Blog

Your Guide to the R Value of Spray Foam Insulation Chart

When you're looking at spray foam insulation, the conversation always comes back to one thing: R-value. It's the industry yardstick for measuring how well a material stops heat from moving through it. The higher the R-value, the better the insulation. For us here in Florida, a high R-value is non-negotiable for battling the relentless heat and humidity.

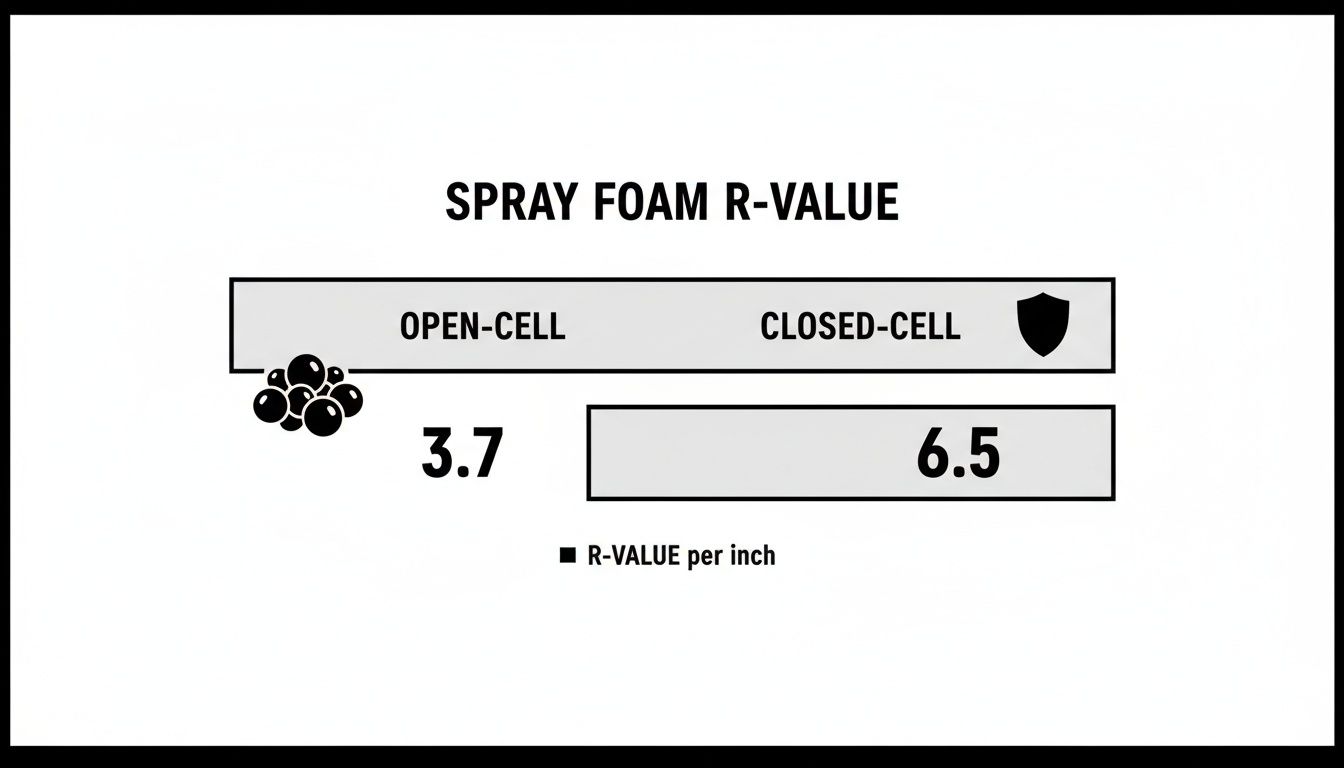

The R-value of spray foam insulation isn't a one-size-fits-all number. It depends entirely on which type you're using. Open-cell foam typically gives you about R-3.7 per inch, while its denser counterpart, closed-cell foam, packs a much bigger punch at around R-6.5 per inch. Knowing this distinction is the first step in making the right call for your home or project.

