Blog

A Homeowner’s Guide to Vapor Barrier Ceilings in Florida

In South Florida, the air is thick with humidity. That same heavy, moist air is constantly trying to push its way into your cooler, air-conditioned home. Your ceiling is often the primary entry point, and without the right protection, it can act like a sponge, leading to mold, rot, and shockingly high cooling bills.

A vapor barrier ceiling isn’t just a fancy construction term; it’s your home's first line of defense. Think of it as a crucial protective layer that stops this relentless moisture migration in its tracks, keeping your attic and living spaces dry and healthy.

Why Florida Homes Need a Ceiling Vapor Barrier

Picture your home as a sealed container. In places like West Palm Beach and Jupiter, the outside air is almost always saturated with moisture, creating immense vapor pressure. This pressure is always pushing inward, searching for a way into the cooler, drier environment you've created inside. Without a proper barrier, your ceiling assembly is an easy target.

When that warm, humid air infiltrates your attic, it hits the cooler surfaces of your drywall and insulation. Condensation forms immediately. Before you know it, your insulation is a soggy, useless mat, and you’ve created the perfect five-star resort for mold and mildew. This not only destroys your insulation's performance but creates serious health risks and can even lead to structural decay over time.

The Consequences of an Unprotected Ceiling

Leaving your ceiling unprotected is an open invitation for problems. The outcome is almost always a costly mess that hits your wallet and jeopardizes the structural integrity of your home. Here’s what you’re up against:

- Skyrocketing Energy Bills: Once insulation gets damp, its ability to resist heat transfer plummets. Your A/C has to run constantly just to keep up, and your utility bills go through the roof.

- Persistent Mold and Mildew: Trapped moisture is all mold needs to thrive. It will grow on drywall, wood framing, and deep within the insulation, fouling your indoor air quality with that unmistakable musty smell.

- Structural Wood Rot: Constant dampness is the enemy of wood. Over time, that moisture will rot the wooden trusses and roof decking in your attic, weakening your home's entire structure and setting you up for major repairs.

- Reduced Indoor Comfort: High indoor humidity makes your home feel clammy and uncomfortable, no matter what the thermostat says. It's that sticky feeling that forces you to crank the A/C down even lower, just compounding the energy waste.

In South Florida, a properly installed vapor barrier isn't a luxury—it's essential for a healthy, efficient, and long-lasting home. It stops the cycle of moisture infiltration before it has a chance to cause real damage.

Anyone who has gone through the process of repairing water damaged ceilings knows it’s something you want to avoid at all costs. This is where modern solutions like spray foam insulation really shine, creating a seamless and powerful barrier. At Airtight Spray Foam, we specialize in sealing homes from the top down, giving you a rock-solid defense against Florida's demanding climate.

How Moisture Finds Its Way Into Your Home

To really get why a vapor barrier in your ceiling is so important, you first have to understand how moisture moves. Think about boiling a pot of water on the stove. That steam doesn't just hang out above the pot—it spreads everywhere, looking for cooler, drier air. The exact same thing, a principle called vapor drive, is happening on a massive scale right outside your house.

Here in South Florida, the air is thick with humidity pretty much year-round. This creates a relentless, invisible pressure that's always trying to push water vapor from the humid outdoors into the cooler, drier, air-conditioned space inside your home. Your attic and ceiling are the front lines in this constant battle.

This unseen force pushes moisture through your home's structure in two main ways. Getting a handle on both is the key to building a solid defense.

