Blog

How to insulate ductwork in attic: Simple Tips to Save Energy

Learning how to insulate the ductwork in your attic is hands-down one of the smartest upgrades you can make to a South Florida home. The project is all about sealing and wrapping the metal or flexible ducts that snake through your unconditioned attic. Get it right, and you'll stop energy loss, prevent condensation, and see a real drop in your cooling bills.

Why Insulating Your Attic Ductwork Is So Critical in South Florida

Think of your attic as the frontline in the battle against the Florida sun. When your HVAC ducts are routed through this super-heated space without any protection, you're fighting a losing war against energy waste. It’s like trying to keep a drink cold by sipping it through a hot metal straw—it just doesn't work.

The Battle Against Attic Heat and Humidity

Ever been in a South Florida attic in July? Temperatures can easily rocket past 130°F. That intense heat turns your uninsulated ducts into energy thieves, warming up your expensive, conditioned air long before it ever reaches the rooms below.

For homes in places like Jupiter, Palm Beach Gardens, or Wellington, properly insulating those ducts can boost your HVAC’s efficiency by an extra 10-15% on top of whatever attic insulation you already have.

Humidity is the other half of the problem. When that hot, sticky attic air hits your cold metal ducts, condensation forms instantly. We call it "duct sweating," and it’s a recipe for disaster. This constant moisture leads to rust, corrosion, and the kind of mold issues that plague older homes built before modern energy codes kicked in.

A good insulation job creates a thermal barrier, cutting the strain on your AC and potentially extending its lifespan by 3-5 years. The result? 15-30% in total energy savings.

Key Takeaway: Uninsulated ductwork in a South Florida attic doesn't just waste energy; it forces your AC to run harder and longer while creating the perfect environment for rust and mold.

The Real-World Benefits of Insulated Ducts

Taking the time to insulate your attic ductwork is a strategic investment that pays off almost immediately. Homeowners who get it done right see a few major improvements.

- Lower Energy Bills: Your AC system doesn't have to work nearly as hard to keep your house cool. That means less runtime and a direct reduction in your monthly FPL bill.

- A More Comfortable Home: Those annoying hot spots and rooms that never seem to get enough cold air? They often disappear once the ductwork is properly sealed and insulated. You get consistent temperatures everywhere.

- Better Indoor Air Quality: Sealing ductwork stops it from sucking in dusty, musty attic air and spreading it through your home. It’s a huge deal for anyone with allergies or respiratory issues.

Ultimately, a well-insulated duct system is a core part of what makes a house perform well. It's a key piece of the puzzle in our comprehensive Airtight Comfort System.

Choosing the Right Duct Insulation for Florida's Climate

When you decide to insulate ductwork in your attic, you quickly learn that not all materials can handle South Florida's brutal climate. Our combination of extreme heat and suffocating humidity can make a lot of standard insulation methods completely ineffective.

What you need is a solution that’s both a powerful thermal barrier and an impenetrable moisture shield. It's a two-front war up there.

For most homeowners, the decision boils down to two paths. You can go the traditional DIY route with fiberglass duct wrap and mastic sealant, or you can bring in a pro for spray foam insulation. Both have their uses, but how they perform long-term in our region is a night-and-day difference.

Traditional Duct Wrap and Mastic

Think of duct wrap as a fiberglass blanket, usually with a foil backing to act as a vapor barrier. It's what you'll find stacked high at the local hardware store, and honestly, it’s a decent choice if you're on a tight budget or have a very simple, easy-to-reach duct layout.

The old-school process starts with painting a thick, goopy substance called mastic sealant over every single seam, joint, and connection. Once that cures, you wrap the ducts with the insulation blanket, pulling it tight and sealing all the new seams with foil tape.

While it’s certainly better than nothing, this method has some serious weak spots in our climate:

- Seam Failure: Every single taped seam is a potential leak. After years of baking in a 140°F attic, that adhesive gives up, creating gaps that let hot, humid air right back in.

- Inconsistent Coverage: It's almost impossible to get a perfect, airtight wrap around complex T-joints, sharp bends, and plenum connections. You'll always have little exposed spots.

- Moisture is the Enemy: If that outer foil barrier gets torn or a seam fails, the fiberglass inside acts like a sponge. It soaks up moisture, gets compacted, loses its R-value, and becomes a prime spot for mold.

