Blog

A Guide to the Types of Spray Foam Insulation

Picking the right insulation is a huge decision, especially here in South Florida where summer cooling bills can feel endless. When it comes to spray foam, you’ll hear two terms pop up constantly: open-cell and closed-cell.

Think of them as two different tools for the same job. One is like a soft, flexible sponge that’s great at absorbing sound, while the other is a dense, rigid shield that’s completely waterproof.

Choosing the Right Insulation for Your Home

Trying to decide between insulation types can feel a bit overwhelming, but it gets a lot simpler once you understand their core differences. Each foam is engineered for specific jobs—from controlling moisture in a humid climate to dampening noise between rooms—and that choice directly impacts your home’s comfort, energy bills, and even its structural strength.

Making the right call is all about matching the foam to the application. This guide will break down how each type works, where it shines, and how picking the best fit will lead to some serious savings and a much healthier home. Investing in a top-notch insulation like spray foam is one of the best ways to cut down on energy waste; you can find more smart tips for saving electricity to see just how big of an impact it can make.

Why This Choice Matters

Good insulation does a lot more than just keep your house cool. It creates a complete air barrier, stopping that expensive conditioned air from leaking out and preventing sticky, humid outdoor air from creeping in. That’s a game-changer in South Florida.

Here’s what you get with the right choice:

- Lower Energy Bills: When you seal up all those tiny air leaks, your AC doesn’t have to work nearly as hard. That means it runs less often and uses less power.

- Improved Air Quality: A properly sealed home keeps outdoor allergens, dust, and pollutants where they belong—outside.

- Enhanced Sound Control: Open-cell foam, in particular, is fantastic for reducing noise from the outside world or between rooms. We dive deeper into how insulation as an effective sound barrier works in another one of our articles.

It’s no surprise that homeowners are catching on. Residential projects make up the largest piece of the global spray foam market, accounting for a massive 41% of market share in 2025. People are realizing just how effective it is at sealing homes and slashing energy costs. After reading this guide, you’ll know exactly which type is the perfect fit for your own home.

A Closer Look at Open-Cell Spray Foam

When you start digging into spray foam, you’ll quickly come across two main types. Let’s start with the lighter, more flexible option: open-cell spray foam.

The easiest way to think of it is like a high-tech, dense sponge. Once it’s sprayed out of the nozzle, it expands like crazy—growing up to 100 times its liquid size. This massive expansion is key because it lets the foam creep into every single nook, cranny, and weirdly shaped gap in your attic or walls, creating an incredible air seal.

Its name comes from its physical structure. The tiny bubbles, or “cells,” that make up the foam are left open, which is what gives it that soft, spongy, and lightweight feel. That structure is what makes it so good at stopping air leakage, which is its biggest strength. It literally stops drafts in their tracks and keeps your expensive conditioned air right where it belongs: inside your home.

The Unsung Hero of Sound Dampening

One of the best, and often overlooked, benefits of open-cell foam is how well it absorbs sound. Those interconnected air pockets don’t just insulate; they act like a maze, trapping sound waves and deadening the noise that tries to travel through your walls and floors.

This makes it the perfect choice for certain parts of the house where peace and quiet are a priority.

- Home Offices: Finally get a quiet workspace without hearing everything else going on in the house.

- Media Rooms: Keep that immersive movie sound inside the theater room, not bleeding into the living room.

- Bedrooms: Block out noise from the street or an adjacent TV for a much better night’s sleep.

- Between Floors: Drastically reduce the sound of footsteps and activity from the floor above.

By completely filling the wall cavity, open-cell foam puts a serious damper on airborne noise, making your home feel much more calm and quiet.

R-Value Isn’t the Whole Story

Now, if you’re just looking at the numbers, you’ll see that open-cell foam has a lower R-value—that’s the measure of thermal resistance—than its denser cousin, closed-cell. Open-cell foam typically provides an R-value of around R-3.7 per inch.

But here’s a common mistake people make: thinking a lower R-value automatically means it’s a worse insulator. R-value alone is only half the battle. A huge amount of energy loss in a home comes from air leaking through tiny gaps and cracks.

