Blog

Spray Foam vs Batt Insulation for South Florida Homes

When it comes to choosing between spray foam vs batt insulation for a South Florida home, spray foam consistently proves to be the high-performance champ. While traditional batt insulation might seem appealing with its lower upfront cost, spray foam creates a far superior building envelope. It delivers exceptional thermal resistance, a seamless air seal, and unmatched moisture control—three absolute must-haves in our humid climate.

The Definitive South Florida Insulation Comparison

Picking the right insulation is one of the biggest decisions you'll make for your home's long-term comfort and energy bills. The classic debate pits spray foam against batt insulation, which usually boils down to a simple question: upfront cost or long-term performance? Here in South Florida, where intense heat and relentless humidity are a given, that choice becomes even more critical.

This guide gives you a straight, side-by-side comparison to help you really understand the core differences. We’re going beyond the basic R-value ratings to look at how each material actually performs in the real world, giving you the clarity you need to make a smart investment. Looking for other ways to button up your home? These general tips to improve home insulation are always a great place to start.

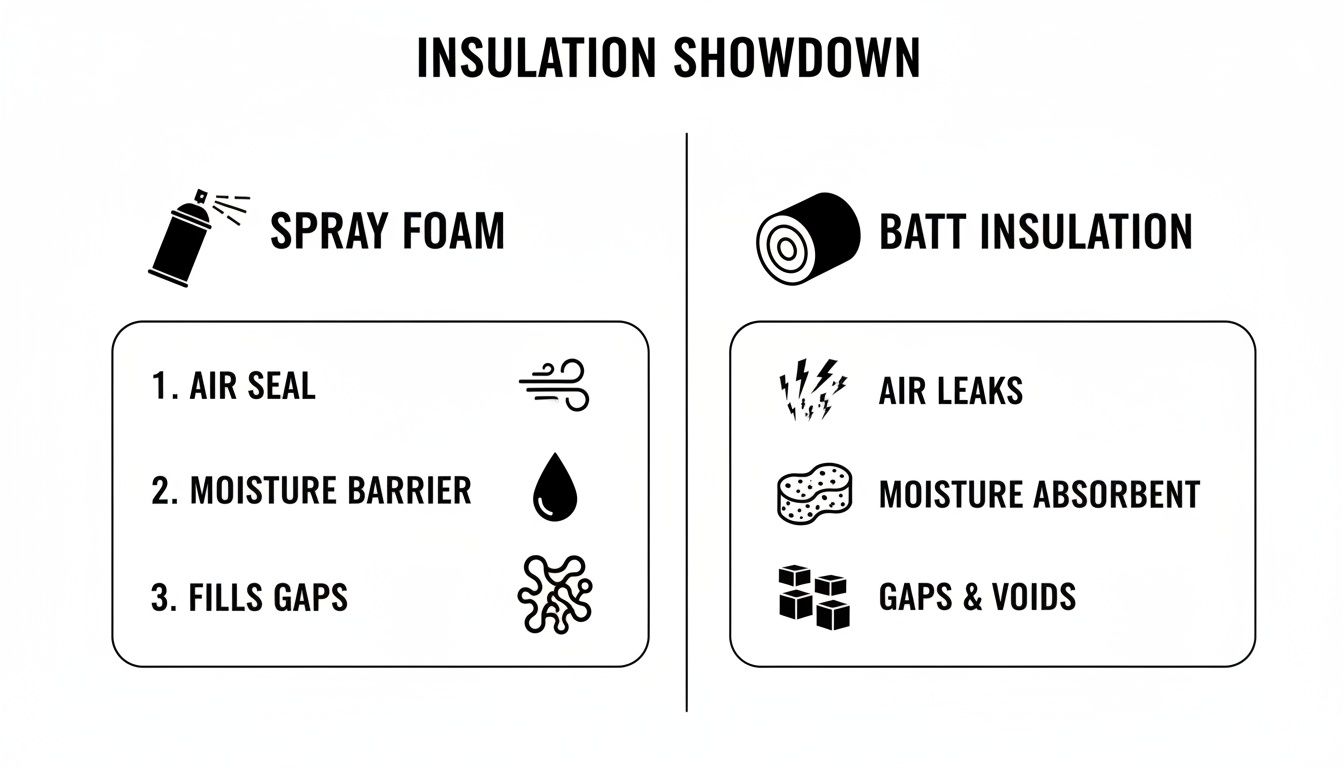

This infographic really drives home the fundamental differences: spray foam creates a single, unbroken barrier against air and moisture, while batt insulation is naturally prone to gaps and can act like a sponge for humidity.

