Blog

Foam Versus Fiberglass Insulation: The Definitive Homeowner Guide

When you get right down to it, the foam versus fiberglass insulation debate is really about performance versus price. Spray foam insulation is the premium option—it creates an incredible air and moisture barrier that leads to higher long-term energy savings. On the other hand, traditional fiberglass is easier on the wallet upfront, which is why it's been a go-to choice for decades. Your decision really hinges on what you value more: maximum efficiency and a rock-solid building envelope, or immediate affordability.

Foam vs Fiberglass Insulation: An Essential Comparison

Choosing the right insulation is one of the biggest calls you'll make for your home's comfort, energy bills, and even its structural health. While both spray foam and fiberglass are designed to slow down heat transfer, they go about it in completely different ways. Getting a handle on these differences is the first step to making a smart choice that fits your home and your budget.

You know fiberglass—it’s that familiar pink or yellow stuff you see in rolls or batts. It works by trapping little pockets of air to slow down heat flow. It’s been the standard for years mainly because it’s cost-effective. But here’s the catch: it does next to nothing to stop air leaks, and that's where a huge chunk of your energy loss comes from.

Spray foam is a different animal altogether. It’s a liquid that expands on contact, creating a solid, seamless barrier that fills every single crack and gap. It doesn't just insulate; it air-seals your home at the same time. This two-in-one punch is what really sets it apart, giving you superior control over air, moisture, and temperature.

