Blog

Blown insulation vs spray foam: Which Is Best for Your Home

When you’re trying to decide between blown insulation and spray foam, it really comes down to what you’re trying to achieve with your budget, moisture control, and long-term energy goals. Frankly, spray foam offers superior air sealing and higher R-values, making it the premium choice for anyone serious about efficiency. On the other hand, blown insulation provides a cost-effective way to upgrade existing spaces, especially attics.

For us here in South Florida, making the right call is absolutely critical.

Comparing the Core Insulation Methods

Choosing the right insulation is one of the most important decisions you can make for your home’s comfort and energy bills. It’s not just about stuffing material in your attic; it’s about creating a complete thermal envelope that shields your living space from our relentless heat and humidity. The first step is getting a real handle on the fundamental differences between blown-in and spray foam.

Blown insulation, often called “loose-fill,” is pretty straightforward. It’s made of small particles of either fiberglass or cellulose (which is mostly recycled paper). A machine blows these particles through a hose into an attic or wall cavity, where they settle around obstacles like pipes and wiring. It’s a popular pick because it’s affordable and does a decent job adding R-value to big, open attic floors.

Spray foam insulation is a whole different animal. It’s a two-part chemical that’s applied as a liquid and expands like crazy, turning into a solid foam right before your eyes. This expansion is key—it fills every single crack and crevice, creating a powerful, seamless air barrier that blown insulation just can’t touch on its own.

You’ll hear about two main types:

- Open-Cell Spray Foam: This is a softer, more flexible foam. It’s fantastic for dampening sound and provides an excellent air seal.

- Closed-Cell Spray Foam: This is a rigid, dense foam. It offers a much higher R-value per inch and acts as a moisture barrier, even adding a bit of structural strength to whatever it’s sprayed on.

The Bottom Line: The biggest difference is how they work. Blown insulation fills a space to slow down heat transfer. Spray foam seals a space, stopping both heat transfer and air leakage at the same time.

Quick Comparison Blown Insulation vs Spray Foam

To make things simpler, here’s an at-a-glance summary of the core differences. This table helps you quickly grasp the key trade-offs between these two popular insulation methods.

| Feature | Blown Insulation (Cellulose/Fiberglass) | Spray Foam (Open & Closed-Cell) |

|---|---|---|

| Primary Benefit | Cost-effective coverage | Superior air sealing and high R-value |

| R-Value (Per Inch) | R-2.2 to R-3.8 | R-3.5 (Open-Cell) to R-7.0 (Closed-Cell) |

| Air Sealing | Low (Requires separate sealing) | Excellent (Creates an inherent air barrier) |

| Moisture Resistance | Limited to Moderate | Excellent (Especially closed-cell, which is a vapor retarder) |

| Installation Method | Blown in with a hose | Sprayed as a liquid, then expands |

| Best Use Case | Attic top-ups, empty wall cavities | New construction, unvented attics, moisture-prone areas, metal buildings |

| Typical Lifespan | 15-30 years (can settle) | 50+ years (structurally stable) |

This quick comparison makes it clear: while both materials insulate, they really solve different problems. Your choice hinges on whether your main priority is a budget-friendly thermal boost or you’re ready to invest in a high-performance system that tackles air, heat, and moisture all in one shot.

Comparing Thermal Performance and R-Value

When we talk insulation performance, one number matters most: R-value. It’s simply a measure of how well a material resists heat flow. The higher the R-value, the better the insulation, and this is where blown-in and spray foam go their separate ways. But it’s not just the final number that counts—it’s what you get per inch.

This “R-value per inch” is a total game-changer, especially in construction where every inch of space matters. Think about the standard 2×4 wall cavities in older Florida homes or the shallow rafter bays in a vaulted ceiling. You can only pack so much insulation in there, so you need every single inch to pull its weight.

Understanding the R-Value Gap

Let’s be blunt: the thermal resistance these materials offer isn’t even in the same ballpark. Blown-in insulation, whether it’s fiberglass or cellulose, provides a decent but pretty modest R-value for its thickness.

Spray foam, on the other hand, is an absolute powerhouse, especially the closed-cell version. Its dense, rigid structure is engineered from the ground up to stop heat dead in its tracks, and it does it in far less space.