Your Quick Reference R-Value Chart for Spray Foam

Spray foam's real magic isn't just its R-value; it's the combination of high thermal resistance and a top-notch air seal, all in one shot. This is a huge advantage over traditional insulation like fiberglass batts, which can't stop air leakage nearly as effectively. That air leakage is a major source of energy loss and, in our climate, a big-time humidity problem.

But the final R-value you achieve comes down to the foam you choose.

Open-Cell vs. Closed-Cell R-Value

The difference in performance between the two types of spray polyurethane foam (SPF) comes down to their physical structure. It's all about the cells.

- Open-Cell Spray Foam: Think of a sponge. The cells aren't totally sealed off from each other, which gives the foam a softer, more flexible consistency. This structure results in an R-value between R-3.6 and R-3.9 per inch.

- Closed-Cell Spray Foam: This is a much more rigid and dense material. Its cells are completely sealed and packed tightly together, trapping an insulating gas. This structure is why it delivers a much higher thermal resistance, typically between R-6 and R-7 per inch.

This chart gives you a quick visual of the average R-value you get from each type.

As you can see, closed-cell foam offers almost double the insulating power for every inch of thickness.

This performance difference has real-world implications. It means you can hit your target R-value with less material when you use closed-cell foam. For example, getting a proper air seal requires about 3 inches of open-cell foam, but you can achieve the same result with only 2 inches of closed-cell foam. You can find some more great info on application depths and spray foam R-values over at RetroFoamofMichigan.com. This makes closed-cell the go-to choice for tight spaces, like standard 2×4 wall cavities where every fraction of an inch counts.

Spray Foam R-Value Per Inch Quick Lookup

For those who want the key details at a glance, this table breaks down the essentials for both open-cell and closed-cell spray foam.

| Insulation Type | R-Value Per Inch | Air & Moisture Barrier | Best For |

|---|---|---|---|

| Open-Cell SPF | ~ R-3.7 | Air barrier; not a vapor barrier | Sound dampening, filling large cavities (attics, crawl spaces) |

| Closed-Cell SPF | ~ R-6.5 | Air and vapor barrier | Wall cavities, areas needing high R-value in limited space, structural rigidity |

This lookup chart is a great starting point, but remember that the right choice always depends on the specific needs of your project, from building code requirements to your budget and long-term energy goals.

Comparing Open-Cell and Closed-Cell Spray Foam

When it comes to spray foam, picking between open-cell and closed-cell isn't as simple as just glancing at an R-value chart. While the R-value is a great starting point, the right foam for your Florida home really boils down to your budget, where you're installing it, and what you need it to do—like fight humidity or quiet down a room.

The two types have completely different physical structures, which gives each of them a unique set of pros and cons. Getting a handle on these differences is the key to making a smart investment that delivers real performance. Let's break down what sets them apart.

Thermal Performance and Density

The biggest distinction between the two is their cell structure. Open-cell foam is light and flexible, with a texture almost like a sponge. Its cells aren't fully sealed, which gives it a thermal resistance of about R-3.7 per inch.

Closed-cell foam, on the other hand, is dense and rigid. Its cells are completely sealed and packed tightly together, trapping a specialized insulating gas. This is what supercharges its thermal performance to a powerful R-6.5 per inch. To put that in perspective, a standard 2×4 wall filled with closed-cell foam can hit an R-value of around R-20, while the same wall with open-cell foam would top out at R-13.

Moisture Permeability and Structural Strength

Down here in Florida, keeping moisture out is just as critical as keeping heat out. This is where closed-cell foam really proves its worth. Its dense, sealed-cell structure makes it essentially waterproof. It acts as a powerful vapor barrier, stopping our humid air and any bulk moisture dead in its tracks—a non-negotiable for preventing mold and rot.

On top of that, its rigidity adds significant structural integrity to whatever it’s applied to. When we spray it on roof decks or walls, it can actually increase the building's racking strength, making your home more resilient during the high winds of a hurricane.

Open-cell foam is a different animal—it's vapor-permeable. While it does a fantastic job of stopping airflow, it will let water vapor pass through. That’s not always a bad thing; some wall designs need to "breathe" to allow drying. However, it simply doesn't offer the moisture protection or the structural reinforcement that closed-cell does.

Expert Insight for Florida Homes: For unvented attics and roof decks in South Florida, closed-cell spray foam is the only way to go. Its high R-value, added strength, and formidable moisture resistance create the trifecta of protection your home needs to withstand our unique climate challenges.

