Blog

Spray Foam Insulation: spray foam insulation closed cell vs open cell

When you get down to it, the real difference between closed-cell and open-cell spray foam is all about density and how it handles moisture. Think of it this way: closed-cell foam is a dense, rigid material that completely blocks water, which is exactly what you want for roofs and crawl spaces in a humid place like South Florida. On the other hand, open-cell foam is much lighter and softer, making it a champion at sound-dampening for a lower cost—a perfect fit for interior walls.

Open Cell vs. Closed Cell: The Right Choice For South Florida's Climate

Picking the right insulation in South Florida isn't just about R-value; it’s about making a smart, strategic choice against our relentless heat and humidity. The whole "closed cell vs. open cell" debate is especially critical here because each type has unique strengths that can be used in different parts of the very same building.

Getting these nuances right is the first step toward creating a home or commercial space that’s truly energy-efficient, comfortable, and built to last. Let's break down the essential differences so you can make a solid decision based on performance, cost, and where you plan to install it.

Key Differences At a Glance

Before we get into the nitty-gritty, it helps to see how these two stack up side-by-side. Both types of spray foam do an incredible job of creating an air seal that stops drafts and keeps your conditioned air inside. But their core structures are worlds apart, leading to very different performance on the job.

The real question isn't about which foam is 'better' overall, but which one is the right tool for the job. Here in South Florida, moisture resistance often becomes the deciding factor, especially for any area exposed to the elements.

This quick table hits the highlights and shows the main trade-offs you'll be considering.

Quick Comparison: Open Cell vs. Closed Cell Foam

| Feature | Open Cell Spray Foam | Closed Cell Spray Foam |

|---|---|---|

| Density | Low-density, soft, and flexible | High-density, rigid, and strong |

| Moisture Behavior | Vapor permeable (allows moisture to pass through) | Vapor barrier (blocks moisture completely) |

| R-Value per Inch | ~3.5 to 3.8 | ~6.0 to 7.0 |

| Sound Dampening | Excellent | Good |

| Cost | Lower upfront cost | Higher upfront cost |

| Structural Strength | Adds no structural strength | Adds significant structural rigidity to the building |

As you can see, the choice involves balancing thermal performance, moisture control, and budget.

Making The Right Call For Your Property

For homeowners and builders in South Florida, the best choice really boils down to two things: where is it going, and what is its main job?

Closed-cell foam's ability to act as a complete vapor barrier is a massive advantage in our fight against moisture intrusion and mold. You can learn more about the role of a vapour barrier in insulation. It is hands-down the go-to choice for attics, crawl spaces, and exterior walls where blocking humidity is non-negotiable.

In contrast, open-cell foam gives you fantastic soundproofing for interior walls, home theaters, or quiet office spaces, all at a friendlier price point. It’s a master at filling every tiny crack and crevice to deliver a perfect air seal, but because it lets vapor pass through, you’ll want to keep it to interior applications where it won't be directly exposed to moisture.

How Each Spray Foam Type Really Works

Before you can pick a side in the open-cell vs. closed-cell debate, you have to understand what’s happening on a microscopic level. These two foams are built completely differently, and that core structure dictates everything—from how they handle moisture to whether they can add strength to your walls.

It’s the science here that explains why one acts like a soft, sound-absorbing cushion while the other becomes a rigid, water-blocking shield.

Think of a basic kitchen sponge. It’s full of tiny, interconnected bubbles that let water and air pass right through. That’s the perfect picture of open-cell spray foam. The "cells" are not sealed off from each other, which creates a soft, flexible, and very lightweight material.

Now, imagine a tightly packed bundle of tiny, individual water balloons. That's closed-cell spray foam. Each cell is a completely sealed, distinct pocket filled with a special gas (a blowing agent). This dense, compact structure is precisely what makes the foam rigid, incredibly strong, and completely impermeable to air and water.

The Nitty-Gritty of Open-Cell Foam

The interconnected, air-filled structure gives open-cell foam a very low density, typically around 0.5 pounds per cubic foot. When it’s sprayed, it expands like crazy—often up to 100 times its liquid volume—filling every last crack and cranny in a wall cavity. This massive expansion is what makes it such a fantastic air sealer.

But here’s the trade-off: its open structure is vapor-permeable. It doesn’t stop moisture; it lets water vapor pass through. While that can be a benefit in certain building designs where walls need to "breathe," it’s a non-starter for high-humidity areas like a South Florida attic or crawl space.