You can see right away how spray foam’s ability to expand and seal every little crack makes all the difference, while the pre-cut form of batt insulation can leave behind vulnerabilities that kill your home's performance.

Key Differences At a Glance

For a quick rundown, this table breaks down the most critical performance metrics between spray foam and traditional batt insulation. It’s a great starting point for seeing where each one wins and loses.

| Performance Metric | Spray Foam Insulation (Open & Closed-Cell) | Batt Insulation (Fiberglass & Mineral Wool) |

|---|---|---|

| Air Sealing | Excellent; creates a monolithic air barrier. | Poor; gaps and seams allow significant air leakage. |

| Moisture Control | Excellent; closed-cell acts as a vapor barrier. | Poor; can absorb and hold moisture, risking mold. |

| R-Value/Inch | High (R-3.7 to R-7.0). | Moderate (R-3.1 to R-4.3). |

| Installation | Professional installation is required. | Can be a DIY project but is often installed poorly. |

| Durability | Lasts the lifetime of the building without sagging. | Can sag, settle, and degrade over 15-20 years. |

The market trends back this up. More and more builders and homeowners are choosing higher-performing solutions. In fact, the global market for spray foam is projected to hit an incredible USD 4,452.1 million by 2035. This growth is all about its superior ability to expand and seal every single gap, slashing air leakage in a way that batt insulation just can't match.

Comparing Core Performance in Real-World Conditions

When you're comparing spray foam vs. batt insulation, you have to look past the R-value printed on the package. Out here in the real world, especially in the relentless heat and humidity of South Florida, how an insulation actually performs day-in and day-out is what counts. A lab-tested R-value is one thing; holding that performance under pressure is something else entirely.

Batt insulation, like fiberglass or mineral wool, looks good on paper with a typical R-value of R-3.1 to R-4.3 per inch. But in a real attic or wall, its effectiveness is fragile. The moment a batt is compressed to squeeze around a pipe or an electrical box, its R-value drops. And it drops fast.

This is a huge problem because getting a perfect, seamless fit with pre-cut batts is next to impossible. Every tiny gap, every compressed corner, and every seam becomes a thermal weak point—an open invitation for heat to pour into your home.

The Decisive Factor: Air Sealing

This is where spray foam completely changes the game. Unlike batts that are just placed into wall cavities, spray foam is applied as a liquid that expands on contact. It creates a seamless, monolithic barrier that bonds directly to the studs and sheathing.

This process does more than just insulate; it air-seals the entire building envelope. Spray foam gets into every crack, crevice, and awkward corner, stopping the drafts and air leaks that plague homes insulated with batts.

Key Insight: Batt insulation resists heat flow (that’s the R-value), but it does absolutely nothing to stop air movement. Spray foam does both. This dual-action performance is why it’s a much better solution for creating a truly sealed and efficient home, particularly in a climate as demanding as ours.

Think of it this way: batt insulation is like wearing a thick wool sweater on a windy day. It's warm, but you still feel the chill cutting right through. Spray foam is like putting a windbreaker jacket on over that sweater—it stops the wind completely, making the insulation far more effective. For a deeper dive against another popular option, check out our guide on spray foam vs blown-in insulation.

Moisture Management in Humid Climates

In South Florida, moisture is public enemy number one for building materials. When humid air gets into your walls, it doesn't just make your home feel sticky and force your AC into overdrive. It creates the perfect breeding ground for mold and mildew.

Batt insulation essentially acts like a sponge. It can absorb moisture right out of the air, leading to a cascade of problems:

- Reduced R-Value: A damp batt loses a huge chunk of its insulating power.