Sound Dampening and Cost Considerations

While closed-cell takes the crown for R-value and moisture defense, open-cell has a clear advantage when it comes to acoustics. Its soft, porous structure is fantastic at absorbing and deadening sound waves.

- Best for Soundproofing: If you’re trying to create a quiet home office or just stop noise from traveling between rooms, open-cell foam in your interior walls and floors is the perfect solution.

- Cost-Effectiveness: Open-cell foam also requires less material to manufacture, which makes it a more budget-friendly choice. It expands dramatically, so it's great at filling large, awkward spaces, giving you a lot of bang for your buck on projects where moisture isn't the primary enemy.

To get a true side-by-side look, we’ve put together this detailed comparison table.

Comprehensive Feature Comparison: Open-Cell vs. Closed-Cell Foam

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam | Winner for South Florida |

|---|---|---|---|

| R-Value per Inch | R-3.7 | R-6.5 | Closed-Cell |

| Vapor Barrier | No (vapor permeable) | Yes (vapor impermeable) | Closed-Cell |

| Air Barrier | Excellent | Excellent | Tie |

| Density | Low (0.5 lb/ft³) | High (2.0 lb/ft³) | Closed-Cell |

| Structural Strength | No additional strength | Adds significant rigidity | Closed-Cell |

| Sound Dampening | Excellent | Good | Open-Cell |

| Expansion Rate | High (fills large cavities) | Low (controlled application) | Depends on Application |

| Cost | Lower | Higher | Depends on Budget |

Ultimately, there's no single "best" foam—it all comes down to the job at hand. For a deeper dive, check out our guide comparing open-cell vs. closed-cell insulation. The real expert choice is about matching the foam's unique properties to the specific demands of your project.

How to Calculate Total R-Value for Your Project

Knowing the "R-value per inch" is a great start, but the real magic happens when you apply it to your home. Figuring out the total thermal resistance you'll get is actually pretty simple once you know the formula. This is the crucial step for planning your project, setting a budget, and most importantly, making sure you nail Florida's specific building code requirements.

The math boils down to simple multiplication. You just need two key numbers: how many inches of foam you plan to install and its specified R-value per inch.

The Basic R-Value Formula

Here’s the straightforward formula we use to plan every job:

Thickness in Inches x R-Value Per Inch = Total R-Value

It really is that easy. For instance, if we install 5 inches of a high-performance closed-cell foam with an R-value of 6.5 per inch, the math is just 5 x 6.5 = R-32.5. This quick calculation gives you the power to plan with precision and ensure you aren't under-insulating the most important parts of your home.

Real-World Examples in Florida Homes

Let’s put this formula to work in a couple of common scenarios we see every day here in South Florida. This shows you exactly how different thicknesses and foam types hit those critical insulation targets.

-

Example 1: Hitting the R-38 Attic Code

- The Goal: Reach the standard R-38 minimum for attics in our climate zone.

- With Closed-Cell Foam (R-6.5/inch): You'd need about 5.85 inches (38 ÷ 6.5) to hit that number. Its incredible R-value density makes it a perfect fit for maximizing performance without eating up valuable headroom.

- With Open-Cell Foam (R-3.7/inch): To get the same R-38, you'd need closer to 10.25 inches (38 ÷ 3.7).

-

Example 2: Insulating Standard 2×4 Walls

- The Constraint: A typical 2×4 wall cavity gives you exactly 3.5 inches of depth to work with.

- With Closed-Cell Foam: Filling that cavity gets you 3.5 inches x R-6.5 = a Total R-22.75. This is a massive performance boost for exterior walls where space is tight but stopping heat is non-negotiable.

- With Open-Cell Foam: The same 3.5 inches would give you a Total R-12.95 (3.5 x R-3.7). This is often a great choice for interior walls where sound dampening is the main priority.

This is especially critical when you're thinking about tightening up your home's thermal envelope. Our guide on attic insulation in Florida dives deeper into meeting these regional codes.

To make it even simpler, we've put together a quick-reference chart. The r value of spray foam insulation chart below shows you exactly how the R-value stacks up as you add more inches of both open-cell and closed-cell foam.