Spray foam delivers a much higher R-value per inch, which is why it took off in high-performance building back in the 1990s. Closed-cell spray foam typically gives you R-6 to R-7 per inch, while open-cell offers around R-3.5 per inch. Compare that to blown-in cellulose at R-3.2 to R-3.8 per inch or blown-in fiberglass, which lags behind at R-2.2 to R-2.7 per inch.

What does that mean in the real world? A 3-inch layer of closed-cell foam can give you the same insulating power as 6 to 9 inches of blown-in fiberglass. For a deeper dive into how these R-values impact performance, check out the insights on sprayworksequipment.com.

The takeaway is simple: to hit an R-30 target in your attic, you might need 10-12 inches of blown-in cellulose. With closed-cell spray foam, you could get there with less than five inches.

What This Means for Your South Florida Home

In a climate like ours, where the sun is relentless, maximizing the R-value in your roof and walls isn’t just a good idea—it’s essential. The superior performance of spray foam translates directly into real, tangible benefits for homeowners and builders.

Imagine you’re building a new home with a modern, unvented attic. By applying closed-cell spray foam directly to the underside of the roof deck, you can hit a high R-value (like R-38) with just 5-6 inches of material. This creates a conditioned attic space, which keeps your ductwork out of the blistering heat and lets your HVAC system run far more efficiently.

- Smaller HVAC Systems: Because spray foam creates such a tight, well-insulated home, you can often get by with a smaller, less expensive HVAC unit. It simply doesn’t have to work as hard to fight the heat.

- Lower Energy Bills: Better thermal resistance means less heat creeping into your home. This leads directly to lower cooling costs every single month, delivering a strong return on your investment.

- Serious Indoor Comfort: By stopping heat transfer so effectively, spray foam gets rid of hot spots and drafts. The result is a more stable, comfortable indoor environment, no matter how high the thermometer climbs outside.

When Space Is the Deciding Factor

The R-value-per-inch advantage is what truly seals the deal in retrofits or any area with limited depth.

For example, trying to insulate the walls of an existing block home or a metal building is a classic challenge. The cavities might only be a few inches deep. If you fill that space with blown insulation, you might only get an R-value of R-10 to R-13.

But fill that exact same cavity with closed-cell spray foam, and you could hit an R-value of R-21 or more. This often makes spray foam the only practical choice for meeting modern energy codes in shallow spaces without having to rebuild the walls. When you compare blown insulation vs spray foam on thermal performance alone, spray foam’s ability to pack maximum power into minimal space gives it a clear and decisive edge.

Analyzing Air Sealing And Moisture Control

In a climate as humid as South Florida’s, just stopping heat isn’t enough—controlling moisture is the other half of the battle. The main way humid, salty air gets into your home is through tiny leaks and gaps in the structure. This drives up your cooling bills and creates the perfect environment for mold and mildew to thrive.

This is where the real differences between blown insulation and spray foam become crystal clear.

Blown-in insulation does a great job of filling big, open spaces like an attic floor to hit a target R-value. The problem? It doesn’t actually stop air from moving. Think of it like a thick wool sweater: it’s warm, but the wind can still cut right through it. For blown-in insulation to work properly, it needs a completely separate air-sealing step where a contractor meticulously foams and caulks every gap around pipes, wires, and joints.

The Power of an Integrated Barrier

Spray foam insulation works on a totally different principle. When it’s applied, it goes on as a liquid and expands into a solid, but it does more than just fill the space. It sticks to everything it touches, creating one solid, seamless barrier that seals every crack and crevice along the way.

This built-in ability to both insulate and air seal is a game-changer for moisture control.

- Closed-Cell Spray Foam: This is the heavy hitter. It creates a powerful, non-permeable barrier that blocks both air and water vapor, effectively locking out humidity. It’s our go-to choice for any area where moisture is a concern.

- Open-Cell Spray Foam: While it’s softer and allows vapor to pass through, open-cell foam still creates an incredible air seal. It stops humid air from getting in but allows the structure to breathe and dry out if any moisture ever gets trapped.

The core difference is simple: Blown insulation just resists heat and needs a separate air barrier. Spray foam is both the insulation and the air barrier in one shot, giving you a much stronger defense against air and moisture.

Performance in High-Humidity Environments

Down here in South Florida, an insulation’s ability to handle our relentless humidity is what determines if it will succeed or fail long-term.

