Blog

Is Expanding Foam Waterproof? A Guide for Florida Homeowners

So, is expanding foam waterproof? That’s a common question, and the answer isn’t a simple yes or no. It all comes down to which type of foam we’re talking about.

The short answer is that closed-cell spray foam is waterproof, creating a solid barrier against moisture. On the other hand, open-cell foam is not waterproof and will soak up water like a sponge.

The Critical Difference in Water Protection

When people hear “expanding foam,” they often think of one single product. In reality, there are two very different materials with opposite reactions to water. Getting this right is the first and most crucial step in protecting your property, especially in the humid, storm-prone climate we have here in South Florida.

One type seals your home tight against moisture. The other can actually trap it, leading to serious problems down the road.

Think of it like this: closed-cell foam is like a wall of tightly packed, individually sealed balloons. Each “cell” is a tiny, independent pocket that water simply can’t get into. When sprayed, these cells lock together to form a rigid, impermeable barrier that blocks both liquid water and water vapor.

Open-cell foam, however, is built more like a kitchen sponge. Its cells are all interconnected and not sealed off from one another. If this foam gets wet, water can travel from one cell to the next, quickly saturating the material. That water absorption risk makes it a poor choice for any area where moisture is a concern.

Why Closed-Cell Foam Is the Waterproof Champion

The secret to closed-cell foam’s performance lies in its dense, packed structure. With over 90% of its cells sealed shut, it traps tiny gas bubbles that provide incredible insulation and stop water in its tracks. This makes it the go-to choice for attics, crawl spaces, and exterior walls in rainy places like Jupiter and West Palm Beach.