Because open-cell foam expands so aggressively, it creates a nearly perfect air barrier, stopping that leakage far better than traditional insulation like fiberglass batts ever could. The combination of its solid thermal resistance and its superior air-sealing power is what creates a truly efficient home.

Key Insight: A slightly lower R-value with a perfect air seal almost always outperforms a higher R-value insulation that’s full of air gaps. Open-cell spray foam is a master at eliminating those gaps, and that’s a game-changer for energy bills.

Letting Your Home “Breathe”

That “open” cell structure we talked about does something else important: it allows the foam to be vapor-permeable. In simpler terms, it lets water vapor pass through it. This is what building science pros mean when they say it allows the structure to “breathe.”

In our humid South Florida climate, this can be a huge plus. Imagine a small, hidden roof leak develops in an attic. With open-cell foam, that water can pass through the insulation and reveal itself as a small spot on your ceiling. You can spot the problem early and get it fixed before the moisture gets trapped against your roof deck, causing wood rot. The foam itself is hydrophobic—it doesn’t soak up water—but it allows liquid to drain through, which is exactly what you want.

A Smart Choice for Your Budget

When it comes to cost, open-cell is typically the more economical of the two main types of spray foam. Because it expands so much, you simply need less raw material to fill a space compared to closed-cell foam.

That lower density means a lower installation cost, especially when you’re tackling big, open areas like an entire attic roofline or the walls of a new construction project. It really hits the sweet spot between performance and price, giving you a premium air seal and fantastic soundproofing without the higher material cost of high-density foams. It’s a popular choice for homeowners who want to see major energy savings without breaking the bank.

Exploring Closed-Cell Spray Foam

While open-cell foam offers flexibility and sound control, closed-cell spray foam brings sheer power and resilience to the table. If open-cell is like a dense sponge, think of closed-cell as a rigid, waterproof shield. It’s the heavy-hitter in the world of insulation, engineered for maximum performance and durability.

The difference is all at the microscopic level. Its structure is made of tiny, individual cells that are completely sealed off from one another. These cells are packed with a specialized gas that’s a fantastic insulator, giving closed-cell foam its incredible strength and high R-value.

Unpacking the Power of a High R-Value

The most celebrated feature of closed-cell foam is its exceptional thermal resistance. It boasts a seriously high R-value of R-6 to R-7 per inch—that’s nearly double what open-cell foam offers and miles ahead of traditional insulation like fiberglass.

What does that mean for you? You get more insulating power in less space. In a standard 2×4 wall, for example, you can achieve a much higher total R-value with closed-cell foam than with any other product. This maximizes your home’s energy efficiency without needing to build thicker walls.

This high performance isn’t just a number on a spec sheet. It translates directly into a more stable indoor temperature and significantly lower energy bills, as your HVAC system doesn’t have to struggle to keep up with the brutal Florida heat.

A Fortress Against Moisture and Air

In a humid climate like South Florida, controlling moisture is just as important as controlling temperature. This is where closed-cell foam truly shines. Because its cells are sealed and packed tightly together, it’s virtually impermeable to both air and water vapor.

It acts as an all-in-one insulation, air barrier, and vapor barrier. This is a critical advantage in our region, as it prevents humid, moisture-laden air from seeping into wall cavities where it can condense and lead to destructive mold, mildew, and wood rot.

South Florida Advantage: Closed-cell foam’s ability to block water vapor makes it an indispensable tool for protecting homes from the constant threat of humidity-related damage. It creates a robust, waterproof layer that safeguards your home’s structure.

This dual role is a primary reason closed-cell spray foam has become so dominant across the U.S. spray foam insulation market, especially in regions that demand top-tier thermal and moisture control. While it’s popular in cold climates for its R-value, its moisture-blocking properties are just as valuable here in the subtropics.