The Superior Seal of Spray Foam

Spray polyurethane foam (SPF) is a completely different animal. Instead of wrapping, we apply a liquid that expands instantly, creating a seamless, solid layer of insulation that fits every curve and connection perfectly. No gaps, no seams, no tape.

There are a couple of types, but for ductwork sitting in a hot and humid Florida attic, closed-cell spray foam is the hands-down winner. It’s dense, rigid, and creates its own powerful air and vapor barrier.

When we apply closed-cell foam directly to ductwork, it doesn't just insulate—it completely encases the metal in an airtight, watertight shell. This process eliminates "duct sweating" for good and stops energy loss cold.

Because spray foam creates one continuous, monolithic barrier, it delivers a level of performance that taped-up blankets just can't touch. It even adds structural integrity to the ducts themselves.

If you're looking at insulation options, understanding how spray foam's air-sealing capabilities stack up against other materials is key. You can check out a detailed comparison of spray foam vs. blown-in insulation to see why this matters so much. For our homes here in South Florida, that permanent, perfect seal is how you finally win the battle against attic heat and humidity.

To make the choice clearer, here’s a quick rundown of how the most common materials stack up for our unique challenges.

Duct Insulation Material Comparison for South Florida Homes

| Material | Best For | Pros | Cons for South Florida |

|---|---|---|---|

| Closed-Cell Spray Foam | Unvented attics, maximum performance, and moisture control. | Forms a complete air and vapor barrier. Prevents condensation ("duct sweating"). Adds structural rigidity. Highest R-value per inch. | Higher upfront cost. Requires professional installation. |

| Fiberglass Duct Wrap | Basic insulation on a budget, simple and accessible duct layouts. | Low material cost. Readily available for DIY projects. | Prone to seam failure over time. Absorbs moisture if vapor barrier is compromised, leading to mold and lost R-value. Difficult to air seal perfectly. |

| Reflective/Foil Insulation | Supplementing existing insulation. Mild climates (not ideal as a primary solution here). | Reflects radiant heat. Lightweight and easy to handle. | Provides minimal R-value on its own. Does not stop conductive heat transfer effectively. Can trap moisture if not installed with an air gap. |

| Duct Mastic Sealant | Sealing joints and seams before applying insulation. | Excellent for creating an initial air seal at connections. Flexible and durable. | Not an insulator. Must be combined with an insulation material like duct wrap or foam. Messy to apply. |

Ultimately, while traditional methods can offer a temporary fix, only a seamless, monolithic solution like closed-cell spray foam provides the permanent protection needed to truly conquer a South Florida attic.

Preparing Your Attic for Duct Insulation

If you think you can just jump in and start wrapping your ducts, I've got some bad news. That's easily the biggest mistake I see homeowners make when they decide to insulate ductwork in attic spaces.

Proper prep work is what makes the difference between a job that saves you money for years and one that’s a complete waste of a weekend. Think of it like this: you wouldn't paint a car without sanding it down first, right? Same principle applies here. The goal isn't just to get things clean; it's to create a perfectly airtight surface so your sealants and insulation can form a bond that actually lasts.

Safety First—Don't Skip This

Let's be real: working in a South Florida attic, especially in July, is brutal. The heat is a serious hazard, and you're surrounded by things you don't want to touch or breathe. Before you even think about crawling up there, you need to gear up.

Here's your non-negotiable safety checklist:

- A High-Quality Dust Mask or Respirator: Attics are nasty. They're filled with dust, old fiberglass particles, and who knows what else. Don't breathe that stuff in.

- Goggles: Protect your eyes. You’ll have debris and insulation fibers falling all over the place.

- Gloves: A good, sturdy pair will save your hands from sharp sheet metal edges and itchy insulation.

- Long Sleeves and Pants: This is all about keeping that irritating fiberglass off your skin.

You also need to watch your step. Lay down some plywood boards to create a safe path across the ceiling joists. Never, ever step on the drywall between the joists. It won't hold you, and you'll find yourself in the living room much faster than you intended.

Inspect and Clean Every Single Inch

Once you're safely geared up, it’s time to play detective. The mission is to find every single air leak before you cover anything up. Get hands-on and run your fingers along every seam, joint, and connection on your metal ducts. You’re hunting for gaps, loose connections, or any damaged spots.

