Blog

Spray Foam Insulation for Metal Buildings The Ultimate Guide

Spray foam insulation isn’t just an option for metal buildings; it’s the modern solution. It creates a seamless, airtight seal that sticks directly to the metal, eliminating condensation, stopping air leaks, and dramatically cutting energy bills. Think of it as an all-in-one insulator, air barrier, and vapor barrier in a single application.

Why Spray Foam Is the Best Choice for Metal Buildings

Metal buildings are fantastic—they’re strong, affordable, and go up fast. But that same metal skin is also a superhighway for heat. In a South Florida summer, heat pours right in. In the cooler months, it escapes just as quickly. This leads to massive temperature swings inside and energy bills that can make you sweat.

Unfortunately, traditional insulation like fiberglass batts just can’t keep up.

Imagine trying to stay warm on a windy day with just a wool sweater. It helps, but the cold wind still cuts right through. That’s fiberglass. Spray foam, on the other hand, is like putting on a high-performance ski jacket. You get the warmth (insulation) plus a completely windproof and waterproof shell (the air and moisture barrier), all in one go.

This dual-action performance is exactly why spray foam insulation for metal buildings has become the go-to standard. It doesn’t just slow heat down; it stops costly air movement cold.

A Modern Solution for a Classic Problem

The challenges that come with metal structures demand something more advanced than old-school insulation. Spray foam is engineered to solve these problems head-on:

- Eliminates Thermal Bridging: Those metal studs and purlins in the frame act like bridges for heat, letting energy sneak right past traditional insulation. Spray foam covers everything—studs, panels, and all—creating a continuous, unbroken thermal blanket.

- Stops Condensation and Rust: The biggest enemy of a metal building is moisture. Spray foam stops condensation before it can even start by preventing warm, humid indoor air from ever touching the colder metal surfaces. No condensation means no rust and no water damage.

- Adds Structural Rigidity: This is a huge bonus, especially with closed-cell spray foam. It’s incredibly dense and, once cured, acts like a structural glue. It bonds the panels to the framing, adding serious racking strength and making the whole building more rigid and durable.

By creating a monolithic, airtight seal, spray foam insulation fundamentally changes how a metal building performs, turning an energy-draining structure into a highly efficient and stable environment.

The industry has taken notice. The global spray foam insulation market was valued at around USD 2.09 billion and is expected to keep growing, largely because of how effective it is in commercial and industrial buildings like these. Its ability to shut down thermal bridging in metal structures is a game-changer for long-term operational costs.

And it’s not just about temperature and moisture. That seamless seal also makes for an incredible sound barrier, deadening the noise from rain, wind, and outside activity. You can learn more about how spray foam insulation acts as a sound barrier in our detailed guide.

Choosing Your Armor: Open-Cell vs. Closed-Cell Foam

When it comes to spray foam for metal buildings, you’ve got two main choices: open-cell and closed-cell. Think of them as different types of armor for your building. Each one offers a unique set of protections, and picking the right one is critical for hitting your goals, whether that’s climate control, moisture prevention, or even adding a bit of structural support.

At a glance, the difference is all in their cell structure. Open-cell foam is the softer, more flexible option. Its cells are intentionally left open, which allows it to expand like crazy when we apply it, filling every last nook and cranny. Picture a high-tech sponge that’s amazing at stopping air drafts and soaking up sound.

Closed-cell foam is the complete opposite—it’s rigid and dense. Its cells are totally sealed off and packed together tightly, trapping an inert gas that seriously boosts its insulating power. It’s less like a sponge and more like a solid, waterproof shield that actually adds strength to your building’s frame.

Getting to Know Open-Cell Spray Foam

Open-cell spray foam is a lower-density product, weighing in at about 0.5 pounds per cubic foot. That sponge-like quality makes it a fantastic sound-dampening material. If you want to quiet the noise of rain hammering on a metal roof or muffle sounds from a workshop, it’s a great choice.