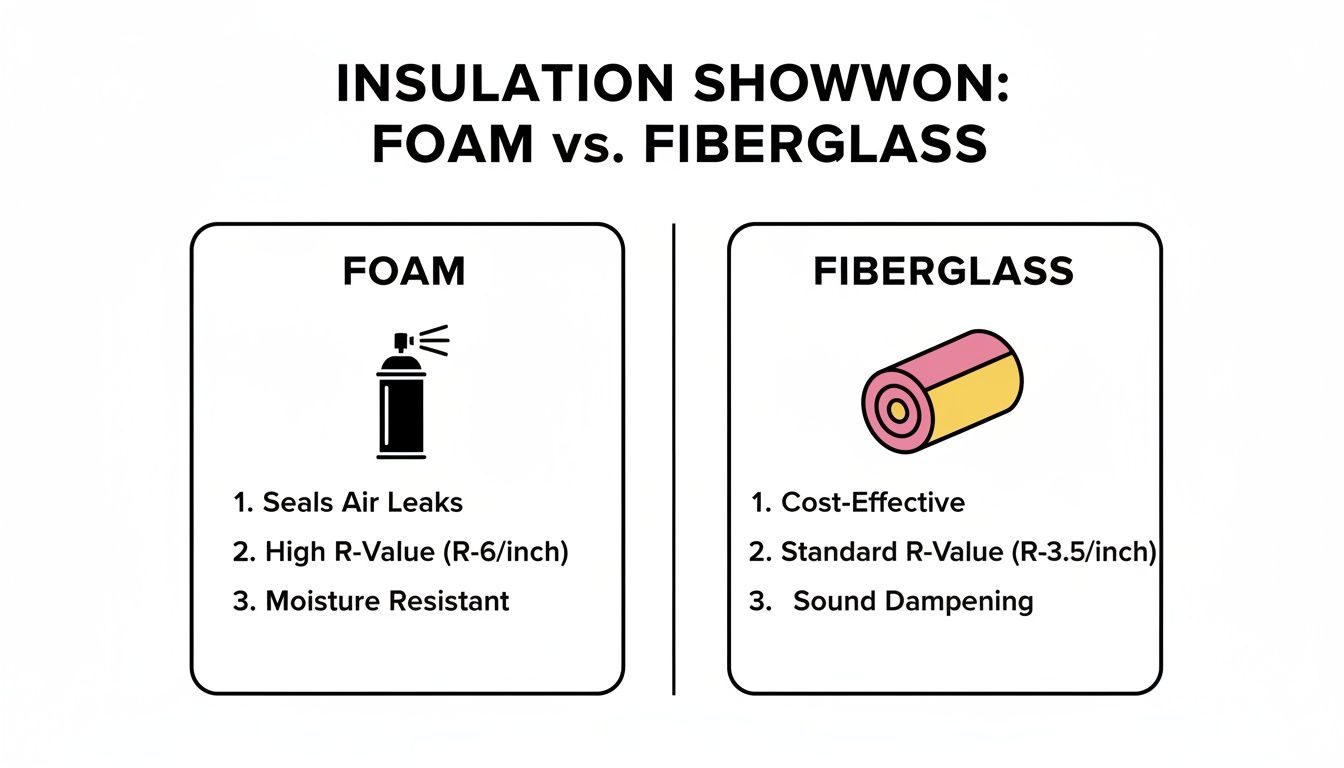

This side-by-side comparison chart gives you a quick visual on the key differences between the two.

The infographic makes it clear: while fiberglass is a decent insulator for the price, spray foam delivers a far more complete solution for sealing and protecting your home's thermal envelope.

The core of the debate is this: Fiberglass insulates, but spray foam performs. It seals the building envelope, providing thermal, air, and moisture control in a single application.

For a quick breakdown, here’s a table that gets straight to the point, summarizing the essential differences between these two popular insulation options.

Quick Comparison: Foam vs Fiberglass Insulation

| Feature | Spray Foam Insulation | Fiberglass Insulation |

|---|---|---|

| Air Sealing | Excellent; creates a complete air barrier. | Poor; does not stop air leakage. |

| Moisture Barrier | Excellent (especially closed-cell foam). | Poor; can absorb and hold moisture. |

| R-Value Per Inch | High (R-3.7 to R-7). | Moderate (R-2.2 to R-4.3). |

| Installation Cost | Higher upfront investment. | Lower upfront cost. |

| Longevity | Lifespan of the building; does not sag. | 15-20 years; can sag and settle. |

| Sound Dampening | Good (especially open-cell foam). | Good. |

This table lays out the fundamental trade-offs. You're either investing more now for long-term performance and durability with spray foam, or you're saving money on the initial installation with fiberglass but accepting its limitations.

Beyond R-Value: The Critical Role of Air Sealing

Everyone gets hung up on R-value, but it only tells half the story. It’s a lab-tested number for an insulation's resistance to conductive heat, but your home isn't a lab. In the real world, a huge chunk of your energy bill is driven by air leakage—all the tiny gaps and cracks that let your conditioned air sneak out and the Florida heat sneak in.

This is where the foam versus fiberglass insulation debate really gets interesting.

Fiberglass batts can have a decent R-value on paper, but they do absolutely nothing to stop air movement. You can pile it on thick, but air will just whistle right through and around it, taking your heating and cooling dollars along for the ride. It’s like wearing a thick wool sweater on a windy day. The sweater itself is warm, but the wind cuts right through, leaving you shivering.

Spray foam is a completely different animal. It doesn’t just resist heat flow; it creates a solid, continuous air barrier that stops leaks cold.

How Spray Foam Creates an Airtight Seal

When we apply spray foam, it goes on as a liquid and then expands like crazy, filling every single nook, cranny, and imperfection in your home’s frame. It molds itself around pipes, wires, and studs, leaving zero room for air to get through. The result is a truly airtight building envelope.

This isn't just a minor perk—it's a complete game-changer for your home's performance. By stopping all that uncontrolled air exchange, spray foam ensures the R-value you paid for is the R-value you actually get. Your HVAC system can finally take a break instead of constantly fighting drafts. That means real energy savings and a much more comfortable, consistent temperature inside your home.

If you want to see just how much air your home is leaking, it's worth understanding what a blower door test is and how we use it to pinpoint these problem areas.

A home insulated with fiberglass is like a boat with a bunch of tiny, invisible leaks. It’ll float, but you’re constantly bailing water. A spray foam home is like a sealed submarine—it gives you complete control over the interior environment.

The Impact on Your "Effective" R-Value

The raw insulating power is another area where the materials differ. Foamed plastics deliver a much higher R-value per inch, typically between R-3.6 to R-7, while fiberglass sits in the R-2.2 to R-4.3 range. This makes foam a no-brainer for tight spaces, especially in our humid climate here in Jupiter and Palm Beach Gardens.