Closed-cell spray foam is a beast against moisture. Its dense structure doesn’t absorb water and acts as a vapor retarder, making it perfect for crawlspaces, metal buildings, and coastal homes where keeping moisture out is non-negotiable.

On the other hand, blown-in cellulose is basically recycled paper. If a roof leak happens or the attic humidity gets out of control, it can absorb and hold that moisture. Even though it’s treated to resist mold, getting soaked can cause it to compact, lose its R-value, and even start to decay. Blown-in fiberglass won’t grow mold since it’s inorganic, but it can trap moisture against the wood framing, leading to rot if the area isn’t properly ventilated.

When you’re comparing blown insulation vs. spray foam for a humid climate, the tough, impermeable nature of closed-cell foam offers a level of protection that loose-fill materials just can’t provide by themselves. Our decades of experience installing all types of spray foam insulation have shown us time and again that it’s the clear winner for preventing the moisture problems we see every day in South Florida.

Breaking Down Installation Costs and Long-Term ROI

Let’s move past the initial sticker shock and get into the real lifetime value of your insulation investment. When you put blown-in insulation vs. spray foam side-by-side, the upfront cost is usually the first thing that jumps out, and it’s a big deal. But making a smart decision for your home’s thermal envelope means looking beyond the first invoice.

The real story isn’t just about what you pay on day one. It’s about how that investment holds up over decades of punishing South Florida heat. True value comes from digging into the long-term energy savings, durability, and a few other benefits you might not see right away.

Unpacking the Upfront Investment

I won’t sugarcoat it: spray foam insulation costs more to install. The materials are more advanced, and the job requires specialized gear and certified pros, which all adds to the price. Blown-in insulation, on the other hand, is a simpler material with a quicker, less technical installation, making it the more budget-friendly choice upfront.

The installed cost for spray foam has always been higher than blown-in, and that fact alone often drives the decision in the mainstream residential market. Industry data shows spray foam typically runs between $1.50 and $4.90 per square foot, depending on whether you choose open-cell or closed-cell, the thickness you need, and local labor rates. At the same time, blown-in cellulose or fiberglass usually lands somewhere between $0.75 and $1.50 per square foot for similar attic coverage. This often makes spray foam two to four times more expensive right out of the gate. For a deeper dive into these numbers, One Nation Exteriors offers a solid cost and performance breakdown.

Calculating the True Return on Investment

While blown insulation is cheaper on paper, the conversation flips when we start talking about return on investment (ROI). Spray foam’s higher price is directly connected to its superior performance, which leads to significant, long-term energy savings that can claw back its initial cost over time.

Its ability to create an almost perfect air seal is the game-changer. By stopping air from leaking in and out of your home, spray foam takes a massive load off your HVAC system. In a climate like South Florida where your AC runs nonstop, this means you’ll see immediate and noticeable drops in your monthly FPL bill.

Key Insight: The payback period for spray foam is often much shorter here in our hot, humid climate. The harder your AC has to work, the faster a high-performance insulation system pays for itself.

Blown insulation absolutely improves energy efficiency, but because it can’t stop air leakage on its own, the savings potential just has a lower ceiling.

When we look at the total cost of ownership over two decades, the numbers start telling a different story. The upfront savings of blown-in insulation can be eroded by lower energy savings and the potential need for a top-up, while spray foam’s initial investment is offset by deeper, more consistent savings year after year.

Cost and ROI Comparison Over a 20-Year Lifespan

This table models the total cost of ownership, factoring in installation, estimated annual energy savings, and potential maintenance over two decades for a typical South Florida home.

| Financial Factor | Blown-In Insulation (Cellulose) | Closed-Cell Spray Foam |

|---|---|---|

| Upfront Cost (1,500 sq. ft. attic) | $1,500 – $2,250 | $4,500 – $7,350 |

| Est. Annual Energy Savings | $200 – $400 | $400 – $700+ |

| Potential Maintenance (20 Yrs) | $500 – $750 (for top-up) | $0 |

| Total 20-Year Savings (Net) | $3,250 – $7,500 | $8,000 – $14,000+ |

| Breakeven Point (Est.) | 4 – 8 Years | 7 – 12 Years |

| 20-Year ROI | Strong | Exceptional |

Ultimately, while spray foam takes longer to break even, its superior performance delivers a far greater net financial benefit over the life of your home, making it a powerful long-term asset.