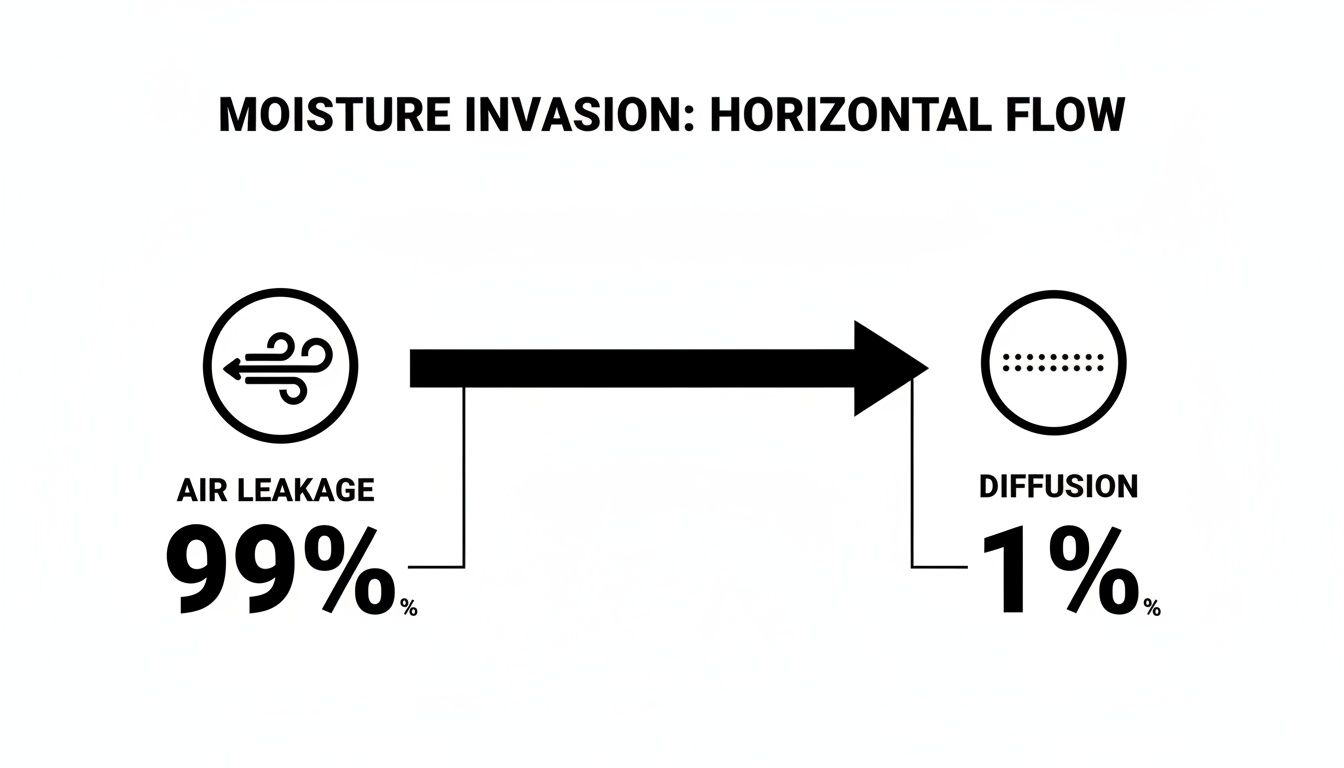

Air Leakage: The Real Culprit

By far, the biggest way moisture gets in is through air leakage. We're talking about all the little gaps, cracks, and unsealed holes in your home's structure—things like recessed light fixtures, plumbing pipes, electrical wires, and attic hatches. Every single one acts like a superhighway for humid air to march right into your attic.

Make no mistake, air leakage is the undisputed champion of moisture problems. It's responsible for carrying up to 99 times more water vapor into your home than the other method, diffusion. Just one tiny, unsealed gap can let gallons of water vapor pour into your attic over a single summer. This is why simply laying down a sheet of plastic doesn't work; you have to stop the air itself from moving.

Diffusion: The Slow-Moving Intruder

The second way moisture gets in is through diffusion. This is a much, much slower process where water vapor molecules pass straight through solid materials, almost like a ghost moving through a wall. While every material lets some vapor diffuse through it, this process is a very minor player in the grand scheme of things.

Diffusion accounts for just a tiny fraction of the total moisture that gets into a home. This is a critical point because for decades, builders focused almost entirely on stopping diffusion with basic "vapor barriers" like kraft paper on fiberglass batts. All the while, they were mostly ignoring the far bigger threat of air leakage.