- Mold and Mildew Growth: Trapped moisture inside wall cavities is a recipe for serious indoor air quality issues and rot.

- Structural Damage: Over time, that constant dampness can contribute to the decay of wood framing and sheathing.

Closed-cell spray foam, on the other hand, is a completely different animal. It's a non-permeable material that doesn’t just resist moisture—it flat-out repels it, acting as a true vapor barrier. This is an invaluable feature in places like Jupiter and West Palm Beach, where humidity is a year-round battle. By stopping moisture-laden air from ever entering the wall cavity, closed-cell foam protects both your home's structure and your family's health.

The proof is in the performance. Studies consistently show that spray foam can slash energy bills by 20-50% compared to traditional batts. That's because it creates an airtight seal that prevents up to 50% more air infiltration. While batts lose 20-30% of their R-value in gaps or when compressed, closed-cell spray foam maintains its powerful R-6 to R-7 per inch and locks out moisture—a critical advantage in humid spots like Palm Beach Gardens and Stuart, where batts often become damp, moldy messes.

For homeowners serious about peak energy efficiency, looking into Passive House principles shows just how crucial superior insulation and airtightness are. This approach is built on creating a building envelope that's completely sealed from the outside elements, a goal that spray foam helps achieve perfectly.

Evaluating Installation and Structural Integrity

When you're comparing spray foam vs. batt insulation, it's about more than just R-values. How the material gets into your walls and attic—and what it does once it's there—is just as critical. The two couldn't be more different. One is a precise, professional process, while the other is notorious for performance-killing mistakes.

Here in South Florida, where intense weather tests both installation quality and structural strength, this difference is huge. Making the right choice goes beyond a simple upgrade; it's a fundamental improvement to your home's durability.

Professional Application vs. DIY Pitfalls

Batt insulation is often sold as a DIY-friendly product. And sure, a homeowner can physically stuff batts into wall cavities, but getting an installation that actually performs as advertised is a whole different story. The reality is that attics and walls are cluttered with wiring, plumbing, and electrical boxes—all obstacles that get in the way of a perfect fit.

Every time you cut, tear, or compress a batt to work around an obstacle, you create a gap. These little imperfections add up, becoming major highways for air and heat to blow right past your insulation, tanking its real-world effectiveness. A professional can do a better job, of course, but even they are limited by the awkward, pre-cut shape of the material.

Spray foam, on the other hand, requires a professional installer for good reason. Certified technicians use specialized equipment to mix chemical components at exact temperatures and pressures. The liquid foam is then sprayed right onto the surface, expanding in seconds to create a perfect, seamless seal.

This process ensures the foam conforms flawlessly to every single nook, cranny, pipe, and wire. There are no gaps. No seams. No compromises.

Key Takeaway: The "perfect fit" of spray foam isn't just a nice feature; it's a core part of its function. It eliminates the installation errors common with batt insulation, guaranteeing the R-value you pay for is the R-value your home actually gets.

A Structural Upgrade for Hurricane Resilience

Living in South Florida means any conversation about building materials has to include hurricane readiness. While batt insulation is just a filler with zero structural benefit, closed-cell spray foam actually makes your home stronger.

When closed-cell spray foam cures, it hardens into a dense, rigid material that acts like a powerful glue, bonding the framing and sheathing of your walls and roof together. This turns separate components into a single, monolithic structure that is far more resilient.

This added rigidity significantly increases the building's racking strength—its ability to resist the shearing, twisting forces of hurricane winds. It's a massive benefit that batts just can't deliver.

- Wall Assemblies: Spray foam can increase wall racking strength by up to 300%, helping them stand firm against winds that could otherwise cause catastrophic failure.

- Roof Decks: Applying closed-cell foam to the underside of the roof deck locks the sheathing to the rafters, dramatically reducing the risk of panels being ripped off in a storm.

