Blog

How Does Spray Foam Insulation Work? Boost Energy Savings and Comfort

To really get a handle on how spray foam insulation works, don’t think of it like traditional insulation that’s cut and fit into place. Instead, picture it as a custom-molded protective shield that’s created right inside your walls.

It all starts with two separate liquid compounds. When our technicians mix and spray them, they trigger a rapid chemical reaction, causing the mixture to expand and harden almost instantly. The result is a solid, seamless barrier that fiberglass batts or blown-in cellulose simply can’t match.

How Spray Foam Insulation Creates a Perfect Seal

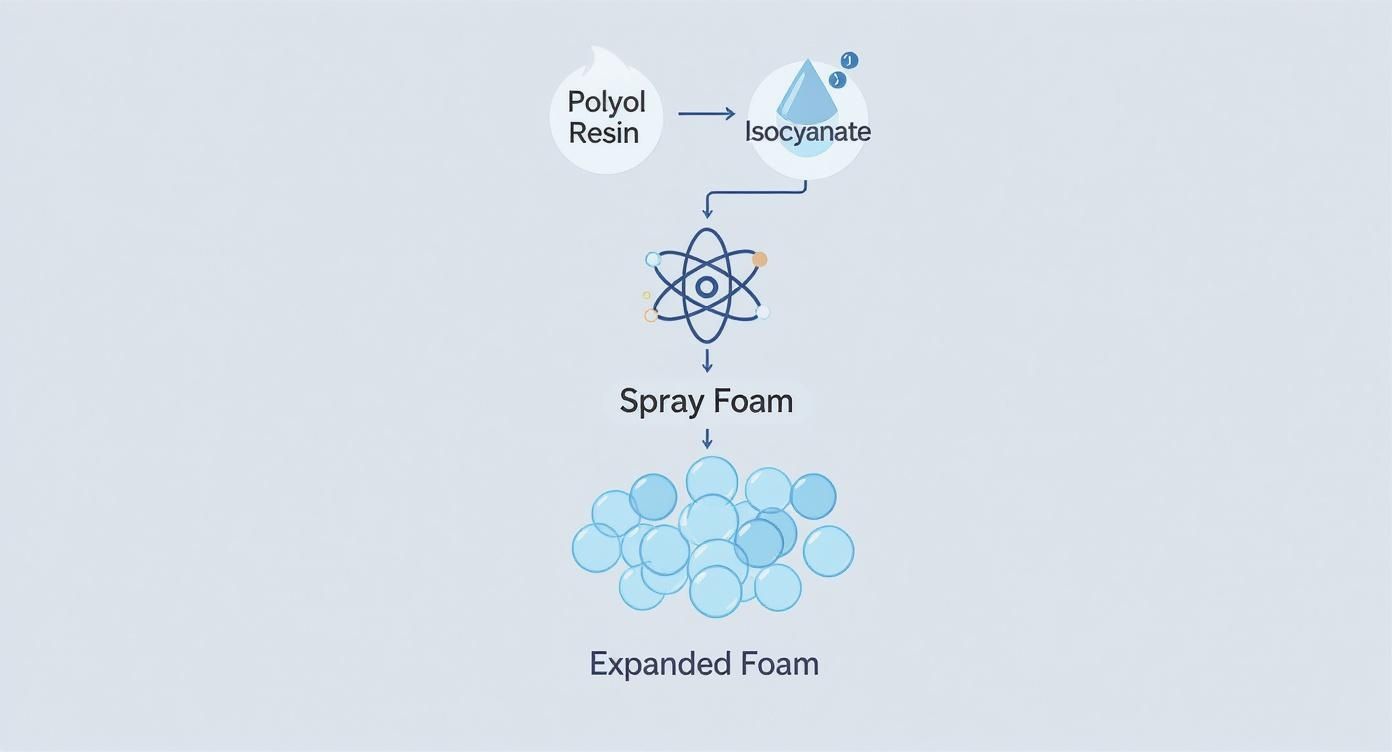

The magic of spray foam insulation lies in how it’s applied. Unlike pre-cut fiberglass that leaves gaps or loose-fill that can settle over time, spray polyurethane foam (SPF) is basically manufactured on-site, tailored to the unique framing of your home. It’s a two-part system—an isocyanate and a polyol resin—that only becomes “foam” the second it leaves the spray gun.

