Blog

A Complete Guide to Metal Building Roof Insulation

An uninsulated metal building in the South Florida sun is basically an oven. That steel roof soaks up the intense heat all day and radiates it straight down, turning the inside into a sweltering, humid mess that can ruin stored goods and make the space completely unusable. The only way to win this battle against the heat and the inevitable condensation is with proper metal building roof insulation.

Why Your Metal Building Needs the Right Insulation

Imagine leaving a cast-iron skillet on a hot stove. That's your uninsulated metal roof. It heats up fast and transfers that heat directly to everything underneath. Here in South Florida, that means the sun turns your building into a sauna, forcing your HVAC system to work overtime and sending your energy bills through the roof.

But the heat is just one part of the problem. You've got hot, humid air outside and a cooler metal roof surface inside. That's the perfect recipe for condensation. This "building sweat" drips on everything—your inventory, equipment, and even the building's structure. Before you know it, you're dealing with rust, mold, and expensive water damage.

The Core Challenges of an Uninsulated Metal Structure

Ignoring these issues isn't just about being uncomfortable; it's a serious financial risk. An uninsulated building is an inefficient one, and that leads to predictable problems that hit your bottom line hard.

You're pretty much guaranteed to face:

- Intense Heat Gain: The sun’s energy gets absorbed by the metal and blasted inward, driving up indoor temperatures and cooling costs.

- Damaging Condensation: Moisture forms on the underside of the roof deck, creating a constant threat of rust, mold, and damage to whatever you're storing.

- High Energy Bills: Your air conditioner will run nonstop trying to fight the heat radiating from the roof, wasting a massive amount of energy.

- Unusable Space: For much of the year, the extreme heat and humidity can make workshops, storage bays, or commercial spaces practically uninhabitable.

The Solution is an Effective Thermal Barrier

The only real fix is to create a complete thermal break—a shield between the hot exterior metal and your interior space. This is where high-performance insulation is non-negotiable. The right metal building roof insulation stops heat transfer in its tracks and prevents condensation before it even starts. Different materials like spray foam, batt insulation, or rigid board offer different levels of protection.

Choosing the right one is a critical decision. It directly impacts your building’s performance, its long-term value, and your day-to-day operating costs. This isn't a niche concern, either. The broader insulation market is projected to hit USD 144.7 billion by 2035, with the United States seeing a 6.3% increase in retrofit projects driven by this exact need to improve energy efficiency.

A properly insulated structure, especially one treated with our Airtight Comfort System, goes from being a hotbox to a stable, dry, and energy-efficient asset. It's an investment that protects your building and everything in it while creating a comfortable and productive environment all year long.

Comparing the Top Metal Roof Insulation Methods

Choosing the right insulation for your metal building is a lot like picking the right gear for a job. You wouldn't use a wrench to hammer a nail, and you definitely shouldn't use the wrong insulation for South Florida's brutal heat and humidity. Each type of metal building roof insulation comes with its own set of pros and cons, so it's critical to see how they stack up against each other.