This structural reinforcement is an invaluable layer of protection that goes far beyond just saving on energy bills. For homeowners in Jupiter or West Palm Beach, choosing closed-cell foam is an investment in both efficiency and peace of mind. It's also a vital consideration for our region's common construction types; knowing the insulation value of concrete block walls is key, and spray foam is the ideal solution to maximize their performance.

A Practical Cost and ROI Analysis

Let’s talk money. When you’re looking at quotes for spray foam vs. batt insulation, it's easy to get fixated on the initial number. And yes, batt insulation is always going to be the cheaper option upfront. For projects on a tight budget, that lower price can be really tempting.

But focusing only on the installation cost is like judging a car by its paint job—it misses the whole story of performance, ownership costs, and long-term value.

The higher price tag for spray foam isn't arbitrary. It accounts for sophisticated materials, specialized application gear, and the certified pros needed to install it safely and correctly. It’s best to frame the decision as a strategic investment, not just an expense—especially here in the demanding South Florida climate.

Understanding the Upfront Cost Difference

The sticker price for an insulation job is driven by more than just the material. With batt insulation, the cost is pretty simple: you pay for the product itself and the labor to cut and stuff it into wall cavities. It’s a straightforward, predictable process.

Spray foam, on the other hand, is basically a small-scale chemical manufacturing plant on wheels. The higher cost is a direct reflection of what it takes to do the job right:

- Specialized Equipment: We're talking high-pressure pumps, long heated hoses, and precision mixing guns needed to apply the foam perfectly.

- Professional Labor: Technicians aren't just installers; they're trained specialists in chemical handling, safety protocols, and application techniques that create that perfect air seal.

- Advanced Materials: The two-part chemical compound that creates the foam is inherently more complex and costly than spun fiberglass or mineral wool.

This initial investment is precisely what unlocks the superior performance that pays you back for years.

The Real ROI: Energy Savings and Beyond

The financial argument for spray foam is built on its power to slash your long-term expenses. The first place you'll see a return is on your monthly FPL bill. By creating a nearly airtight seal, spray foam can cut heating and cooling costs by a whopping 20% to 50%.

In a South Florida home where the AC runs nonstop for much of the year, those savings add up fast, quickly chipping away at the higher installation cost. But the financial perks don't end with your utility bill.

The Big Picture: The true ROI of spray foam isn't just about energy savings. It’s about increasing your property value, avoiding future headaches like mold remediation, and never having to replace your insulation again. Spray foam is engineered to last the lifetime of your home.

Think about the "avoided costs." A home with traditional insulation in our humid climate is a prime candidate for moisture getting trapped in the walls. That can lead to thousands of dollars in mold remediation and structural repairs down the road. Closed-cell spray foam doubles as a vapor barrier, stopping that problem before it ever starts.

Plus, its rigid structure actually adds strength to your walls and roof deck—a valuable bonus that can appeal to home insurance companies and definitely impresses future buyers.

Hypothetical 10-Year ROI Comparison

To put this into perspective, let's run some numbers. This simplified financial model compares the estimated long-term savings and payback for spray foam versus batt insulation in a typical South Florida home.

| Financial Metric | Spray Foam Insulation | Batt Insulation |

|---|---|---|

| Initial Installation Cost | $9,000 | $3,500 |

| Average Annual Energy Savings | $850 | $300 |

| Cumulative 10-Year Savings | $8,500 | $3,000 |

| Payback Period | ~10.5 Years | N/A (ongoing costs) |

| Avoided Replacement Cost | $0 (lasts 50+ years) | ~$3,500 (may need replacing) |

| 10-Year Net Financial Impact | -$500 (before property value) | -$4,000 (with replacement) |

As the table shows, batt insulation starts cheaper, but its weaker performance and shorter lifespan mean it actually costs more over a decade. The payback for spray foam comes from consistent, high-impact energy savings and incredible durability.

When you also consider the added resilience against storms and dramatically improved indoor air quality, spray foam stops looking like an expensive upgrade and starts looking like one of the smartest long-term investments you can make in your property.