Pay extra close attention to the "takeoffs"—that's where the smaller round ducts branch off from the big rectangular trunk line. In my experience, these connections are almost always poorly sealed from the day the house was built.

Pro Tip: A neat trick is to turn on your HVAC fan (just the fan, not the AC) and hold an incense stick near the duct seams. If the smoke starts dancing around or gets blown away, congratulations—you've found an air leak.

After your inspection, it's time to clean. And I mean really clean. Every square inch of the ductwork has to be free of dust and grime. A damp rag with a simple household cleaner like 409 works just fine. This step is critical because mastic sealant will not adhere properly to a dirty surface. Skipping this pretty much guarantees the whole job will fail down the road. For homeowners in Palm Beach County, years of fine dust can make proper sealing impossible; our guide on attic spray foam insulation in Palm Beach County explains why a clean slate is the most important part of any successful insulation job.

Seal Every Seam Before You Insulate

This is it. This is the step that matters most. Every single joint, seam, and connection must be sealed with mastic. Please, do not rely on foil tape alone. It will eventually fail. Mastic is a thick, goopy sealant that dries into a permanent, flexible, and truly airtight seal.

Grab a cheap paintbrush and slather a generous layer of mastic over all the seams. If you find any gaps wider than a credit card, press a piece of fiberglass mesh tape into the wet mastic first, then paint another coat right over the top.

Let the mastic fully cure before you even think about wrapping the ducts. By sealing first, you ensure you're insulating an airtight system, not just putting a blanket over leaky pipes.

The Right Way to Seal and Insulate Your Ducts

Alright, your attic is prepped and you’ve got your materials. Now for the most important part: the actual hands-on work.

Whether you're tackling this yourself or just want to understand how the pros do it, knowing how to properly insulate ductwork in an attic is what separates a job well done from a project that fails in a year. The smallest gaps or a bit of sloppy technique can undo all your hard work, so precision really is everything here.

