Blog

A Homeowner’s Guide to Attic Insulation in Florida

Thinking about attic insulation here in Florida? You can toss out most of the advice you'd hear up north. It just doesn't work here. Our homes are in a constant battle with two major enemies: brutal solar heat beating down on our roofs and thick, soupy humidity that never quits.

Why Florida Homes Demand a Smarter Insulation Strategy

Let's think about it this way. Imagine you're taking a cooler to the beach. The cheap, flimsy styrofoam one might keep things chilly for a little while, but it's no match for the Florida sun. Before you know it, it’s sweating on the outside and your ice is just cold water. That’s exactly how most older Florida attics perform—they're completely outmatched by our climate.

Now, picture one of those high-end, roto-molded coolers. Its thick, solid walls don't just slow down the heat; they create a perfect seal that locks out the hot, humid air altogether. This is precisely the mindset we need for attic insulation in Florida. We’re not just trying to slow the heat down; we're fundamentally changing how the attic works as part of your home.

The Old Way: A Ventilated Attic Heat Trap

For decades, the standard practice was to ventilate attics. The idea was to create airflow that would flush out all the hot air that builds up. But in a place as humid as South Florida, that strategy usually backfires spectacularly.

Instead of pushing hot air out, these vents often suck in heavy, moisture-laden air. This turns your attic into the perfect damp, stagnant environment for mold and mildew to thrive. On top of that, all that super-heated, humid air forces your air conditioner to work overtime, fighting a losing battle to keep your living space comfortable. Your attic basically becomes a giant oven sitting on top of your house, often hitting 150°F or more and radiating that heat right down through the ceilings.

The Modern Solution: A Sealed and Conditioned Space

The far better approach for homes in communities like Jupiter and Palm Beach Gardens is to create a sealed, or "unvented," attic. Instead of putting insulation on the attic floor (the top of your ceilings), we apply it directly to the underside of the roof deck itself. This simple change brings the attic inside your home's conditioned envelope.

By sealing the attic, you transform it from a sweltering heat trap into a semi-conditioned buffer zone. This protects your fragile HVAC ductwork from extreme temperatures, slashes energy loss, and creates a powerful barrier against moisture getting in.

This method works so well that it dramatically cuts down how much you need to run your AC. In fact, a study by the Florida Solar Energy Center found that sealed attics reduce cooling energy use by an average of 8%—a massive improvement, especially for homes with older, leaky ducts.

Let's take a quick look at how this modern approach directly tackles the classic problems we see every day in Florida homes.

Florida Attic Problems vs Modern Insulation Solutions

| Common Problem in Florida Attics | How a Sealed Attic Solves It |

|---|---|

| Extreme Heat Buildup (150°F+): Vented attics bake in the sun, radiating heat down into your home. | Temperature Regulation: A sealed attic stays much closer to the temperature of your house (around 80-85°F). |

| High Humidity & Moisture Intrusion: Vents pull in damp, humid air, creating a breeding ground for mold. | Moisture Control: The airtight seal blocks humid outside air, keeping the attic dry and protecting wood from rot and mold. |

| Leaky, Inefficient Ductwork: Ducts running through a blazing hot attic lose a huge amount of cool air before it ever reaches your rooms. | HVAC Efficiency: Ducts are now inside a semi-conditioned space, so the air stays cold and your AC runs less. |

| Pest & Pollen Entry Points: Open vents and soffits are an open invitation for rodents, insects, and allergens. | Airtight Barrier: Sealing all gaps and vents keeps pests and outdoor pollutants out of your home for good. |

This shift in strategy isn't just about comfort or saving a few bucks on your FPL bill. It's about protecting the long-term health of your house, from its structural integrity to the quality of the air you breathe. It’s the foundation for using advanced insulation like spray foam, which is the key to achieving real energy efficiency and resilience in our demanding climate.

Choosing Your Armor: Open-Cell vs. Closed-Cell Spray Foam

Stepping into the world of spray foam insulation feels a lot like choosing armor for your home. You know you need serious protection, but the options—specifically open-cell and closed-cell foam—serve very different purposes. Making the right call is absolutely critical, especially when you're installing attic insulation in Florida, where the twin enemies are intense heat and relentless humidity.

Let's use a simple analogy. Think of open-cell foam as a dense, high-quality sponge. It’s soft, flexible, and fantastic at absorbing things—especially sound waves, which makes it an incredible sound barrier.

