. Our air is saturated with moisture, and if that humidity gets into your walls, you're setting the stage for mold, mildew, and rot. Closed-cell foam’s ability to shut that moisture out makes it the superior choice for protecting your home’s exterior walls.

Why Closed-Cell Foam is the Champ for Florida's Exterior Walls

In a region where we deal with hurricanes and year-round humidity, closed-cell foam does so much more than just keep your house cool. Its dense, rigid structure bonds directly to the sheathing and studs, essentially gluing the wall assembly together from the inside. This adds a serious amount of structural strength, making your home more resilient against high winds during a storm.

For South Florida homeowners, choosing insulation isn't just about R-value. It's about protecting the building itself. Closed-cell foam gives you a thermal barrier, a moisture barrier, and structural reinforcement—all in one shot.

The numbers back this up. With rising energy costs and stricter building codes, closed-cell foam now commands about a 68% share of the market, primarily because of its powerful R-value and moisture-blocking capabilities. As homeowners look to upgrade their existing homes to meet modern standards, spray foam offers a way to get massive performance gains without tearing the house apart.

To help you visualize the best choice for your project, here’s a simple breakdown of how the two types of foam stack up for a Florida home retrofit.

Open-Cell vs Closed-Cell Foam for Florida Homes

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value | R-3.5 to R-4.0 per inch | R-6.0 to R-7.0 per inch |

| Moisture Barrier | No (vapor-permeable) | Yes (acts as a vapor barrier) |

| Structural Strength | No additional strength | Adds significant rigidity |

| Sound Dampening | Excellent | Good |

| Cost | Lower | Higher |

| Best For | Interior walls, ceilings, noise reduction | Exterior walls, crawl spaces, flood zones |

Ultimately, while both are great products, their applications are very different. You need the right tool for the right job, especially when it comes to protecting your home's structure.

Finding the Right Place for Open-Cell Foam

While closed-cell is the clear winner for exterior walls, open-cell foam definitely has its place. Its lower price point and incredible sound-dampening qualities make it a perfect fit for interior projects.

We often recommend open-cell foam for:

- Interior Walls: To quiet down noise transfer between a home office and a living room, or between bedrooms and a laundry room.

- Ceilings and Floors: To cut down on the sound of footsteps and conversations between stories.

This kind of strategic approach gives you the best of both worlds: the unyielding protection of closed-cell where it’s needed most and the cost-effective sound control of open-cell where it can add the most comfort. Spray foam is a huge leap forward from older methods, and it's worth seeing how it compares directly. You can read our detailed guide on spray foam versus blown-in insulation to learn more. At the end of the day, a professional assessment is the only way to map out the perfect combination for your home's specific needs.

Breaking Down the Injection Foam Installation Process

You might be picturing a massive construction project when you think about upgrading the insulation inside your walls, but the reality is surprisingly clean. For existing homes, we use a specialized "drill-and-fill" method that skips the messy demolition. It’s a precise, almost surgical technique that transforms your home’s comfort without turning it into a construction zone.

Think of it as a well-rehearsed play. It all kicks off with a detailed assessment where our technicians map out your walls. We don't just guess where to work; we often use tools like thermal imaging cameras to see exactly where the empty cavities are, find the studs, and identify any old, failing insulation. This planning stage is everything—it ensures the whole process is efficient and as non-disruptive as possible.