Our specialized equipment pumps these two liquids through a heated hose, mixing them at the very tip of the nozzle. That’s when the chemical reaction kicks off, causing the liquid to expand at an incredible rate—up to 100 times its original volume, depending on the type of foam we’re using.

The Expansion and Adhesion Process

This massive, rapid expansion is what makes spray foam so incredibly effective. As it grows, it flows like a liquid into every last crack, gap, and crevice in the wall cavity. It doesn’t matter how tiny the space or how irregular the shape is.

It also aggressively bonds to just about everything it touches—wood studs, roof sheathing, plumbing pipes, and even electrical wiring.

In a matter of seconds, this process achieves several critical jobs all at once:

- It Insulates: The foam’s cellular structure is designed to trap gas, which is what slows down the transfer of heat and keeps your home cool.

- It Air Seals: By filling every gap, it creates a continuous, airtight barrier that stops drafts and energy-sapping air leaks in their tracks.

- It Adds Rigidity: Closed-cell foam, in particular, cures into a very hard and dense material, which can actually add structural strength to your walls and roof deck.

Within moments, the foam cures and hardens into a solid, durable mass. What you’re left with is a custom-fit layer of insulation that’s permanently bonded to your home’s structure.

This on-site creation is what truly sets spray foam apart. It doesn’t just sit in the space; it becomes a part of the structure itself, creating an airtight and often watertight seal that’s impossible to achieve with older, conventional materials.

To make it even clearer, here’s a quick breakdown of the key differences between the two main types of spray foam.

Key Properties of Spray Foam Insulation at a Glance

This table offers a quick reference to the core mechanics and properties of both open-cell and closed-cell spray foam.

| Property | Open-Cell Foam | Closed-Cell Foam |

|---|---|---|

| Expansion Rate | Expands up to 100x, filling large cavities quickly. | Expands around 30-60x, creating a dense structure. |

| Cell Structure | Soft and flexible with interconnected, open cells. | Rigid and dense with sealed, gas-filled cells. |

| Air Barrier | Creates an effective air seal. | Forms a superior, impermeable air barrier. |

| Moisture Control | Allows moisture to pass through (vapor permeable). | Blocks moisture completely (vapor barrier). |

| Application | Best for interior walls, attics, and sound dampening. | Ideal for roofs, basements, and exterior walls. |

Ultimately, spray foam works by combining chemistry and physics to deliver a multi-purpose solution from a single product. It gives you thermal resistance (R-value), an air barrier, and, with closed-cell foam, a moisture barrier—all professionally applied in one go.

The Magic Behind the Mix: How Spray Foam Is Made On-Site

The real showstopper with spray foam isn’t just how it’s applied—it’s the powerful, split-second chemical reaction that happens right on your property. It’s a bit like baking a cake. You start with two simple liquid ingredients, but once you mix them, they transform into something much bigger, stronger, and totally different. This instant transformation is the secret to creating a perfect, airtight seal.

The whole process hinges on two liquid components we keep in separate, climate-controlled tanks on our rigs. It’s only when our technician pulls the trigger on the spray gun that these two liquids are forced together under high pressure, kicking off an immediate and powerful chemical change.

The Two-Part Formula

At its core, spray foam is a type of plastic called polyurethane. To create this insulating foam right before your eyes, we mix two key liquid compounds:

- The ‘A-Side’ (Isocyanate): Think of this as the hardener in the recipe. It’s a highly reactive compound that provides the foam’s rigid structure and durability.

- The ‘B-Side’ (Polyol Resin): This is where the magic happens. This side is a blend of polyol resins, catalysts that control the reaction speed, and—most importantly—a blowing agent. The blowing agent is what gives the foam its incredible volume.