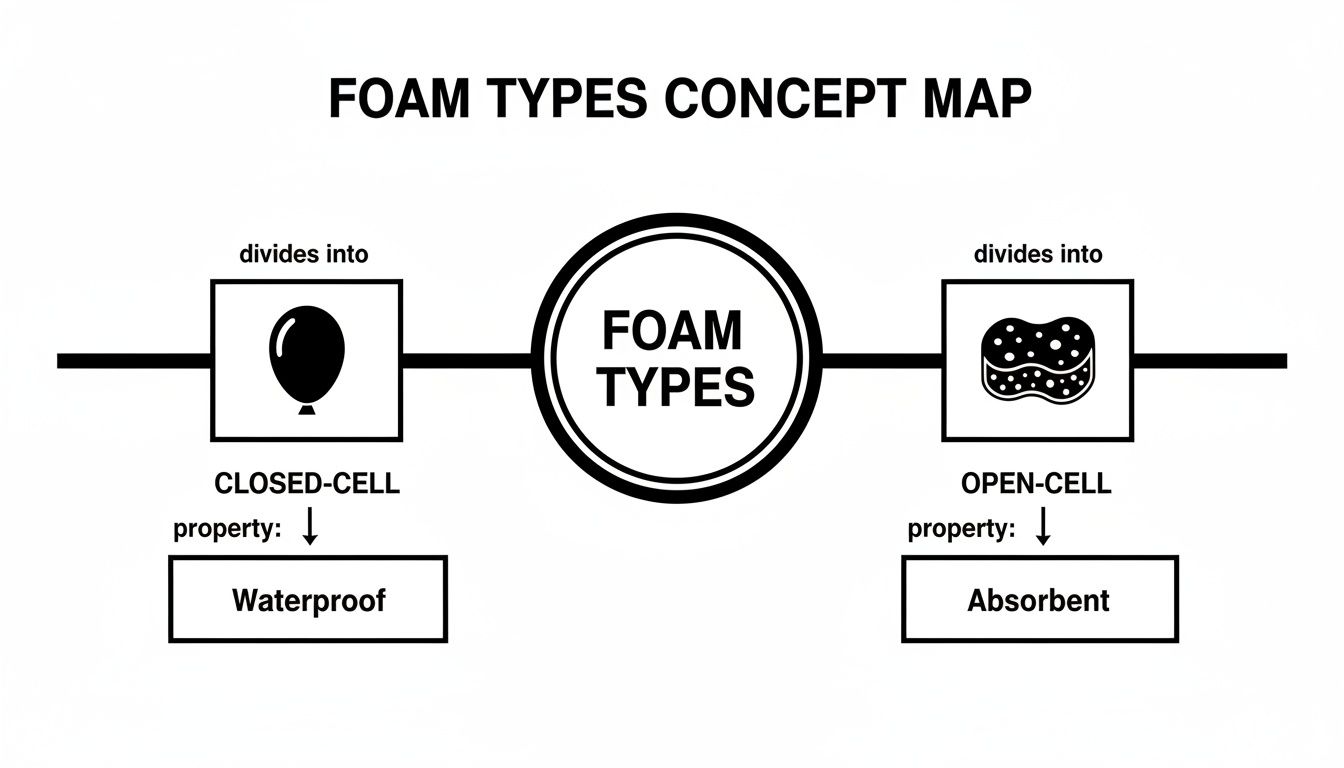

This diagram offers a simple visual to help see the difference.

As you can see, the tightly locked cells give closed-cell foam its waterproof quality, while the interconnected structure of open-cell foam makes it absorbent.

To make this even clearer, here’s a quick comparison of how the two types of foam handle water.

Open-Cell vs Closed-Cell Water Performance at a Glance

| Property | Closed-Cell Foam | Open-Cell Foam |

|---|---|---|

| Water Barrier | Yes, it is waterproof. | No, it absorbs water. |

| Cell Structure | Dense, with >90% sealed cells. | Spongy, with interconnected cells. |

| Moisture Vapor | Blocks vapor (low perm rating). | Allows vapor to pass through. |

| Best For | Exterior walls, crawl spaces, roofs. | Interior walls, soundproofing. |

This table sums it up: when you need to keep water out, closed-cell foam is the only reliable choice.

Market Trends Confirm Its Effectiveness

The construction industry knows how effective closed-cell foam is for moisture control. The U.S. spray foam insulation market was recently valued at USD 750.02 million and is expected to keep growing, largely because of the demand for high-performance materials like closed-cell foam.

Here in South Florida, that matters. Properly installed, closed-cell foam can reduce mold risk by up to 95% compared to other options in damp environments. For homeowners in Jupiter and West Palm Beach, where we see an average of 60 inches of rain a year, that’s a game-changer. You can dig into more data on the U.S. spray foam market to see these trends for yourself.