But because its cells are open, it’s vapor-permeable. That means moisture can pass right through it. While this might be okay in some wall systems, it’s a huge problem here in South Florida’s humidity. Since our number one enemy is moisture, this is a major drawback. It is generally cheaper than closed-cell foam, so it can be tempting for projects on a tighter budget where moisture isn’t the main concern.

The Power of Closed-Cell Spray Foam

For nearly every metal building in our climate, closed-cell spray foam is the undisputed champ. With a density of around 2.0 pounds per cubic foot, it delivers a much higher R-value per inch—typically R-6 to R-7, compared to open-cell’s R-3.5 to R-4. You get way more insulating power without having to use as much material.

Its real superpower is its structure. Those sealed cells create a true air and vapor barrier. This is the knockout punch for condensation in metal buildings. It completely stops warm, humid air from ever touching the cooler metal surface, which prevents sweating and the rust that follows. On top of that, its rigid nature adds serious structural integrity, basically acting like a glue that bonds the panels and framing together.

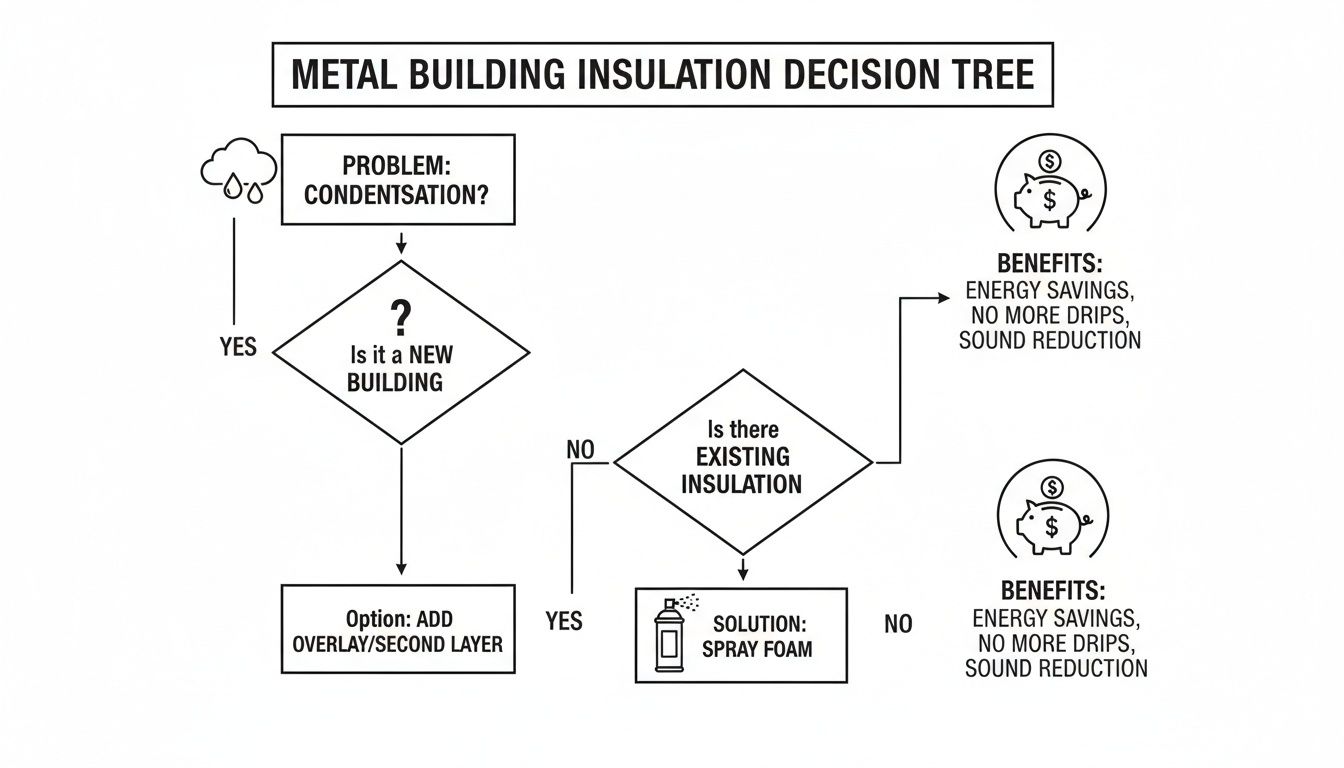

To see how the right insulation strategy solves these problems, this decision tree lays it all out.