Getting the ratio between these two sides exactly right is non-negotiable. Our professional equipment is meticulously calibrated to mix them perfectly every single time. Even a tiny imbalance can ruin the foam’s quality, density, and insulating power, which is why those DIY kits from the big-box stores often deliver disappointing, inconsistent results.

As explained by experts at paragon-protection.com, this chemical reaction between the two liquids is what allows the foam to expand so rapidly. It’s this expansion that lets it fill every nook, cranny, and gap in your walls or attic, creating a continuous thermal barrier that virtually eliminates air leakage.

Heat, Bubbles, and Rapid Expansion

The moment the A-Side and B-Side meet in the nozzle, they create an exothermic reaction. That’s just a scientific way of saying the chemical process generates its own heat. If you’re standing nearby, you can literally feel the warmth coming off the freshly sprayed surface. This heat isn’t just a side effect; it’s a critical part of what makes the foam expand.

The heat generated by the reaction instantly turns the liquid blowing agent in the B-Side into a gas. This creates millions of tiny, uniform bubbles inside the polyurethane mixture, causing it to swell up.

This sudden explosion of gas bubbles is what makes the foam expand so dramatically—growing up to 100 times its original liquid volume in the case of open-cell foam. In mere seconds, it fills every available space, no matter how awkward or tight the fit.

The structure of these bubbles is what determines the type of foam we’re installing:

- In closed-cell foam, the bubbles remain intact, sealed, and packed tightly together. This traps the blowing agent gas inside, making the foam incredibly dense, rigid, and resistant to moisture.

- In open-cell foam, the bubbles are designed to burst, forming an interconnected network of air pockets. This results in a softer, more flexible, sponge-like foam that’s fantastic for dampening sound.

This entire transformation—from two liquids into a solid, fully cured foam—happens almost instantly. The mixture leaves the gun as a liquid but hits the wall or roof sheathing as an expanding solid that cures and hardens within minutes. It’s this rapid curing process that allows spray foam to adhere so tenaciously to almost any surface, becoming a permanent part of your home’s structure and delivering the unmatched insulation and air sealing it’s famous for.

Choosing Between Open-Cell and Closed-Cell Foam

Once you get the basic idea behind spray foam, the next step is understanding that not all foam is the same. The two main players are open-cell and closed-cell spray polyurethane foam (SPF), and knowing the difference is critical for getting the right results for your home. This isn’t just a minor technical detail—it completely changes the insulation’s performance, cost, and best-use scenarios.

Think of it this way: open-cell foam is like a dense, firm sponge. Its microscopic cells are intentionally left open, creating a web of interconnected air pockets. This makes the final product soft, flexible, and very lightweight.

Closed-cell foam, on the other hand, is more like a tightly packed collection of tiny, individual balloons. Each cell is completely sealed off and filled with a special insulating gas, creating a rigid, dense material that’s incredibly strong and won’t let water pass through.

This diagram shows how both types start from the same chemical reaction but end up with completely different structures.

As you can see, the initial chemistry is similar, but the final cellular structure makes all the difference in the world.

To really get a feel for how these two types of foam stack up, it helps to see their key characteristics side-by-side.

Detailed Comparison: Open-Cell vs. Closed-Cell Spray Foam

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value (per inch) | R-3.5 to R-3.8 | R-6.0 to R-7.0 |

| Density | Low-density (soft, flexible) | High-density (rigid, strong) |

| Moisture Barrier | Vapor-permeable (allows drying) | Vapor barrier (blocks moisture) |

| Air Barrier | Excellent | Excellent |

| Structural Strength | No structural support | Adds significant strength |

| Sound Dampening | Excellent sound absorption | Moderate sound absorption |

| Expansion Rate | High expansion (fills large cavities) | Lower expansion (more controlled) |

| Ideal Use Cases | Interior walls, attics, soundproofing | Exterior walls, roofs, crawl spaces |

| Cost | Less expensive per board foot | More expensive per board foot |

This table gives you a quick snapshot, but let’s dive into what those numbers and terms actually mean for your property.