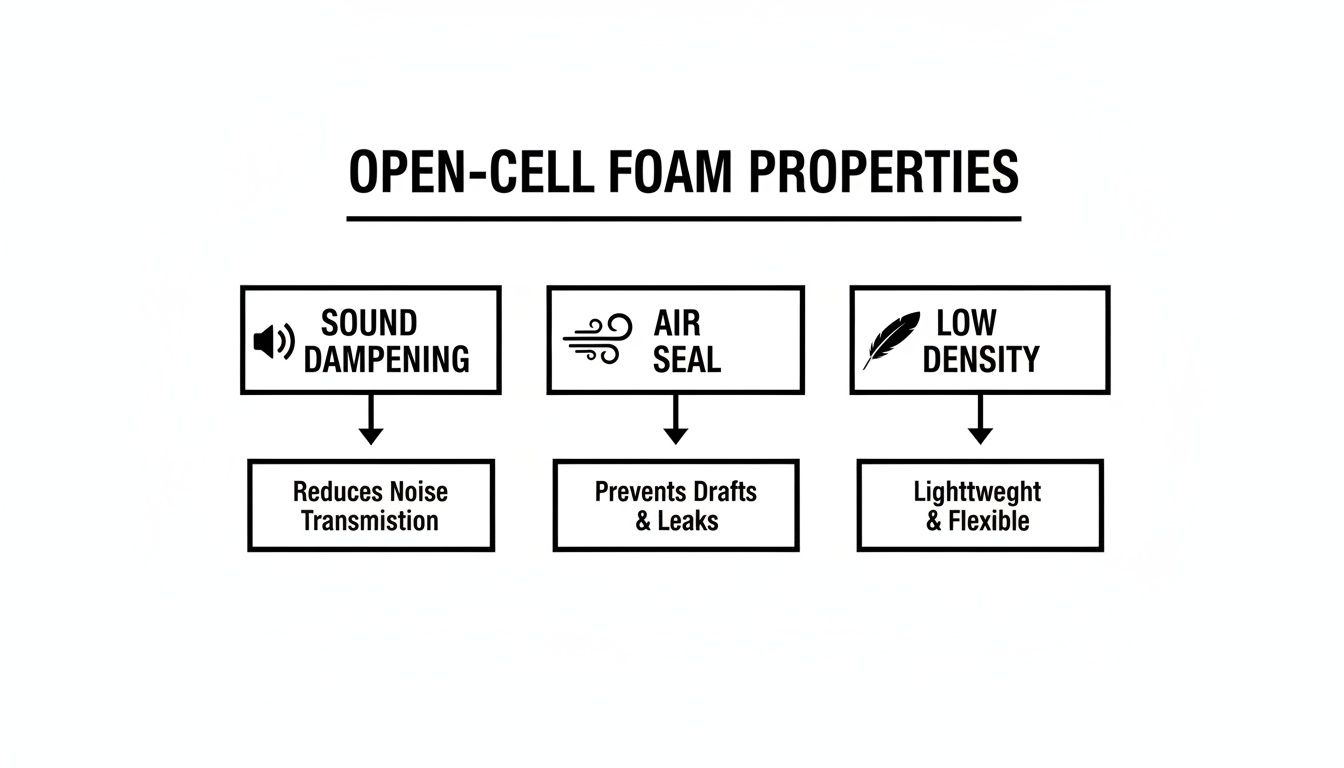

The flowchart below breaks down some of the key properties that make each foam type unique for specific jobs.

As you can see, each foam has distinct strengths—like sound dampening or air sealing—that make it the right choice for a particular application.

To make the comparison even clearer, here’s a quick side-by-side look at the two main types of spray foam.

Open-Cell vs. Closed-Cell Spray Foam At a Glance

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-3.5 to R-3.8 | R-6 to R-7 |

| Density | Low (0.5 lbs/ft³) | High (2.0 lbs/ft³) |

| Moisture Permeability | Vapor permeable (lets moisture pass) | Vapor impermeable (acts as a barrier) |

| Air Barrier | Yes | Yes |

| Structural Strength | No, remains flexible | Yes, adds significant rigidity |

| Sound Dampening | Excellent | Good |

| Cost | Lower | Higher |

| Expansion | Expands significantly (up to 100x) | Expands less (around 30-40x) |

This table highlights the core trade-offs. Open-cell is fantastic for sound and filling large cavities affordably, while closed-cell is the premium choice for thermal performance, moisture protection, and structural support.

Adding Structural Strength to Your Home

Another unique benefit of closed-cell spray foam is its rigidity. Once it cures, it becomes incredibly hard and dense, adhering tenaciously to any surface it’s applied to. This process adds significant structural reinforcement to walls and roof decks.