Building science has come a long way in the last 40 years. The industry's focus has thankfully shifted from just trying to block diffusion to creating a complete air barrier. We now know that controlling air movement is what really matters for moisture management.

This huge shift in building science really took hold in the 1970s and '80s. Researchers discovered that diffusion was only responsible for about 1-5% of moisture movement, while air leakage was causing over 95% of the problems. This completely changed how we approach moisture control, leading to systems that make airtightness the top priority. You can discover more insights on the history of air barriers and how they've impacted modern construction.

For anyone owning a home in Florida, this means a proper vapor barrier ceiling has to be a top-notch air barrier, too. It needs to do more than just slow down diffusion—it has to create a seamless, solid seal that stops humid air from flowing into your attic in the first place. This is where modern materials like closed-cell spray foam really shine, giving you an all-in-one defense against both air leakage and diffusion to keep your home dry and comfortable.

Comparing Materials For Your Vapor Barrier Ceiling

Choosing the right material for your ceiling's vapor barrier isn't just a small detail—it's the single most important decision you'll make in the fight against Florida's oppressive humidity. The effectiveness of your entire system, and the long-term health of your home, really hangs on this choice.

While you've got a few options, they deliver wildly different results, especially in our demanding coastal climate. Let's walk through the common materials, starting with the old-school methods and moving to the advanced solutions that actually solve the moisture puzzle in homes from Jupiter to Palm Beach Gardens.

Traditional Materials And Their Shortfalls

For decades, builders relied on a couple of standard, go-to materials to create a vapor barrier. And while they were a step in the right direction at the time, they come with some serious drawbacks that make them a poor fit for the unique challenges we face in a hot, humid climate.

The two you’ll see most often in older homes are:

- Polyethylene Plastic Sheeting: This is what most people picture when they think "vapor barrier"—a thin sheet of plastic, usually 4-6 mils thick, stapled up before the drywall goes on. It's a fantastic Class I vapor retarder on paper, but its biggest failure is in the real world. It's almost impossible to install perfectly. Every staple, every seam, and every cutout for a light fixture or wire creates a hole, compromising the whole system.

- Kraft-Faced Fiberglass Batts: This is your typical fiberglass insulation with a paper facing on one side. That paper is treated with asphalt to slow down vapor diffusion. But just like the plastic sheeting, it does nothing to stop air movement. Air and all the moisture it carries simply flow right around the batts, making that paper facing pretty much useless.

The fundamental issue with these old-school materials is that they completely fail to stop air leakage. And as it turns out, air leakage is the real enemy here.

Look at that diagram again. Air leakage isn't just part of the problem—it's 99% of it. This makes an airtight seal the absolute most critical factor for success.

The Modern Solution: Spray Foam Insulation

To truly protect your home, you need a material that can do three jobs at once: insulate, stop air, and block vapor. This is where spray polyurethane foam (SPF) blows everything else out of the water, creating a single, seamless layer of protection that older methods just can't touch.

We apply spray foam as a liquid, and it expands instantly to fill every last crack, gap, and crevice, bonding directly to the ceiling or roof deck. This process creates a perfect, continuous air seal that eliminates leakage entirely. It doesn't just slow vapor down; it stops the superhighway of air that carries it.

Of course, not all spray foam is created equal. Understanding the difference between closed-cell vs. open-cell polyurethane foam is key to getting the performance you need. You can also get a deeper look at the pros and cons in our guide to open-cell and closed-cell spray foam.

To make it even easier, here’s a quick breakdown of how the most common materials stack up for our unique climate.