Closed-cell spray foam, in particular, offers an impressive R-value of up to 6.5 per inch and doubles as a vapor barrier, stopping moisture in its tracks. In head-to-head testing, it's been shown to reduce air leakage by up to 24% more than fiberglass batts.

When you combine that high R-value with near-perfect air sealing, you get a material that simply works better in the real world. An attic with R-30 fiberglass riddled with air leaks will perform far worse than its rating suggests. That same attic with just R-20 of spray foam will deliver rock-solid performance because it has solved the air leakage problem at the source.

To take it a step further, you can pair a well-sealed building envelope with solutions like professional Aeroseal duct sealing to eliminate energy loss from your HVAC system. When your home's shell and its ductwork are both airtight, you achieve total control over your home's climate and energy use. It's about making every part of your thermal system work together, not against each other.

Winning The Battle Against Moisture And Mold

Here in South Florida, insulation has to do more than just keep your house cool. It’s on the front lines of a daily battle against moisture. Get it wrong, and you’re looking at serious problems—mold, wood rot, and terrible indoor air quality. This is where the debate between foam versus fiberglass insulation gets really interesting, and the winner becomes crystal clear.

Fiberglass is fundamentally porous. You can think of it like a giant sponge stuffed into your walls or attic. Its fine glass fibers are great at trapping air, but they also trap moisture right along with it. When humid Florida air works its way into a wall cavity, fiberglass batts just soak it up.

This is a huge problem for two reasons. First, wet insulation is useless insulation. The R-value of damp fiberglass plummets, which means your AC has to run constantly just to keep up. Second—and this is the scary part—that trapped moisture creates a perfect petri dish for mold and mildew to grow hidden inside your walls.

How Foam Insulation Manages Moisture

Spray foam, especially closed-cell foam, takes a completely different tack. It doesn't just manage moisture; it flat-out rejects it. Because it's non-permeable, water vapor can't pass through it. It’s an insulator, an air barrier, and a vapor barrier all in one shot.

When we install spray foam, it creates a single, seamless layer that bonds directly to the wood and sheathing. There are no gaps or seams for humid air to sneak through and condense on cooler surfaces. By stopping moisture dead in its tracks, we protect your home’s wood framing from rot and deny mold the water it needs to survive.

In the fight against humidity, fiberglass is always on defense, trying to deal with moisture after it’s already inside. Closed-cell spray foam goes on offense, creating an impenetrable barrier that stops moisture from ever becoming a problem.

This is a game-changer in South Florida, where managing humidity is a full-time job for homeowners and business managers trying to keep costs down. Closed-cell foam's powerful moisture resistance is what keeps attics dry and mold-free. In stark contrast, fiberglass can absorb a shocking amount of moisture, rendering it ineffective. In fact, we see it all the time: homes with spray foam are 15-25% more energy-efficient than those with fiberglass. As utility rates keep climbing, that translates to hundreds of dollars in real savings every year.

Real-World Scenarios in Damp Climates

Picture a standard vented attic in West Palm Beach on a hot August day. With fiberglass on the attic floor, hot, sticky air is constantly being pulled in through the soffit vents. That moisture condenses on any cool surface it finds and gets absorbed by the insulation, wrecking its R-value and setting the stage for mold.

Now, imagine that same attic, but with closed-cell spray foam applied to the underside of the roof deck. This creates an unvented, conditioned space. The foam completely blocks moisture from getting in, stabilizes the attic temperature, and protects the entire roof structure from humidity. You can get a deeper dive into how this works with vapor barriers in attics in our detailed guide.

This is why foam is always the superior choice for any area that gets damp:

- Attics and Roof Decks: It stops moisture infiltration and prevents attic mold from ever starting.

- Crawl Spaces: It seals out ground moisture, protecting the floor joists and subfloor from rot.

- Exterior Walls: It functions as a powerful vapor barrier, keeping condensation out of your wall cavities.

- Basements: It creates a continuous barrier against water seeping through foundation walls.

Choosing the right insulation is a critical first step, but total moisture control is how you win the war on mold. A big part of that is knowing how to avoid mold in basement areas and other trouble spots. By investing in a material that actively repels water, you're not just insulating—you're protecting your home's structure and your family's health.