Think of it as a super-strong glue holding your building’s frame together. This added stiffness can actually increase the racking strength of a wall, making the entire structure more resistant to the high winds we often see during coastal storms and hurricane season.

It’s a powerful secondary benefit that other insulation types simply can’t offer.

Weighing the Pros and Cons

Like any building material, closed-cell foam has its own set of advantages and disadvantages to consider.

Key Advantages:

- Highest R-value per inch: Delivers maximum insulation performance in minimal space.

- Blocks moisture: Acts as a complete vapor barrier, preventing mold and rot.

- Adds structural integrity: Its rigid nature strengthens walls and roofs.

- Extremely durable: Resists settling, sagging, and degradation over time.

Potential Downsides:

- Higher Cost: The materials and installation are more expensive than open-cell foam.

- Rigidity: Its inflexibility means it won’t move with a shifting structure, which can be a consideration in some applications.

- Less Sound Dampening: Its dense structure reflects sound waves rather than absorbing them, making it less effective for soundproofing than open-cell.

Ultimately, choosing closed-cell spray foam is an investment in superior performance, moisture protection, and structural resilience—making it an ideal solution for many critical areas of a South Florida home.

Where Each Insulation Type Works Best

Knowing the technical differences between spray foam types is one thing, but knowing where to put them in a South Florida home is where the real value is. Each foam is a specialized tool. Using the right one in the right place is the key to maximizing your comfort, energy savings, and home protection.

Let’s move from theory to what actually happens in the field.

Open-Cell Foam for Attics and Interior Walls

Open-cell spray foam is our go-to for creating a cool, conditioned attic. When we apply it directly to the underside of your roof deck, it completely seals the attic from the blistering outdoor heat. This simple step transforms your attic from a super-heated oven into a semi-conditioned buffer zone, taking a massive load off your AC system.

Because open-cell foam expands so dramatically, it fills every tiny gap around trusses and vents, creating a perfect air seal. Its unique structure is also vapor-permeable, which is a huge advantage here. If a small roof leak ever happens, the water can pass through the foam, alerting you to the problem before it causes hidden wood rot—a critical feature in our rainy climate.

Interior walls are another place where open-cell shines. Its soft, sponge-like texture is a fantastic sound dampener.

- Home Office: Installing it in the walls of a home office can mute the noise from a busy living room or kitchen, giving you a quiet, productive workspace.

- Bedrooms and Nurseries: It significantly reduces noise transfer between rooms, ensuring a more peaceful night for light sleepers and young children.

- Media Rooms: It helps contain the sound from home theater systems, keeping the rest of the household undisturbed.

This shows how different types of spray foam insulation solve specific comfort issues that go way beyond just temperature control.

Practical Application: By spraying open-cell foam on the attic roof deck, you can drop the temperature in your attic by 40-50°F on a hot day. That directly translates to a less stressed HVAC unit and lower monthly cooling bills.

Closed-Cell Foam for Crawl Spaces and Exterior Walls

When the job calls for brute strength against moisture and structural stress, closed-cell spray foam is the undisputed champ. Its dense, rigid structure and moisture-impermeable nature make it essential for protecting the most vulnerable parts of a South Florida home.

Take a vented crawl space, for example. The humid air constantly flowing through leads to condensation, mold, and rot in your floor joists. Applying closed-cell foam to the crawl space ceiling (the underside of your floor) and foundation walls completely seals this area from outside moisture.

It acts as a powerful vapor barrier, stopping humidity in its tracks and protecting the structural foundation of your home. This is a place where open-cell would be the wrong tool for the job; its permeable nature just can’t provide the moisture blockade you need.

Closed-cell is also the top choice for insulating exterior walls, especially in new construction. Its high R-value of up to R-7 per inch packs maximum thermal performance into the limited space of a wall cavity. This is incredibly important for homes built with concrete blocks, which are everywhere in South Florida. Properly insulating these walls is a game-changer for energy efficiency, a topic we cover more in our guide to the insulation value of concrete block walls.

Better yet, its rigidity adds significant racking strength to the wall assembly, making the entire structure more resilient against high winds during coastal storms.