Exploring the Science Behind Waterproof Foam

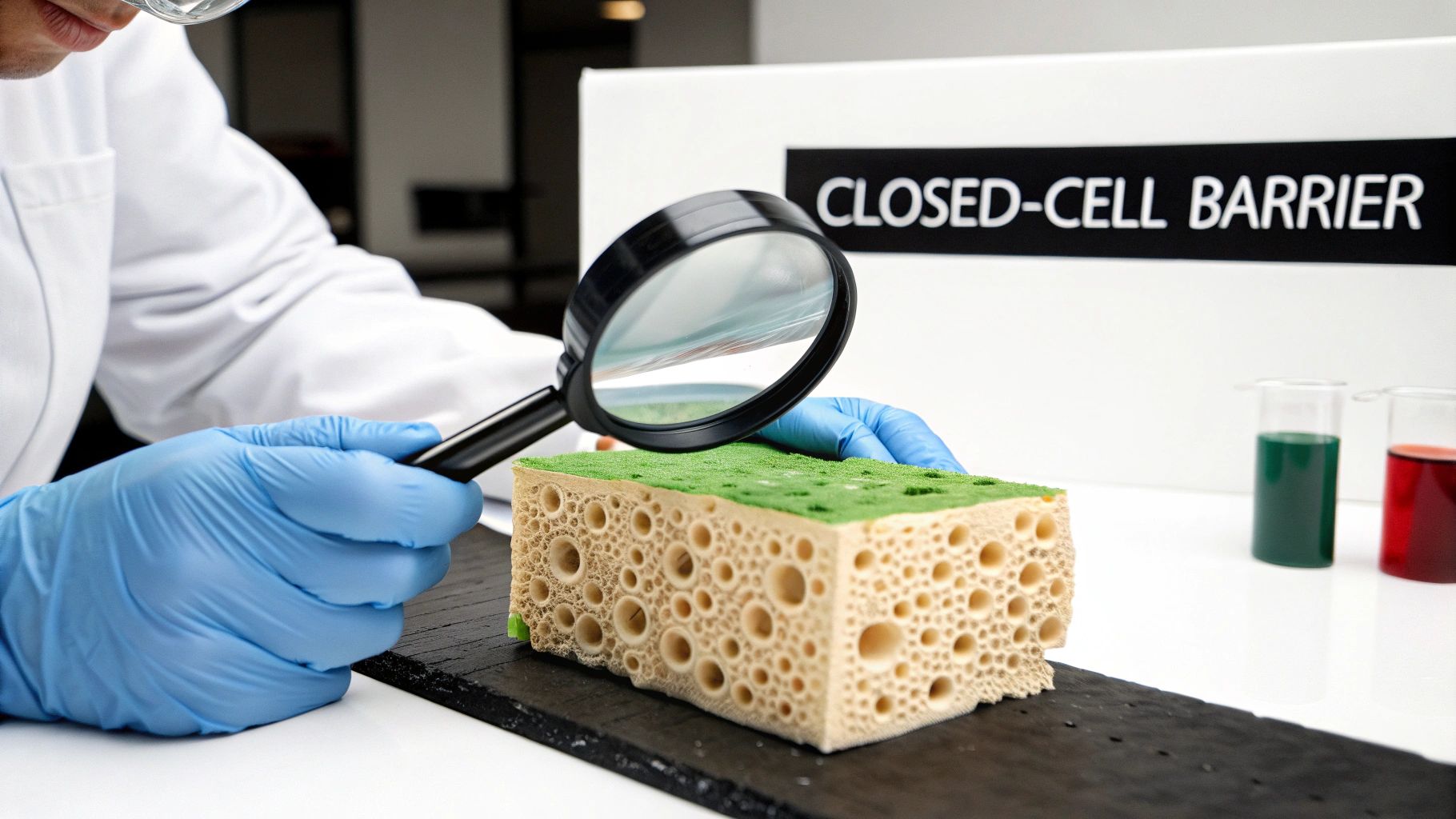

To really get why one type of expanding foam is waterproof and another is basically a sponge, you have to look at how it’s made. It’s not about some special coating; the secret is baked right into the foam’s DNA. The difference in performance all comes down to how millions of tiny bubbles, or “cells,” are formed when the chemicals react.

Think of closed-cell foam as a huge cluster of microscopic, individual balloons. Each cell is a totally sealed, self-contained bubble filled with an insulating gas. As the foam expands, these tiny balloons press up against each other, locking together into a solid, rigid mass.

This design creates an incredibly tough barrier. Because every cell is sealed off, there’s simply no path for liquid water to travel through the material. It stops moisture dead in its tracks right at the surface, making it the go-to choice anywhere you need to keep water out.

Understanding Closed-Cell Foam Structure

The dense, rigid nature of closed-cell foam is what makes it so powerful. Its structure does more than just stop leaks; it actually adds to the structural integrity of your walls or roof deck. This is a huge plus, especially here in South Florida where our buildings have to stand up to hurricane-force winds.

The key features of its structure include:

- High Density: Closed-cell foam is much denser and more rigid than its open-cell cousin.

- Sealed Cells: Over 90% of its cells are completely closed, blocking the passage of liquid water.

- Gas Pockets: The trapped gas inside each sealed cell gives it a high thermal resistance, or R-value.

This unique mix of properties means that when you ask, “is expanding foam waterproof?” the answer for closed-cell foam is a loud and clear “yes.” It acts as your insulation, air seal, and waterproofer all in one shot.

Why Open-Cell Foam Absorbs Water

Now, let’s switch gears and picture open-cell foam. Instead of sealed balloons, think of it like a kitchen sponge—a complex network of interconnected bubbles. The cells are intentionally left open, creating a web of tiny passages all through the material.

While this structure is great for absorbing sound and creating an air seal, it offers zero resistance to water. If open-cell foam gets wet, water will wick right through these interconnected pathways and saturate the foam completely. This leads to trapped moisture inside your walls, which is a perfect recipe for mold, mildew, and rot.