Durability and Lifetime Value

The lifespan of your insulation is another critical piece of the ROI puzzle. Over time, blown-in materials can settle, compress, or get shifted around, creating gaps and weak spots that tank their R-value. This means a slow decline in performance, and you might even need a “top-up” application every 15 to 20 years to keep it effective.

Spray foam, especially the closed-cell kind, is a one-and-done solution.

- Structural Stability: Once it cures, it becomes a solid, permanent part of your home’s structure. It won’t sag, settle, or shrink over its 50+ year lifespan.

- Moisture Resistance: It’s built to resist moisture, which stops degradation and prevents mold from getting a foothold, protecting its performance for good.

- Structural Reinforcement: Closed-cell foam brings another hidden benefit to the table: it glues itself to surfaces, actually increasing the structural strength of walls and roof decks. In a hurricane zone, that extra rigidity is a huge plus.

This incredible durability means the performance you pay for on day one is the same performance you’ll have decades from now, with basically zero maintenance. When you add up the potential cost of re-insulating with blown-in and the structural upgrade you get from closed-cell foam, the long-term case for spray foam becomes rock solid. It stops being an expense and starts looking like a permanent, high-value upgrade to your home.

Finding the Right Application for Each Insulation Type

When you’re comparing blown insulation and spray foam, it’s never about which one is flat-out “better.” It’s about picking the right tool for the job. Each material is engineered to solve different problems, and understanding where they shine is the key to a smart, confident investment.

The right choice really depends on your house, its age, its construction, and what you’re trying to achieve.