Here’s a quick-glance guide for where each foam works best:

| Location | Recommended Foam Type | Primary Reason |

|---|---|---|

| Attic Roof Deck | Open-Cell | Creates a conditioned space, allows moisture detection. |

| Interior Walls | Open-Cell | Excellent sound dampening for noise reduction. |

| Vented Crawl Space | Closed-Cell | Acts as a powerful vapor barrier to prevent mold and rot. |

| Exterior Walls | Closed-Cell | High R-value and adds structural strength. |

| Metal Buildings | Closed-Cell | Prevents condensation and provides superior insulation. |

By strategically choosing between the types of spray foam insulation for each part of your house, you create a complete system that tackles temperature, sound, and moisture with expert precision.

Key Considerations for South Florida’s Climate

Insulating a home in Palm Beach Gardens is a world away from insulating one in Boston. Our climate is an entirely different beast—defined by relentless heat, suffocating humidity, and the yearly threat of hurricanes. This environment demands more than just a high R-value; it requires a strategic defense against the unique pressures we face every single day.

This isn’t just about your comfort or lowering your FPL bill. It’s about protecting the very bones of your home from moisture-driven threats like mold, mildew, and wood rot. The right spray foam acts as an impenetrable shield against these constant attacks.

The Battle Against Humidity and Mold

Here in South Florida, humidity is the enemy. That heavy, moisture-saturated air is constantly trying to sneak into your home through thousands of tiny, invisible gaps in your walls and roof. When that warm, humid air hits a cooler, air-conditioned surface inside a wall cavity, it condenses. This creates the perfect damp breeding ground for mold.

This is exactly where the choice between types of spray foam insulation becomes so critical. For this fight, closed-cell spray foam is a true game-changer.

- It’s a Vapor Barrier: Unlike pretty much any other insulation, closed-cell foam is non-permeable. It completely stops water vapor in its tracks, creating a waterproof seal inside your walls and roofline.

- It Prevents Condensation: By blocking humid air from getting into the wall cavity in the first place, it starves mold of the moisture it needs to grow.

In our climate, an insulator must also be a moisture barrier. Closed-cell foam’s dual function is its greatest strength, providing a robust defense against the mold and decay that can ruin air quality and structural safety.

Open-cell foam, while fantastic for soundproofing and air sealing in attics, does allow vapor to pass through it. So for areas with high moisture exposure like crawl spaces or specific exterior walls, closed-cell is hands-down the better choice for guaranteed moisture protection. While picking the right foam is key, it’s also worth understanding how local climate impacts HVAC system choices to create a home that truly works as a system.

Building Resilience for Hurricane Season

Beyond the daily humidity, our homes need to be built tough. Coastal storms and hurricanes put incredible stress on a building’s frame. A home that is tightly sealed and structurally reinforced is far more likely to survive high winds and torrential rain. Both types of spray foam help with this, but they do it in different ways.

Spray foam doesn’t just sit in a cavity; it adheres directly to the sheathing, studs, and trusses, creating a monolithic bond. This “gluing” effect dramatically increases the structural rigidity of your walls and roof, helping the entire structure resist the violent forces of wind uplift. When you compare it to traditional methods, the difference is night and day, a topic we dive into in our guide on spray foam vs. blown-in insulation.

Closed-cell foam, thanks to its dense and rigid structure, offers the highest level of reinforcement. Applying it directly to a roof deck can increase its strength by up to 300%, making it far less likely to peel off during a major storm. This isn’t just insulation; it’s a structural upgrade that brings priceless peace of mind when a hurricane is on the radar.

What to Expect During a Professional Installation

Choosing the right type of spray foam is a big decision, but knowing what a professional installation looks like is the final piece of the puzzle. Hiring a contractor shouldn’t feel like a shot in the dark. A reputable company follows a careful, transparent process to ensure safety, efficiency, and a perfect result.

It all starts long before any foam gets sprayed. The process kicks off with a detailed consultation where a real expert assesses your home. They’ll listen to your goals—whether it’s crushing high energy bills or just soundproofing a noisy room—and recommend the right foam for each specific area. You should always get a clear, itemized estimate that breaks down the scope of work and all the costs. No surprises.