Vapor Barrier Material Comparison For South Florida Ceilings

When deciding on a vapor barrier for your South Florida home, it's crucial to understand how different materials perform in our high-humidity environment. The table below compares the most common options based on their ability to control vapor, block air, and withstand our climate's demands.

| Material | Vapor Retarder Class | Air Barrier Effectiveness | Best Use Case in South Florida | Key Drawback |

|---|---|---|---|---|

| Closed-Cell Spray Foam | Class I (<0.1 perms) | Excellent | Roof decks & unvented attics. The premier all-in-one solution. | Higher upfront cost. |

| Open-Cell Spray Foam | Class III (10+ perms) | Excellent | Best for soundproofing interior walls, not for moisture control in attics. | Vapor permeable; not a vapor barrier. |

| Polyethylene Sheeting | Class I (<0.1 perms) | Poor | Not recommended. | Impossible to create a true air seal due to seams and penetrations. |

| Kraft-Faced Fiberglass | Class II (0.1 – 1.0 perms) | Poor | Not recommended. | Air leaks around the batts, rendering the vapor retarder useless. |

As you can see, when it comes to creating a true air and vapor barrier in one shot, there's a clear winner for our ceilings.

Why Closed-Cell Spray Foam Is The Gold Standard For Ceilings

While both types of spray foam are great insulators, closed-cell spray foam is the undisputed champion for ceilings and unvented attics here in South Florida. Its dense, rigid structure is made up of millions of tiny, closed-off bubbles, giving it some major advantages.

Closed-cell spray foam’s unique structure makes it a Class I vapor retarder, which means it’s essentially waterproof. This incredibly low permeability is exactly what we need to shut down the intense vapor drive pushing into our homes, providing moisture resistance that no other material can match.

Here’s why it stands out:

- Exceptional R-Value: It packs a powerful insulation punch, offering around R-6.5 per inch. This means you get maximum thermal performance without needing a ton of space.

- Structural Strength: Once it cures, closed-cell foam actually adds significant rigidity and strength to the roof deck. That’s a huge bonus, especially during hurricane season.

- The Total Package: Its closed-cell structure blocks both air and vapor. It’s the ultimate all-in-one solution for your ceiling, period.

The market backs this up. The global demand for high-performance vapor barriers hit USD 12.0 billion in 2024 and is on track to reach USD 18.2 billion by 2033, driven by smarter energy codes and a better understanding of building science. Here in South Florida, where older homes can be as leaky as a sieve (with air leakage rates of 5-10 ACH50), sealing the attic with closed-cell foam can slash that number to less than 0.1 ACH50. The result? A healthier home and energy savings of 30-50%.

Navigating Florida's Building Codes and Best Practices

Trying to decipher the Florida Building Code can make your head spin. But when it comes to ceiling vapor barriers, the rules are often more flexible than homeowners think. The real key is understanding what the code is trying to achieve—moisture control—so you can make smart decisions that protect your home for the long haul.

Think of the code as the absolute minimum for safety and performance. True protection in our climate often means going a step beyond.

Here’s a surprising fact for most South Florida homeowners: our building codes for Climate Zones 1 and 2 usually do not require a separate, dedicated vapor barrier like a big plastic sheet on the ceiling. Why? Because in our hot and humid world, the main goal is to let the home’s structure dry out if it ever gets wet. Slapping a non-permeable barrier on the wrong side (the interior) could actually trap moisture, causing a bigger mess than it prevents.

Code Minimums Versus High-Performance Standards

The building code sets the floor for what’s acceptable, not the ceiling for what’s possible. Even though you might not be required to install a plastic sheet, you're still on the hook for managing moisture and stopping condensation. This is where best practices and modern building science really shine, offering a much smarter approach than just checking a box.

The gold standard for high-performance homes in places like Jupiter and Wellington involves completely rethinking the attic. Instead of putting insulation and a barrier on the attic floor (which is your ceiling), the best strategy is to apply insulation directly to the underside of the roof deck.

Creating a Conditioned Attic Space

When we apply closed-cell spray foam directly to the roof deck, we create what’s called a conditioned attic. This move effectively brings your entire attic inside the thermal and air-controlled envelope of your home. Suddenly, that sweltering, humid, vented attic is transformed into a clean, dry, semi-conditioned space that stays within a few degrees of your living area.

This approach gives you some powerful advantages:

- Eliminates Condensation Surfaces: By insulating the roof deck, you stop hot, humid outdoor air from ever hitting a cold, air-conditioned surface inside the attic. Problem solved.