Analyzing Lifetime Cost and Return on Investment

Let’s be honest: when you’re comparing foam versus fiberglass insulation, the first thing everyone looks at is the price. And yes, fiberglass is definitely cheaper on day one. It's a tempting choice if you're watching the budget closely.

But if you want the real financial picture, you have to look beyond the initial quote. Think about the total cost of ownership over the entire time you live in your home.

That higher upfront investment for spray foam? It often pays for itself, and then some, through massive long-term savings. I'm not talking about trimming a few bucks off your power bill. I'm talking about a fundamental change in your home's energy use. By creating a nearly perfect air seal, spray foam can cut heating and cooling costs by 20% to 50%.

Those savings add up, month after month, year after year. Eventually, the initial investment is paid back, and the savings just keep coming for as long as you own the home.

The Hidden Costs of Fiberglass

Fiberglass seems like the budget-friendly choice at first, but its limitations can lead to a lot of hidden costs down the road. Since it doesn't actually stop air from leaking through your walls and attic, your HVAC system has to work overtime, day in and day out. That means higher energy bills, every single month.

It gets worse. Over time, fiberglass insulation is notorious for sagging, settling, and absorbing moisture. After 15 or 20 years, it can lose a huge chunk of its R-value. To get that performance back, you'll need to pay for a "top-up" or even a full replacement. You could end up paying to insulate your home twice.

The "cheaper" fiberglass job often becomes a recurring expense, not a one-and-done investment. You have to factor in the constant energy waste and the eventual replacement costs to see the true lifetime price.

Why Spray Foam Is a Long-Term Asset

Spray foam is different. It’s a permanent upgrade to your home. Once it’s installed, it doesn’t sag, compress, or lose its insulating power. It actually becomes a structural part of your home, adding strength to your walls while delivering consistent performance for decades.

Here’s a practical look at where the value comes from:

- Serious Energy Savings: By getting rid of air leaks, foam takes a huge load off your HVAC system. You'll see those savings on your very next bill.

- Zero Maintenance or Replacement: Unlike fiberglass, you'll never have to top up or replace spray foam. The job is done, for good.

- Higher Property Value: A home with a completely sealed, high-performance building envelope is a massive selling point for potential buyers.

Let's break down the financial side-by-side.

Cost and Value Analysis Foam vs Fiberglass

This table lays out the financial story, comparing the upfront costs against the long-term savings and overall return on investment for both insulation types.

| Financial Factor | Spray Foam Insulation | Fiberglass Insulation |

|---|---|---|

| Upfront Cost | Higher initial investment (2-3x more) | Low initial cost |

| Energy Savings | Significant savings (20-50% reduction) | Moderate savings (stops conduction, not air leaks) |

| HVAC Longevity | Reduces strain, potentially extending system life | HVAC works harder due to air leakage |

| Maintenance Costs | None. Permanent, no settling or degradation. | Potential costs for top-ups or replacement in 15-20 years. |

| Return on Investment | High ROI over 5-7 years through energy savings | Lower ROI, offset by higher lifetime energy costs |

| Property Value | Increases resale value as a premium feature | Considered a standard feature with no added value |

When you look at the whole picture, the choice becomes much clearer. The financial case for spray foam is incredibly strong once you stop thinking of it as a simple expense and start seeing it as a long-term investment in your home's performance and value.

For a deeper dive into the numbers, check out our guide on whether spray foam insulation is worth it for homeowners like you.

Where Does Each Type of Insulation Actually Belong?

Choosing the right insulation isn’t a one-size-fits-all deal. When you’re weighing foam versus fiberglass insulation, the best choice really comes down to the specific part of your home you're working on. Different areas demand different things—a crawl space needs moisture resistance, while a complex attic needs a perfect air seal.

Think of it like buying tires. You wouldn't put racing slicks on an off-road truck, right? In the same way, the insulation that’s perfect for your interior walls might be a terrible choice for a roof deck in our humid climate. To get the best performance, durability, and value, you need to match the material to the job.

That means looking at each part of your home—the attic, walls, and even unique structures like metal buildings—and figuring out what it truly needs. This is the key to creating a home that’s genuinely comfortable and efficient.