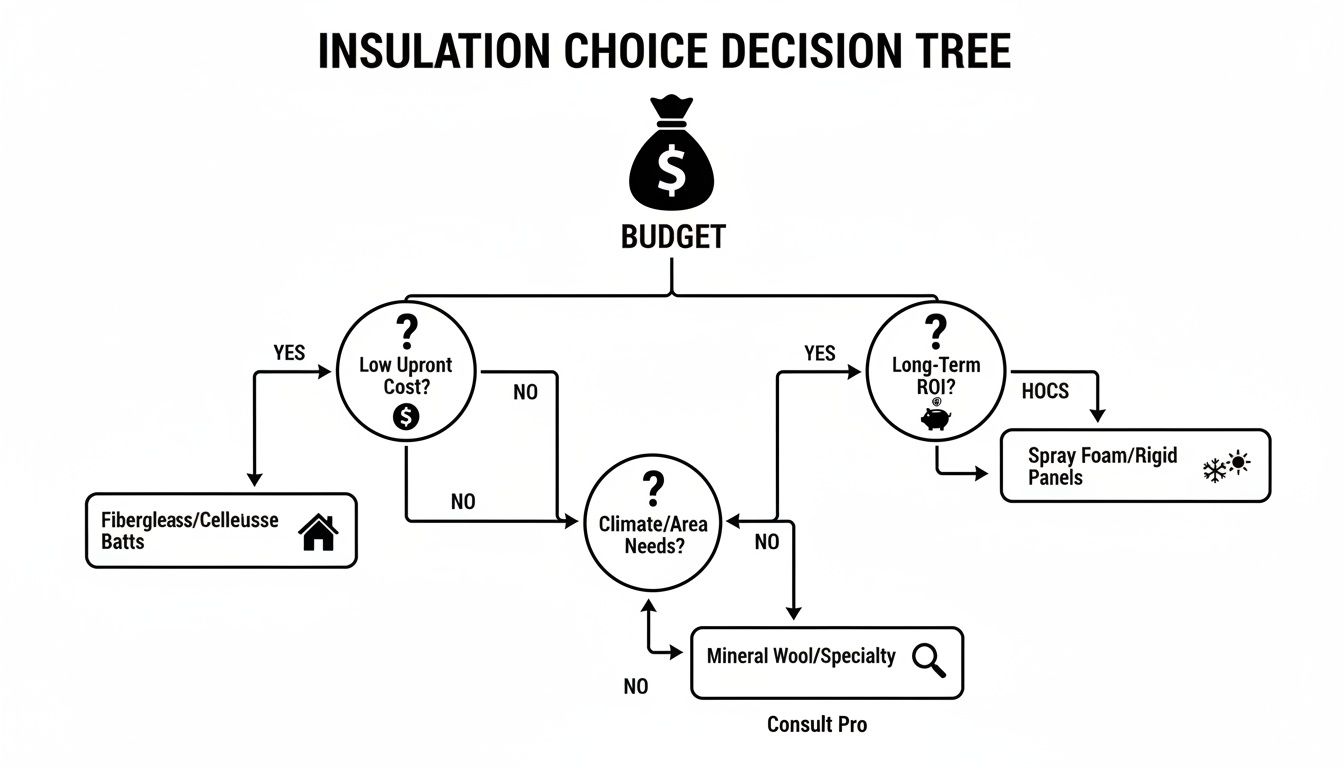

This flowchart maps out the decision-making process perfectly. It all starts with one question: is your primary driver the upfront budget or the long-term ROI?

As you can see, projects driven by budget almost always point toward blown-in solutions. But when performance, air sealing, and durability are the priority, the investment in spray foam starts to make a lot more sense.

Ideal Scenarios for Blown-In Insulation

Blown-in insulation is at its best when budget and simple coverage are the main goals. Its biggest advantages are speed and affordability, making it a fantastic choice for specific retrofit jobs.

We see blown-in insulation work great when:

- Topping Up Existing Attic Insulation: If you already have old insulation that’s settled or just isn’t thick enough to meet today’s codes, blowing in a fresh cap of fiberglass or cellulose is the fastest, most effective way to boost your R-value.

- Insulating Empty Wall Cavities: For older homes with zero insulation in the walls, we can install blown-in material with minimal mess. We just drill a few small holes, blow the insulation in to fill the empty space, and you get a major thermal upgrade without tearing out the drywall.

Think of blown insulation as the pragmatic choice. It’s for improving the thermal performance of existing, easy-to-access spaces where a perfect air seal isn’t the number one goal. It delivers a solid performance boost for a much lower upfront cost.

Strategic Advantages of Spray Foam Insulation

Spray foam is the high-performance option we bring in for the tougher jobs. It’s for situations where its unique properties solve complex building science challenges that other materials just can’t handle.

This isn’t just an R-value booster; it’s a complete thermal, air, and moisture management system.

Open-Cell Spray Foam Applications

Open-cell spray foam is the softer, more flexible version, which makes it perfect for certain indoor applications. Its real superpower is creating a phenomenal air seal while also being an incredible sound absorber.

- Soundproofing Interior Walls: Its spongy texture is fantastic for deadening airborne noise. We use it all the time for home theaters, bedrooms, or any walls between living spaces where you want some peace and quiet.

- Complex Rooflines: For attics with complicated truss systems, dormers, and other hard-to-reach corners, open-cell foam is a lifesaver. It expands to fill every single nook and cranny, creating a monolithic seal that eliminates the air leaks that plague those tricky spots.

Closed-Cell Spray Foam Applications

When the job demands maximum performance, we turn to closed-cell spray foam. It’s the ultimate problem-solver for areas that need serious thermal resistance, moisture control, and structural integrity. Its rigid, dense structure makes it uniquely suited for the toughest jobs in South Florida.

- Moisture-Prone Zones: This is the undisputed champion for crawl spaces, basements, and any concrete block walls below grade. It forms a completely non-permeable vapor barrier that locks out moisture, preventing mold and rot before they can start.

- Maximum R-Value in Minimal Space: When you’re dealing with shallow 2×4 walls or the tight cavities inside concrete block construction, closed-cell foam is often the only way to hit modern energy code R-values. You can read more about how we improve the insulation value of concrete block walls in our detailed guide.

- Hurricane-Prone Regions: In South Florida, this is a big one. Closed-cell foam acts like a high-strength glue, adhering tenaciously to framing and sheathing. This adds significant structural rigidity to walls and roof decks, helping the entire building envelope resist the uplift and racking forces of high winds.

At the end of the day, the blown insulation vs. spray foam decision is a strategic one. Blown insulation offers an affordable, effective upgrade for straightforward jobs. Spray foam, on the other hand, provides a powerful, multi-faceted solution for the critical areas of your home that demand superior, long-lasting performance.

Common Questions: Blown Insulation vs. Spray Foam

Even after weighing all the pros and cons, homeowners still have a few lingering questions when choosing between blown-in insulation and spray foam. It’s the practical, real-world stuff that often trips people up—things like soundproofing, what to do with existing insulation, and how the choice impacts their home’s future value.