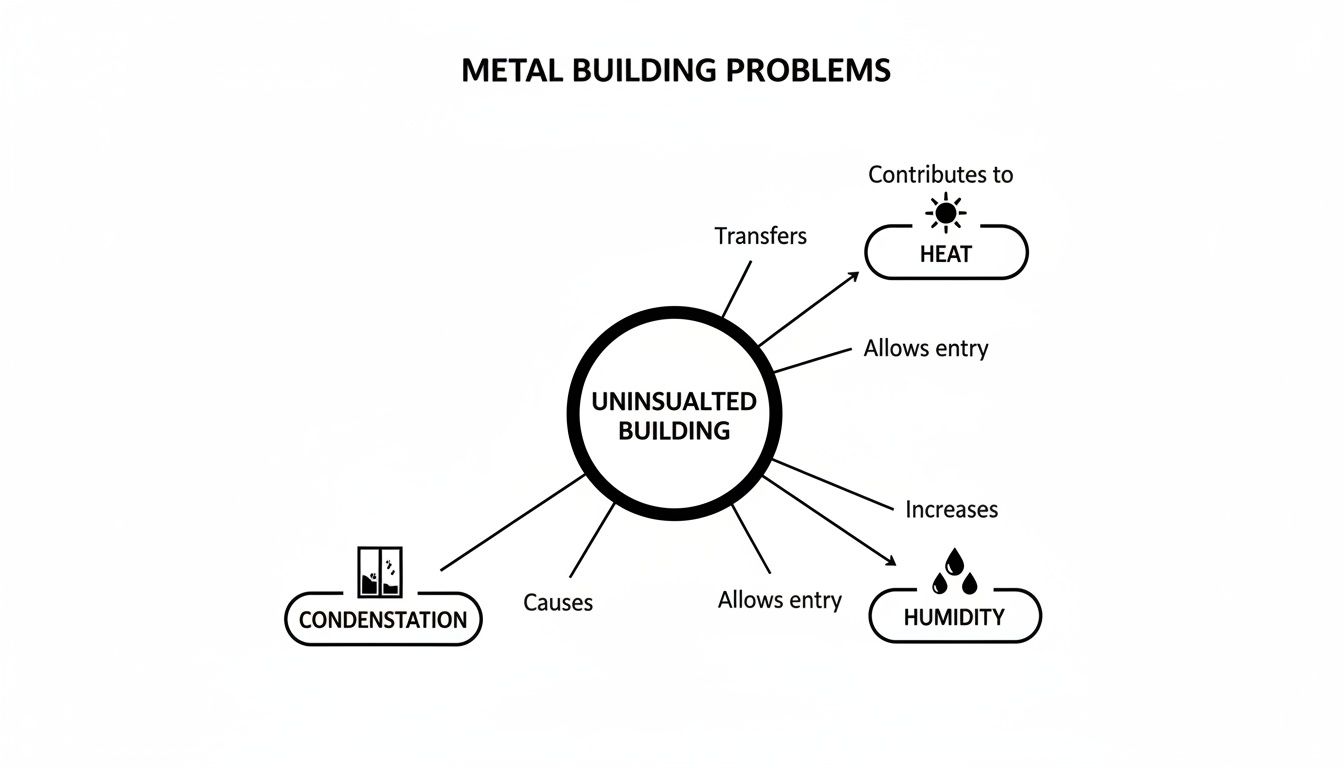

This diagram really highlights how an uninsulated building becomes a magnet for problems—creating a vicious cycle of intense heat, suffocating humidity, and damaging condensation.

It’s easy to see how these issues are all tangled together. They all stem from one root cause: the lack of a proper thermal barrier. Let's break down the common fixes to see how they actually perform in our unique South Florida climate.

Spray Foam Insulation The Seamless Solution

Imagine getting a jacket that was custom-molded to your body, leaving no gaps, seams, or weak points. That's exactly what spray foam insulation does for your building. When we apply it, it expands to fill every single crack, crevice, and awkward angle in your metal roof structure. The result is one solid, continuous, and completely airtight barrier.

This seamless seal is its biggest superpower. There are no joints, fasteners, or gaps for air or moisture to sneak through. For stopping condensation and energy loss in their tracks, it's a total game-changer.

- Pros: Delivers the highest R-value per inch, creates a complete air and moisture barrier, adds structural strength, and eliminates condensation before it even starts.

- Cons: It’s not a DIY job—it demands professional installation and usually has a higher upfront cost than other methods.

Batt and Blanket Insulation The Traditional Choice

Batt and blanket insulation, typically made of fiberglass, is the old-school wool sweater of the insulation world. It’s designed to trap pockets of air to slow down heat transfer, and it's one of the most common and cheapest options out there.

But just like a wool sweater, it really doesn't like water. The moment fiberglass gets wet, it loses most of its insulating ability and can quickly become a breeding ground for mold and mildew. Because it comes in pre-cut rolls, it’s also nearly impossible to fit perfectly around beams and purlins, leaving small gaps that become highways for air leaks and thermal bridging.

A common mistake we see is people thinking that just stuffing the cavities with batts is good enough. In a metal building, any unsealed gap creates a cold spot where condensation will form, turning your "solution" into a moisture trap.

Rigid Board Insulation The Sturdy Barrier

Think of rigid board insulation as a suit of armor for your roof. These firm panels, made from materials like polystyrene or polyisocyanurate, offer solid thermal resistance and are pretty tough. They also stand up well to moisture, which is a big deal in our humid climate.