Key Takeaway: The difference is simple but absolutely critical. Closed-cell foam is a water barrier because its cells are sealed. Open-cell foam is a water absorber because its cells are interconnected, giving moisture a highway to travel on.

Demystifying Performance Ratings

To put some hard numbers on these differences, we use specific industry metrics. Understanding these terms helps translate the science into real-world performance, showing you exactly why closed-cell foam is the clear winner for waterproofing.

Two of the most important ratings are the Water Absorption Rate and the Perm Rating.

- Water Absorption Rate: This tells you how much water a material will soak up by volume when it’s submerged. Closed-cell foam has an extremely low absorption rate, often less than 0.5% by volume. Open-cell foam, on the other hand, can absorb a huge amount of its own weight in water.

- Perm Rating (Permeability): This measures how much water vapor (think humidity) can pass through a material. The lower the number, the better the barrier. Closed-cell foam has a very low perm rating—typically under 1.0 perm—which qualifies it as a Class II vapor retarder, or what most people call a “vapor barrier.”

That low perm rating is a game-changer in South Florida’s humid climate. It stops that heavy, moisture-filled air from passing through your insulation and condensing on cooler surfaces inside your walls—a leading cause of hidden mold. The foam’s ability to block vapor is just as important as its ability to block liquid water, especially when you’re trying to boost the insulation value of concrete block walls so common in our area. Open-cell foam, with its high perm rating, lets that vapor pass right through, offering no defense against this kind of moisture problem.

How Spray Foam Became a Waterproofing Powerhouse

Spray foam wasn’t always the go-to solution for sealing up homes. Its journey from highly specialized industrial jobs to a key player in modern construction is a story of incredible innovation, and it completely changed how we think about waterproofing—especially here in the tough climate of South Florida. At first, it was all about insulation, but it didn’t take long for builders to realize its potential was much, much bigger.

The real turning point came during the energy crisis of the 1970s. As everyone scrambled for better ways to make buildings more efficient, closed-cell polyurethane spray foam stepped into the spotlight. Its dense, rigid structure did more than just stop heat transfer; it created an incredible all-in-one air, vapor, and water barrier. This was a massive leap forward from old-school methods that required multiple products and a whole lot of labor.

From Industrial Roots to Protecting Your Home

Decades ago, you’d only find spray foam in places like commercial freezers or used for flotation in boats—environments where an absolute, non-negotiable seal against moisture and temperature was critical. Forward-thinking builders and architects saw how well it performed under these extreme conditions and started asking, “Why can’t we use this to protect houses?”

That shift to residential building proved to be a game-changer. Homeowners in hurricane-prone areas soon discovered that spray foam could do what other materials simply couldn’t. Applied as a liquid, it expands to fill every single crack, gap, and seam, creating a seamless, solid barrier with no joints for water to sneak through. As spray foam continues to push the boundaries, understanding how to make your home leak-proof is the first step in truly protecting your property.

Real-World Waterproofing in South Florida

Here in South Florida, this technology proves its worth every single day. Between the relentless humidity, torrential downpours, and the constant threat of hurricanes, you need a waterproofing solution that is both tough and adaptable.

We see its power in action all the time in applications like:

- Sealing Roof Decks: Applying closed-cell foam to the underside of a roof deck creates a powerful secondary water barrier. If hurricane-force winds tear off some shingles, this foam layer is the last line of defense, preventing water from pouring into your attic and causing devastating damage.

- Waterproofing Crawl Spaces: Ground moisture is a constant battle in Florida. Sealing crawl space walls and rim joists with closed-cell foam stops that moisture in its tracks, preventing the rot, mold, and pest infestations that thrive in damp spaces.

- Protecting Metal Buildings: For the metal structures you see all over Stuart and Wellington, temperature swings can cause condensation—”sweating”—on the interior panels. Spray foam insulation stops this by keeping the metal surface from getting cold enough to reach the dew point.

Proven Performance Over Time: The global polyurethane foam market was valued at USD 52.55 billion, which speaks volumes about its effectiveness. The building and construction industry alone accounts for 21.6% of that, driven by foam’s incredible insulation and waterproofing abilities.