Key Differences in Performance and Application

That cellular structure we talked about directly impacts four things that matter most: how well it insulates (R-value), how it handles air and moisture, and whether it adds any strength to your walls.

Thermal Resistance (R-Value)

This is probably the biggest and most-cited difference.

- Closed-cell foam is the clear winner here, with an impressive R-value of R-6.0 to R-7.0 per inch. The special gas trapped in its sealed cells is a much worse conductor of heat than plain air, giving it amazing insulating power even in a thin layer.

- Open-cell foam offers a respectable R-value of around R-3.5 to R-3.8 per inch. It’s still a great insulator, but since its cells are filled with air, it’s not quite as powerful at stopping heat transfer.

The bottom line? You need almost twice the thickness of open-cell foam to get the same insulating muscle as closed-cell.

Moisture Permeability

This is a complete game-changer, especially here in South Florida’s humid climate.

- Closed-cell foam acts as a true vapor barrier. Its sealed-cell structure makes it impermeable to water, meaning it flat-out stops moisture from passing through. This makes it the go-to choice for foundations, crawl spaces, and exterior walls where moisture is the enemy.

- Open-cell foam is vapor-permeable, meaning it behaves more like that sponge. It stops airborne moisture carried in drafts, but it will absorb liquid water from a leak. In some situations, this can be a good thing, as it allows building materials to “breathe” and dry out. However, it’s not the right pick for any area that might get wet.

Structural Strength and Sound Dampening

Beyond keeping your home cool, these foams offer very different secondary benefits.

- Structural Reinforcement: When closed-cell foam cures, it becomes a very dense, rigid plastic that glues itself to whatever it’s sprayed on. This adds serious racking strength to walls and roof decks. In fact, studies show it can boost a building’s structural integrity by up to 300%—a huge advantage when facing South Florida’s high winds. Open-cell foam is soft and flexible, so it offers no structural support.

- Sound Absorption: This is where open-cell foam really shines. Its soft, spongy texture is fantastic at absorbing and deadening sound waves. It’s the perfect choice for insulating interior walls, floors between stories, or home theaters to create a much quieter and more peaceful living space. The rigidity of closed-cell foam makes it less effective at soundproofing.

The Takeaway: It’s never about which foam is “better”—it’s about which one is the right tool for the job. Closed-cell is your high-performance champion for thermal insulation and moisture protection, while open-cell is the specialist for sound control and economically filling large spaces like attics.

If you’re trying to decide how these options compare to older materials, take a look at a detailed comparison between spray foam and blown-in insulation to get even more clarity. Using the right material in the right place is the key to getting the comfort, protection, and energy savings you’re investing in.

How the Airtight Seal Maximizes Energy Efficiency

Most people think a high R-value is the only thing that matters with insulation. And while thermal resistance is definitely important, it’s only half the story. The real energy killer in most homes is uncontrolled air leakage—something traditional insulation just doesn’t solve.

This is where spray foam completely changes the game by creating an airtight seal.

Think of old-school insulation, like fiberglass batts, as a cozy wool sweater. It’s great for keeping you warm on a calm day by trapping a pocket of air around you. But the second a stiff wind kicks up, you feel the chill right through it. The sweater slows down heat loss, but it does absolutely nothing to stop the air from moving through it.

Spray foam, on the other hand, is like a high-tech windbreaker jacket layered over that sweater. It expands to fill every single gap, crack, and pinhole, creating a solid, continuous air barrier. It stops drafts dead in their tracks. This powerful seal is the secret to how spray foam boosts a home’s energy efficiency so dramatically.

Eliminating the Hidden Energy Drains

Your home is full of tiny, hidden air leaks—around light fixtures, plumbing pipes, electrical outlets, and where your walls meet the attic floor. On their own, they seem minor. But add them all up, and they’re the equivalent of leaving a window wide open all year round.

This constant, invisible air exchange is what building scientists call the “stack effect,” and it makes your HVAC system work overtime, 24/7. Here in the sweltering South Florida summer, your cool, conditioned air gets pushed out through gaps in the attic. At the same time, hot, humid outdoor air is sucked in through leaks lower down in the house.