The real challenge with rigid board is getting a truly perfect seal. Every single board has to be cut with precision to wedge between the building's framing, and every seam needs to be meticulously taped and sealed. Any tiny imperfection creates a thermal bridge, undermining the effectiveness of the entire system.

- Pros: Good R-value, resistant to moisture, and can provide a clean, finished appearance.

- Cons: Installation is very labor-intensive. Sealing every seam flawlessly is incredibly difficult, often resulting in air leakage.

Radiant Barriers The Heat Reflector

A radiant barrier isn't like a jacket at all—it’s more like one of those shiny, reflective emergency blankets. Its main job isn't to slow down heat transfer (which is what R-value measures), but to reflect radiant heat. It’s a thin, foil-like material that’s incredibly effective at bouncing the sun’s intense heat away from your building before it gets in.

Here in sunny South Florida, that can make a huge difference in your cooling bills. The catch? Radiant barriers provide almost zero R-value on their own, so they don’t do much to stop heat transfer on a cool day. They work best when paired with another type of insulation.

The demand for high-performance insulation is exploding, and it's easy to see why. The market for metal structural insulation panels, valued at USD 42.88 billion in 2022, is on track to hit USD 50.5 billion by 2025, driven by a push for more energy-efficient buildings.

While each of these methods has its place, spray foam consistently comes out on top in the areas that matter most for a metal building: air sealing, moisture control, and thermal performance. To see how it compares to other application methods, check out our guide on the differences between spray foam and blown-in insulation. This powerful combination of features makes it the smartest choice for protecting your investment for the long haul.

The Unbeatable Advantage of Spray Foam Insulation

When it comes to insulating a metal building roof, spray foam isn't just another option on the menu—it’s in a different league entirely. Unlike traditional materials that are cut and wedged into place, spray polyurethane foam (SPF) starts as a liquid. It's sprayed directly onto the surface and expands on contact, creating a single, unbroken, and completely airtight seal.

Think of it this way: trying to seal a leaky roof with fiberglass batts is like trying to patch a boat with a quilt. It might slow the leaks, but water and air will always find the seams. Spray foam is more like coating the entire hull in a solid, waterproof resin. It eliminates every gap, crack, and pinhole, forming a truly monolithic barrier.

This airtight quality is a game-changer for metal buildings, where a sneaky problem called thermal bridging runs rampant. That’s when heat zips right through the building’s steel frame, completely bypassing the insulation. Because spray foam sticks to everything—the panels and the framing—it wraps the steel in a thermal blanket, stopping that energy loss dead in its tracks.

Open-Cell vs. Closed-Cell Foam

Now, not all spray foam is the same. The two big players are open-cell and closed-cell, and knowing the difference is critical for getting the right performance from your metal building.

Open-cell spray foam has a soft, sponge-like feel. As its name suggests, its tiny cells are left open, which makes it fantastic for deadening sound. It’s a great pick for workshops or garages where you want to quiet things down. But that open structure is also its Achilles' heel in a humid climate—it can absorb and hold moisture, making it the wrong choice for a metal roof where condensation is public enemy number one.

Closed-cell spray foam, on the other hand, is the undisputed champion for metal buildings. Its cells are completely sealed and packed together, creating a dense, rigid, and incredibly strong material. This structure makes it an absolute fortress against air, moisture, and vapor.

When we apply closed-cell foam to the underside of a metal roof, it does more than just insulate. It creates an impermeable shield that stops warm, humid indoor air from ever touching the cooler metal surface. Condensation doesn't stand a chance.

Before we go any further, let's break down the key differences in a head-to-head comparison. This should make it crystal clear which one is the right fit for a South Florida metal building.