Let’s clear up those final, critical questions. Here are the straight-up answers to the most common concerns we hear from our clients right here in South Florida.

Which Insulation Is Better for Soundproofing?

When it comes to hushing unwanted noise, what you’re trying to block matters most. Both blown-in and spray foam insulation can quiet things down, but they tackle different types of sound.

For airborne noises—think conversations, TV sounds, or nearby traffic—the soft, fluffy nature of open-cell spray foam and blown-in cellulose is your best bet. Their porous structure is fantastic at absorbing and deadening sound waves, making them perfect for interior walls between bedrooms, home theaters, or floors separating living areas.

On the flip side, rigid closed-cell spray foam isn’t great at absorbing airborne sounds; its dense structure tends to reflect them. Where it truly shines is in stopping vibrational or impact noise. Because it glues itself directly to the structure, it dampens vibrations like footsteps from upstairs or the rumble of machinery.

Want to go deeper? Our guide on using insulation as a sound barrier breaks down the science behind how different materials dampen sound.

Can You Install New Insulation Over Old Insulation?

This comes up all the time, especially when you’re looking to upgrade an older home without tearing everything apart. The short answer is a hard “it depends,” because the installation process for each material is completely different.

You can absolutely install new blown-in insulation right on top of most existing attic insulation. We call this “topping up,” and it’s a quick, budget-friendly way to boost your home’s overall R-value.

But first, you have to inspect what’s already there. Before adding anything new, you must check for:

- Moisture Damage: Any insulation that’s wet, matted down, or moldy has to come out.

- Pest Infestations: Old insulation can be a hiding spot for rodents and insects, and that needs to be handled first.

- Air Leaks: The attic floor needs to be professionally air-sealed around every light fixture, vent, and wire before it gets buried.

Spray foam is a different story. It absolutely cannot be installed over old insulation. For spray foam to work, it needs to form a chemical bond with a clean, bare surface—like the underside of your roof deck or the exposed wall studs. That means all the old stuff must be completely removed first, which makes it a more involved and costly job for retrofits.

Key Takeaway: Blown-in insulation is great for adding to what you already have in an attic. Spray foam requires a total clean slate, offering a complete reset for your home’s thermal envelope.

Are There Any Health or Environmental Considerations?

It’s smart to be conscious of the materials going into your home. Blown insulation and spray foam each have their own health and environmental story.

Blown-in cellulose really shines as an eco-friendly choice. It’s made from up to 85% recycled paper, keeping a massive amount of waste out of landfills. The material is also treated with non-toxic borates, giving it permanent resistance to fire, mold, and pests without nasty chemicals.

Spray foam’s profile is a bit more complex. The installation is a chemical reaction that creates temporary off-gassing of volatile organic compounds (VOCs). That’s why professional installers wear full protective gear and ventilate the area thoroughly during and right after application. Once it’s fully cured—usually within 24 hours—modern spray foam becomes a stable, inert plastic that’s completely safe and doesn’t off-gas. Plus, the industry has come a long way, with many new formulas using blowing agents with a much lower global warming potential (GWP), making them far better for the environment.

How Does Insulation Choice Affect Home Resale Value?

Good insulation isn’t just a hidden feature anymore; it’s a major selling point. It tells potential buyers that your home is well-maintained and energy-efficient. While any insulation upgrade is a plus, your choice can change how people see your property.

A home with professionally installed blown-in insulation checks the box for a modern, comfortable property. It’s a solid, expected feature that helps keep energy bills in check.

A home with spray foam, however, can be marketed as a high-performance upgrade, especially if you have a sealed and conditioned (unvented) attic. The benefits are tangible and impressive: dramatically lower utility bills, incredible comfort, better air quality, and even added structural strength from closed-cell foam. These are compelling features that can justify a higher asking price. Smart buyers recognize that long-term value, making your home a standout in a competitive market and potentially even boosting its appraisal.

Ready to invest in a permanent solution for your South Florida home? At Airtight Spray Foam Insulation, we specialize in creating comfortable, energy-efficient spaces that stand up to our unique climate. Request your free, no-obligation quote today and discover the difference a professional installation can make. Learn more about our services at https://airtightsprayfoaminsulation.com.