Choosing the Right Insulation for Your Property

Deciding between spray foam and batt insulation isn't about finding one "best" option—it's about matching the material to the job at hand. For those of us in South Florida, where intense heat, relentless humidity, and the threat of hurricanes are just part of life, this decision takes on even more weight. So, let's move past the generic advice and dig into real-world scenarios to see where each insulation type really proves its worth.

This practical, scenario-based approach will help you pinpoint the right solution for your attic, new build, or unique structure, making sure you get the performance and protection you actually need.

The South Florida Attic: The Unvented Approach

In a typical vented attic, summer temperatures can easily skyrocket past 130°F. All that super-heated air radiates straight down into your living space, forcing your AC unit to work overtime just to keep you comfortable. It also means any ductwork running through that attic is essentially trying to push cold air through an oven.

This is where spray foam offers a game-changing solution: creating an unvented, conditioned attic. Instead of laying insulation on the attic floor (your home's ceiling), we apply closed-cell spray foam directly to the underside of the roof deck. This single step completely transforms your home's thermal boundary.

The process seals the attic from the outside world, effectively bringing it inside the conditioned envelope of your home. Suddenly, the temperature in your attic stays much closer to your living space, usually within 5-10 degrees.

The results are immediate and powerful:

- Lower Cooling Load: Your HVAC system is no longer battling a scorching hot ceiling all day long.

- Protected Ductwork: Your ducts can finally deliver cold air efficiently without massive energy loss.

- Better Air Quality: Sealing the attic stops dust, pollen, and humid air from getting sucked into your home through vents.

For any homeowner in South Florida, creating a conditioned attic is one of the most impactful energy efficiency upgrades you can make. Batt insulation just can't do this—it doesn't create the critical air seal needed on the roof deck to make it happen.

New Construction: The Modern Energy Code Standard

If you're building a new home in Florida today, meeting modern energy codes is non-negotiable. These codes are tougher than ever, demanding high levels of airtightness and thermal performance that old-school methods struggle to meet. This is exactly where spray foam becomes a builder's best friend.

Trying to hit modern airtightness targets with batt insulation is a tough, painstaking process. It means chasing down every possible air leak with caulk, tape, and gaskets—a method that’s prone to human error and often falls short of the mark.

Spray foam cuts right through that complexity. Because it creates a seamless, monolithic air barrier in one application, builders can meet and even exceed energy code requirements with confidence.

Key Insight: For new construction, choosing spray foam isn't just about insulation. It's a strategic decision to build a high-performance home from the very start, streamlining code compliance while delivering a fundamentally better product to the homeowner.

This approach results in a tighter, more efficient, and more comfortable home built to perform for decades. It sets a new standard that batt insulation simply wasn't designed to achieve.

Specialized Applications: Metal Buildings and Sound Control

Beyond homes, spray foam shines in situations where batt insulation isn't even a realistic option.

Metal Buildings and Workshops: Metal is a fantastic heat conductor, which means workshops and warehouses can become unbearable ovens in the Florida sun. Even worse, those drastic temperature swings cause condensation to form on the inside of the metal panels. This "sweating" can rust the structure and ruin whatever you're storing inside.

Closed-cell spray foam is the definitive answer here. Applying it directly to the interior metal panels accomplishes two critical things:

- Creates a Thermal Break: It completely halts heat transfer, keeping the inside cool.

- Controls Condensation: By stopping warm, humid air from hitting the cool metal surface, it eliminates condensation entirely.

Interior Sound Dampening: While spray foam wins in most categories, there is one specific niche where batt insulation can be a practical choice: sound dampening for interior walls. If your only goal is to reduce noise between rooms—like a home office or bedroom—and thermal performance isn't a factor, the lower cost of batt insulation makes it a reasonable choice for this limited use.

For any exterior wall or ceiling, however, the comprehensive benefits of spray foam—its R-value, air sealing, and moisture control—make it the overwhelmingly superior investment for any property in South Florida.

Making an Informed Decision for Your Home

When it comes down to the spray foam vs batt insulation debate, it’s really about what you value most for your South Florida property. This isn't just another line item in a renovation budget; it's a long-term investment in your home's comfort, energy bills, and ability to withstand our climate.