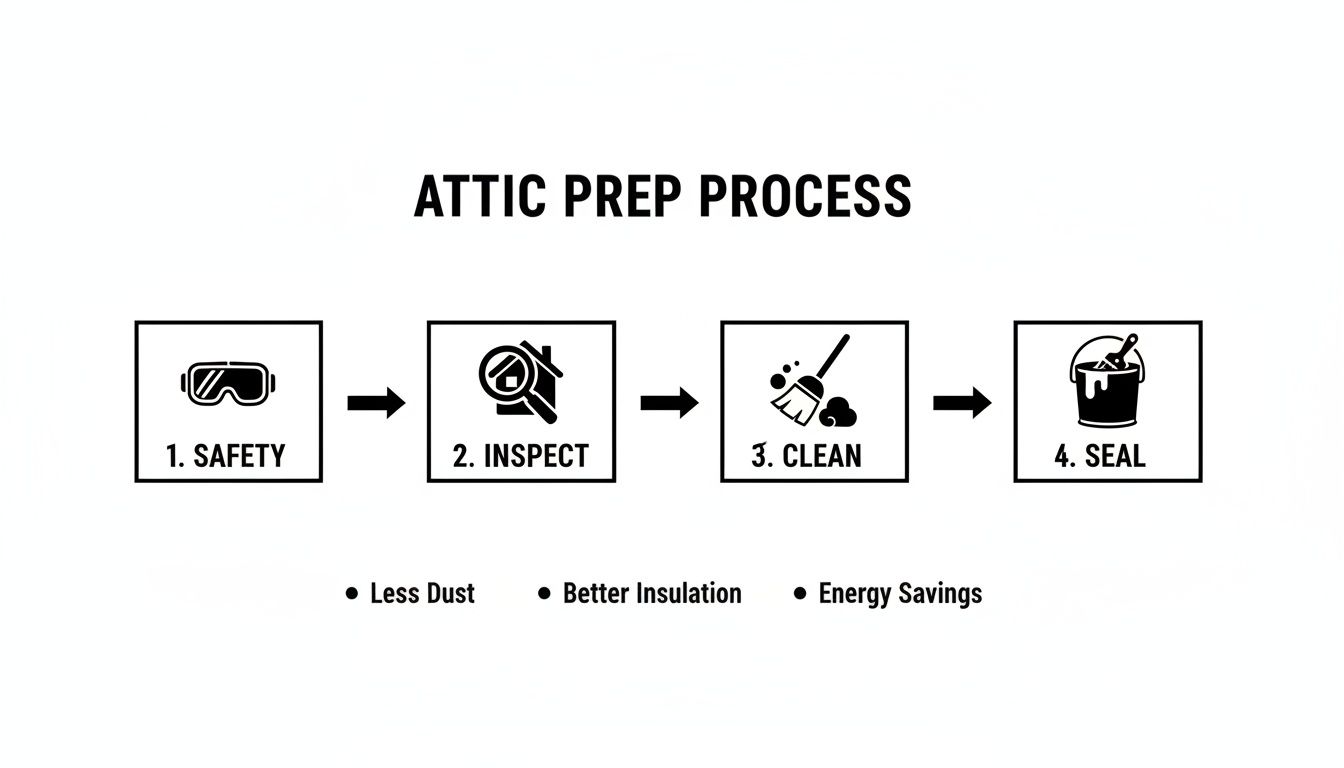

This quick visual guide shows the prep work that has to happen before you even think about insulating.

Hitting these four steps—safety, inspection, cleaning, and sealing—is non-negotiable if you want your new insulation to perform from day one.

The DIY Approach with Duct Wrap and Mastic

If you're going the traditional route with duct wrap, the process starts long before you touch the insulation itself. Your first, and most critical, job is to get that duct system completely airtight using mastic sealant.

- Get Messy with Mastic: Grab a disposable paintbrush and slather a thick layer of mastic over every single seam, joint, and connection. And I mean thick—the coating should be at least as thick as a nickel. Pay extra attention to where the smaller round ducts connect to the main trunk line; those spots are notorious for leaks.

- Reinforce Bigger Gaps: Find a gap wider than a credit card? Press a piece of fiberglass mesh tape right into the wet mastic. Immediately follow up with another layer of mastic over the tape to embed it completely. This creates a patch that's built to last.

- Wrap It Up: Once the mastic is fully cured (always check the bucket for instructions), you can start wrapping. Begin at one end and wrap the insulation snugly around the duct with the foil vapor barrier facing out. Make sure to overlap the seams by at least two inches to prevent any gaps.

- Seal Every Last Seam: Use a high-quality foil tape to seal every single seam on the duct wrap. This means the long seam running down the duct and the circumferential seams where one piece of wrap ends and the next one starts. The goal is a continuous, unbroken foil barrier.

A Common DIY Failure: Just slapping foil tape over duct seams without using mastic first is a recipe for disaster. That tape is not a true air sealant, and its adhesive will absolutely fail in the brutal heat of a South Florida attic, letting all those leaks come right back.

The Professional Method with Spray Foam

When we get a call at Airtight Spray Foam Insulation, we take a different approach. We’re not just patching; we’re creating a single, seamless, monolithic barrier that completely encapsulates the ductwork. This is how you solve the problem for good.

Our technicians apply closed-cell spray foam directly onto the sealed ducts. As the foam expands, it gets into every tiny crevice and bonds directly to the metal, creating a rigid, durable, and permanent shell.

- No Seams, No Gaps, No Worries: Spray foam creates one continuous layer of insulation. There are no tapes that can fail or seams that can pull apart over the years.

- A Total Air and Moisture Barrier: Closed-cell foam is a certified air and vapor barrier. It stops air leaks dead in their tracks and prevents condensation—that dreaded "duct sweating"—from ever forming on the metal.

- Perfect for Tricky Spots: Those T-joints, sharp elbows, and plenum boxes are nearly impossible to wrap perfectly with a blanket. Spray foam covers these complex shapes effortlessly with a consistent, thick layer of insulation.

This professional application is, hands down, the most effective way to insulate attic ductwork because it handles heat transfer, air leakage, and humidity all in one shot.

When you consider that heating and cooling can make up 50-70% of a home's energy bill, that level of precision becomes pretty critical. In fact, ENERGY STAR estimates that proper air sealing and insulation can save homeowners around 15% on cooling costs—a huge number in our climate. You can learn more about the methodology behind these savings on ENERGY STAR's website. The Airtight method is designed to make sure you capture every single bit of that potential savings.