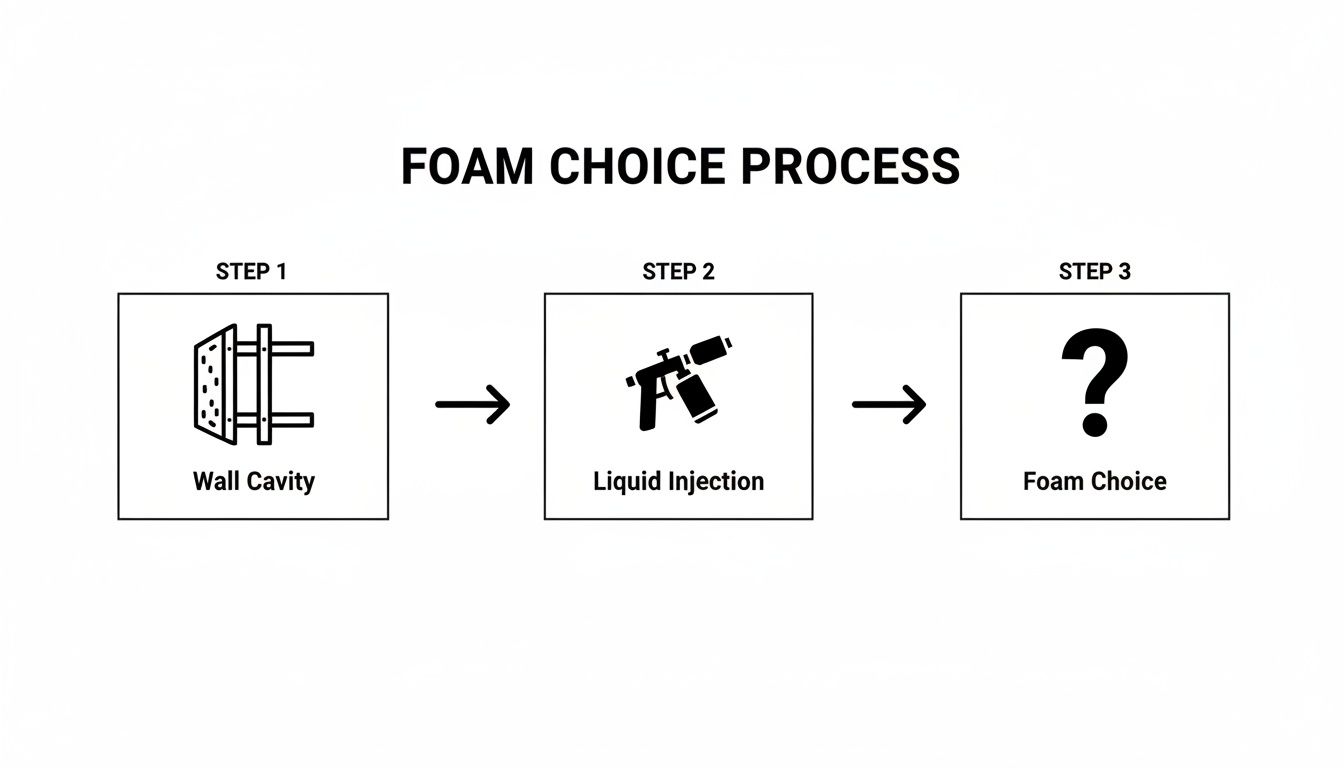

This visual gives you a quick look at the journey from an empty wall cavity to a perfectly sealed, insulated space.

As you can see, the most critical decision—choosing the right foam for the job—happens right before we inject the material to fill the wall.

The "Surgical" Drill-and-Fill Method

With a clear plan in hand, the real work begins. Instead of tearing down drywall, the process relies on drilling small, strategically placed holes to get the job done.

- From the Outside: Our first choice is always to work from the exterior. If you have vinyl siding, we can often carefully pop a few pieces off to get to the sheathing underneath. For homes with brick or stucco, we drill tiny holes into the mortar joints, which are super easy to patch up later.

- From the Inside: If we can’t get access from the outside, or if we're insulating interior walls, we use the same careful approach indoors. We’ll drill small holes (usually around 2.5 inches) through the drywall, making sure to protect your floors and furniture with plastic sheeting first.

Every access point is meticulously planned. An experienced crew knows how to work around the hidden network of wires, pipes, and framing inside your walls, guaranteeing complete coverage without causing any damage.