Open-Cell Vs Closed-Cell Spray Foam for Metal Buildings

| Feature | Open-Cell Foam | Closed-Cell Foam | Airtight's Recommendation |

|---|---|---|---|

| Structure | Soft, flexible, sponge-like | Rigid, dense, and strong | Closed-cell offers superior strength. |

| Moisture Barrier | Permeable (absorbs water) | Impermeable (blocks water) | Closed-cell is essential for condensation control. |

| R-Value | R-3.5 to R-4 per inch | R-6 to R-7 per inch | Closed-cell provides double the thermal resistance. |

| Air Barrier | Effective air barrier | Superior air and vapor barrier | Both are great, but closed-cell is better. |

| Structural Strength | Adds minimal strength | Significantly adds to structural rigidity | Closed-cell reinforces your building's roof. |

| Best Use Case | Interior walls, soundproofing | Roofs, walls, areas needing moisture control | Closed-cell is the only choice for metal roofs here. |

The verdict is pretty clear. For the unique challenges of a metal building in our climate—high heat, intense humidity, and the threat of storms—closed-cell foam is the only way to go.

Why Closed-Cell is the Gold Standard

Here in South Florida, the case for closed-cell foam is overwhelming. Its dense structure delivers a much higher R-value per inch (typically R-6 to R-7), giving you incredible thermal protection without eating up a ton of headroom.

What's more, its rigidity adds serious structural integrity to the building. Once cured, it acts like a high-strength glue, reinforcing the roof deck and dramatically increasing its resistance to wind uplift—a massive advantage during hurricane season. To take it a step further, the foam can be top-coated with advanced elastomeric coatings for bulletproof weather and UV protection.

The global construction industry is catching on. The roof insulation market was valued between USD 12.31 and USD 12.54 billion in 2024 and is expected to soar to USD 22.12 billion by 2035. While old-school materials are still around, the shift toward high-performance solutions like closed-cell foam is undeniable.

Choosing closed-cell spray foam is an investment in a complete system that manages heat, stops condensation cold, and strengthens your building—all in one application. You can dive deeper into the benefits on our blog dedicated to spray foam insulation. It is hands-down the most effective way to protect your metal structure and everything inside it from the tough Florida elements.

Solving Condensation in Your Metal Building

Here in South Florida, condensation is the number one enemy of any metal building. It's more than just a little dripping; it's a relentless force that kickstarts rust, invites mold, and can seriously damage whatever you're storing inside. This "building sweat" is just simple science playing out over your head every single day.

It all happens when the warm, moist air inside your building rises and hits the cooler surface of the metal roof panels. Think about a glass of iced tea on a hot day—that’s exactly what’s happening to your roof. The metal cools the air past its dew point, forcing all that humidity to turn from an invisible vapor back into liquid water. And that's where the real trouble begins.

Why Some Insulation Fails to Stop Moisture

When you're fighting condensation, you quickly learn that not all insulation is created equal. The wrong choice won't just fail to solve the problem; it can actually make it worse by creating a hidden moisture trap right against the steel you’re trying to protect.

Traditional fiberglass batt insulation is a perfect example of what not to do. Sure, it can slow down heat transfer a bit, but it does absolutely nothing to stop air and vapor from moving right through it. That fluffy material lets humid air pass through to the cool metal, where it immediately condenses.

What happens next is even worse. The fiberglass acts like a sponge, soaking up all that moisture. A wet batt loses almost all its R-value, making it useless for insulation. More importantly, it holds that dampness directly against your metal panels, creating the perfect recipe for rust and mold.

The Power of an Impenetrable Vapor Barrier

To truly win the battle against condensation, you have to stop humid air from ever reaching the cool metal surface in the first place. This means you need an insulation that doubles as a complete, seamless vapor barrier. This is exactly where closed-cell spray foam is in a league of its own.

When we apply it directly to the underside of the roof deck, closed-cell foam creates a single, solid layer. It doesn't just insulate; it actually bonds to the metal and seals every single seam, gap, and fastener. It becomes part of the structure.

This airtight, waterproof shield physically blocks the warm, moist interior air from making contact with the metal. By stopping that interaction, you stop condensation before it even has a chance to form. You’re not just managing moisture—you’re preventing it entirely.

Figuring out exactly where moisture problems are starting is key. These days, advanced tools can pinpoint issues with incredible precision. For instance, the thermal imaging capabilities of drone roof inspection software can show you hidden gaps or moisture spots, proving just how critical a flawless seal really is.