Preparing the Workspace for Application

Once you’ve scheduled the job, the most critical step before spraying begins is site preparation. This is non-negotiable. It protects your home and guarantees the foam adheres exactly where it’s supposed to. Our crews take a ton of pride in masking and covering everything that isn’t getting sprayed.

This prep work includes:

- Flooring: Every floor in and near the work area gets covered with heavy-duty plastic sheeting.

- Windows and Doors: We carefully tape off and protect all windows, doors, and trim.

- Fixtures: Lights, electrical outlets, and HVAC vents are sealed up to prevent any overspray.

- Personal Belongings: Any furniture or other items in the area are moved out or securely covered.

This level of prep is a dead giveaway that you’re working with a professional team. It shows a commitment to leaving your home just as clean as we found it.

Safety First: During the application, our technicians wear full personal protective equipment (PPE), including respirators and full-body suits. This is absolutely essential. Spray foam is created by a chemical reaction that releases vapors, a process called off-gassing, which are only safe after the foam has fully cured.

The Application and Curing Process

With the site prepped and protected, our technicians use specialized equipment to apply the foam. Proper ventilation during this stage is crucial. We set up high-powered fans to exhaust any fumes and maintain safe air quality while the foam cures, which typically takes 24 to 72 hours. Nobody should re-enter the space without PPE until our crew gives the all-clear.

But the job isn’t over once the foam is applied and cured. Our team removes all the protective coverings and does a thorough cleanup of the entire work area. We wrap up with a final quality control check to make sure the foam is at the correct thickness and the air seal is complete. This step-by-step, safety-first process is how we guarantee your insulation performs exactly as promised for decades to come.

Frequently Asked Questions About Spray Foam Insulation

Even after digging into the different types of spray foam, you probably still have a few questions. That’s completely normal—and smart. Making the right call for your home is a big deal, so we’ve put together answers to the questions we hear most from South Florida homeowners.

Is Spray Foam Insulation Safe for My Family?

Absolutely. Once spray foam is professionally installed and fully cured, it’s completely safe. The application itself is a chemical process, which is why our technicians wear full protective gear and use powerful ventilation systems on every job.

After about 24 hours, the foam hardens into an inert, stable plastic. It doesn’t off-gas or release any harmful vapors. In fact, it actually makes your indoor air cleaner by sealing off the cracks and gaps that let in outdoor dust, allergens, and pollutants.

How Long Does Spray Foam Insulation Last?

This is one of the best parts about spray foam—its staying power. Unlike fiberglass batts that can sag, get compressed, or lose their effectiveness over the years, spray foam is a permanent fix.

It bonds directly to your home’s structure, becoming a part of it. It won’t shrink, settle, or degrade, holding its shape and R-value for the entire life of your home. It’s a true one-and-done investment you’ll never have to worry about replacing.

Key Takeaway: Spray foam insulation is a lifetime product. It will not degrade, compress, or lose its insulating power, providing consistent performance and energy savings for decades to come.

Can I Install Spray Foam Insulation Myself?

We strongly recommend against DIY spray foam kits. It’s not like painting a room. The consumer-grade kits you find at big-box stores just don’t have the power, pressure, or temperature controls of our professional equipment. This almost always leads to a bad chemical mix, giving you foam that doesn’t cure right, pulls away from the studs, or fails to deliver the R-value you paid for.

Professional installation is non-negotiable for both safety and performance. Our certified technicians are trained to handle the materials safely, apply the foam to the correct thickness, and manage the powerful ventilation needed for a perfect, safe application.

How Does Spray Foam Compare in Cost?

There’s no sugarcoating it—the upfront investment for spray foam is higher than for old-school materials like fiberglass or cellulose. But that’s only half the story. Because it works as both a top-tier insulator and an air barrier, it leads to major long-term savings on your energy bills.

Most homeowners discover that the sharp drop in their monthly cooling and heating costs delivers a powerful return on their investment. The final cost will depend on the size of your project, any prep work needed (like removing old insulation), and which of the types of spray foam insulation is right for the job.

At Airtight Spray Foam Insulation, we believe in giving you straight answers and clear, transparent estimates so you can make the best choice for your home. Request a free estimate online today and let our expert team show you how we can boost your comfort and slash your energy bills. Learn more about our spray foam insulation services in Jupiter, FL and how they’re designed for South Florida homes.