Total R-Value Accumulation Chart

| Thickness | Open-Cell Foam (R-3.7/inch) | Closed-Cell Foam (R-6.5/inch) |

|---|---|---|

| 1 inch | R-3.7 | R-6.5 |

| 2 inches | R-7.4 | R-13 |

| 3 inches | R-11.1 | R-19.5 |

| 4 inches | R-14.8 | R-26 |

| 5 inches | R-18.5 | R-32.5 |

| 6 inches | R-22.2 | R-39 |

| 7 inches | R-25.9 | R-45.5 |

| 8 inches | R-29.6 | R-52 |

| 9 inches | R-33.3 | R-58.5 |

| 10 inches | R-37 | R-65 |

Meeting Florida Building Code Insulation Requirements

Navigating Florida’s building codes is something we deal with on every single project. It’s not just a box to check; it’s the absolute minimum standard for building a home that can handle our climate. The state is divided into different climate zones, each with its own R-value requirements specifically designed to tackle Florida’s intense heat and humidity.

If you don't get this right, you're looking at failed inspections, costly project delays, and a house that’s going to struggle from the moment you move in. The Florida Building Code, Energy Conservation lays out these targets, and understanding them is the foundation of a smart insulation plan. For us here in South Florida, these numbers are the starting line for true energy efficiency.

Florida Climate Zones and R-Value Minimums

Most of South Florida, including all of Palm Beach County, sits squarely in Climate Zone 1. This is the hottest, most humid part of the state, so the codes are strictest here to maximize cooling efficiency.

For new construction or major renovations in our area, these are the typical minimum R-values you have to hit:

- Ceilings/Attics: R-38 is the magic number for unvented attics, which is the only way to build when you’re using spray foam properly.

- Frame Walls: All exterior walls need to hit at least R-13.

- Floors: Any floors above unconditioned spaces (think vented crawlspaces or garages) require R-13.

Remember, these are just the minimums. Meeting code is one thing; building a genuinely comfortable, high-performance home is another. This is where spray foam completely changes the game.

How Spray Foam Exceeds Code Requirements

Looking back at the r value of spray foam insulation chart, you can see how easily spray foam blows past these requirements. To get that mandatory R-38 in an attic, all it takes is a little under 6 inches of closed-cell foam.

For walls, a standard 2×4 stud bay has 3.5 inches of depth. Fill that with closed-cell foam, and you get a powerful R-22.75—massively outperforming the R-13 minimum. It's not even a fair fight.

The Blower Door Test Advantage

Today's Florida building codes mandate a blower door test for all new homes. This test physically measures how much air leaks out of the building. It's a make-or-break inspection, and it’s where spray foam truly proves its worth. Because spray foam creates a seamless, monolithic air barrier, our homes pass this test with flying colors. Homes insulated with traditional materials often struggle, and sometimes fail.

This air-sealing capability is a huge deal for builders and homeowners alike. It guarantees you’ll pass inspection, but more importantly, it slashes the uncontrolled air infiltration that drives up cooling bills and creates those sticky, high-humidity problems we all know too well.

Choosing spray foam isn't just about hitting a number on an inspector's checklist. It’s about building a fundamentally tighter, more resilient, and more efficient home from the very start.

Why R-Value Is Only Part of the Insulation Story

Look, an R-value of spray foam insulation chart gives you a great starting point for thermal performance. But if you stop there, you're making one of the biggest mistakes a homeowner can make, especially here in Florida. Relying on R-value alone just doesn't cut it.

R-value only measures an insulation's ability to resist conductive heat flow—that’s heat moving through solid stuff. It tells you absolutely nothing about the real energy hog in our climate: air leakage.

Uncontrolled air leakage, or convection, is the movement of outdoor air into and out of your home through countless tiny gaps you can't even see. In Florida, that means hot, thick, moisture-laden air is constantly pushing its way into your living space. This swampy air forces your AC to work overtime, not just to cool things down, but to wring out all that extra moisture. It's what drives up your FPL bill and creates that familiar, sticky feeling inside.