- Protects Ductwork: Your A/C ducts are no longer fighting for their lives in a scorching hot space. Now they run through a conditioned area, which dramatically boosts their efficiency and slashes energy waste.

- Creates a Superior Air Barrier: Spray foam creates a perfect seal on the roof deck, shutting down the number one driver of moisture problems—air leakage.

This shift from just meeting minimum code to creating a high-performance, conditioned attic is the single most effective way to protect your home from moisture, lower your energy bills, and improve your indoor air quality.

The way we think about controlling air and vapor has come a long way. Early research after WWII focused on stopping condensation in the then-new cathedral ceilings, which didn't have traditional ventilation. Those studies showed that low-permeance barriers helped, but the real breakthrough was realizing that air leakage—not just vapor diffusion—was the main villain. Today, solutions like closed-cell spray foam, which acts as a seamless air and vapor barrier, are perfectly in line with modern building codes and have been shown to cut energy loss from air leakage by 20-50%.

At Airtight Spray Foam Insulation, our whole philosophy is built around this high-performance strategy. We focus on creating a complete system that tackles both air and vapor, giving you a level of protection that goes far beyond what the basic code demands. You can learn more about how vapor barriers and insulation work together in our detailed guide.

Why Professional Installation is Everything

A high-performance vapor barrier is only as good as the hands that install it. You can pick the most advanced material on the market, but if it’s put in poorly, you've just installed a false sense of security while humid air quietly wreaks havoc above your head. This is one of those home improvement projects where calling a pro is truly non-negotiable.

When it comes to something this critical, DIY attempts or work from a jack-of-all-trades crew often lead to failures that completely defeat the purpose of the barrier. Even the smallest slip-up can turn your investment into the very moisture trap you were trying to prevent.

The Pitfalls of DIY and Amateur Installation

Weekend warrior projects and cut-rate installers almost always leave a trail of hidden vulnerabilities. These "minor" mistakes are basically open doors for moisture, nullifying your investment and putting your home on a path to long-term damage.

We see the same failure points time and time again:

- Leaky Joints and Gaps: When using materials like plastic sheeting, every single seam is a potential weak spot. Without the right tapes and a meticulous sealing process, those joints become direct highways for air and moisture.

- Hidden Tears and Punctures: It’s ridiculously easy to accidentally poke a hole in a thin plastic barrier while wrestling it into place. Those tiny, often invisible punctures are more than enough to compromise the entire system.

- Bad Seals Around Penetrations: Attics are a maze of light fixtures, plumbing stacks, electrical wires, and vents. Amateurs really struggle to create a perfect, durable seal around these awkward shapes, leaving gaps that humid air will hunt down and exploit.

A vapor barrier is an all-or-nothing system. A barrier that's 99% sealed is 100% ineffective. Air and moisture will find that 1% point of failure and concentrate there.

This is the unforgiving reality of moisture control. A flawless, unbroken, monolithic seal is the only standard that matters. Achieving that level of precision takes specialized equipment, professional-grade materials, and a deep understanding of how buildings breathe.

The Airtight Spray Foam Process

Getting that perfect seal isn’t an accident; it’s the result of a disciplined, professional process from start to finish. Our method is designed to eliminate the guesswork and ensure your vapor barrier ceiling performs exactly as it should, giving you peace of mind that no DIY job ever could. We're not just spraying foam—we’re engineering an integrated, high-performance building component.

Our commitment to a flawless installation breaks down into a few key stages:

- Expert Assessment: First, we get in your attic and do a thorough inspection. We identify all potential problem spots, assess ventilation, and map out the precise application your home's unique structure needs.

- Meticulous Site Preparation: Before any foam is sprayed, our crew carefully masks and protects everything that isn't getting insulated—HVAC units, trusses, and any stored items—to ensure a clean, contained job.

- Precise, Computer-Monitored Application: We use state-of-the-art equipment that monitors the foam's temperature and pressure in real-time. This is critical. It guarantees the two parts of the foam are mixed perfectly and applied at the right thickness, creating that seamless, monolithic bond with the surface.