The real superpower of open-cell foam is its sound-dampening ability. The soft, spongy texture is brilliant at absorbing sound waves, making it the go-to choice for reducing noise between rooms or muffling outside traffic.

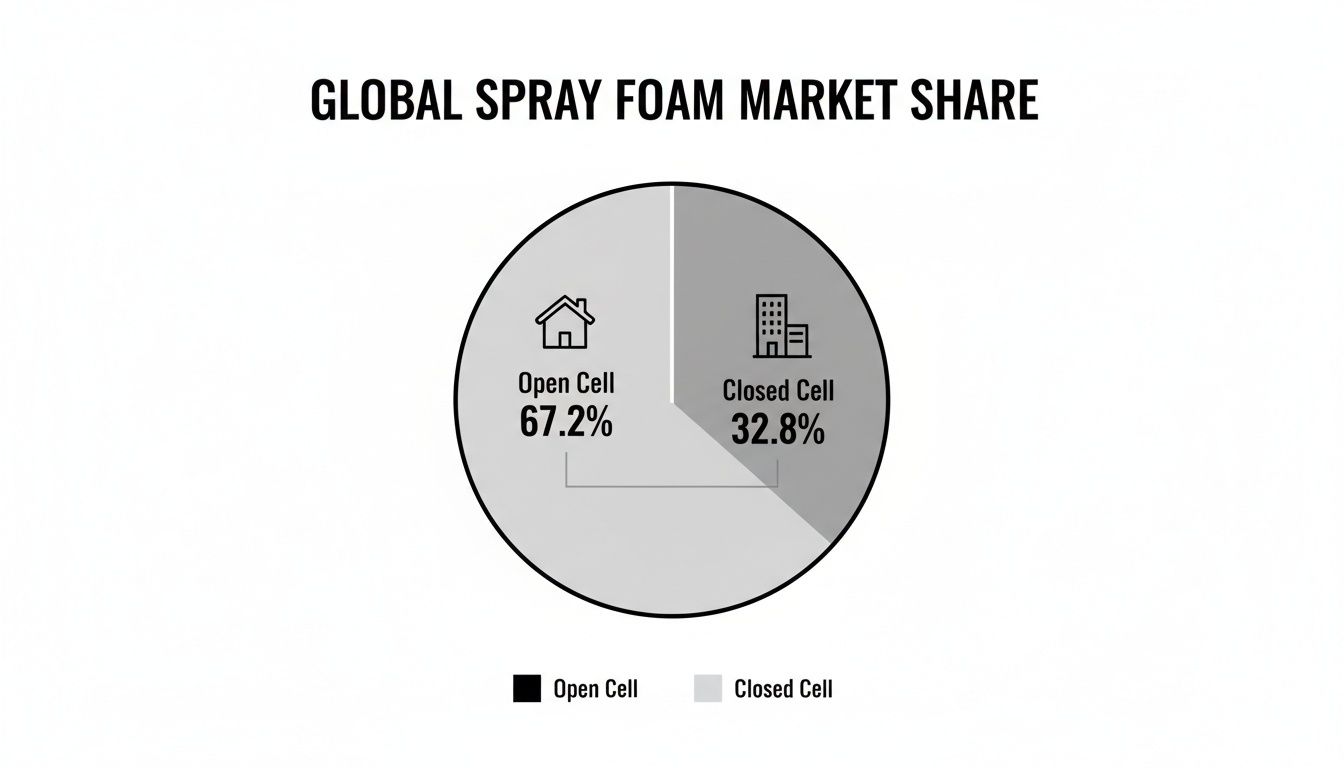

Its lower cost and fantastic air-sealing capabilities have made it a huge player in the insulation world. In fact, open-cell foam dominated the market with a 67.2% revenue share in 2023, largely because it expands to fill gaps so effectively at a lower price point.

The Mechanics of Closed-Cell Foam

Closed-cell foam is a different beast entirely. It has a much higher density—around 2.0 pounds per cubic foot—and its entire performance is built on rigidity and its ability to block everything. The specialized gas trapped inside each sealed cell is a terrible conductor of heat, which gives closed-cell foam its much higher R-value per inch.

This dense, locked-down structure delivers three key benefits:

- Superior Thermal Resistance: You get more insulation power per inch, which is perfect for tight spots where you can't afford to lose space.

