Blog

Cellulose vs Spray Foam Insulation for Florida Homes

Here's the core difference you need to understand: cellulose is a loose-fill product that slows down air movement, while spray foam is an expanding liquid that stops it cold. The right choice really hinges on what you value more—a lower upfront cost with decent thermal performance, or a top-tier system that creates an airtight seal and offers superior moisture control. For us here in South Florida, that second point is a game-changer.

Why Insulation Choice Is So Critical In South Florida

For anyone building or owning a home in South Florida, choosing insulation is a decision that goes way beyond keeping the house cool. We’re not just fighting the heat; we're in a constant battle with oppressive humidity and the ever-present threat of severe weather. The call you make between cellulose and spray foam will directly hit your energy bills, your indoor air quality, and even the structural health of your property over time.

To make a smart decision for a Florida home, you have to look past the basics. It helps to start by understanding R-value insulation for Florida custom homes, but that's just one piece of the puzzle. R-value measures thermal resistance, but it tells you nothing about how an insulation handles air leakage and moisture—two of the biggest enemies in our climate.

Key Differences at a Glance

This guide is designed to cut through the marketing fluff and show you how each material actually performs against the unique challenges we face from Jupiter to West Palm Beach. The numbers tell a story, too. The global insulation market, which heavily favors high-performance materials like spray foam, was valued at USD 69.43 billion and is projected to soar to USD 127.70 billion by 2033. Compare that to the cellulose market, valued at just USD 4.46 billion, and you can see where modern, energy-efficient construction is heading.

Here’s a quick breakdown of how they stack up:

| Feature | Cellulose Insulation | Spray Foam Insulation |

|---|---|---|

| Primary Material | Recycled paper fibers treated with borates. | Two-part polyurethane or polyisocyanurate chemical foam. |

| Air Sealing | Does not create an air seal; requires separate air sealing. | Creates a monolithic air barrier in one application. |

| Moisture Control | Absorbs moisture; requires excellent ventilation to dry. | Closed-cell blocks moisture; open-cell is vapor permeable. |

| Application | Blown into cavities or attics as a loose-fill product. | Sprayed as a liquid that expands to fill gaps. |

| Best For | Budget-conscious attic retrofits and sound dampening. | Creating a complete thermal and air barrier, especially in humid climates. |

Comparing Core Performance in High-Humidity Conditions

When it comes to insulation in South Florida, our climate is the ultimate test. Performance isn't just about a number on a spec sheet; it's about how the entire system stands up to thermal pressure, air leakage, and most importantly, our relentless humidity. One wrong choice here can lead to a world of problems—from uncomfortable rooms and sky-high FPL bills to serious structural damage down the road.

This is where the real difference between cellulose and spray foam becomes clear. Spray foam creates a single, solid barrier that insulates and air-seals in one shot. That's its game-changing advantage. Cellulose, on the other hand, is a loose-fill product. It does a decent job slowing down heat, but it does absolutely nothing to stop air from moving right through it. In our climate, that's a critical flaw.

Thermal Resistance and R-Value Nuances

Look at the numbers on paper, and you might think cellulose and open-cell spray foam are neck and neck. Cellulose usually comes in at R-3.2 to R-3.8 per inch. Open-cell spray foam is right there with it, offering a very similar R-3.5 to R-4.0 per inch.

But here's the catch: R-value is measured in a perfect lab setting. It doesn't tell you what happens when hot, humid air is blowing through every tiny crack and gap in your walls and attic. Since cellulose can't stop that air movement, its real-world, effective R-value takes a massive hit.

Closed-cell spray foam is in a completely different class. It delivers a powerful R-6.0 to R-7.0 per inch. That density not only provides incredible thermal resistance but also adds structural strength to whatever it's applied to. For anyone trying to get the absolute most performance out of a tight space, closed-cell foam is the hands-down winner.

Key Takeaway: While the initial R-values look similar, spray foam's ability to create a seamless air barrier means its actual installed performance blows cellulose out of the water.

The Critical Role of Air Sealing

In a place like South Florida, I'd argue that air sealing is even more important than R-value. Uncontrolled air leakage is the number one reason for high cooling costs and moisture issues in our homes.