Insulating Attics for Real-World Efficiency

Your attic is probably the most important spot to get right. It's where you lose the most cool air in the summer and heat in the winter. The goal is twofold: stop heat from transferring and, just as important, stop air and moisture from moving through the roof assembly.

Fiberglass, either in batts or blown-in, has been the go-to for attic floors for years. It's affordable and can hit high R-values if installed perfectly. The problem is, its real-world performance is almost always compromised by air leaks around can lights, vents, and attic hatches—gaps it does absolutely nothing to seal.

This is where spray foam completely changes the game. By applying open-cell or closed-cell foam directly to the underside of the roof deck, you create what's called an unvented, conditioned attic. This approach has massive advantages:

- Airtight Seal: Foam expands into every nook and cranny, stopping hot, humid South Florida air from getting sucked into your attic in the first place.

- Moisture Control: Closed-cell foam acts as a vapor barrier, which is critical for protecting your roof structure from condensation and mold.

- Temperature Stability: It brings your attic inside the "conditioned envelope" of your home, protecting your ductwork and HVAC equipment from brutal temperature extremes.

When you insulate the roof deck with spray foam, you’re doing more than just insulating—you’re fundamentally changing how your attic works. It becomes a clean, dry, and temperature-stable buffer that protects the entire house.

Fortifying Exterior Walls for Comfort and Strength

Exterior walls have their own set of challenges. They’re full of obstacles like wiring, plumbing, and electrical boxes that make it tough to get a continuous layer of insulation.

Fiberglass batts are cut and squeezed to fit between studs, but this process always leaves small gaps and voids around every single obstruction. These little gaps become superhighways for air to move through, creating cold spots in the winter and letting heat creep in during the summer.

Spray foam, on the other hand, expands to fill the entire wall cavity, creating one solid, monolithic barrier. It molds perfectly around pipes and wires, killing every gap and draft. As a bonus, closed-cell spray foam adds significant structural rigidity to the wall, increasing its racking strength and making the whole house feel more solid.

Tackling Unique Structures Like Metal Buildings

Metal buildings, workshops, and warehouses are notoriously hard to insulate well. The steel frame acts as a thermal bridge, bleeding energy right through the walls, and the wide-open spaces are magnets for condensation and wild temperature swings. Fiberglass is usually a poor fit here because it can trap moisture against the metal panels, which leads to rust and a total loss of performance.

For these jobs, spray foam is the undisputed winner. In South Florida's metal buildings, warehouses, and commercial spaces, spray foam seals off thermal bridges so effectively that it can cut HVAC loads by 30-40% compared to fiberglass, according to industry benchmarks. We hear it from owners all the time—stabilized temperatures and much lower bills. One study in humid zones found that foam-insulated structures slashed cooling costs by 25% a year.

Our Airtight Comfort System is designed for this exact challenge, combating our regional humidity with a durable, high-R-value application that lasts for decades. It won't settle or sag like fiberglass, which can lose 10-20% of its volume over time. You can find more insights on the commercial insulation market at fortunebusinessinsights.com.

Why Professional Installation Is Non-Negotiable

When you're weighing foam versus fiberglass insulation, it's easy to get lost in the details of R-values and material specs. But here’s something I’ve learned over years in this business: the performance you actually get depends almost entirely on the quality of the installation. Even the most advanced insulation is basically useless if it’s put in wrong.

This isn’t a weekend warrior project. Both spray foam and fiberglass demand a level of precision that only comes from professional training and hands-on experience. A sloppy job can lead to air leaks, moisture problems, and terrible thermal performance, completely wiping out your investment and potentially causing expensive damage down the line.

The Risks of Improper Spray Foam Application

Spray foam insulation is a sophisticated chemical product. It has to be mixed and applied under very specific conditions to work as intended, and professional installers are experts at managing this entire process safely and effectively.

Here are a few critical factors that a pro has dialed in:

- Temperature Control: The surface getting sprayed and the chemicals themselves have to be at just the right temperature. If not, the foam won't expand or cure correctly.

- Ratio Accuracy: The two chemical components must be mixed at a precise 1-to-1 ratio. If that mixture is off even slightly, the foam can shrink and pull away from the studs, or worse, never fully cure, leaving a sticky, smelly mess behind.