Ventilation: The Second Half of the Solution

While the right insulation is your primary weapon, a complete strategy for moisture control also includes proper ventilation. A great insulation system narrows the temperature gap between the air and the roof, but good airflow is the essential backup plan.

Ventilation helps to:

- Exhaust Excess Moisture: It actively pushes out humid air that builds up from daily activities or running equipment.

- Regulate Temperature: It keeps the air moving, so you don't get pockets of hot, stagnant air trapped up by the roofline.

- Maintain Air Quality: It ensures a steady flow of fresh air, which makes for a much healthier indoor environment.

When you combine closed-cell metal building roof insulation with a smart ventilation system, you get a powerful, one-two punch. The spray foam creates that impenetrable barrier, and the ventilation system manages the air inside. Together, they ensure your building stays dry, rust-free, and protected for decades to come.

What to Expect from a Professional Installation

Hiring a professional to insulate your metal building roof is the right call, but it helps to know exactly what goes on behind the scenes. Understanding the process not only builds confidence in your contractor but also shows you the true value of their work. A top-tier installation isn't just about spraying foam—it's a meticulous, multi-stage process built for safety, performance, and a lifetime of results. It’s worlds away from a DIY job, which almost always misses the critical details that matter most.

From our first conversation to the final walkthrough, a professional service follows a well-defined path. This journey is designed to deliver a perfect, seamless seal that protects your investment for decades. When you know what to look for, you can easily spot a quality contractor and feel confident you’re getting the job done right.

The Initial Consultation and Assessment

Everything starts with a thorough, hands-on evaluation of your building. An experienced technician will come out to your property to inspect the structure, take precise measurements, and identify any potential challenges. This could be anything from complex framing to signs of existing moisture problems. This isn't just a quick glance; it's a diagnostic deep-dive.

Based on that assessment, you’ll get a detailed, customized quote. This proposal will lay everything out: the recommended foam (which is almost always closed-cell for metal roofs), the exact thickness needed for your target R-value, and a clear, itemized breakdown of the cost. There should be no guesswork or hidden fees.

A professional quote is more than a price tag—it's a complete game plan. It should clearly explain the scope of work, the specific materials being used, the project timeline, and the safety protocols we follow from start to finish.

Preparation and Safety Protocols

Once you give the green light, the real work begins with extensive prep. Honestly, this is one of the most important stages, because it lays the groundwork for a clean, flawless application. Our crew will meticulously mask and cover every single surface that isn't getting insulated.

This includes:

- Covering Floors: We lay down heavy-duty plastic sheeting to protect your concrete slab or any other flooring.

- Masking Walls and Equipment: All walls, doors, windows, and any machinery or stored items are carefully draped and sealed off.

- Protecting Electrical Fixtures: Outlets, junction boxes, and lights are all covered to keep them completely free of overspray.

Safety is our absolute priority. We establish a controlled work area, set up industrial-grade ventilation, and our team gears up in full personal protective equipment (PPE), including respirators and full-body suits. This protects both our crew and your property during the entire application.

Application and Final Inspection

With the building fully prepped and secured, the technical work begins. Our certified technicians use specialized equipment to apply the spray foam in precise, even layers. They methodically build it up to the specified thickness, a skill that requires a steady hand and years of experience to create a uniform, monolithic seal across the entire roof deck.

After the foam has fully cured, the team performs a final quality control check, inspecting for consistent depth and a perfect bond to the metal. Then comes the cleanup—we remove all the masking materials and leave your space cleaner than when we arrived. We wrap up with a final walkthrough with you to ensure 100% satisfaction with the finished job.

Your Metal Building Insulation Checklist

Choosing the right insulation for your metal building roof can feel like a huge decision, but it gets a lot simpler once you start asking the right questions. Think of this as your final walkthrough—a checklist to help you focus on what really matters for your South Florida property before you make a commitment.

Before you sign on the dotted line with anyone, take a minute to run through these key points. Answering them honestly will almost always point you straight to the solution that gives you the best value, performance, and peace of mind for years to come.

Evaluating Your Building and Needs

First things first, what are we trying to accomplish? The "best" insulation is simply the one that solves your specific problems.

- What's the building used for? The needs of a climate-controlled workshop are worlds apart from a basic storage shed. Get clear on how important stable temperature and humidity are for your day-to-day work or the items you're storing.