In a place like South Florida, a professionally installed closed-cell foam application from a team like Airtight Spray Foam Insulation acts as a true vapor barrier. It’s engineered to prevent up to 99% of water absorption, even after being soaked for long periods. This isn’t just an upgrade; it’s a critical safeguard for protecting your home and family from the costly and unhealthy consequences of water damage.

The Hidden Dangers of a Bad Install

Even a material as tough as closed-cell spray foam is only as good as the person installing it. So, when you ask, “is expanding foam waterproof?” the answer is yes—but with a huge asterisk. A perfect material in the wrong hands can quickly go from a protective shield to a source of serious damage. The performance you’re paying for is directly tied to the expertise of the person behind the spray gun.

A bad installation isn’t just a minor slip-up; it’s an open invitation for moisture intrusion, structural decay, and expensive headaches down the road. The most common mistakes completely cancel out the foam’s waterproof benefits, leaving your home vulnerable despite your investment. These aren’t just hypotheticals—they are cautionary tales we see in the field far too often.

A poorly done job can trap moisture, creating the very problems you were trying to prevent. That’s why professional application isn’t just a good idea—it’s absolutely essential for a truly waterproof seal.

Choosing the Wrong Foam for the Job

The single worst mistake you can make is using the wrong type of foam for the environment. Picture this: a homeowner in a flood-prone area of Jupiter decides to insulate their crawl space. If an inexperienced installer uses open-cell foam, they’ve essentially lined the foundation with a giant sponge.

When floodwaters rise or ground moisture gets high, that open-cell foam will soak up and hold onto water, pressing it against the wooden subfloor and joists. This creates the perfect breeding ground for wood rot, termites, and dangerous mold. The “insulation” becomes a constant source of moisture, silently destroying the home’s structure from below.

A Cautionary Tale: We once consulted on a project where a DIYer used open-cell foam in their West Palm Beach attic to save a few bucks. After a minor roof leak, the foam soaked up gallons of water, hiding the problem until the sheer weight of it all brought a section of the drywall ceiling crashing down. What should have been a simple roof patch turned into a massive remediation project.

The Critical Role of Proper Application

Beyond picking the right foam, the technical skill of the application itself is everything. Several key factors can make or break the waterproof barrier, and they all come down to the installer’s training and attention to detail.

Here are three of the most common ways an installation can fail:

- Improper Thickness: To act as a true vapor barrier, closed-cell foam has to be applied at a specific thickness—usually 2-3 inches. If the layer is inconsistent or too thin, it creates weak spots, giving moisture vapor a path to get inside your walls and condense.

- Off-Ratio Mixing: Spray foam is made by mixing two chemical components at a precise ratio and temperature. If that mixture is even slightly off, the foam won’t cure correctly. You end up with a weak, brittle, or sticky barrier that can shrink, crack, and pull away from surfaces, leaving gaps in your waterproof seal.

- Poor Surface Prep: Spray foam needs a clean, dry surface to grab onto. Applying it over dust, debris, or dampness will cause it to peel away over time. This creates hidden pockets where moisture can collect and cause rot without you ever seeing it.

These might sound like small technical details, but any one of them can lead to a complete failure of the waterproofing system. An installer’s expertise is what ensures these variables are perfectly managed, guaranteeing the foam works like it’s supposed to. At the end of the day, the difference between a secure, dry home and a moisture-damaged one often comes down to the quality of the installation.

Achieving a Waterproof Seal in South Florida

Getting a truly waterproof seal in South Florida isn’t just about picking the right material; it’s about the entire strategy behind the installation. Around here, where humidity, torrential downpours, and hurricanes are just part of the yearly calendar, your building’s outer shell—its envelope—needs a seamless, bulletproof defense. This is exactly where closed-cell spray foam, installed by a seasoned pro, becomes the undisputed champion of waterproofing.

For homes and businesses from Palm Beach Gardens to Jupiter, closed-cell foam is the only real choice for vulnerable areas like attics, exterior walls, and crawl spaces. Its dense, rigid structure doesn’t just insulate—it creates a solid, impermeable barrier that shuts down both liquid water and our relentless humidity. While other insulation materials can get soggy, sag, or break down over time, closed-cell foam becomes one solid piece that actually adds strength to whatever it’s sprayed on.