An airtight seal from spray foam effectively short-circuits this entire process. It stops that uncontrolled air movement, allowing your HVAC system to easily maintain the temperature you set without constantly fighting to cool down all the hot air sneaking inside. This dramatically reduces its workload and runtime.

By creating this solid barrier, the benefits go way beyond just feeling more comfortable.

- Drastically Lower Energy Bills: When your HVAC system runs less, you see a real, significant drop in your monthly utility costs.

- More Consistent Indoor Temperatures: The seal gets rid of hot and cold spots, creating a uniform, comfortable feeling in every single room.

- Improved Air Quality: By blocking unfiltered outside air, spray foam helps keep dust, pollen, and other pollutants from getting into your home.

- Longer HVAC Lifespan: A lighter workload means less wear and tear on your air conditioner, which can help extend its service life.

The Financial Impact of an Airtight Home

The effect this airtight seal has on your energy use isn’t just theoretical—it’s well-documented. Buildings account for about 40% of global energy consumption, and spray foam directly attacks that waste. By stopping air leakage, it can slash heating and cooling costs by 20-50%, depending on the home’s starting condition.

This is especially true for the concrete block construction so common in our area. To see how this powerful seal improves thermal performance in local homes, check out our guide on the insulation value of concrete block walls.

Ultimately, spray foam works by delivering two powerful solutions in one: it both insulates and air-seals. This one-two punch is what maximizes your home’s energy performance and delivers real, long-term savings.

What to Expect During the Installation Process

Knowing the science behind spray foam is one thing, but understanding what happens when our crew shows up at your door is another. A professional installation isn’t just about spraying foam; it’s a methodical process broken down into three key phases. It’s this attention to detail that ensures the foam performs exactly as it should for decades to come.

The entire job is a well-oiled machine, moving from careful prep work to expert application and ending with a crucial curing period. Let’s walk through what a typical installation day looks like so you know exactly what to expect.

Phase One: The Preparation Stage

Before a single drop of foam leaves the hose, our crew gets to work protecting your property. Think of it like a professional painter meticulously taping off a room—it’s the prep work that guarantees a clean, sharp result instead of a mess.

This first phase involves a few critical steps:

- Clearing the Area: We’ll need unobstructed access to spots like your attic or crawl space, so any items stored there will need to be moved out of the way.

- Masking and Protecting: We use heavy-duty plastic sheeting and tape to cover everything that shouldn’t get foam on it. This means protecting windows, floors, light fixtures, and any furniture in the vicinity from overspray.

- Setting Up Ventilation: This is non-negotiable for safety. We set up powerful fans to create controlled airflow, pulling any vapors or off-gassing directly out of your home during the application.

This detailed setup makes sure the foam goes only where it’s meant to, keeping your home clean and creating a safe work environment.

Phase Two: The Application Stage

Once everything is prepped and protected, the real work begins. Our trained technicians fire up specialized, high-pressure equipment to apply the spray polyurethane foam. The two liquid parts are pumped through heated hoses, mixing right at the tip of the spray gun, which kicks off that instant chemical reaction you see as expanding foam.

With a steady, practiced hand, our technicians apply the foam to achieve the exact thickness needed for your home’s R-value and air-sealing goals. They work methodically, ensuring every nook and cranny is covered, from the underside of the roof deck down to the wall cavities.

Important Safety Note: During the application and the curing phase that follows, the work area must be completely empty of residents and pets. The chemical reaction releases vapors, and strict safety protocols require the home to be unoccupied until the air is cleared and the foam is stable.

Phase Three: The Curing Stage

After the last bit of foam is sprayed, the job still isn’t quite finished. The final and most important phase is curing. This is when the foam fully hardens, completes its chemical reaction, and becomes a solid, inert plastic. It transforms from a tacky, expanding liquid into the tough, durable insulation that will protect your home.

The typical curing time before it’s safe to re-enter your home is 24 hours. Our team will always confirm the specific re-entry timeline with you. This waiting period ensures all vapors have dissipated and the foam is chemically stable, making the space perfectly safe for your family and pets to return to a more comfortable, airtight, and energy-efficient home.

