Blog

Spray Foam Vs Blown In Insulation a Guide for Florida Homes

When it comes to insulating a home in South Florida, you’re really battling two things: intense heat and oppressive humidity. While both spray foam and blown-in insulation will boost your home’s energy efficiency, spray foam’s ability to create a superior air and moisture seal often makes it the hands-down winner for slashing high cooling costs and keeping mold at bay.

Choosing the Right Insulation for Your Florida Home

Deciding on insulation for your property here isn’t just about R-value. It’s about building a complete thermal envelope that shields your home from our unique climate—relentless sun, thick humidity, and the constant threat of moisture getting in where it shouldn’t.

The contest between spray foam vs. blown-in insulation is really a clash of two different philosophies. One is all about filling empty space, while the other is about sealing that space completely.

Blown-in insulation, usually made of fiberglass or cellulose, is a budget-friendly option that’s blown into attics or wall cavities. It works by trapping tiny pockets of air in its loose fibers, which slows down heat transfer. It’s a solid choice for adding some extra R-value to an existing attic or for projects where the upfront cost is the biggest factor.

Spray foam, on the other hand, is a whole different beast. It acts as both an insulator and an air barrier. When we apply it, the liquid expands to fill every single crack, gap, and crevice, creating a solid, monolithic seal that flat-out stops air leakage. This is a game-changer in Florida, where preventing cool, conditioned air from escaping—and hot, humid air from sneaking in—is the key to HVAC efficiency and real comfort.

In South Florida, an insulation’s power to block air and moisture is just as critical as its R-value. Air leaks can be responsible for a huge chunk of a home’s energy loss, making spray foam’s airtight seal incredibly valuable.

Comparing Insulation at a Glance

To make a smart call, it helps to see how these materials stack up side-by-side on the features that matter most in our climate. This quick-reference table gives you a high-level look at how closed-cell spray foam, open-cell spray foam, and traditional blown-in insulation compare.

Think of this as your cheat sheet. We’ll dig deeper into what these differences mean for your home in the sections that follow.

Quick Comparison of Insulation Types for Florida Climates

| Attribute | Closed-Cell Spray Foam | Open-Cell Spray Foam | Blown-In Insulation |

|---|---|---|---|

| R-Value (per inch) | High (R-6.0 to R-6.5) | Moderate (R-3.5 to R-3.8) | Low to Moderate (R-2.2 to R-3.7) |

| Air Sealing | Excellent (Creates an air barrier) | Excellent (Creates an air barrier) | Poor (Requires separate air sealing) |

| Moisture Resistance | Excellent (Acts as a vapor barrier) | Poor (Vapor permeable) | Poor (Can absorb moisture) |

| Typical Upfront Cost | High | Moderate | Low |

| Best Use in Florida | Unvented attics, metal buildings, crawl spaces | Sound dampening, interior walls | Budget-friendly attic top-ups |

As you can see, the right choice really depends on your specific goals—whether you prioritize budget, moisture control, or the highest possible thermal performance.

Understanding the Different Types of Insulation

Before we get into a head-to-head comparison, it’s important to understand that spray foam and blown-in insulation aren’t just two products on a shelf. They represent completely different philosophies for creating a thermal barrier in your home. One loosely fills cavities with material, while the other creates a solid, monolithic seal.

Blown-in insulation, also called loose-fill, is the more traditional method you’ve likely seen before. It’s made of small chunks of fibrous material, usually fiberglass or cellulose. Installers use a powerful hose to blow these materials across an attic floor or pack them into wall cavities.

The magic behind this method is simple: it traps millions of tiny air pockets within the fibers, which dramatically slows down heat transfer. Think of it as a thick, fluffy blanket for your house. It’s a solid choice for covering large, uniform areas and is often the go-to for adding more insulation on top of what’s already there.

The Chemical Innovation of Spray Foam

Spray foam insulation works on a totally different level. It’s a two-part chemical product that’s applied as a liquid. Almost instantly, it undergoes a chemical reaction, expanding up to 100 times its initial volume to create a solid foam barrier. This rapid expansion is its superpower, letting it fill every single crack, seam, and weirdly shaped gap for a truly continuous, airtight seal.

You’ll hear about two main types:

- Open-Cell Spray Foam: This version has a softer, spongier feel because its microscopic cells aren’t fully closed. It’s a fantastic air sealer and is also great at dampening sound, making it a popular pick for interior walls and media rooms.

- Closed-Cell Spray Foam: This is a much denser and more rigid material. Its cells are completely sealed and filled with a special gas that gives it a higher R-value per inch. It’s incredibly strong and acts as a vapor barrier, which is a massive advantage in our humid South Florida climate.