And this is where the debate gets pretty one-sided.

- Cellulose Insulation: As a blown-in material, cellulose just settles into cavities. It doesn't stick to anything, so it can't seal the hundreds of little penetrations around wires, pipes, and framing. Every one of those gaps is a highway for humid air.

- Spray Foam Insulation: We apply this as a liquid that expands on contact, filling every single crack and crevice before it hardens. It creates a truly airtight building envelope, stopping hot, humid air from getting in and your expensive conditioned air from getting out.

That air-sealing power is exactly why spray foam delivers such dramatic energy savings. We’ve seen it time and time again with our clients from West Palm Beach to Stuart—a properly insulated home can see a 30-50% reduction in AC runtime during the summer peaks. For a typical 2,000 sq ft home, that can easily mean $500 to $1,000 back in your pocket every year.

For a deeper dive into how these materials stack up, check out our detailed comparison of spray foam vs. blown-in insulation.

Moisture Management: A Deciding Factor

In Florida, how an insulation material deals with moisture isn't a feature—it's a requirement. Cellulose and spray foam have two completely different approaches here.

Cellulose is hygroscopic, which is a fancy way of saying it acts like a sponge, readily absorbing moisture from the air. Its borate treatment helps keep mold at bay, but in a constantly humid space like an unvented attic, it can get saturated. If it can't dry out, its R-value plummets, and you're creating a perfect environment for mold and rot.

Spray foam, especially the closed-cell version, is a true vapor barrier. It doesn't just resist moisture; it completely blocks it. This makes closed-cell foam the only real choice for tough areas like crawl spaces, rim joists, and unvented roof decks where moisture control is everything. Open-cell foam is vapor-permeable, meaning it lets moisture pass through, which is fine as long as the rest of the building assembly is designed to let that moisture escape.

Cellulose vs Spray Foam Key Performance Metrics

This table breaks down the most critical differences that directly impact how these materials perform in the real world, especially in a demanding climate like South Florida's.

| Performance Metric | Cellulose Insulation | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|---|

| Typical R-Value | R-3.2 to R-3.8 per inch | R-3.5 to R-4.0 per inch | R-6.0 to R-7.0 per inch |

| Air Sealing | Poor. Requires separate air sealing measures. | Excellent. Creates a complete air barrier. | Excellent. Creates a complete air barrier. |

| Moisture Control | Absorbs moisture. Relies on ventilation to dry. | Vapor permeable. Allows moisture to pass through. | Vapor barrier. Blocks moisture completely. |

While over 50% of cellulose is used in homes due to its "green" marketing, it's important to look at the whole picture. Open-cell spray foam not only matches its R-value but also offers superior sound dampening—often up to 50% better. This makes it a fantastic choice for quieting down noisy garages or metal buildings while still providing a great thermal and air barrier.

Installation and Application: A Tale of Two Methods

You can talk about R-values all day, but how an insulation material actually gets into your walls and attic is what truly determines its real-world performance. The installation process isn't just a technical detail—it's the difference between a genuinely sealed home and one full of hidden gaps bleeding conditioned air. Comparing cellulose and spray foam installation really brings this point home.

Cellulose is what we call a loose-fill insulation, usually made from recycled newspaper. Crews use a big hose to blow the fluffy fibers into an attic or wall cavity. It’s a fast way to fill up big, empty spaces, but it has its limits. The material just settles around pipes, wires, and framing, and it’s almost impossible to avoid leaving small air pockets behind. Over the years, cellulose also tends to compact under its own weight, which shrinks its thickness and reduces its effectiveness.

Spray foam is a completely different animal. It starts as a two-part liquid that’s mixed right at the nozzle of a sprayer. As soon as it hits a surface, it sticks and expands like crazy, filling every single crack, gap, and weirdly shaped corner before it cures into a solid, rigid mass. It doesn't just insulate; it air-seals in one go, creating a single, unbroken barrier.

Different Foams for Different Jobs

Not all spray foam is the same, and picking the right one is critical, especially here in South Florida. The two big players are open-cell and closed-cell, and they each have their place.