You might think of spray foam as a modern invention, but its roots go back nearly a century. The story doesn’t start in a house—it starts with high-stakes military applications that demanded extreme performance.

The core technology, polyurethane, was first put to the test insulating military aircraft during World War II. Think about it: if this material could hold up under the brutal conditions of high-altitude flight, it was more than ready for a residential attic. This history gives spray foam a legacy of reliability that very few other insulation products can match.

From Wartime Innovation to Household Staple

So, how did a military-grade technology end up in our homes? For decades, it remained a specialist material for industrial and military use. That all changed with the 1970s energy crisis.

As fuel prices shot through the roof, homeowners and builders scrambled for ways to slash heating and cooling costs. This is where spray foam stepped into the spotlight. People quickly realized it did something traditional insulation like fiberglass just couldn’t do: it created a complete airtight seal. This unique ability to both insulate and air-seal was a game-changer for energy efficiency.

The original chemistry dates back to the 1930s and 1940s, pioneered by German chemist Otto Bayer. His work laid the foundation for the material that would eventually protect military planes. You can read more about the detailed history of spray foam insulation on ezatticinsulation.com.

This background isn’t just trivia—it proves that spray foam is a mature, field-tested technology. It has been refined over decades of real-world use to become one of the most effective insulation solutions on the market today.

What began as a critical component for military hardware has evolved into the safe, efficient, and advanced product we install in South Florida homes. It’s a history built on a foundation of proven performance, from the battlefield to your backyard.

Common Questions About Spray Foam Insulation

Even after you get the basics, it’s totally normal to have practical questions about what spray foam insulation means for your home, your family, and your wallet. Getting a straight answer is key, so we’ve put together our responses to the most common questions we hear from South Florida homeowners.

Is Spray Foam Insulation Safe for My Family and Pets?

Yes, once it’s fully cured, spray foam insulation is completely safe. The material hardens into an inert, solid plastic that’s non-toxic and doesn’t release any harmful gases or chemicals into your living space.

The only critical window is during the installation and the initial curing period, which usually takes about 24 hours. During this time, the home needs to be well-ventilated, and we require all residents and pets to be out of the house. Our professional crews follow strict safety protocols to make sure the area is 100% safe before you re-enter.

How Long Does Spray Foam Insulation Last?

Think of spray foam as a one-and-done investment. It’s designed to last for the entire life of your home. Unlike fiberglass or cellulose, which can sag, settle, and lose effectiveness over time, spray foam holds its shape and function forever.

Because it chemically bonds to the structure, its insulating and air-sealing power doesn’t degrade. It will perform just as well decades from now as it does on day one. You’ll never have to think about replacing it.

One of the biggest long-term advantages is its stability. Spray foam insulation doesn’t lose its R-value over time, so your home will be just as energy-efficient in 30 years as it was the day we finished the job.

Can Spray Foam Be Installed in an Existing Home?

Absolutely. Spray foam is a fantastic upgrade for existing homes, delivering a major boost in energy efficiency and comfort. We can easily apply it in open areas like attics, crawl spaces, and unfinished basements.

For finished walls, we use a specialized “slow-rise” injection foam. This product is designed to fill an existing wall cavity through small, discreet holes, so there’s no need to tear out your drywall. This makes it a clean and effective solution for older homes and a great option if you’re looking for an insulation as a sound barrier to quiet down interior walls.

What Is the Typical Return on Investment?

While spray foam has a higher upfront cost than traditional materials, the return on investment is huge. Most homeowners see a full payback in just 3 to 7 years from energy savings alone.

By creating an airtight seal, spray foam can slash your heating and cooling costs by 20-50%. But the ROI goes beyond your monthly utility bills—it also adds lasting value to your home by improving comfort, adding structural strength (with closed-cell foam), and preventing expensive moisture damage down the road.

Ready to transform your home’s comfort and efficiency? The team at Airtight Spray Foam Insulation has the experience and expertise to deliver a flawless installation. Request your free, no-obligation quote today!