- A True Vapor Barrier: It completely blocks water and water vapor, qualifying as a Class II vapor retarder. In our humid climate, this is a game-changer.

- Serious Structural Strength: Once cured, it becomes rock-hard and actually adds significant racking strength to the structure it's applied to, essentially gluing the building together.

Because it doesn't expand nearly as much as open-cell, the application has to be more precise, but the result is a bulletproof barrier against heat, air, and moisture. This difference at the molecular level is what you need to understand to see how each foam performs in the real world. For a deeper look, check out our guide on how spray foam insulation works. Getting this science right is the key to making a smart decision that will protect your property for decades.

A Detailed Comparison of Key Performance Metrics

Once you get past the basic structural differences, the real-world performance gap between closed-cell and open-cell spray foam becomes crystal clear. For any property in South Florida, three things really matter: thermal resistance (R-value), how well it seals up air leaks, and the way it handles our relentless moisture. Looking at these factors side-by-side shows you exactly why one type of foam might be perfect for your attic while the other is a definite non-starter.

This isn't just a technical decision—it directly impacts your FPL bill, your indoor air quality, and the long-term health of your home or building. Getting these key performance indicators right is how you make a choice that pays you back for years.

Thermal Resistance: The R-Value Showdown

The first number everyone asks about is the R-value, which is simply a measure of how well the insulation resists heat trying to flow through it. In this category, the numbers don't lie.

Closed-cell spray foam is the powerhouse here, delivering a seriously high R-6 to R-7 per inch. Its dense structure means you can pack a major thermal punch in a small space. This is a huge win for spots like cathedral ceilings or 2×4 wall cavities where you just don't have a lot of depth to work with.

On the other hand, open-cell spray foam comes in around R-3.5 to R-3.8 per inch. Now, while that’s lower, don’t write it off. R-value is only one piece of the puzzle. Both foams create an incredible air seal, and honestly, that often does more for your energy savings than the R-value alone. You can get a deeper look at the numbers in our complete guide to the R-value of spray foam insulation.

This chart gives you a sense of how the global market is split, which reflects how each foam is used.

You can see that open-cell's lower cost and massive expansion make it a popular pick worldwide, but closed-cell's specialized performance gives it a solid grip on more demanding jobs.

Air Sealing: A Shared Superpower

Here’s where both open-cell and closed-cell are absolute champions. They both function as top-tier air barriers. When the liquid foam is sprayed, it expands and worms its way into every last crack, gap, and pinhole, creating a single, solid seal. This is something traditional insulation like fiberglass batts just can't do. This air-sealing magic is arguably the biggest benefit of spray foam—it stops your expensive cold air from leaking out and our thick, humid air from creeping in.

But there is a subtle difference in how they do it.

- Open-Cell Foam: This stuff expands like crazy (think up to 100 times its liquid size). This makes it fantastic for filling up big, awkward spaces like the cavities between your wall studs. Its soft, spongy texture also means it can flex and move as the building settles over the years without breaking the seal.

- Closed-Cell Foam: It doesn't expand nearly as much, but it cures into a hard, rigid material. This creates an unbelievably tough air seal that also happens to add a bit of structural muscle to whatever surface it’s sprayed on.

In South Florida, a top-notch air seal is completely non-negotiable. It's your number one defense against our crushing humidity and the secret to keeping your AC from running 24/7. Both foams get the job done, but their physical forms make them better suited for different parts of the building.

Moisture and Vapor Behavior: The Critical Differentiator

Okay, now we get to the single most important metric for our climate: how each foam deals with moisture. In this arena, the two are polar opposites, and picking the wrong one can lead to disaster.

Closed-cell spray foam is vapor-impermeable. Think of it as a plastic barrier. Its dense, sealed-cell structure acts as a true vapor barrier, completely shutting down the movement of water and water vapor. This makes it the undisputed champ for any part of a building that gets hit with moisture, including:

- Roof decks and attics

- Crawl spaces

- Exterior walls

- Masonry block walls

By slamming the door on moisture, closed-cell foam stops condensation from ever forming inside your walls or attic—which is what fuels mold, mildew, and wood rot in a place like South Florida.