Injecting and Expanding the Foam

Once the access holes are ready, the magic happens. We mix the two-part liquid foam components right at the nozzle of a specialized injection gun and carefully pump the liquid into the wall cavity.

Almost instantly, a chemical reaction kicks off, causing the foam to expand up to 100 times its original liquid volume. It flows like water into every nook, cranny, and hairline crack, creating a seamless, airtight seal that’s custom-molded to your home. This is what sets injection foam apart—it doesn't just sit in the wall; it becomes one with the wall, bonding directly to studs and sheathing.

The secret to the effectiveness of existing wall spray foam insulation lies in its expansion. It creates a single, solid barrier that completely stops air and moisture, something that traditional fiberglass batts or blown-in insulation just can't do in an enclosed wall.

Our technicians are trained to know exactly how much foam to inject. They listen and feel for the expansion, ensuring the cavity is filled perfectly without being over-pressurized, which could potentially harm the drywall. That hands-on expertise is crucial for a safe and successful job.

The Final Patch and Cleanup

The job isn’t done until it looks like we were never there. Restoring your home to its original condition is the final, critical step.

- Plugging the Holes: After the foam has cured solid, we plug the access holes. We typically use wooden plugs for wood siding or Styrofoam plugs and mesh tape for interior drywall.

- Siding Reinstallation: If we removed any siding, we put it back on with expert care. You’ll never know it was touched.

- Patching and Finishing: For brick walls, we refill the drilled mortar joints with mortar that’s color-matched to your home. On interior drywall, we apply a rough coat of drywall mud over the patch, getting it ready for you to handle the final sanding and painting.

- A Squeaky-Clean Finish: A professional team always cleans up after themselves. We’ll remove all debris and leave your property looking pristine.

Most of these projects are wrapped up in just a few hours to a single day, making it an incredibly fast and effective way to upgrade your home.

Real Benefits and Potential Risks for Florida Homes

Deciding to retrofit your existing walls with spray foam insulation is a big decision, especially here in Florida. You're weighing some serious rewards against some very real risks. On one hand, the benefits are fantastic. Creating a nearly perfect airtight seal means you're locking out that soupy, humid summer air we all know and love.

This does more than just make you comfortable—it fundamentally changes how your home performs in our climate, giving your AC system a much-needed break from its constant battle against the heat.

Beyond just cooling, closed-cell spray foam adds a surprising amount of structural muscle to your walls. It bonds directly to the studs and sheathing, acting like a super-strong glue that reinforces the entire wall assembly. When hurricane season rolls around, that extra rigidity can make a tangible difference in how your home stands up to high winds.

Maximizing Gains While Avoiding Pitfalls

But we have to have an honest conversation about what can go wrong with a bad installation. Spray foam is a powerful material, but in the wrong hands, it can create more problems than it solves. The biggest issue, unsurprisingly for Florida, is moisture.

Because closed-cell foam is a true vapor barrier, it completely stops moisture from moving through the wall. Now, if you have an existing leak or a hidden moisture source that isn't fixed before the foam goes in, you’re just trapping that water. That’s a recipe for hidden rot and mold.

A professional installation isn't just about squirting foam into a wall cavity. It's a whole process, and it starts with a thorough inspection. A seasoned expert who actually understands Florida building science knows exactly what to look for—and how to fix potential moisture problems before a single drop of foam is ever injected.

Another risk is a botched application. If the chemicals are mixed improperly—what we call "off-ratio"—or applied in the wrong conditions, the foam won't cure correctly. That can lead to a weak seal, lingering chemical odors, or even off-gassing. This is exactly why you can't cut corners. Choosing a certified, experienced installer who lives and breathes by strict safety and quality standards is non-negotiable.

The Airtight Advantage: Expertise in Action

A successful retrofit comes down to one thing: professional expertise. An experienced team knows how to navigate the unique quirks of Florida homes, making sure you get all the benefits while completely sidestepping the potential disasters.