The core difference isn’t just the material, but the function. Blown-in insulation fills a space, but spray foam seals it, acting as an all-in-one insulator and air barrier.

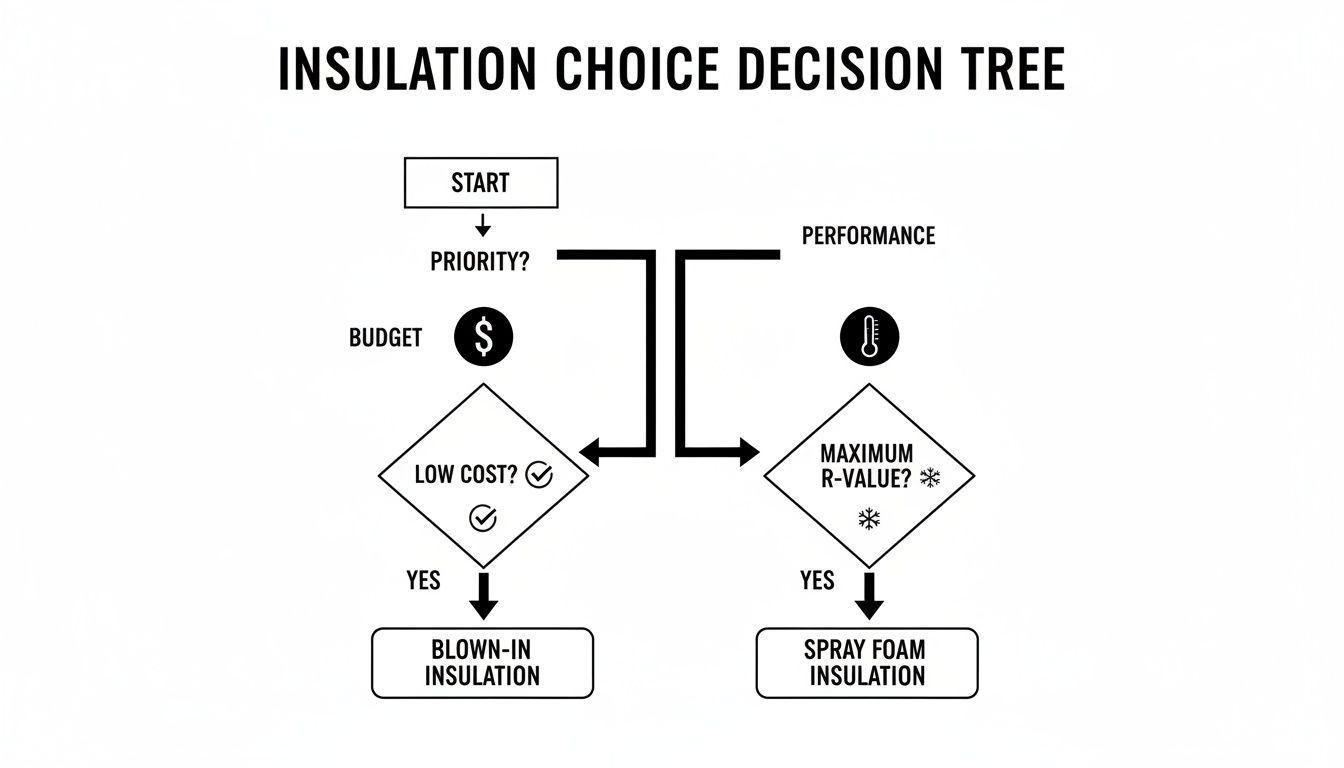

This decision tree helps simplify the choice by getting straight to the point: are you prioritizing budget or peak performance?

As you can see, your end goal points you directly to the right solution for your specific project.

The demand for this sealing technology has exploded, largely thanks to stricter energy codes and a growing focus on high-performance buildings. The global spray foam market is now valued at over $2.0 billion, with North America driving much of that growth. Here in the U.S., the market was pegged at around $750 million in 2024, a testament to spray foam’s unmatched ability to air-seal complex structures and slash energy waste.

Grasping these fundamental differences is the first step. You can dig deeper into the specific benefits of different spray foam insulation applications in our other guides. Now, let’s build on this foundation and see how these materials really stack up against each other in real-world Florida conditions.

Comparing R-Value and Air Sealing Performance

When you get into the spray foam vs. blown-in insulation debate, the first thing everyone brings up is R-value—that number that measures how well a material resists heat flow. On paper, it looks like a simple numbers game. But here in South Florida, judging insulation on R-value alone is like judging a car’s performance by its horsepower. You’re missing the most critical part of the story: air sealing.