While batt insulation definitely has a lower price tag upfront, its performance just doesn't hold up in our intense heat and humidity. It's an okay solution, but "okay" doesn't cut it when your AC is running non-stop.

Spray foam, on the other hand, is a powerhouse combination of benefits that feels like it was engineered specifically for Florida. Its high-end thermal resistance keeps the heat out, and its seamless air seal stops sticky, humid air from getting inside. That means lower energy bills and cleaner, less allergen-filled air for your family.

And let's be honest, the peace of mind you get from closed-cell foam's moisture-blocking and structural support is a huge deal here. It’s real protection against humidity, mold, and even storm damage—benefits that completely change the conversation from cost to value.

Your Contractor Vetting Checklist

Choosing the right insulation is only half the job. A sloppy installation can make even the best material worthless. Before you hire anyone, make sure you get straight answers to these questions.

- Are your technicians certified? Ask to see proof of certification from a reputable group like the Spray Polyurethane Foam Alliance (SPFA). Proper training means they know the chemistry, the equipment, and the safety rules inside and out.

- What kind of foam do you recommend for my attic and why? A real pro will explain exactly why open-cell or closed-cell is the right fit for your specific space. They won't just give you a generic, one-size-fits-all answer.

- What are your safety procedures? A professional crew will have a clear plan for sealing off the work area, using proper ventilation during and after the job, and telling you exactly when it's safe for your family to return.

- Can I see local references and your insurance? Any trustworthy company will be happy to share references from recent jobs in Jupiter, Palm Beach Gardens, or your neighborhood. They should also provide proof of liability and worker's comp insurance without hesitation.

Final Takeaway: The decision really boils down to balancing the upfront cost with the lifetime performance. For South Florida homeowners who want serious energy savings, a more comfortable home, and real protection against the elements, spray foam insulation is the smart, strategic choice.

Making the right choice here empowers you to build a stronger, more efficient home. The next step is getting an expert to look at your property and figure out exactly what it needs.

Common Questions About Insulation Choices

When you're weighing spray foam against traditional batt insulation, a few key questions always come up. Homeowners want straight answers, and frankly, you deserve them. Let’s tackle some of the most common concerns I hear from clients.

Is Spray Foam Insulation Safe for My Home?

Absolutely. Once modern spray foam has fully cured—usually within a few hours—it becomes a completely inert and stable material. Think of it as a permanent, non-toxic part of your home's structure.

The entire safety of the process comes down to professional installation. Certified technicians are trained to manage ventilation and follow strict protocols for when it's safe to re-enter the area. This ensures that by the time you and your family are back in the space, the air is clean and the insulation is perfectly safe.

Can Spray Foam Be Installed in an Existing House?

Yes, and it’s one of the most effective energy efficiency upgrades you can make to an older home. While it’s certainly easier to install during new construction, professional installers are experts at retrofitting foam into existing attics, crawl spaces, and even walls.

This process is so impactful because it seals up all the tiny air leaks and thermal weak spots that have likely been driving up your energy bills for years. For an older property, there’s hardly a better bang for your buck.

Key Insight: The longevity of spray foam is a major differentiator. It is engineered to last the lifetime of your building without sagging, settling, or degrading.

How Long Does Spray Foam Insulation Last?

Spray foam is designed to last for the life of your home. It’s a one-and-done solution. Unlike other materials, it doesn’t settle, compress, or lose its R-value over time because it forms a rigid, permanent bond with your home’s structure. It will perform just as well in year 30 as it does in year one.

In contrast, you can expect batt insulation to start losing its effectiveness after 15-20 years. It inevitably sags, gets compressed, or absorbs moisture, which means it will eventually need to be replaced. Spray foam’s durability makes it a true long-term investment. While its main job is thermal control, it’s also a great way to quiet your home—you can learn more about using insulation as a sound barrier in our detailed guide.

Ready to transform your home’s comfort and efficiency? The expert team at Airtight Spray Foam Insulation is here to provide a professional assessment and a free, no-obligation quote. Discover how our tailored solutions can lower your energy bills and create a healthier indoor environment. Request Your Free Quote Today!