This disciplined process ensures every last square inch of your ceiling or roof deck is sealed tight, forming a continuous, unbroken barrier against air and vapor. When you invest in a professional installation, you're not just buying a product. You're buying long-term performance, real energy savings, and the lasting health of your home. You can learn more about what a professional job entails and how it influences the cost of spray foam insulation installation in our detailed guide.

Got Questions About Vapor Barrier Ceilings? We've Got Answers.

When it comes to vapor barriers and ceilings, we get a lot of questions. As the go-to experts for South Florida's unique climate, we've heard just about everything from homeowners between West Palm Beach and Stuart. Here are some straightforward answers to the questions that come up most often.

Is a Vapor Barrier Actually Required in My Florida Ceiling?

This is easily the most common question we get, and the answer usually catches people off guard. While the Florida Building Code for our specific climate zone doesn't require a separate plastic sheet labeled "vapor barrier" on the ceiling, it absolutely demands effective moisture control. The real mission here is to stop condensation before it ever starts.

So, how do you do that? The most effective approach is an integrated air and vapor control layer. A product like closed-cell spray foam does just that—it's both an air barrier and a powerful vapor retarder. This kind of system doesn't just meet the minimum code; it provides the high-performance protection a home truly needs to stand up against our relentless humidity.

Can I Just Install a New Vapor Barrier Over My Old Attic Insulation?

Let me be direct: this is a catastrophic mistake. You absolutely cannot do this. Laying a new vapor barrier, especially something impermeable like spray foam, on top of old, existing insulation creates what we call a “moisture sandwich.” Think about it—any water vapor rising from your living space gets trapped in that old insulation with nowhere to go.

When that happens, you're signing up for a disaster:

- Mold Explodes: That trapped moisture turns old insulation into a damp, stagnant breeding ground for mold.

- Wood Rot Sets In: Ceiling joists and drywall begin to decay from the constant moisture.

- Insulation Fails Completely: The old insulation becomes a soggy, useless mat, losing all its thermal resistance.

The only right way to handle this is to start with a clean slate. All old, contaminated, or sagging insulation must be professionally removed first. This allows the new system to bond directly to the attic floor or roof deck, creating the seamless, airtight, and watertight seal your home needs to perform correctly.

What’s the Real Difference Between Open-Cell and Closed-Cell Foam?

This is a critical distinction. While both are types of spray foam, they behave in completely different ways, especially when it comes to moisture. Getting this wrong can ruin your ceiling.

Open-Cell Spray Foam: Picture a sponge. Open-cell foam is light, flexible, and has cells that are intentionally left open. It’s a great air barrier and does a fantastic job of deadening sound. However, it’s also vapor-permeable, which means moisture can pass right through it. That makes it totally wrong for a ceiling vapor barrier in our humid climate.

Closed-Cell Spray Foam: Now, think of a rigid, solid material. Closed-cell foam is dense and strong because its cells are completely sealed off from each other. This structure makes it highly resistant to both air and moisture. In technical terms, its low permeability classifies it as a Class I vapor retarder—exactly what you need to stop powerful vapor drive in its tracks. It also adds significant structural strength. For just about every ceiling and roof deck in Florida, closed-cell is the only choice.

How Much Is This Going to Cost?

The cost for a spray foam vapor barrier depends on the attic size, job complexity, and whether we need to remove old insulation first. I'll be honest—the initial investment is higher than tossing in some traditional fiberglass batts. But you have to look past the upfront price tag and see the long-term return.

A professionally installed closed-cell foam system isn't an expense; it’s an investment in your home's health, comfort, and value. Homeowners often see their energy bills drop by a staggering 30-50%. By creating a near-perfect air seal and preventing moisture damage, you also wipe out future repair costs. Over time, the system more than pays for itself, all while making your home a healthier, more comfortable place to live every single day.

Ready to protect your home with a high-performance vapor barrier ceiling that can actually handle the South Florida climate? The experts at Airtight Spray Foam Insulation are here to help. Request your free, no-obligation quote today!