Blown-in insulation does a respectable job slowing down heat transfer. But at the end of the day, it’s just loose material piled high. It does nothing to stop air from moving right through it or around it. That’s a huge weak point in our climate, where hot, humid air is always looking for a way into your cool, air-conditioned home through thousands of tiny gaps.

This is where spray foam insulation completely changes the game. It’s not just an insulator; it’s an all-in-one insulation and air barrier. As it’s applied, it expands to fill every single crack, crevice, and penetration, creating a solid, monolithic seal that air just can’t get through.

R-Value Per Inch: A Closer Look

Looking at the numbers, you can see a clear difference in the insulating power you get for every inch of material.

- Closed-Cell Spray Foam: This is the undisputed champion, delivering an impressive R-6.0 to R-6.5 per inch. Its dense, rigid structure packs the most insulating power into the least amount of space.

- Open-Cell Spray Foam: A lighter, more flexible foam that still offers a solid R-3.5 to R-3.8 per inch.

- Blown-In Insulation: This category, which includes fiberglass and cellulose, typically provides R-2.2 to R-3.7 per inch, depending on the specific material and how densely it’s packed.

But these raw numbers don’t tell the whole story of real-world performance. While closed-cell spray foam clearly has the highest R-values, its true advantage comes from its air-sealing properties. By stopping air leakage, its overall impact on a building’s energy efficiency is massive, with studies showing it can cut heating and cooling loads by 10–30% in homes where air leakage is the main problem. You can find more insights about these market performance analyses and their findings.

Air Sealing: The Real Performance Multiplier

In Florida, air leakage is the #1 enemy of an efficient home. It’s what forces your HVAC system to work overtime, trying to cool down the hot, humid air that’s constantly sneaking into your living space. This is where the true value of spray foam becomes undeniable.

An attic with a code-required R-38 of blown-in insulation can still perform worse than an attic with a lower R-20 of spray foam if it’s not properly air-sealed. The spray foam creates a perfect air barrier, stopping energy loss at its source, while the blown-in material allows air to move freely through hidden gaps.

Think of your attic like a boat. Blown-in insulation is like filling that boat with sponges—they’ll absorb some water, but they won’t stop the leaks. Spray foam, on the other hand, is like patching every single hole in the hull. It doesn’t just manage the problem; it eliminates it.

A Tale of Two Attics

Let’s walk through a practical South Florida scenario to really see the difference.

Scenario 1: The Blown-In Attic

A homeowner has R-38 of blown-in fiberglass on their attic floor, which meets local building code. But the attic is still riddled with small air leaks around recessed lights, plumbing vents, and the attic hatch. On a hot August afternoon, that humid attic air seeps down into the living space, forcing the AC to run nonstop. The homeowner is stuck with high energy bills and rooms that never feel quite cool enough, all while having “enough” insulation.

Scenario 2: The Spray Foam Attic

A neighbor decides to insulate their unvented attic by applying closed-cell spray foam directly to the roof deck. Even with a slightly lower R-value on paper, the spray foam creates a complete, airtight seal. This stops the superheated attic air from ever forming in the first place and prevents any air from getting in or out. The result? A much lower cooling load, a longer life for their HVAC unit, and a home that stays consistently comfortable.

This comparison makes it clear: effective air sealing isn’t just a bonus feature—it’s the heart of high-performance insulation in our climate. While blown-in insulation can be a decent budget option, it needs a lot of extra, meticulous air-sealing work to even come close to the performance that spray foam delivers right out of the box.

Analyzing Moisture and Humidity Control

In South Florida, insulation isn’t just about temperature; it’s about waging a constant war against humidity. The relentless moisture in our air can infiltrate building materials, leading to mold, rot, and a serious hit to your indoor air quality. When you stack spray foam against blown-in insulation, how they handle moisture is a critical difference—one with long-term consequences for your property’s health and durability.

Blown-in insulation, whether it’s fiberglass or cellulose, essentially acts like a sponge. These fibrous materials will absorb and hold onto moisture, either from the humid air or a small roof leak. Once it gets damp, blown-in insulation loses a huge chunk of its R-value, making it far less effective. Even worse, that trapped moisture creates the perfect breeding ground for mold and mildew, which can spread quietly in an attic or wall cavity.

Spray foam insulation brings a completely different game plan to the table. For our climate, closed-cell foam is nothing short of a game-changer for moisture management.