On the other hand, closed-cell foam is like a rigid, waterproof, and incredibly strong shell. Its structure is made of tiny, sealed bubbles packed tightly together, creating an impenetrable barrier that stops air and water dead in their tracks. This fundamental difference in their DNA dictates exactly where and why each one should be used in a South Florida home.

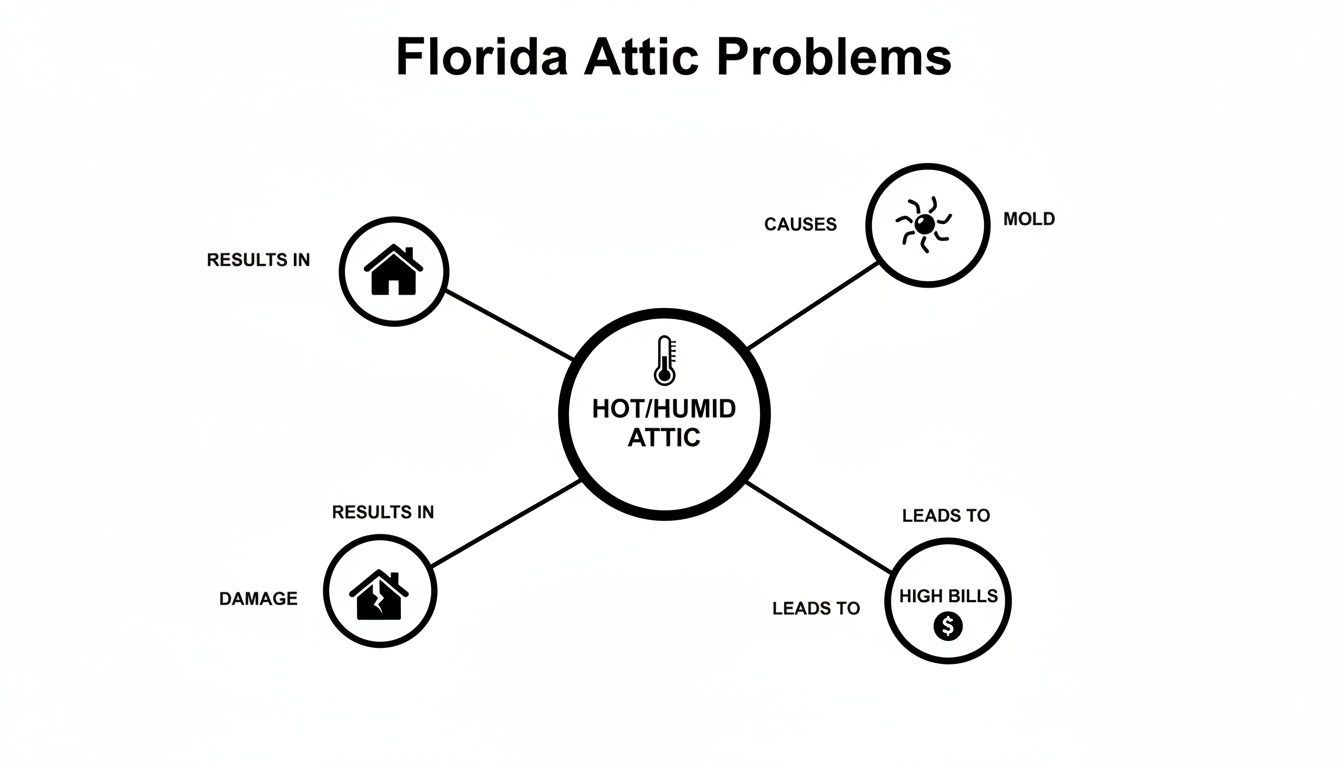

The problems we're trying to solve all start in one place: the attic.

As you can see, a hot, humid attic is ground zero for major consequences like mold growth, structural damage, and sky-high energy bills. The right insulation goes straight to the source and shuts the problem down.

The Sponge: Open-Cell Spray Foam

Open-cell spray foam is the lighter of the two, with a density around 0.5 pounds per cubic foot. Its cell structure is intentionally left "open," which is what gives it that spongy, flexible texture. As the foam expands, the gas used in the process escapes, leaving behind a web of interconnected pockets.

This structure leads to a few key characteristics:

- Excellent Sound Dampening: Those open cells are pros at trapping and deadening sound waves. It’s a popular choice for home theaters or between walls where you want some peace and quiet.