As the chart shows, fixing a sweating building with the right insulation isn’t just a repair—it’s a direct path to long-term savings and a much stronger structure.

Head-to-Head Comparison: A Clear Winner for South Florida

So, how do you choose? It really comes down to what your building needs to fight against. To make it simple, we’ve put together a quick comparison chart focusing on the factors that matter most for metal buildings right here in our area.

Open-Cell vs. Closed-Cell Spray Foam Comparison for Metal Buildings

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-3.5 to R-4 | R-6 to R-7 |

| Moisture Barrier | No (Vapor Permeable) | Yes (True Vapor Barrier) |

| Air Barrier | Yes | Yes |

| Structural Strength | Minimal | High (Adds Rigidity) |

| Sound Dampening | Excellent | Good |

| Cost | Lower | Higher |

The takeaway is pretty clear. For metal buildings in South Florida, the superior R-value, built-in vapor barrier, and structural reinforcement of closed-cell foam make it the hands-down winner for long-term performance and protection.

While open-cell has its place, closed-cell is practically engineered to solve the biggest headaches for metal building owners: energy loss, condensation, and structural flexing. It’s an all-in-one solution. Of course, spray foam isn’t the only option out there. To get the full picture, check out our detailed comparison of spray foam vs. blown-in insulation to see how different materials perform in various situations.

Winning the War Against Condensation and Rust

If you own a metal building in South Florida, you’re familiar with its silent enemy: condensation. It shows up as harmless “sweat” on the inside of your roof and walls, but it’s the start of a much bigger problem. Before you know it, that moisture leads to rust, mold, and even structural damage.

The science behind it is simple. Your building’s thin metal skin gets cool, especially overnight. When the warm, humid air inside touches that cooler surface, the air can’t hold its moisture anymore. The water vapor instantly turns into liquid droplets, right there on your panels.

Think about a cold can of soda on a hot day. The condensation on the outside isn’t a leak—it’s just moisture from the air collecting on the cold aluminum. Your building is doing the exact same thing, just on a much more destructive scale.

The Definitive Solution: A Seamless Vapor Barrier

This is where closed-cell spray foam insulation for metal buildings completely changes the game. It’s not just another layer of insulation; it’s a permanent solution that creates a seamless, airtight barrier. This barrier physically separates the warm, moist interior air from the cooler exterior metal.

Unlike fiberglass batts that leave gaps, spray foam is applied as a liquid and expands to fill every single crack, seam, and void. It bonds directly to the metal, creating a monolithic seal. That direct bond is everything.

By preventing warm, humid air from ever touching the cold metal surface, spray foam completely eliminates the “dew point”—the temperature where condensation happens. If the two can’t meet, the building can’t sweat. Simple as that.

This is why modern construction relies so heavily on this technology. The foam insulation sector already accounts for nearly 38.19% of the total insulation market in building and construction. With its unmatched moisture control and fast installation, the global foam insulation market is projected to hit USD 30.33 billion. You can read more about the trends in the global foam insulation market on Mordor Intelligence.

Protecting Your Investment for the Long Haul

Stopping condensation isn’t just about keeping things dry. It’s about protecting the long-term value of your investment.

- Preventing Rust and Corrosion: Moisture is rust’s best friend. Keep the metal panels dry, and you dramatically extend the life of your building, avoiding the headache and cost of replacing panels down the road.

- Stopping Mold and Mildew: Damp, dark spaces are a breeding ground for mold. A dry building is a healthy building, protecting both people and stored property.