The Vapor Barrier Advantage of Closed-Cell Foam

Closed-cell spray foam is non-permeable. That means water and water vapor just can’t pass through it. Its tightly packed, sealed cellular structure makes it an incredibly effective vapor barrier. When we spray it in, it creates a solid, seamless, and waterproof layer of protection.

This is a massive advantage here in South Florida for a few key reasons:

- It Blocks Humidity: It literally stops humid outdoor air from working its way through your building envelope. This takes a huge load off your HVAC system, which no longer has to fight so hard to dehumidify your home.

- It Prevents Condensation: It helps stop condensation from forming inside your walls or attic, a common source of hidden moisture damage.

- It Adds Resilience: Think of it as an extra layer of water resistance for your structure. During our intense rainstorms, that can be a lifesaver.

Open-cell spray foam, on the other hand, is vapor-permeable, so it does let moisture pass through. While it won’t trap water like blown-in fibers, it doesn’t provide that same bulletproof barrier as its closed-cell cousin.

A Real-World Leak Scenario

To really see the difference, just picture a small, slow roof leak starting over your attic. How each insulation type reacts tells you everything you need to know about its long-term value.

Scenario A: Blown-In Insulation

The dripping water slowly soaks into the fiberglass or cellulose. The material gets heavy, compresses, and loses its insulating power. Because it’s holding all that moisture right up against the wood framing and drywall, it accelerates rot and feeds mold growth. You could be looking at costly structural repairs and remediation long before you even know you have a leak.

Scenario B: Closed-Cell Spray Foam

The water hits the rigid surface of the closed-cell foam and stops dead. It can’t get through. Instead, the water is forced to run down the surface of the foam, which actually makes the leak much easier to spot from below. The foam itself is completely unaffected, its R-value is intact, and it’s actively shielding the wood and ceiling from water damage.

Closed-cell spray foam doesn’t just insulate; it actively defends your home’s structure against water intrusion. It turns a potential disaster into a manageable repair by preventing moisture from ever reaching vulnerable building materials.

This resilience makes closed-cell spray foam the superior choice for unvented attics, crawl spaces, and any other spot where moisture is a constant threat. While blown-in insulation might have an attractive upfront cost, its vulnerability to our humidity can lead to far bigger expenses down the road, from mold remediation to replacing compromised materials. For any Florida property owner, picking an insulation that doubles as a moisture barrier isn’t just an upgrade—it’s essential protection.

Let’s be honest: when people compare spray foam to blown-in insulation, the first thing they look at is the price tag. And yes, blown-in is definitely easier on the wallet upfront. But if you stop the conversation there, you’re missing the bigger picture—the total cost of ownership and the real, long-term return on your investment.

To make the right call for your South Florida property, you have to look beyond the initial quote.

Blown-in insulation has a lower material and labor cost, which makes it a very common choice for homeowners trying to save cash or for contractors on a tight budget. It’s a straightforward way to meet building code requirements without a major financial commitment.

But the higher initial cost of spray foam isn’t just for a different material; it’s an investment in a permanent, high-performance system. Its ability to create a flawless air and moisture seal means it starts paying for itself immediately through drastically lower energy bills.

Understanding the Price Spectrum

The initial cost for insulation can swing quite a bit depending on the material, how complex the job is, and the total square footage. Here’s a rough idea of what to expect:

- Blown-In Insulation: You’ll typically see prices from $0.40 to $2.50 per square foot. Its low starting price makes it the go-to for big, open attics or for adding a fresh layer over old insulation.

- Open-Cell Spray Foam: This usually runs between $0.55 and $2.50 per square foot. It’s a great middle-ground option that gives you fantastic air sealing and soundproofing.

- Closed-Cell Spray Foam: As the top-tier choice, closed-cell costs anywhere from $0.75 to $4.50 per square foot. You’re paying for its best-in-class R-value, structural strength, and the fact that it acts as its own vapor barrier.

While these numbers are a decent starting point, they don’t tell the whole story. The money you save upfront with blown-in insulation can get eaten up pretty quickly by higher FPL bills, especially during our brutal South Florida summers.

Calculating the True Return on Investment

The ROI on insulation is about much more than just knocking a few bucks off your monthly bills. It’s a combination of energy savings, the lifespan of your HVAC system, and even your property’s value.

Spray foam’s airtight seal takes a massive load off your air conditioner. When your HVAC unit doesn’t have to fight so hard to keep the house cool, you’re not just saving on electricity—you’re extending the life of one of the most expensive appliances in your home. Fewer repairs and pushing back a full system replacement can save you thousands over the years.

While blown-in insulation can cut energy bills by up to 25%, the complete air seal from spray foam can slash energy use by as much as 40%. That difference is where spray foam’s long-term ROI really shines.