- Vapor Permeability: This is the deal-breaker for Florida attics. Open-cell foam lets water vapor pass right through it. While this can sometimes help a structure "breathe," it’s a huge liability in a high-humidity attic where your goal is to block moisture, not invite it in.

- Lower R-Value: It provides an R-value of about R-3.5 to R-3.8 per inch. This is decent, but it's a far cry from what closed-cell can deliver.

Because it doesn't stop moisture, we almost never recommend open-cell foam for insulating a roof deck in Florida. If a roof leak ever happened, the foam would soak up water like a sponge. You might not even know you have a leak while moisture is trapped against your home's wooden structure, creating the perfect conditions for rot.

For a closer look at its applications, check out our guide on open-cell spray foam insulation in Palm Beach.

The Shell: Closed-Cell Spray Foam

This is the heavy-duty champion for Florida attics. Closed-cell spray foam is much denser, typically around 2.0 pounds per cubic foot, and cures into a rigid, solid structure. During application, the cells are filled with a special blowing agent that gets trapped inside, creating countless tiny, airtight bubbles.

This powerful structure delivers a set of benefits that are perfectly matched for our climate:

- Superior R-Value: Closed-cell foam boasts an impressive R-value, often ranging from R-6.5 to R-7.0 per inch. You get far more insulating power with less thickness.

- Moisture Impermeability: This is its superpower. Closed-cell foam is a true vapor barrier—it completely blocks the movement of moisture. It will not absorb water, making it the ultimate defense against Florida’s humidity and potential roof leaks.

- Structural Strength: When it cures, closed-cell foam is incredibly rigid and actually adds structural integrity to whatever it's applied to. It can literally help strengthen your roof deck, giving it extra resilience against high winds during a storm.

For a sealed attic in Florida, there is no better solution than applying closed-cell spray foam directly to the underside of the roof deck. It creates a single, monolithic barrier that insulates from heat, blocks humid air, and strengthens your roof—all in one go.

Open-Cell vs. Closed-Cell: A Head-to-Head Comparison

To make the choice crystal clear, let's put the two side-by-side and see how they stack up on the features that matter most for your home.

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| Density | Low (approx. 0.5 lb/ft³) | High (approx. 2.0 lb/ft³) |

| R-Value per Inch | R-3.5 to R-3.8 | R-6.5 to R-7.0 |

| Moisture Barrier | No (Vapor Permeable) | Yes (Vapor Impermeable) |

| Air Barrier | Yes | Yes |

| Structural Rigidity | Flexible and soft | Rigid and strong |

| Ideal Florida Use | Interior walls for soundproofing | Attic roof decks, flood zones |

| Cost | Lower upfront cost per inch | Higher upfront cost per inch |

While open-cell foam definitely has its uses, closed-cell foam is the undisputed winner for insulating a Florida attic. Its ability to create a seamless air, thermal, and moisture barrier is exactly what our homes need to win the fight against our demanding climate.

Winning the War Against Moisture in Your Attic

Here in Florida, we all know the battle against the sun's heat is relentless. But there’s another enemy, a sneakier one, that can do far more damage to your home: moisture. This silent invader can wreck your home's structure, tank your air quality, and create a genuinely unhealthy living space.

When you're choosing attic insulation in Florida, keeping moisture out isn't just a nice-to-have feature. It's the absolute most important job it has to do.

For decades, the go-to solution was a vented attic. The thinking was pretty straightforward—let air flow through to carry heat out. But in our swampy subtropical climate, that logic backfires spectacularly. Instead of getting a cool breeze, those vents suck in heavy, humid air, essentially turning your attic into a giant terrarium.

This swampy environment is a five-star resort for mold and mildew, which then gets a free ride into your living space through the HVAC system. During our long rainy seasons, and especially during a hurricane, a vented attic isn't just inefficient; it's a liability, actively pulling water into the bones of your home.

Lessons Learned from Hurricane History

You don't have to look far to see what happens when attic moisture isn't taken seriously. Hurricane Andrew in 1992 was a brutal, real-world lesson. As the storm tore across South Florida, it revealed the catastrophic failure of traditional insulation that simply wasn't built for a massive water event.