Best Practices for a Resilient Barrier

Any professional installer will tell you that the real work begins long before the foam even leaves the truck. Proper surface prep is completely non-negotiable. The surface has to be clean, totally dry, and free of any dust, oil, or debris that could mess with the bond.

This painstaking prep work is what ensures the foam sticks for good, preventing it from ever peeling or pulling away down the road. Once the surface is ready, the application itself is a skill. The installer has to maintain the perfect distance and speed to build the foam up to the right thickness, layer by layer.

Thickness is Everything: For closed-cell foam to act as a true vapor barrier (what we call a Class II vapor retarder), it has to be applied to a specific depth. A thickness of 2 to 3 inches is the magic number needed to get the low perm rating required to stop moisture vapor in its tracks—a non-negotiable in our swampy climate.

Integrating Foam Into Your Home’s System

Spray foam doesn’t work in a vacuum. A smart waterproofing strategy makes sure the foam is perfectly integrated with every other part of your home’s exterior. Think of closed-cell foam as the seamless, waterproof liner in a complete system that also includes your roof flashing, drainage plains, and weather-resistant barriers.

For instance, when we’re insulating an attic, we meticulously seal the foam around every single roof penetration, like vents and plumbing stacks. On exterior walls, the foam has to tie directly into the window and door flashing to create a continuous, unbroken shield. This holistic approach eliminates the weak spots where water loves to sneak in—right at the seams where different materials meet.

It’s this integration that transforms a collection of building parts into a single, unified defense against South Florida’s worst weather.

The Clear Choice for Our Local Conditions

Here in South Florida, the question isn’t just if expanding foam is waterproof, but how to guarantee it performs flawlessly, year after year. The combination of closed-cell foam’s natural toughness and a professional installation gives you that guarantee. It’s a solution built specifically for our local challenges.

- Attics and Roof Decks: Spraying closed-cell foam directly to the underside of the roof deck gives you a powerful secondary water barrier. If a hurricane damages your shingles, this layer can be the difference between a small leak and a catastrophic failure.

- Exterior Walls: It seals every tiny crack and pinhole in concrete block or wood frame construction, stopping humid air from getting inside and condensing into damaging moisture within the wall. You can dig deeper into how it stacks up by comparing spray foam vs. blown-in insulation for wall assemblies.

- Crawl Spaces: Encapsulating a crawl space with closed-cell foam locks out ground moisture from our damp soil, preventing the rot, mold, and pest infestations that are so common down here.

The numbers back it up. Expanding foam’s effectiveness is why it dominates roofing applications in the global waterproofing membrane market, which is set to hit USD 54.15 billion by 2033. Closed-cell spray foam, with an impressive R-value of up to 7 per inch, not only provides top-tier insulation but also forms that critical seamless waterproof layer. For metal buildings and commercial properties battling 80-90% humidity, it’s a game-changer. Its use in floors, walls, and ceilings is growing because it seals air leaks 24 times better than old-school fiberglass and is a master at blocking moisture. You can explore more data on the waterproofing market to see why foam-based systems are taking over the industry.

Ultimately, getting a durable, waterproof seal is a science. It demands the right material, meticulous prep, and an expert hand. For property owners in South Florida, investing in a professional closed-cell foam installation from a team like Airtight Spray Foam Insulation is the single most reliable way to protect your home from the elements.

Why Professional Installation Is the Only Option

So, let’s circle back to the big question: is expanding foam waterproof? The answer is a solid maybe. More specifically, closed-cell foam is waterproof, but only if it’s installed perfectly. We’ve walked through the science and seen just how much can go wrong with a sloppy application. The bridge between the foam’s potential and its actual performance is a professional installer.

Those DIY kits you see at the hardware store? They’re great for filling small gaps around a window frame. They are not designed to create a building-wide waterproof shield. They just don’t have the power, precision, or chemical consistency of professional gear. Trying to waterproof an attic or crawl space with a can of foam is a recipe for failure, leaving you with gaps, thin spots, and a leaky seal that leaves your home completely vulnerable.