- Application Thickness: You can't just blast it on. Applying foam too thick in one go can trap heat and create a serious fire hazard. Professionals apply it in controlled layers, or "lifts," to build up a safe and stable final product.

An experienced contractor isn't just spraying foam; they are performing a chemical reaction inside the walls of your home. Their expertise is your best guarantee of safety, performance, and long-term durability.

Why Even Fiberglass Installation Requires a Pro

Fiberglass might look straightforward—just unroll and stuff it in, right? Wrong. Its effectiveness also hinges on a perfect installation. Those batts have to be meticulously cut and fitted to tuck in snugly around every single pipe, wire, and outlet box without getting squished.

These are the common DIY mistakes that absolutely kill fiberglass performance:

- Compression: Shoving a batt into a space that's too small crushes the air pockets that do the insulating work, drastically dropping its R-value.

- Gaps and Voids: Even tiny gaps create "thermal bridges," which are basically highways for heat to bypass the insulation completely.

- Improper Facing: The paper or foil vapor retarder has a specific job to do, and it must face the right direction (toward the heated/cooled living space) to stop moisture from getting trapped inside your walls.

A professional makes sure every single cavity is filled completely and correctly, letting the material do the job it was designed for.

What to Look for in an Insulation Contractor

Choosing the right installer is just as critical as choosing the right material. A reputable contractor will give you a detailed quote, walk you through their process, and stand behind their work. Make sure they are licensed, fully insured, and happy to provide references.

At the end of the day, professional installation is what turns a good product into a great solution for your home. It ensures you get a complete air seal, the right application depth, and the full value of your investment. Whether you go with foam or fiberglass, hiring a certified expert is how you get the comfort, savings, and peace of mind you’re paying for.

Answers to Your Top Insulation Questions

When it comes to foam versus fiberglass insulation, we hear the same great questions from homeowners all the time. Getting straight answers is the only way to feel confident about what you’re putting in your home. Here are a few of the most common things people ask us across South Florida.

We’ll cover everything from long-term safety and performance to what actually happens during installation, so you can understand the real-world impact of your decision.

Is Spray Foam Insulation Safe for My Home and Family?

Absolutely, as long as it’s installed by trained, certified professionals. The key is the curing process. Modern spray foam is completely safe once it has fully cured, which usually takes about 24 hours. After that, it becomes a stable, inert solid that doesn't release any fumes or "off-gas."

A reputable installer will follow strict safety rules during the application, like using powerful ventilation and wearing personal protective equipment. This isn't just for show—it ensures your home's air is clean and healthy after the job is done. Plus, many of today’s foams use blowing agents that are much friendlier to the environment.

Can Spray Foam Be Installed Over Existing Insulation?

Technically, you can do it in certain situations, but it's almost never the right call. For spray foam to do its job properly, you really need to take out all the old insulation first. This step is critical because it allows the foam to bond directly to the wood and sheathing, creating that seamless air and moisture barrier it’s famous for.

Removing old, dusty, and potentially damp insulation isn’t just about performance; it’s about starting with a clean slate. You get rid of lingering allergens, dust mites, or hidden moisture problems, giving your home a healthy foundation for a new, high-performance system.

Going this route guarantees you aren't just trapping old issues behind a new wall. A true expert will look at your attic or walls and explain the best way forward to make sure the foam works like it should for the long haul.

How Long Does Spray Foam Insulation Last Compared to Fiberglass?

Spray foam is a one-and-done solution. It’s engineered to last for the entire life of your home. Because it’s a rigid polymer, it won’t sag, settle, or break down over time. Its R-value and air-sealing power remain consistent decade after decade with zero maintenance.

Fiberglass, on the other hand, has a definite shelf life. It can get compressed, soak up moisture from our humid Florida air, and settle in wall cavities, all of which cause its thermal performance to drop significantly. You’ll often find it needs a top-up or a complete replacement after 15 to 20 years. This makes spray foam a much more durable investment that pays off with consistent comfort and energy savings for decades.

Ready to see how the right insulation can transform your home's comfort and efficiency? The experts at Airtight Spray Foam Insulation are here to help. Request your free, no-obligation quote today!