- Maintaining Structural Integrity: Over time, constant moisture can weaken key structural components. A dry building is a strong building that will stand the test of time.

Spray foam isn’t just an insulator—it’s a complete building protection system. It acts as your thermal barrier, air barrier, and vapor barrier all in one shot. For any metal building owner in a climate like ours, it’s not a luxury; it’s an essential defense.

How We Get the Job Done: The Professional Installation Process

Applying spray foam insulation to a metal building is a science, not a weekend DIY job. The final result—that perfect, seamless thermal barrier you’re after—is all about the details. It comes down to a meticulous process handled by certified pros who know exactly what they’re doing.

Let’s walk through what a professional installation actually looks like. It’s a mix of careful prep work, precise application, and smart post-installation steps. Understanding this will show you why hiring a true expert is non-negotiable for getting it right.

Step 1: Crucial Surface Preparation

Honestly, this is where the magic really begins. Spray foam needs a perfectly clean surface to grab onto and form a permanent bond. Think of it like painting a car—you wouldn’t just spray over dust and grease and expect a showroom finish. The prep work has to be flawless.

Our professional installers live by a strict checklist:

- A Deep Clean: Every single metal panel, purlin, and frame has to be spotless. We’re talking zero oil, dust, or grime. Any little bit of residue can create a weak spot where the foam won’t stick properly.

- Bone Dry Surfaces: The metal must be 100% dry. Spraying foam on even a slightly damp surface is a recipe for disaster. It kills the bond and can trap moisture right where you don’t want it.

- The Right Temperature: We constantly monitor both the metal’s temperature and the air temperature. If it’s too cold, the foam won’t cure and expand the way it’s supposed to, which compromises its performance from the start.

Step 2: The Precision Application

Once the building is prepped and ready, it’s time to spray. This is where you see the difference between an amateur and a pro. We use specialized equipment that mixes two chemical components on-site at exact ratios, temperatures, and pressures to create the foam.

This isn’t just a point-and-spray job. The installer applies the foam in controlled layers, or “lifts.” For closed-cell foam, that’s usually no more than two inches thick at a time. This allows each layer to cure perfectly before the next one goes on, ensuring the foam hits its target density and R-value without overheating.

A professional’s goal is to create a single, unbroken seal. They methodically cover every inch of the building—walls, roof deck, and all the tricky junctions—to completely eliminate air leaks and thermal bridging. It’s all about creating that monolithic barrier.

Step 3: Post-Installation Curing and Ventilation

After the last layer is sprayed, we’re not quite done. The foam needs time to finish its chemical reaction, harden completely, and off-gas.

- Curing Time: While spray foam gets hard to the touch very quickly, it takes longer to fully cure. We’ll give you a specific timeline, but typically you’re looking at about 24 hours where the area needs to be left unoccupied.

- Proper Ventilation: This is a big one for safety. We use high-powered fans and air movers during and after the job to vent the building thoroughly. This pushes out the volatile organic compounds (VOCs) released during the curing process, making the space safe for you to re-enter.

Skipping any of these steps can lead to a failed application, costing you in energy efficiency and creating potential safety issues down the road. This methodical, expert-led process is exactly why spray foam insulation for metal buildings should always be left to a qualified and experienced team.

Calculating Your Investment and Long-Term ROI

When looking at spray foam insulation for metal buildings, it’s easy to get fixated on the initial price tag. But that’s the wrong way to look at it. The smart move is to see it as a powerful investment—one that pays you back month after month, year after year.

Let’s shift the conversation from a one-time cost to a long-term return on investment (ROI) and see how this upgrade delivers real, measurable financial gains for your South Florida property.

What Goes Into the Initial Quote?

The upfront investment depends on a few key factors. These variables determine the final quote for your project and make sure the job is done right for your building’s specific needs.

- Type of Foam: As we’ve covered, closed-cell foam costs more per board foot than open-cell. But with its superior R-value and built-in vapor barrier, it’s almost always the more cost-effective choice for metal structures in our humid climate.