- Open-Cell Spray Foam: Think of this as the lighter, fluffier foam. It expands massively and is fantastic for air sealing and sound dampening. I love using it for interior walls or under a roof deck to quiet down a house. The one thing to remember is that it's vapor-permeable, meaning moisture can pass through it.

- Closed-Cell Spray Foam: This is the dense, heavy-duty option. It gives you a much higher R-value per inch and, most importantly for Florida, it’s a full-on vapor barrier. It completely blocks moisture. This makes it the only choice for crawl spaces, rim joists, and any area where you absolutely have to stop humidity in its tracks.

For builders and property managers I work with, the precision of spray foam is a game-changer. Its seamless application guarantees 100% coverage, even in the most awkward spaces. We've seen this cut down on frustrating, costly callbacks for performance issues by as much as 70%.

The Installer Makes All the Difference

Spray foam installation is a chemical process, not just a construction task. It demands certified pros who know what they’re doing. Our technicians wear full protective gear, and the home needs to be empty for 12-24 hours while the foam cures and any off-gassing dissipates. This isn't just for safety—it’s to ensure the foam performs exactly as it’s designed to.

Putting in cellulose is a simpler, less disruptive job that usually doesn't require the homeowners to leave. But don't be fooled; getting the right density to prevent it from settling over time still takes skill. A shoddy application means you're not getting the R-value you paid for from day one.

In the commercial world, long-term reliability is king. While you might read about the market for cellulose products growing since 2018, its adoption for high-performance insulation is pretty slow. This really underscores how spray foam’s superior performance aligns with modern building science, especially when it comes to locking in energy efficiency and cutting down on lifecycle emissions. You can learn more about the trends in the cellulose insulation market to see how the numbers stack up.

When it comes down to it, choosing between cellulose and spray foam installation is about precision versus convenience. Cellulose is quick and less invasive, but spray foam is an engineered solution that creates a truly airtight building envelope—and in the fight against South Florida's heat and humidity, that's a massive advantage.

Calculating Long-Term Value and Total Cost of Ownership

When you’re looking at insulation, just comparing the price per square foot is like buying a car based only on the sticker price—you're completely missing the bigger picture. The real financial story in the cellulose vs. spray foam debate isn't about the initial check you write; it's about the total cost of ownership over decades.

You have to factor in everything: energy savings, durability, maintenance, and even the lifespan of your HVAC system. While cellulose often looks like the cheaper option upfront, spray foam is engineered for a powerful long-term return on investment (ROI). It's a classic case of shifting from a "cost to install" mindset to a "cost to own" reality.

Breaking Down the Upfront Investment

Let’s be direct: spray foam insulation costs more at the start. You can generally expect it to be two to three times more expensive than blown-in cellulose. The final price tag really hinges on whether you go with open-cell or the much denser, higher-performance closed-cell foam.

Cellulose is appealing because of its low price point. That’s why it's so common for big, open attics where installers can blow it in quickly and cheaply. But that initial savings comes with a major trade-off. It doesn't create an air seal, which leaves your home vulnerable to air leakage—a massive energy drain, especially in a hot, sticky climate like South Florida's.

Projecting Long-Term Energy Savings and ROI

Here’s where spray foam really starts to pull ahead. Its value is tied to its dual role as both an insulator and a complete air barrier. By stopping uncontrolled air leakage in its tracks, it dramatically lightens the load on your HVAC system. A home properly sealed with spray foam can see energy savings between 25% and 40%. That translates to real, noticeable drops on your FPL bill, month after month.

Let's run some practical numbers:

- Scenario A (Cellulose): A homeowner spends $3,000 to insulate their attic with cellulose. They notice a 15% reduction in cooling costs, saving about $450 a year.

- Scenario B (Spray Foam): That same homeowner invests $7,500 in closed-cell spray foam. Their cooling costs plummet by 35%, saving them $1,050 annually.

In this example, the spray foam pays for its higher upfront cost in just over six years from energy savings alone. After that, it’s putting an extra $600 back in the owner's pocket every single year.

Expert Insight: The ROI goes far beyond just your energy bills. Because spray foam seals the building envelope so effectively, your HVAC system doesn't have to cycle on and off constantly to keep the temperature stable. That reduced strain can add years to the life of your expensive equipment, pushing back a costly replacement.