Post-storm assessments were shocking. An incredible 65% of exposed homes suffered major water damage. Hurricane-force winds drove rain through every tiny gap in roofs and soffits, completely soaking porous insulation like fiberglass and cellulose. It was a clear demonstration of how the wrong insulation made a bad situation infinitely worse.

Once that old-school insulation got wet, it became a heavy, waterlogged blanket. The sheer weight caused ceilings to collapse all over South Florida, turning what might have been a simple roof leak into a total interior gut job. The attic basically became a sponge, holding water and slowly dripping it into the home's structure for days.

The takeaway from history is crystal clear: your attic's defense system has to be built for the worst-case scenario. It needs to be totally and completely waterproof.

Creating a Monolithic Moisture Barrier

This is where closed-cell spray foam completely changes the game and proves why it’s the top choice for attic insulation in Florida. Unlike old-school fibrous materials that act like a sponge, closed-cell foam creates a single, solid, and totally waterproof barrier. Think of it as a custom-molded, seamless shell that’s bonded directly to the underside of your roof.

When it's sprayed by a pro, the foam expands to fill every single crack, crevice, and potential entry point for water or humid air. It doesn't just resist moisture; it flat-out rejects it. This monolithic seal gives you several layers of critical protection:

- Prevents Mold Growth: No moisture means no food for mold. This is huge for protecting your family's health and keeping your indoor air clean.

- Protects Structural Integrity: The foam acts as a shield for the wood in your roof deck and trusses, stopping the slow rot that can destroy your home’s structure over time.

- Adds Storm Resilience: The rigid strength of closed-cell foam actually adds structural reinforcement to your roof, helping it hold up better against high winds. And if a roof shingle does get blown off, water can't get past the foam, containing the damage to a small area.

While other materials like blown-in have their place, they just can't compete on moisture control. You can see a direct comparison of spray foam vs. blown-in insulation to understand the key differences. At the end of the day, winning the war on moisture requires a solution that’s just as tough and unforgiving as a Florida summer.

Let's Talk Cost and Return on Your Investment

I get it. When you first see the price for a professional spray foam job, it can feel like a lot. But it's crucial to look at this differently—not as just another home repair expense, but as a genuine, long-term investment in your home's performance and your own comfort.

Unlike slapping on a new coat of paint, high-performance attic insulation in Florida starts giving back the day it’s installed.

The final price tag isn't something you can pull from a simple chart. Every home is unique, and several factors come into play, which is why a thorough, on-site estimate is the only way to get an accurate number. Let’s break down what actually goes into that final quote.

Breaking Down the Cost Factors

The price you'll see is a blend of materials, labor, and the specific quirks of your attic. As professionals, we calculate the cost using the board foot—a standard industry measurement that accounts for both the area and the thickness (think one square foot of foam, one inch deep).

Here’s what drives the final cost of your project:

- Total Square Footage: It’s simple math—the bigger your attic's roof deck, the more material and time it’s going to take to seal it up right.

- Foam Type (Open-Cell vs. Closed-Cell): We've already discussed why closed-cell is the only way to go for Florida attics. Because it’s denser and packs a bigger punch with a higher R-value per inch, it naturally costs more per board foot than its lighter, open-cell cousin.

- Attic Complexity: A wide-open attic with a simple roofline is a pretty straightforward job. But an attic packed with complex trusses, tight spaces, or a maze of HVAC ducts requires a lot more finesse and time, which will be reflected in the labor cost.

- Required Thickness (R-Value): We don't guess how much insulation you need. Florida's building codes mandate a minimum R-value for attics, and the thickness we apply to meet or beat that standard directly affects the amount of material used.

Here's a good way to think about it: You're not buying an off-the-shelf product. You're investing in a custom-tailored, high-performance system for your home—one that will deliver real, measurable returns for decades to come.

Calculating Your Return on Investment

The upfront cost is only half the story. The real power of spray foam lies in its incredible return on investment (ROI). That return shows up first and fastest in your monthly utility bills. By creating that critical airtight seal, spray foam can literally slash your home's cooling costs by 20% to 40% every single year.

For a typical family in South Florida, that adds up to hundreds, sometimes thousands, of dollars back in your pocket annually. And since this insulation can last for 80 years or more, the system doesn't just pay for itself over time—it ends up making you money.

It's More Than Just Money in Your Pocket

The financial perks go well beyond your FPL bill. A home that’s been properly insulated is simply a better, more valuable asset when it comes time to sell.