- Project Size: This one’s straightforward. The total square footage of the walls and roof deck is the biggest driver of the final cost.

- Application Thickness: If you want a higher R-value, you need a thicker layer of foam. That means more material and labor. Here in South Florida, we have to apply a specific thickness to effectively fight off our intense heat and humidity.

- Surface Preparation: A clean, dry surface is non-negotiable for a perfect bond. The amount of cleaning and prep work needed will influence the project’s overall cost.

Beyond the Initial Quote: The Real ROI

The true value of spray foam really comes into focus when you look past the installation invoice. That airtight seal it creates is where your investment starts generating returns, often much faster than you’d think.

The biggest, most immediate benefit is a massive drop in energy consumption. By killing air leaks and creating a nearly perfect thermal barrier, spray foam can slash your heating and cooling costs by 30-50% annually. In a place like South Florida, where the AC runs practically year-round, those savings hit your bottom line right away.

Think of your metal building like a high-performance vehicle—it needs the right parts to run efficiently. Spray foam is the engine upgrade that stops you from wasting fuel (energy) on a leaky, inefficient system.

This kind of performance is a huge reason the industry is booming. The spray foam insulation market was valued at USD 2.97 billion and is expected to hit USD 4.12 billion by 2031. This growth is being driven by rising energy costs and the demand for more efficient buildings, especially in the commercial world where metal structures are everywhere. You can read more about the spray foam market and its growth on WCONline.com.

Uncovering the Hidden Financial Gains

The ROI of spray foam insulation goes way beyond your monthly power bill. There are several other huge financial perks that add to its long-term value.

1. Increased Property Value

An energy-efficient, climate-controlled, and structurally sound building is way more appealing to potential buyers or tenants. Insulating your metal building is a capital improvement that adds real, tangible value to your asset.

2. Drastically Reduced Maintenance

By stopping condensation in its tracks, spray foam prevents rust and corrosion. This means you avoid the expensive and frustrating cycle of replacing rusted panels or fixing water damage, saving thousands in maintenance over the building’s life. While we’re focused on metal here, the insulation value in other materials like concrete block walls also shows how the right material prevents long-term decay.

3. Potential for Tax Credits and Rebates

Making your building more energy-efficient might qualify you for federal, state, or local tax incentives. These programs are designed to reward property owners for making smarter, more environmentally friendly upgrades, giving you another direct financial return.

When you add up the massive energy savings, the reduced maintenance headaches, and the increased property value, the initial investment in spray foam becomes a clear and intelligent financial decision. It’s an investment in efficiency, durability, and your long-term bottom line.

How to Hire the Right Insulation Contractor

Let’s be blunt: the absolute best spray foam in the world is useless if the crew installing it doesn’t know what they’re doing. When it comes to spray foam insulation for metal buildings, the quality of the final job rests almost entirely on the team holding the spray gun.

Hiring a contractor isn’t just a formality—it’s the single most important decision you’ll make to protect your investment. Think of it like a job interview. A real pro will have straightforward answers and the paperwork to prove it. An amateur? They’ll get cagey, give you vague answers, or try to rush you into signing something.

Your Contractor Vetting Checklist

Before you even think about signing a contract, you need to do some digging. A trustworthy contractor will respect your due diligence; a questionable one will get defensive. That defensiveness is your first and biggest red flag.

Start with the non-negotiables. These are the things that protect you from shoddy work and major financial headaches down the road.

- Verify Licensing and Insurance: Ask to see their general liability insurance and workers’ compensation policies. If someone gets hurt on your property and they aren’t covered, that accident can become your financial nightmare. Make sure their license is active for your specific city or county here in South Florida.

- Request Installer Certifications: The best contractors invest in training their people. Ask if their installers are certified by a legitimate organization like the Spray Polyurethane Foam Alliance (SPFA). This isn’t just a piece of paper; it proves they’ve been properly trained in safety, equipment, and the actual science behind how insulation works.