Factoring in Durability and Maintenance Costs

Durability is another crucial piece of the puzzle that often gets overlooked. Spray foam is an inert, rigid material. It won't sag, settle, or break down. Once it's installed, it performs just as well on day one as it does decades later—its lifespan is often 80 years or more. There’s virtually no maintenance.

Cellulose is a different story. It can settle by as much as 20% over its 20 to 30-year lifespan, creating gaps at the top of wall cavities that kill its effectiveness. It's also a magnet for moisture. If you get a roof leak, any cellulose that gets wet is ruined and has to be professionally removed and replaced, leading to unexpected costs. Spray foam, especially closed-cell, is waterproof and even adds structural strength to your home.

On top of its thermal performance, spray foam's sealing ability makes for a much quieter home, a benefit we cover when discussing insulation as a sound barrier. For property managers and builders, this kind of durability is a huge win. It means fewer calls from unhappy tenants, predictable energy budgets, and no need to plan for insulation "top-offs." The "set it and forget it" nature of spray foam delivers a peace of mind that cellulose just can't match.

Practical Recommendations for Florida Properties

Okay, let's move past the technical specs and talk about what this means for your actual property. There’s no single "best" choice between cellulose and spray foam for South Florida—it all comes down to the specific job, your budget, and what you want to achieve long-term.

I see these scenarios play out all the time in Jupiter, West Palm Beach, and across the region. Let's walk through four common situations to see where each insulation type really shines.