- How bad is the condensation? Are you already dealing with dripping water, or are you just trying to head off a future headache? If you’ve got sensitive equipment or inventory inside, then 100% moisture prevention isn't just a goal; it's a necessity.

- What’s your real budget? It's easy to focus on the upfront price tag, but don't forget to factor in long-term energy savings. A cheap option that fails and needs to be ripped out in a couple of years isn't a bargain—it's just a down payment on a bigger problem.

Vetting Your Insulation Contractor

Once you know what you need, the game shifts to finding the right team for the job. Remember, the quality of the installation is every bit as critical as the material you choose.

Your contractor’s experience is a direct reflection of the results you can expect. A flawless, airtight seal isn’t achieved by accident—it’s the product of years of expertise, especially when working with the unique challenges of metal structures.

Make sure you ask any potential installer these questions:

- Are you licensed and fully insured in Florida? This is non-negotiable. It’s the baseline for protecting your property and making sure they're accountable.

- How many metal buildings have you insulated? Don't be shy about asking for references or to see photos of similar jobs. Insulating a metal structure is a completely different ballgame than working on a residential attic.

- What specific safety protocols do you follow? A true professional crew puts safety first. That means proper ventilation, masking, and personal protective equipment, no exceptions.

Making a confident choice really just comes down to having the right information. This checklist gives you a solid place to start, but every building has its own quirks. For answers tailored specifically to your project, the next logical step is to talk to a pro.

Contact the team at Airtight Spray Foam Insulation today for a free, no-obligation estimate. We’ll help you navigate your options and design the perfect solution for your metal building.

Still Have a Few Questions?

Even after you've mapped out a plan, it's natural to have a few lingering questions about insulating a metal building roof, especially here in South Florida. We get it. Here are some straightforward answers to the questions we hear most often from property owners just like you.

What’s the Right R-Value for a Metal Building in Florida?

Down here, with our relentless heat, you can't skimp on R-value. For a metal roof, we consider R-19 the absolute minimum. Honestly, though, pushing for R-25 or even R-30 is where you'll see a real difference in your cooling costs and indoor comfort.

This is where closed-cell spray foam really shines. It packs a powerful punch, delivering about R-7 per inch, so you get that high R-value without needing a foot of thick insulation eating up your headroom.

Can I Really Put Spray Foam on My Old Metal Roof?

Absolutely. In fact, it's often the single best thing you can do for an aging metal roof. As long as the structure is sound and we have a clean, dry surface to work with, the foam adheres directly and permanently.

It does more than just insulate—it seals up those pesky minor leaks, encapsulates any surface rust (after we prep it, of course), and even adds a surprising amount of structural strength. It’s like giving your old roof a new lease on life.

What Should I Expect to Budget for This?

The final cost really depends on the size of your roof, which insulation you go with, and the nitty-gritty of the job. Here’s a rough breakdown:

- Batt Insulation: This is your most budget-friendly route, usually running between $1.00 to $2.50 per square foot installed.

- Rigid Board: Sits in the middle of the pack, typically costing $1.75 to $4.00 per square foot. The labor is a big factor here because of all the custom cutting and sealing needed.

- Spray Foam: This is more of an investment, generally ranging from $2.00 to $5.00 per square foot, based on whether you choose open-cell or closed-cell and how thick we need to go.

It's true that spray foam has a higher upfront cost. But think of it this way: its ability to create a perfect air and moisture seal means bigger long-term savings on energy bills and, just as importantly, on repairs you won't have to make down the road.

How Long Will Spray Foam Actually Last on a Metal Roof?

When it's installed by a pro and shielded from direct, long-term sunlight, closed-cell spray foam is a once-and-done solution. It's not going to sag, break down, or lose its effectiveness over time like fiberglass batts can.

It literally becomes one with your building's structure, giving you consistent, reliable performance for decades. That incredible longevity is what makes it one of the smartest, most cost-effective choices for protecting your building in the long run.

Ready to get a firm number for your own project? The crew at Airtight Spray Foam Insulation knows what it takes to protect a building from the South Florida climate.

Request a free, no-obligation quote today and let us show you how we can make your metal building comfortable, dry, and efficient for good.