Expertise Isn’t Optional

A professional installation is so much more than just spraying foam on a wall. It’s a meticulous, step-by-step process that guarantees a lasting, truly waterproof barrier. A certified technician is trained to manage every single variable to get the job done right.

Here’s what that looks like in the real world:

- A Thorough Property Assessment: First, we identify where moisture is coming from, check for any existing damage, and make sure the space has proper ventilation.

- Meticulous Surface Preparation: Every surface has to be perfectly clean and dry. This is non-negotiable for creating an unbreakable bond.

- Precise Climate Control: We manage the on-site temperature and humidity because these factors have a massive impact on how the foam cures.

- Calibrated Application: Our specialized equipment mixes the chemicals at the exact right ratio and applies the foam to a consistent, correct thickness every single time.

You simply can’t replicate this level of detail with a DIY approach. It’s the difference between a band-aid fix and a permanent solution.

Investing in a professional installation isn’t about convenience—it’s about making sure the foam actually does what it’s supposed to do. Expertise ensures the chemical reaction is perfect, the application is seamless, and the result is a truly monolithic, waterproof barrier that protects your home for decades.

The Airtight Guarantee for South Florida

Here in South Florida, there’s no room for error. The stakes are just too high. Between the relentless humidity and the threat of hurricane-driven rain, your home’s defense against moisture has to be flawless.

With so much on the line, it pays to understand the benefits of hiring a professional waterproofing company that knows how to deliver a bulletproof solution. Choosing an experienced team like Airtight Spray Foam Insulation is an investment in your peace of mind. Our certified technicians follow a strict, proven process—from the initial free estimate to the final walkthrough—to ensure every inch of your property is sealed, secure, and ready to stand up to the elements.

Got Questions About Waterproof Foam?

When you’re trying to waterproof your home, especially in a place like South Florida, the details around expanding foam can get confusing. You want clear, honest answers to make the right call and avoid a costly mess down the road. Let’s tackle some of the most common questions we hear from homeowners.

We’ll run through a few real-world scenarios you’re likely to face, from dealing with an emergency leak to picking the right foam for the right part of your house. These quick answers should clear things up and help you figure out what to do next.

Can I Use Expanding Foam to Fix a Roof Leak?

This is a big one. While closed-cell foam is waterproof, it’s not a standalone patch for an active roof leak. Think of it this way: professionals apply it to the underside of the roof deck to create a seamless, secondary water barrier. It’s fantastic protection against wind-driven rain, but it’s not meant to plug a hole from the outside. The primary roofing problem still has to be fixed first by a roofer.

Grabbing a can of foam from the hardware store and spraying it on top of a leak is a temporary fix at best. Worse, this approach often traps moisture underneath the patch, creating a perfect environment for wood rot and making the original problem much, much worse over time.

Does Waterproof Spray Foam Need a Protective Coating?

It all comes down to one thing: sunlight. If the foam is installed in a protected area, like inside an attic or a wall cavity, it doesn’t need any coating at all.

However, if the foam is exposed to direct sunlight—like on an exterior wall or as part of a specific roofing system—a protective coating is an absolute must. UV radiation will chew through the foam over time, causing it to break down and completely lose its waterproof integrity. We always apply a professional-grade silicone, acrylic, or elastomeric coating to shield it from the sun and make sure it lasts for decades.

Is Open-Cell Foam Ever a Good Choice in Florida?

Absolutely, but never for waterproofing. Open-cell foam is a rockstar for air sealing and sound dampening in protected interior spaces. Think between floors or in walls that will never see moisture.

Because it’s vapor-permeable, it allows the structure to “breathe,” which can be a good thing in certain building designs. You can learn more about its different uses in our other articles on spray foam insulation. But for attics, crawl spaces, and exterior walls in Florida’s humid, storm-prone climate? Closed-cell foam is hands-down the superior and safer choice for moisture resistance every single time.

Ready to protect your property with a truly waterproof solution? The expert team at Airtight Spray Foam Insulation has the experience and precision to deliver a flawless installation. Request your free, no-obligation quote today!