In stark contrast, open-cell spray foam is vapor-permeable. Its structure is more like a sponge, allowing water vapor to pass right through it. While that can be a good thing in some cold climates where walls need to dry inward, it's a huge liability down here. Spraying open-cell foam directly on a roof deck, for example, is asking for trouble. It would let humidity from your attic pass through and condense on the cooler underside of the plywood, creating a perfect breeding ground for mold.

This table breaks down the key performance differences in a head-to-head comparison.

Performance Breakdown: Closed Cell vs. Open Cell

| Performance Metric | Open Cell Spray Foam | Closed Cell Spray Foam | Why It Matters in South Florida |

|---|---|---|---|

| R-Value (per inch) | R-3.5 – R-3.8 | R-6.0 – R-7.0 | Closed cell provides maximum thermal resistance in limited space, crucial for fighting intense solar heat gain on roofs and walls. |

| Air Permeability | Very Low | Very Low | Both are excellent air barriers, stopping hot, humid air infiltration which is the #1 driver of high cooling costs and moisture issues. |

| Vapor Permeability | High | Very Low (Class II Vapor Retarder) | Closed cell’s ability to block water vapor is critical to prevent condensation, mold, and rot in our humid climate. This is non-negotiable. |

| Structural Strength | Low (Flexible) | High (Rigid) | Closed cell adds significant racking strength to walls and roof decks, providing extra resilience against hurricane-force winds. |

| Water Absorption | High | Very Low | If a roof leak occurs, open cell will act like a sponge, holding water against wood. Closed cell repels bulk water, protecting the structure. |

As you can see, when it comes to the metrics that count most in our hot, humid, and storm-prone environment, closed-cell foam consistently comes out ahead. Its combination of high R-value, structural rigidity, and—most importantly—its ability to block moisture makes it the technically superior product for South Florida homes and buildings.

Where to Use Each Type of Spray Foam in South Florida

This is where the rubber meets the road—turning technical specs into a smart, real-world insulation plan. In South Florida, we’re up against a unique combination of brutal sun, relentless humidity, and the ever-present threat of hurricanes. This isn’t a one-size-fits-all situation. The “spray foam insulation closed cell vs open cell” decision comes down to putting the right product in the right place to get the job done.

Making the right choice means more than just a lower energy bill. It means creating a home or building that’s cooler, tougher, and genuinely more comfortable to be in, day in and day out. Let’s get practical and look at where each type of foam should go.

Where Closed-Cell Spray Foam Is Essential

Any part of your building that directly faces the South Florida elements needs the protection of closed-cell spray foam. It’s the clear winner here. Its high R-value, incredible strength, and—most critically—its ability to completely block moisture make it the go-to for sealing your building envelope.

Here are the non-negotiable spots for closed-cell foam:

-

Attics and Under Roof Decks: This is the front line in your battle with the sun. Applying closed-cell foam directly to the underside of the roof deck stops heat dead in its tracks before it can bake your attic. This creates a semi-conditioned space and takes a massive load off your AC. Plus, its moisture-blocking power protects your roof structure from condensation.

-

Crawl Spaces and Subfloors: A South Florida crawl space is practically an invitation for mold, rot, and pests. Closed-cell foam seals the entire underbelly of your home, forming a tough, waterproof barrier that stops ground moisture from creeping up into your living space. It won’t sag, absorb water, or lose its insulating power.

-

Exterior Walls: For both concrete block and wood-frame homes, applying closed-cell foam to exterior walls is a game-changer. It delivers an airtight seal, top-tier thermal resistance, and adds significant structural integrity—a huge plus when hurricane season rolls around.

Real-World Example: Take a typical metal warehouse or workshop in Jupiter. Those buildings become unbearable ovens in the summer. Spraying closed-cell foam on the interior of the metal walls and roof doesn’t just insulate; it completely stops the condensation “sweating” and actually makes the entire structure more rigid.

The Best Places for Open-Cell Spray Foam

While closed-cell foam armors your home’s shell, open-cell foam is your best bet for interior applications. Its main advantages are sound control and providing a cost-effective air seal in areas where moisture is a non-issue. You never want to use it where it could get wet or be exposed to high humidity.

These are the interior jobs where open-cell truly excels:

-

Interior Walls for Soundproofing: Want to quiet down a home office, nursery, or create a real home theater experience? Open-cell foam is your answer. Its soft, pliable structure is fantastic at absorbing sound waves and stopping noise from traveling between rooms.