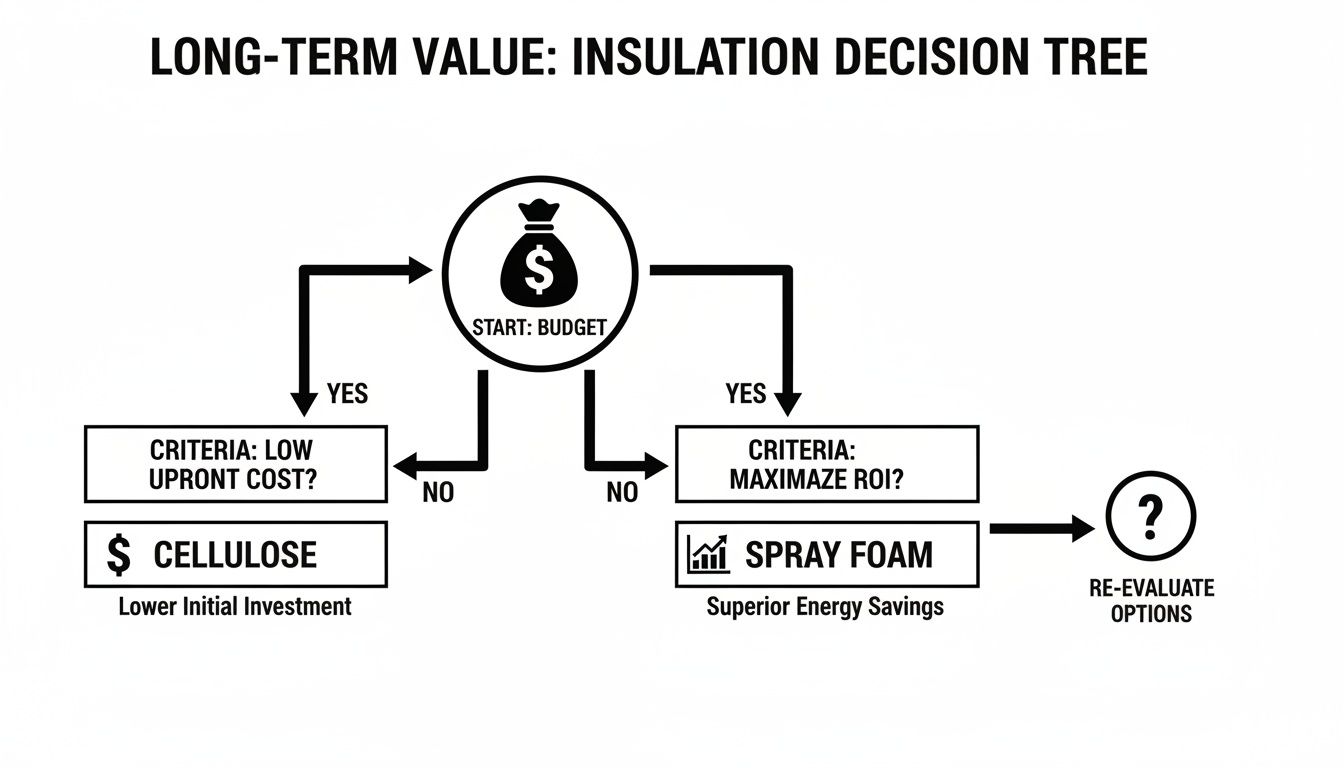

This decision tree breaks it down by what drives most people's choices: upfront cost versus long-term return on investment.

As you can see, if keeping initial costs as low as possible is your number one priority, cellulose is where you start. But if you’re focused on getting the best long-term ROI through massive energy savings and durability, then spray foam is the clear winner.

Scenario 1: New Home Construction

For builders or anyone building their dream home, the goal is peak energy efficiency and a structure that sails through modern code inspections. This is a no-brainer.

Closed-cell spray foam is the only way to go. It’s what you use to create a truly high-performance home from day one.

You get insulation, an air seal, and a vapor barrier all in one shot—something cellulose just can't do. We apply it directly to the underside of the roof deck to create an unvented, conditioned attic. This is the gold standard for handling our brutal heat and humidity. It takes a massive load off the HVAC system and keeps your ductwork from baking in a 140-degree attic.

Scenario 2: Retrofitting an Older Home

I walk into older Florida homes all the time that are leaking air everywhere and have barely any insulation in the attic. The result? Sky-high FPL bills and rooms you can never seem to keep cool. Here, your budget really dictates the path forward.

- The Budget-First Fix: If you need to add R-value to a big, open attic without breaking the bank, cellulose is a solid option. We can blow it right over whatever old insulation is up there to beef up its thermal resistance. But—and this is a big but—it's only truly effective if you meticulously air seal every penetration first. We're talking light fixtures, plumbing vents, and top plates.

- The Performance-First Upgrade: For homeowners ready to invest in a permanent fix, applying open-cell spray foam to the attic floor is a game-changer. It creates a perfect air seal, stopping drafts and stabilizing temperatures in a way that just topping up with cellulose never will.

A lot of these older homes have concrete block walls, which presents its own set of challenges. These walls have unique thermal properties, and understanding the insulation value of concrete block walls is key to figuring out how spray foam can make them perform better.

Scenario 3: Commercial Metal Buildings

Warehouses, workshops, and other steel buildings are like ovens in the Florida sun. Those huge, uninsulated metal surfaces radiate an incredible amount of heat. For these jobs, there's really only one choice that works.

Closed-cell spray foam is the definitive high-performance solution here.

Cellulose isn't even in the running. It can't stick to metal and does nothing to stop condensation, which is a building-killer in these structures.

Here’s why closed-cell dominates in this application:

- It Sticks: It bonds directly to the steel panels, creating a solid, seamless blanket of insulation.

- It Stops Condensation: It forms a powerful vapor barrier, preventing our humid air from condensing on the cooler metal and causing rust and water damage.

- It Adds Strength: It actually adds a surprising amount of rigidity to those thin metal panels, which helps cut down on noise from wind and rain.

Scenario 4: Multifamily Properties

If you're managing an apartment complex or condo association, you're constantly juggling upfront costs, tenant happiness, and long-term operational expenses. A smart, hybrid approach is often the best strategy.

For the walls between units and the floors, cellulose is fantastic. It's a cost-effective way to get great sound dampening—a huge factor in keeping tenants happy. Nobody wants to hear their neighbor's TV all night.

But for the building's main envelope—the roof and exterior walls—you need the durability and energy performance of closed-cell spray foam. Its air-sealing and moisture-blocking power slashes utility costs in common areas and prevents the kind of expensive, long-term maintenance headaches that eat into your bottom line. It's about protecting the investment for decades to come.