- Increased Property Value: An energy-efficient home with a sealed attic is a massive selling point. Today's buyers are smart—they know what high energy bills look like, and they’re willing to pay more for a home that promises lower costs and better comfort from day one.

- Unbeatable Home Comfort: You really can't put a price tag on getting rid of those frustrating hot spots and finally having a consistently cool, comfortable home all year round. Your AC will run less, work more efficiently, and keep your home at the temperature you set it to.

- Long-Term Protection: By completely blocking moisture, closed-cell foam is your home's best defense against the costly threats of mold, mildew, and wood rot. This isn't just an upgrade; it's a preventative measure that can save you from catastrophic repair bills down the road.

When you stack up the initial investment against decades of real energy savings, a higher home value, and rock-solid protection from moisture damage, the choice becomes clear. Professional spray foam insulation is one of the smartest, most valuable upgrades any Florida homeowner can make.

What a Professional Spray Foam Installation Looks Like

Choosing to upgrade your attic with spray foam is a serious investment in your home's comfort and efficiency. So, you need to know that the job will be done right. A proper spray foam installation isn't just about pointing a hose and spraying; it's a meticulous process that a true professional has down to a science.

Let's pull back the curtain on what you should expect when a top-tier crew, like the team here at Airtight Spray Foam Insulation, shows up at your door.

Step 1: The Initial Consultation and a Real Quote

The work begins long before a truck ever pulls up. Any contractor worth their salt will start with a comprehensive attic inspection. This isn't just a quick glance and a square footage measurement.

We're talking about a deep dive: assessing existing ventilation, hunting for any signs of moisture intrusion or old leaks, and mapping out the tricky spots around trusses and ductwork. This is the only way to provide an accurate, transparent quote that details the full scope of work, the right foam for the job (which is almost always closed-cell in our humid climate), and a realistic timeline.

Step 2: Meticulous Site Prep

On installation day, the first order of business is protecting your home. This is a non-negotiable step that immediately separates the seasoned pros from the rookies.

- Covering Surfaces: The crew will carefully lay down plastic sheeting over floors, furniture, and anything else in or near the work zone to protect it from overspray.

- Masking Critical Areas: Windows, vents, electrical boxes, and other fixtures are meticulously taped off. Nothing gets sprayed that shouldn't be.

- Setting Up Ventilation: Powerful fans are strategically placed to create proper airflow, pulling any fumes safely out of your home during the application.

This level of preparation is all about respect for your property. When it's done, the only evidence we were there should be a perfectly insulated attic, not a mess.

A professional installation is as much about what doesn't get sprayed as what does. The crew's attention to detail in protecting your property is a clear indicator of their overall quality and respect for your home.

Step 3: The Application and Quality Control

With the site prepped and safe, our certified technicians gear up in full personal protective equipment (PPE), including respirators and coveralls. Using specialized, high-pressure equipment, they begin applying the foam directly to the underside of your roof deck.

It's a methodical process. They work in controlled passes to build a consistent thickness, hitting the target R-value and creating a single, seamless, monolithic barrier against the Florida heat.

This airtight seal is an absolute game-changer. Field studies in climates just like ours show that a proper thermal barrier can slash the heat coming through your ceiling by up to 25% during the cooling season. This keeps attic temperatures up to 12°F cooler than in homes with old, underperforming insulation. For homeowners in Palm Beach Gardens, that translates directly to less work for your AC. You can read up on more about these radiant heat findings and see the data for yourself.

Step 4: Cleanup and the Final Walkthrough

After the foam has fully cured, the crew shifts into cleanup mode. They remove all the plastic and tape, pack up their gear, and leave your home exactly as they found it—only much better insulated.

The final step is a walkthrough with you. The lead technician will show you the finished work, confirm that every nook and cranny is sealed tight, and answer any questions you have. We aren't finished until you're completely satisfied with the result.

How to Hire the Right Insulation Contractor in South Florida

Picking the right insulation for your attic insulation in Florida is a huge step, but it’s really only half the battle. The real test comes down to the quality of the installation.

A sloppy job can easily lead to air gaps, trapped moisture, and a whole lot of wasted money. This makes your choice of contractor just as critical as your choice of foam—if not more so.

When you hire the right team, you’re not just buying a product; you’re investing in deep, local expertise. A true professional understands the unique building science behind our hot, humid climate. They know a successful project demands meticulous prep work, a precise application, and a deep respect for your home.