-

Between Floors: To kill the sound of footsteps and conversations moving between the first and second floors, applying open-cell foam in the cavity between floor joists is incredibly effective. It completely fills the space, disrupting noise pathways.

By understanding these roles, you can see how a hybrid approach often makes the most sense. Use each foam where it performs best to get a home that’s perfectly optimized for performance, comfort, and budget.

The Bottom Line: Cost and Long-Term Value

Let’s be honest, for any home or building project, the budget is always a driving factor. When you’re looking at spray foam, the initial price tag for open-cell foam often seems more attractive. It’s less dense and expands more, so you need less material to fill a space. But just looking at the upfront quote is a classic case of missing the forest for the trees.

The real financial story isn’t about the initial cost; it’s about the long-term Return on Investment (ROI). This is where the closed-cell vs. open-cell debate gets interesting, shifting from a simple price check to a serious look at lifetime value.

Upfront Cost vs. Long-Term Savings

There’s no getting around it: closed-cell spray foam costs more to install. You can expect it to be anywhere from 30% to 50% more than open-cell for the same area. This is because the material itself is denser and the chemistry behind it is more advanced.

While that higher number might make you pause, you have to connect it back to performance, especially here in South Florida. Closed-cell foam boasts a superior R-value, typically R-6 to R-7 per inch, which gives you incredible thermal resistance. What does that mean for your wallet? It means your AC doesn’t have to battle the brutal sun all day, leading directly to lower energy bills, month after month. Over the life of your home, those savings don’t just offset the higher initial cost—they can blow right past it.

The decision shouldn’t be based on the initial quote alone. It’s an investment in your property’s energy efficiency, structural resilience, and overall comfort—factors that deliver financial returns for decades.

Think about insulating a roof deck. Using closed-cell foam doesn’t just create a powerful thermal break; it also acts as a robust moisture barrier. That dual-action performance prevents incredibly expensive repairs from the rot and mold that can easily take hold when a less moisture-resistant material is used in a high-humidity spot like an attic.

Calculating the Full Return on Investment

Beyond just the numbers on your FPL bill, the true ROI of closed-cell foam includes benefits that are a bit harder to put a price on but are just as real. Its rigid, dense structure actually adds significant racking strength to your walls and roof. In a place like South Florida, where high winds are a fact of life, that extra resilience is invaluable.

Consider these other value-adds:

- Increased Property Value: A well-insulated, durable home is a major selling point. Buyers understand the appeal of lower utility bills and a stronger structure, making your property more attractive on the market.

- Fewer Maintenance Headaches: By keeping moisture out, closed-cell foam helps you avoid the nightmare of structural rot, mold remediation, and other expensive problems that are all too common in our climate.

- Better Quality of Life: This isn’t a direct financial metric, but what’s the value of a comfortable home? Eliminating drafts and hot spots makes your living space more enjoyable every single day.

Ultimately, the right choice boils down to your specific project and how you view the investment. Open-cell foam is a great air sealer and an excellent sound dampener at a lower initial cost, making it a solid pick for interior walls. But for the building envelope—the roof and exterior walls that protect you from the elements—closed-cell foam is the smarter, more robust long-term investment that pays you back in energy savings, structural integrity, and pure peace of mind.

Our Recommendations: Making the Right Call for Your Project

Choosing between open-cell and closed-cell spray foam isn’t just a technical decision—it’s about getting the right performance for the right part of your building. With decades of hands-on experience insulating properties all over South Florida, I’ve seen what works and what doesn’t in our unique climate. The smartest insulation plans often use both types of foam where they make the most sense.

This is more than just picking a product off a shelf. It’s about designing a complete system that keeps you comfortable, slashes your energy bills, and protects your biggest investment for the long haul. Based on what I’ve learned in the field, here’s my advice for homeowners, contractors, and property managers.

Guidance for South Florida Homeowners

As a homeowner, you’re juggling budget, performance, and peace of mind. Your main goal should be creating a tough, resilient building envelope that can handle the punishing heat and humidity we get year-round.

Here’s a simple way to think about it:

- Go with Closed-Cell for Critical Areas: Your roof deck, attic, crawl space, and any exterior walls need to be sealed tight against moisture. For these spots, closed-cell foam is the only way to go. Its ability to act as a vapor barrier is non-negotiable here; it prevents mold and rot while delivering the highest R-value to keep your cooling costs down.