- Examine Their Portfolio: Ask to see photos and case studies of metal building projects they’ve completed. Insulating a wood-frame house is one thing, but a steel structure has its own unique set of challenges. You need a team that knows their way around steel panels and purlins, not someone who’s learning on your dime.

What to Look for in the Quote

A quote tells you more than just the price—it reveals how professional and transparent a contractor really is. If all you get is a single number scribbled on a page, run. A detailed, comprehensive proposal is a sign of a team that knows its stuff.

A low-ball offer that seems too good to be true almost always is. Unusually cheap bids often mean the contractor is cutting corners by using subpar materials, hiring untrained labor, or skipping critical preparation and safety steps.

A proper quote should clearly spell out:

- Material Specifics: It needs to state the exact type of foam they plan to use (e.g., 2 lb closed-cell foam) and the final applied thickness in inches.

- Scope of Work: The document must detail all the areas to be insulated and the total square footage. No surprises.

- Prep and Cleanup: A professional job includes the prep work, like cleaning and prepping all surfaces, and the cleanup afterward. It should be in the quote.

- Warranty Information: You should see two warranties listed: one from the foam manufacturer covering the material itself, and a separate one from the contractor that covers their workmanship.

Walking through this checklist will help you confidently spot the true professionals and hire a partner who will deliver a safe, effective, and lasting insulation solution for your metal building.

Of course. Here is the rewritten section, crafted to sound like an experienced human expert while following all your specific requirements.

Common Questions We Hear About Insulating Metal Buildings

Even after seeing all the benefits, it’s natural to have a few questions. Making a big investment in your property means you need to feel 100% confident. We get it.

Here are some of the most common questions we hear from metal building owners right here in South Florida.

How Long Does Spray Foam Really Last?

This is one of the first things people ask, and for good reason. The short answer? When installed correctly, closed-cell spray foam will likely outlast the building itself.

It’s an inert, permanent material. Unlike fiberglass that sags, settles, or gets compressed over time, spray foam holds its shape and performance for decades. The R-value you get on day one is the same R-value you’ll have 20 years from now.

Can You Insulate an Older Metal Building?

Absolutely. In fact, retrofitting existing structures is a huge part of what we do. It’s a fantastic way to bring an older, inefficient building up to modern standards.

As long as the metal surfaces can be properly cleaned and dried to ensure a solid bond, spray foam will adhere perfectly. It breathes new life and serious efficiency into buildings that have been around for a while.

What About Wiring, Pipes, and Safety?

This is a smart question. People often wonder how spray foam works around the existing guts of their building, like electrical wiring and plumbing.

Our professional installers are meticulous about this. We carefully spray around any wiring or pipes, leaving them accessible. Because closed-cell foam is rigid, it can always be cut away cleanly if you ever need to get to something for repairs or upgrades down the line.

The most important part of the process is the curing time. After the foam is applied, the area needs to be well-ventilated and unoccupied for about 24 hours. This allows the foam to fully “off-gas” and harden, making the indoor air completely safe.

We also get asked about lingering smells. While there’s a distinct odor during the application itself, it dissipates quickly as the foam cures. Modern, low-VOC (volatile organic compound) foams are incredibly stable once cured. There are no odors and no health risks.

Can’t You Just Spray Over Existing Insulation?

We sometimes see people ask if we can just spray over old bubble wrap or failing fiberglass. While you might find an installer willing to do it, we strongly advise against it.

For a permanent, airtight seal, spray foam needs to bond directly to the clean metal substrate. Spraying over another material introduces a weak link. If that old bubble wrap delaminates or the fiberglass shifts, your entire insulation system is compromised. It’s a shortcut that just isn’t worth the risk.

By getting straight answers to these questions, it’s easy to see why professionally installed spray foam insulation for metal buildings is such a durable, safe, and effective solution for new construction and retrofits alike.

Ready to transform your metal building into a comfortable, energy-efficient space? The experts at Airtight Spray Foam Insulation have the experience and skill to deliver a flawless installation. Get your free, no-obligation quote today!