Here’s what that real-world expertise looks like:

- Climate-Specific Knowledge: A pro who works in Florida understands how our relentless humidity tortures building materials. They know that insulating a concrete block wall is a completely different ballgame than a wood-frame one. If you want to dive deeper, we have a whole guide on the insulation value of concrete block walls.

- Building Science Mastery: True professionals can "read" a house. They use tools like thermal cameras to hunt down hidden air leaks and moisture spots, ensuring the foam is only applied where it will be safe and effective.

- Precision and Safety: Certified installers are trained on the exact mixing ratios, temperatures, and application techniques for a perfect cure. This guarantees the foam is stable, safe, and will perform for decades.

This professional approach is what turns a simple upgrade into a lasting investment. Ultimately, the goal is a complete home solution. Just as existing wall spray foam offers big advantages, other improvements—like understanding professional pipe insulation benefits—can provide similar gains in efficiency and risk prevention.

When it's installed correctly by a team that truly gets our unique environment, spray foam insulation does more than just lower your FPL bill. It makes your home stronger, healthier, and a whole lot more comfortable for years to come.

Breaking Down The Cost Of Retrofit Spray Foam Insulation

Alright, let's get straight to the question everyone asks first: what’s this actually going to cost? When it comes to existing wall spray foam insulation, there's no simple, one-size-fits-all price. Think of it less like buying a product off the shelf and more like commissioning a custom upgrade for your home. The price is built around your home's specific situation.

We typically calculate the final quote per square foot of wall area. For most homes, the total project cost usually lands somewhere between $5,000 and $10,000. But that's just a ballpark—several key factors can move that number up or down, making sure you only pay for what your home truly needs.

Key Factors That Shape Your Quote

A few main variables will determine your final price tag. Understanding these helps you see exactly what you're paying for and why it’s such a solid investment.

- Foam Type: As we've covered, premium closed-cell foam is more of an investment upfront than open-cell foam. That's because you're paying for a higher R-value, added structural strength, and that critical moisture-blocking power. For exterior walls here in Florida, it's hands-down the right choice.

- Total Square Footage: This one is pretty straightforward. A larger home with more exterior wall space is going to need more material and more man-hours, which will be reflected in the cost.

- Home Construction and Siding: The complexity of the job itself plays a huge role. A house with vinyl siding that’s easy to remove and reinstall is a much simpler job than, say, a historic home with old brickwork that demands careful, precise drilling and patching.

Viewing Cost as a Return on Investment

I get it, the upfront cost is a big number to consider. But it's really important to see it as an investment that starts paying you back immediately. That perfect air seal created by spray foam goes to work from day one, often slashing monthly energy bills by 15-30% or even more.

Here's how I like to think about it: you are already spending the money for proper insulation. It’s just going straight to your utility company every month instead of into a long-term asset for your home. Investing in spray foam simply redirects that money into an upgrade that pays for itself.

Over time, those energy savings really add up, and the project eventually pays for itself. On top of that, a well-insulated, energy-efficient home is a huge selling point. It seriously boosts your property's market value, giving you a real financial return if you ever decide to sell.

By stopping drafts and taking the strain off your HVAC system, you’re not just saving money—you’re investing in your home’s comfort, durability, and long-term financial health.

Why Trust Airtight With Your Florida Insulation Project?

Picking the right insulation for your Florida home is only half the job. The real success of your existing wall spray foam insulation project comes down to one thing: the crew doing the work. In a climate as unforgiving as ours, a generic, one-size-fits-all approach just doesn't cut it. In fact, it can create more problems than it solves.

This is where having true local knowledge is a must. At Airtight Spray Foam Insulation, we live and breathe South Florida building science. We’re not just some out-of-town crew; we’re your neighbors who deal with the same relentless humidity, blistering heat, and unique home construction, from Jupiter all the way to Wellington. That deep, hands-on experience is the most important tool we bring to any job.