The Unmatched Power of an Air Barrier

This is where spray foam completely changes the game. Traditional insulation like fiberglass batts just sits in your wall cavities and does very little to stop air from moving right through them. Spray foam, on the other hand, does two critical jobs at once. When we apply it, it expands to fill every single crack, crevice, and void, creating a seamless, monolithic air barrier.

Frankly, this air-sealing capability is often more important than the R-value itself. By putting a full stop to uncontrolled air infiltration, spray foam insulation:

- Dramatically cuts the load on your HVAC system, leading to real, noticeable energy savings.

- Keeps indoor temperatures stable, getting rid of those frustrating hot and cold spots from room to room.

- Blocks airborne junk like dust and allergens from getting inside, which means better indoor air quality for your family.

Think of it this way: on a windy day, would you rather wear a thick wool sweater or a thin windbreaker? The sweater has a high "R-value" but does nothing to stop the wind from cutting right through. The windbreaker, your air barrier, is what actually keeps you comfortable. Spray foam is both the sweater and the windbreaker, all in one shot.

Here in South Florida, air leakage can be responsible for up to 40% of a home's cooling costs. A properly installed spray foam air barrier attacks this problem right at the source, giving you a return on your investment that goes way beyond simple thermal resistance.

Conquering Humidity with a Vapor Barrier

Beyond stopping air, we have a relentless battle to fight against moisture vapor—the invisible water hanging in the air. In our humid climate, this is a non-negotiable part of building science. When moisture gets into your walls or attic, it condenses on cooler surfaces, and that’s a perfect recipe for mold, mildew, and eventually, structural rot.

This is where closed-cell spray foam delivers another massive advantage. Thanks to its dense, sealed-cell structure, it acts as a powerful vapor barrier (you'll also hear it called a vapor retarder). It physically blocks moisture from passing through it, protecting your home's structure from the inside out. Open-cell foam is a fantastic air barrier, but it’s vapor-permeable, meaning it doesn't offer this same level of critical moisture protection.

For jobs like unvented attics, roof decks, and exterior walls in Florida, the triple-threat functionality of closed-cell foam is unbeatable. It delivers a high R-value, an airtight seal, and a robust vapor barrier. It’s the complete solution for long-term performance and durability because it addresses the whole picture of home performance, not just a single number on a chart.

Understanding Your Return on Investment

It’s easy to look at spray foam insulation as just another line item on a project budget, but that’s a mistake. Think of it as a strategic investment in your home's long-term value and day-to-day efficiency. The real benefits go way beyond a number on an r value of spray foam insulation chart—they show up in your bank account through lower energy bills, a more comfortable home, and even a higher resale value.

This upgrade is an asset that literally pays you back, month after month. By creating an unmatched air seal and providing serious thermal resistance, spray foam dramatically cuts down the workload on your HVAC system. That translates directly into lower utility bills, and in a demanding climate like South Florida, we often see cooling costs drop by a truly substantial margin.

Long-Term Financial Benefits

The immediate energy savings are just the start of the story. Investing in high-performance spray foam also bumps up your property's appraisal value. Today's homebuyers are smarter than ever about energy efficiency, and a well-insulated, comfortable home has become a massive selling point.

- Significant Energy Savings: The air-sealing power of spray foam can slash energy use for heating and cooling by up to 50%, delivering savings that keep coming.

- Increased Property Value: Homes insulated with professional spray foam are often marketed as "high-efficiency," which helps them command a higher price and attract discerning buyers.

- Structural Longevity: Closed-cell foam adds structural rigidity and acts as a tough moisture barrier, helping you avoid costly future repairs from water damage or rot.

The push for energy-efficient homes is fueling huge growth in the spray foam market. It’s projected that North America will make up 34.9% of global demand by 2025, largely because people are finally recognizing how much it reduces HVAC strain and improves comfort. Homeowners are catching on to the financial upside.

The Critical Role of Professional Installation

Here’s the catch, though: achieving this return on investment is 100% dependent on the quality of the installation. A botched application is one of the most common pitfalls, and it can completely negate the foam's performance benefits.

Common installation mistakes—like applying it at the wrong temperature, getting the chemical mix off-ratio, or not spraying enough thickness—can torpedo the final R-value and leave gaps in the air seal. This is definitely not a DIY project. Professional expertise is absolutely essential to guarantee the performance and safety you’re paying for.