Making an Informed Decision for Your Property

When you’re weighing cellulose against spray foam, what it really boils down to is a single, critical question: what level of performance does your South Florida property actually need? This isn't just about picking the cheaper option; it's about a long-term strategy for your building's health, efficiency, and ability to withstand our climate.

Look, cellulose has its place. It’s a budget-friendly way to bump up the thermal resistance in an old, accessible attic, and its low upfront cost is often the main selling point. But let's be honest about its limitations here in our relentlessly humid environment. It slows down heat, sure, but it does next to nothing to stop the air and moisture that are the real culprits behind high energy bills, mold, and rot.

Spray foam, on the other hand, is a completely different animal. It’s a comprehensive building envelope solution. In one shot, you get insulation, an air seal, and—with closed-cell—a rock-solid moisture barrier. For what South Florida throws at our buildings, from punishing summer heat to the brutal storms of hurricane season, that integrated performance isn't just a nice-to-have. It’s a must.

The right choice isn’t just about R-value; it's about creating a controlled, protected indoor environment. Here in Florida, that means investing in a system that actively defends your property from heat, air, and moisture for decades.

When you factor in the superior energy savings, moisture control, and even the added structural integrity, spray foam becomes the clear choice for truly protecting your investment and ensuring you’re comfortable for the long haul.

But here’s the crucial part: spray foam’s value is only unlocked by an expert application. Installing it correctly is a science. It demands precision and a deep understanding of how a building breathes to get that perfect, airtight seal. To make your property healthier, more efficient, and far more durable, your next step should be talking to seasoned pros who can design a solution that fits your specific building. Your investment deserves an airtight strategy.

Common Questions About Cellulose vs. Spray Foam

When you're trying to decide between spray foam and cellulose, a few key questions almost always come up. After 25 years in this business, I've heard them all. Let's get you the straightforward answers you need to make the right call for your South Florida property.

Is Spray Foam Insulation a Safe Choice?

Absolutely, but with one critical condition: it has to be installed by certified professionals. The process itself involves a chemical reaction that releases fumes, which is why our crews wear full protective gear and we require the home to be vacant for 12-24 hours.

Once the foam cures, it becomes completely inert and stable. It's basically a solid plastic. In fact, by creating a perfect air seal, it can actually improve your indoor air quality by blocking pollen, dust, and other pollutants from getting in.

Can You Install Spray Foam Over Old Cellulose?

I get asked this all the time, and my answer is always a firm no. It’s a terrible idea. Spraying foam over loose, dusty cellulose creates a mess, traps potential moisture, and prevents the foam from bonding correctly to the surfaces it's meant to seal. You end up with a compromised, lumpy layer that doesn't do its job.

The only way to do it right is to remove all the old cellulose first. We need a clean, dry surface for the foam to adhere to. This ensures you get that seamless, monolithic air barrier you're paying for.

Expert Tip: Proper surface preparation isn't just a suggestion; it's everything for spray foam. If you try to cut corners by spraying over old, dirty, or damp insulation, the chemical bond will fail, and you'll completely lose the performance benefits.

How Does Spray Foam Enhance Hurricane Resilience?

This is where spray foam really shines, especially for us in South Florida. Closed-cell spray foam is incredibly dense and acts like an industrial-strength glue. When we apply it to the underside of your roof deck, it literally bonds the sheathing to your trusses.

This makes your entire roof structure significantly more rigid and resistant to the uplift forces from hurricane winds. While it's not a substitute for hurricane straps, it's a powerful secondary reinforcement that adds a serious layer of structural integrity.

Which Is Better for Soundproofing?

It really depends on the kind of noise you're trying to block.

If you're dealing with airborne noise between rooms—like TVs or conversations—cellulose is the clear winner. Its dense, fluffy nature is fantastic at absorbing and deadening sound waves.

But if your problem is low-frequency noise from outside, like traffic, spray foam’s air-sealing power is more effective. Sound travels through air. By eliminating every tiny crack and gap, spray foam stops that pathway, making it much harder for outside noise to get in.

Ready to create a healthier, more efficient, and structurally sound property? The team at Airtight Spray Foam Insulation brings over 25 years of experience to every project in South Florida. Request your free, no-obligation quote today!