Your Home Isn't a Template, and Your Insulation Shouldn't Be Either

We don't just sell spray foam. We design and install a complete "Airtight Comfort System" engineered specifically for your house. That means we start with a detailed assessment of your home, hunting for potential moisture issues and figuring out the smartest, least disruptive way to get the job done right.

Our entire process is built on trust and a commitment to precision:

- Florida-Specific Expertise: We know the critical differences between insulating a concrete block home versus a wood-frame one in a place where humidity is a year-round battle.

- Serious About Safety: Your family’s well-being is our absolute priority. We follow strict safety protocols during and after the job, making sure the foam cures perfectly and is completely inert.

- A Commitment to Quality: We only use best-in-class materials and proven techniques. This guarantees your insulation performs perfectly from day one and for decades to come.

When you choose Airtight, you’re not just hiring another insulation company. You’re partnering with a team that is genuinely committed to protecting your biggest investment—your home—with a system built from the ground up to handle the unique challenges of our climate.

Finding a qualified professional is the single most important decision you'll make for this project. To help you sort through the options, check out this excellent guide on what to ask a general contractor before you hire anyone. It’s full of smart questions that will help you vet any company, including us.

Choosing Airtight Spray Foam Insulation is an investment in your peace of mind. Let our team show you the massive difference that true local expertise can make. Ready to feel the change? Contact us today for a free, no-obligation quote.

Here are some of the most common questions we get from homeowners just before they decide to pull the trigger on an existing wall spray foam insulation project. It's totally normal to want all the details, and getting these answers usually provides the final bit of confidence needed.

Can You Insulate Walls That Already Have Old, Sagging Insulation?

Yes, and honestly, that's the situation in most of the older Florida homes we work on. You'd be amazed at what we find in walls—decades-old fiberglass batts that have slumped down, gotten compressed, or just plain disintegrated, leaving massive gaps for air and humidity to sneak through.

When we inject our slow-rise foam, it's a game-changer. It doesn't just sit on top of the old stuff; it flows around and gently compacts that useless, dusty material. Then, it expands to fill every single crack and crevice, creating that monolithic air seal the original insulation never could. We always do a professional assessment first to make sure it's the right move for your specific walls.

Is This Whole Injection Foam Process Going to Make a Huge Mess?

Not on our watch. The "drill-and-fill" method is designed from the ground up to be as clean and non-disruptive as possible. Our crew treats your home like it's their own.

- Working Inside: We meticulously lay down plastic sheeting to protect all your floors and furniture from any drywall dust.

- Working Outside: Your flower beds, patio furniture, and anything else nearby gets carefully covered or worked around.

- The Final Cleanup: A thorough cleanup isn't an extra—it's a mandatory part of our job. We pack up our gear and leave your home looking exactly as we found it.

How Long Does a Typical Home Installation Take?

This is one of the best parts—it’s surprisingly fast. For an average single-story house, we can typically have the entire exterior wall retrofit done in just one to two days.

Of course, a larger two-story home or one with tricky siding might add a little time, but it's an incredibly efficient process. You get decades of comfort and energy savings for just a couple of days of work.

Are the Chemicals in Spray Foam Actually Safe for My Family and Pets?

Absolutely. Your family's safety is our number one priority, and modern spray foam is engineered to be completely safe once installed. The two liquid parts are mixed right at the tip of the spray gun and the chemical reaction happens almost instantly, safely contained within your wall cavity.

Once the foam is fully cured—which takes about 24 hours—it becomes a solid, inert plastic. It’s completely stable, has no odor, and won't off-gas. It poses no health risks to people or pets.

Our installers are pros who follow strict safety protocols, including using proper ventilation during the job to keep everyone safe. After that short curing window, all you're left with is a quieter, more comfortable home that’s healthier to live in.

Ready to transform your home's comfort and finally win the battle against high energy bills? The team at Airtight Spray Foam Insulation brings over 25 years of local experience to every project, ensuring your home gets the expert attention it deserves. Contact us today for a free, no-obligation quote.