A certified installer makes sure the foam is applied correctly to hit its target R-value and create that perfect, seamless barrier. That precision is what locks in your energy savings for the entire life of your home. To dig deeper, check out our detailed guide on if spray foam insulation is worth it.

And while R-value is key for homeowners, contractors can maximize their own ROI by mastering their digital presence. A solid local SEO guide for contractors can make all the difference. Here at Airtight Spray Foam Insulation, we start with a professional assessment to calculate the potential ROI for your specific property, ensuring your investment pays off exactly as it should.

Answering Your Top Questions About Spray Foam R-Value

Even with a detailed R-value chart for spray foam, it's natural for homeowners and builders to have practical questions. After all, making a smart investment in your home's comfort and efficiency means getting the right answers first. This section tackles the most common questions we hear out in the field every day.

Our goal here is to cut through the noise, clear up some common myths, and give you the confidence you need to move forward. We'll look at how spray foam really performs over its lifespan and see how it stacks up against other insulation options.

Does Spray Foam Insulation Lose R-Value Over Time?

This is a critical question, and I'm happy to say the answer is overwhelmingly no. When installed correctly by certified pros, spray foam insulation holds its R-value for the life of the building. It’s an incredibly stable, durable material that becomes a permanent part of your home’s structure, delivering consistent thermal performance for decades.

Unlike fiberglass that can sag, get compressed, or settle over time, spray foam rigidly locks into place. It doesn't create gaps or lose its effectiveness.

- Closed-Cell Stability: This is especially true for closed-cell foam. While there can be a very minor, initial dip in R-value as the blowing agent settles right after installation, it quickly stabilizes and holds firm for the long haul.

- Long-Term Performance: You can count on reliable thermal resistance year after year, which is what makes spray foam such a solid, long-term investment in your home’s energy efficiency.

Can I Install Too Much Spray Foam Insulation?

From a pure performance perspective, a higher R-value is always better at stopping heat. That said, the law of diminishing returns definitely applies, especially when you look at the cost. The real key is finding that sweet spot—the optimal thickness that gives you the best bang for your buck.

For instance, bumping up your attic insulation from an already excellent R-38 to a massive R-76 won't magically cut your energy bills in half. At Airtight Spray Foam Insulation, part of our job is to help you pinpoint that ideal balance.

The Space Limitation Factor: In a lot of situations, the building itself dictates the thickness. A standard 2×4 wall cavity only has 3.5 inches of depth to work with. This is where closed-cell foam really shines, as its high R-value-per-inch maximizes performance within that limited space.

How Does Spray Foam Compare to Rigid Foam Board Insulation?

This is a great comparison, because on paper, closed-cell spray foam and many rigid foam boards (like XPS or polyiso) have similar R-values per inch. The huge difference comes down to the installation and the final, real-world performance.

Rigid boards have to be meticulously cut and pieced together to fit between studs and around every pipe and wire. This process always leaves tiny seams and gaps, which become little highways for air leakage.

Spray foam, on the other hand, is applied as a liquid and expands to create a perfect, monolithic air seal. It fills every single crack and crevice, completely eliminating the thermal bridging and air leaks that hamstring the "effective" R-value of a rigid board installation. Because of that superior air barrier, spray foam's installed performance is significantly better.

Is a Higher R-Value Always Better for Soundproofing?

Not at all. This is a common mix-up because R-value is strictly a measure of thermal resistance—it has nothing to do with acoustic performance. When it comes to dampening sound, it's the physical structure of the insulation that does all the work.

- Open-Cell for Acoustics: The soft, porous structure of open-cell spray foam makes it a far better sound absorber than dense, rigid closed-cell foam. It’s fantastic at trapping and deadening airborne noises, like conversations or the TV blaring between rooms.

- The Right Foam for the Job: This is exactly why we often recommend open-cell foam for interior walls, ceilings, and floors between stories. Even with its lower R-value, it's the hands-down winner for creating a quieter, more peaceful home.

Ready to see how the right R-value can transform your South Florida home? The experts at Airtight Spray Foam Insulation are here to help. We provide precise, professional installations that maximize comfort and energy savings. Get your free, no-obligation quote by visiting us at https://airtightsprayfoaminsulation.com today.