- Use Open-Cell for Interior Comfort: Think about the walls between a loud living room and your home office, or between bedrooms. Open-cell foam is a fantastic, budget-friendly choice for these interior spaces. You get great sound-dampening without paying for the moisture-blocking power of closed-cell where it simply isn’t needed.

Directives for Contractors and Builders

For contractors, your reputation is on the line with every project. Specifying the right insulation means you’re meeting code, boosting the building’s structural integrity, and giving your clients a high-performance home they’ll love.

In South Florida, if you’re doing new construction or a major gut renovation, specifying closed-cell spray foam for the entire building envelope is the gold standard. It doesn’t just crush energy code requirements in less space—it adds serious racking strength to the structure, a massive benefit when you’re building in a hurricane zone.

Keep these points in mind during your planning phase:

- Nailing Building Codes & Energy Targets: The high R-value of closed-cell foam (R-6 to R-7 per inch) makes it easy to hit and even exceed energy efficiency goals, especially when you’re working with standard 2×4 wall cavities.

- Structural and Durability Needs: When you recommend closed-cell foam for roof decks and exterior sheathing, you’re not just insulating. You’re adding structural rigidity and giving the building an extra layer of defense against high winds.

Solutions for Commercial Property Managers

When you’re managing a commercial property, the game changes. Your focus is on operational costs, long-term durability, and keeping your tenants happy. Here, closed-cell foam provides a clear path to maximizing your return on investment and cutting down on maintenance headaches.

For metal buildings and flat commercial roofs, I strongly recommend closed-cell spray foam. Its rigid structure bonds like glue to metal and concrete, creating a single, seamless waterproof membrane. This stops leaks in their tracks and completely eliminates condensation issues.

The result? You dramatically reduce thermal transfer, which lowers your HVAC costs and actually extends the life of the roof itself. It’s an upfront investment that protects your asset and boosts your bottom line for years to come.

Ultimately, the best approach always starts with a professional assessment of your property. That’s the only way to get a truly tailored recommendation that delivers the maximum benefit for your specific situation.

Answering Your Final Questions

Even after you’ve weighed the pros and cons, a few practical questions always seem to pop up. These are the details that often make the difference, especially when you’re thinking about long-term value and performance here in South Florida. Let’s get them answered so you can feel confident in your decision.

Here are the quick, straight-to-the-point answers we give our clients every day.

How Long Does Spray Foam Insulation Last?

Think of it this way: spray foam is a one-and-done solution. Both open-cell and closed-cell are engineered to last for the entire life of your home or building. Unlike fiberglass that can sag, settle, or get compressed over the years, losing its effectiveness, spray foam bonds directly to the structure.

It won’t break down or lose its R-value, meaning it will perform just as well in 80 years as it does on day one. When installed by a pro, it’s a permanent upgrade to your property.

Is One Foam More Eco-Friendly Than The Other?

This is a great question, and the answer isn’t as simple as you might think. Open-cell foam often uses water as its blowing agent, which has a very low Global Warming Potential (GWP). That’s a definite plus. But, its lower R-value could mean your HVAC system works harder over the decades, potentially using more energy.

On the other hand, closed-cell foam has made huge environmental strides. The old formulas used blowing agents called hydrofluorocarbons (HFCs) with a high GWP. Today’s advanced closed-cell foams use next-generation hydrofluoroolefin (HFO) blowing agents, which have an ultra-low GWP. When you factor in the massive energy savings it provides over the life of a building, a modern closed-cell foam often ends up having a smaller overall carbon footprint.

Which Foam Is Easier to Install?

Frankly, neither is a DIY job. Both require certified professionals who understand the chemistry and have the right safety gear. That said, there are differences in the application process.

Open-cell foam expands like crazy—up to 100 times its liquid volume. This makes it great for quickly and completely filling large, unobstructed spaces like attic rafters. Closed-cell expands much less, so we apply it in thinner, more deliberate layers. This takes a bit more precision from the installer to build up to the right thickness and ensure a perfect, airtight seal.

Ready to see how the right spray foam can transform your South Florida property? The team at Airtight Spray Foam Insulation brings over 25 years of hands-on experience to every project, ensuring you get the perfect solution for your needs. Request a free, no-obligation quote today and start your journey toward a more comfortable and energy-efficient home or business.

If you’re in Jupiter, FL and want expert guidance on which foam is best for your home, explore our Spray Foam Insulation in Jupiter page.