Your Vetting Checklist

Don't just roll the dice on this one. A few minutes of research now can save you from years of headaches down the road. Use this simple checklist to vet potential contractors and make sure you're hiring a real expert who will get the job done right the first time.

Here’s what you absolutely need to look for:

-

Verify Licensing and Insurance: This is completely non-negotiable. Your contractor must have a valid Florida license and carry both general liability and worker's compensation insurance. This is what protects you from any liability if an accident happens on your property.

-

Confirm Specific Spray Foam Experience: Ask them point-blank about their experience with closed-cell spray foam in South Florida attics. General insulation experience just isn't enough; they need to prove they understand our specific moisture and ventilation challenges.

-

Review Their Portfolio and Testimonials: A reputable company will be eager to show you their work and share what past clients have to say. When you're digging into this, it's worth understanding why online reviews matter for Florida businesses, because they offer an unfiltered look into a contractor's reliability and how they treat their customers.

A professional quote should be detailed and transparent, breaking down the cost of materials, labor, and the specific scope of work. Vague, one-line estimates or high-pressure sales tactics are major red flags.

The Airtight Spray Foam Insulation Advantage

At Airtight Spray Foam Insulation, we've built our entire process on transparency and expertise. Our team is led by Christian Cates, who brings 25 years of hands-on experience to every project, and we are absolutely dedicated to a flawless installation.

We always provide detailed, no-pressure estimates and stand behind our work, ensuring your investment is protected for the long haul.

Our deep understanding of South Florida's unique climate is baked into everything we do. For a closer look at how we handle projects in your neck of the woods, you can learn more about our process for attic spray foam insulation in Palm Beach County. We’re here to deliver a solution that provides lasting comfort and real energy savings.

A Few Common Questions About Florida Attic Insulation

When you start digging into attic insulation for a Florida home, a lot of questions pop up. It's a big investment, and you want to get it right. Here are some of the most common questions we get from homeowners, with straightforward answers to help you make a smart decision.

How Long Does Spray Foam Insulation Actually Last?

This is one of the best parts about closed-cell spray foam. Traditional materials like fiberglass or cellulose give you maybe 15-30 years before they start to sag, compress, and lose their effectiveness. Spray foam is a completely different animal.

Properly installed, it's a permanent upgrade. The foam is an inert polymer, meaning it doesn't break down, settle, or degrade over time. You can fully expect it to last for the entire life of your home—think 80 years or more—without losing an ounce of its thermal or moisture-blocking power.

Do I Need to Leave an Air Gap for Spray Foam to Work?

Nope. This is a common mix-up with other types of attic products. Spray foam works by stopping both conductive heat (that’s the R-value) and convective heat (air leakage) right in their tracks. To do that, it needs to be applied directly to the surface, like the underside of your roof deck, creating a solid, seamless barrier.

You might be thinking of a radiant barrier, which is a reflective foil-like material. That product needs an air gap to work properly. Spray foam, on the other hand, creates its powerful seal through direct contact, making it a much more complete solution for our hot, humid attics.

Is Spray Foam Safe for My Family?

Absolutely, as long as it's installed by a certified professional. During the application, two liquid components mix and cause a chemical reaction. We make sure the area is completely ventilated, and only our trained technicians wearing full protective gear are ever present during this phase.

Once the foam has cured, which usually takes about 24 hours, it becomes a hard, stable, and totally inert plastic. It doesn't off-gas or release any harmful particles. In fact, it dramatically improves your indoor air quality by sealing out all the dust, pollen, and other allergens trying to get in from outside.

How Do I Pick a Good Insulation Contractor?

Choosing the right installer is every bit as crucial as choosing the right insulation. You need a contractor who has specific, proven experience installing closed-cell spray foam right here in South Florida's unique climate—it's not the same as insulating a home up north.

Make sure they are fully licensed and insured, give you a detailed quote that breaks everything down, and have a long list of happy customers. But don't stop there. A great company also cares about the customer experience; prioritizing contractors who demonstrate strong call handling best practices is a good sign you'll be kept in the loop. Be wary of anyone using high-pressure sales tactics or giving you a vague, back-of-the-napkin estimate.

Ready to transform your home’s comfort and see a real drop in your energy bills? The expert team at Airtight Spray Foam Insulation has the local experience and commitment to get the job done right. Request your free, no-obligation quote today!