Deciding Between DIY and Professional Installation

Figuring out whether to tackle insulating your attic ductwork yourself or bring in a pro is a big decision. The right call really comes down to an honest assessment of your skills, how complex your duct system is, and what kind of performance you're expecting.

You're essentially weighing a weekend of sweaty, tough work against a long-term, professional-grade solution that you won't have to think about again.

Going the DIY route with traditional duct wrap and mastic can make sense in certain situations. If your ductwork is fairly simple, mostly straight runs, and you can easily get to every inch of it, it's a project you can probably handle. This is often the case for homeowners with smaller attics just looking to patch up a few obvious weak spots.

But a lot of situations are an immediate red flag, pointing straight to the pros.

When to Call an Expert

Some jobs are just too complex or risky to attempt on your own. You should always pick up the phone and call a professional if you run into any of these scenarios:

- Complex Ductwork: If your attic looks like a spaghetti bowl of twists, turns, and T-joints, getting a perfect, airtight seal with duct wrap is next to impossible for a DIYer.

- Signs of Moisture or Mold: See condensation dripping from your ducts? Smell a musty odor? That’s a sign of a bigger problem. You need an expert to diagnose the root cause before you even think about wrapping anything up.

- You Want Spray Foam: Applying spray foam insulation is a completely different ballgame. It demands specialized equipment, serious training, and strict safety protocols. This is never a DIY job.

Key Insight: The real difference isn't just about the material you use; it's the guaranteed outcome. A pro ensures every single seam and connection is perfectly sealed and insulated. It eliminates the guesswork and the risk of costly mistakes that could tank your home's air quality.

If you're leaning toward hiring a professional, it helps to understand how they get their name out there. Many of the best contractors doing this kind of work are HVAC companies. Looking at resources on local SEO for HVAC companies can give you a peek behind the curtain at how these businesses connect with homeowners like you.

Ultimately, choosing a pro is about investing in a permanent fix that starts maximizing your energy savings and home comfort from day one.

Even after laying out a game plan, a few questions always seem to surface right before you get started. Let's walk through some of the most common ones we hear from homeowners deciding to insulate ductwork in their attic, especially right here in South Florida. Getting these final details squared away can give you the confidence that your hard work will actually pay off.

What R-Value Do I Really Need for My Ducts in South Florida?

For our neck of the woods (Climate Zone 1), the Department of Energy sets the minimum at R-8 insulation for any ducts running through an unconditioned attic. This is non-negotiable if you want a real thermal barrier to stop that intense attic heat from seeping into your cool, conditioned air.

This is where materials like closed-cell spray foam really shine. Not only does it easily meet this R-8 standard, but it often blows past it while adding a complete air and moisture seal—something you just can't get from traditional duct wrap and mastic.

Can't I Just Insulate the Attic Floor and Call It a Day?

Look, insulating the attic floor is a fantastic and critical first step. But skipping the ducts is a massive missed opportunity for both savings and comfort. Your ducts are essentially the arteries of your HVAC system.

Imagine those arteries snaking through a 130°F+ attic completely unprotected. The cool air you just paid to create is warming up significantly before it even reaches your vents. This makes your air conditioner run longer and harder just to keep up. For real efficiency, you have to tackle both the attic floor and the ductwork.

Key Insight: In South Florida, your attic floor and ductwork are two sides of the same coin. Insulating one but not the other is like closing a window but leaving the front door wide open—you're still losing the fight against the heat.

How Much Money Will I Actually Save?

The savings aren't just a few bucks here and there; they're substantial. According to ENERGY STAR, a properly sealed and insulated duct system can boost your HVAC efficiency by as much as 20 percent.

For a typical homeowner in our area, that can easily translate to $300-$500 a year—or more—slashed from your cooling costs. The final number will depend on how leaky your ducts are now, the size of your house, and what FPL is charging, but it’s one of the few home improvements that delivers a fast and high return on investment. It's a direct way to knock down that power bill.

At Airtight Spray Foam Insulation, we don’t just insulate—we create high-performance, permanently sealed duct systems designed to win the battle against South Florida's heat and humidity. Request a free, no-obligation quote today and see how our Airtight Comfort System can completely change your home's efficiency.