On top of that, a home with high-performance spray foam is a major selling point. Here in South Florida, where buyers are always worried about high utility costs, an energy-efficient home with a documented air seal gets noticed. This can lead to a higher resale value and a quicker sale, turning your investment into a smart financial move.

And when you consider its 50+ year lifespan with virtually no maintenance, spray foam often ends up being the more cost-effective choice over the long haul.

Finding the Right Insulation for the Right Job

When it comes to insulation, there’s no single “best” product—it’s all about picking the right tool for the job. The real question is which material is superior for a specific application in your South Florida home.

Spray foam and blown-in insulation each have their own sweet spots. Aligning the right product with the right part of your building is the secret to unlocking maximum performance, comfort, and a solid return on your investment.

Where Closed-Cell Spray Foam Is Unbeatable

For the most demanding areas of a home—places where moisture control, air sealing, and structural integrity are non-negotiable—closed-cell spray foam is in a league of its own. It’s a powerhouse product that delivers a high R-value, incredible rigidity, and a true moisture barrier all in one shot.

The tough, dense nature of closed-cell foam makes it an all-in-one fix for problem areas. It doesn’t just insulate; it seals gaps and strengthens the structure at the same time.

- Unvented Attics and Roof Decks: Applying closed-cell foam directly to the underside of your roof deck is the key to creating an unvented, conditioned attic. This move stops that brutal, superheated air from ever forming, seals every crack against air and water, and even adds structural muscle to your roof—a huge plus during hurricane season.

- Crawl Spaces: In our damp, humid crawl spaces, closed-cell foam is a total game-changer. It creates a bulletproof vapor barrier that locks out ground moisture, preventing it from wicking up into your home and fueling mold, wood rot, and pest problems.

- Metal Buildings and Workshops: If you’ve ever been in a metal building in the Florida summer, you know they sweat. Closed-cell foam sticks directly to the metal panels, killing condensation and creating a powerful thermal break that tames those wild temperature swings.

- Concrete Block Walls: Thanks to its vapor-blocking power, closed-cell foam is also a phenomenal solution for insulating concrete block walls. You can dive deeper into the insulation value of concrete block and see how spray foam transforms it in our dedicated guide.

Smart Uses for Open-Cell and Blown-In

While closed-cell handles the heavy lifting, open-cell foam and blown-in insulation have their own ideal uses, especially when budget or specific goals like sound control come into play.

Open-cell spray foam, with its softer, sponge-like texture, is a fantastic choice for interior walls. It’s an excellent sound dampener, perfect for reducing noise between rooms, in a home office, or for a home theater. It also provides a great air seal at a lower price point than its closed-cell counterpart.

Blown-in insulation really shines in two specific scenarios: topping up old, settled attic insulation or insulating walls in new construction where budget is the absolute top priority. It’s a quick, cost-effective way to pile on R-value across a big, open attic floor.

But here’s the catch. For blown-in to work properly in new walls, it demands a completely separate, painstaking air-sealing process to patch up all the gaps that spray foam seals automatically. For most retrofits and high-performance builds in our climate, the spray foam vs. blown-in insulation matchup clearly favors foam’s all-in-one approach to sealing and insulating.

Answering Common Insulation Questions

Even after comparing spray foam vs. blown-in insulation, you probably still have a few questions. That’s normal. Let’s tackle some of the most common concerns we hear from South Florida homeowners and contractors.

Is Spray Foam Insulation Safe for My Family?

Absolutely, once it’s professionally installed and fully cured. During the job itself, our trained installers wear full personal protective equipment (PPE) and use powerful ventilation to manage any off-gassing. This is a crucial step that professionals never skip.

After about 24 to 48 hours, the foam becomes a completely inert, stable plastic. It stops releasing fumes and is 100% safe for your family to be around. Many of the high-performance formulas we use today even incorporate recycled and renewable materials to lessen their environmental impact.

Can I Install Insulation Myself to Save Money?

While you can find blown-in insulation kits at the hardware store for the ambitious DIYer, it’s a lot harder than it looks. Getting the right depth and density is key to its performance, and it’s easy to end up with subpar results that don’t actually save you money on your FPL bill.

Spray foam, on the other hand, is strictly a job for certified professionals. It demands expensive, specialized equipment, precise control over material temperatures and pressure, and serious safety training. A bad application won’t just perform poorly—it can create real health hazards. This is one job that is absolutely non-negotiable for professional installation.

The safety and performance of spray foam are directly tied to the quality of the installation. Always entrust the job to a certified and experienced team to ensure it’s done correctly and safely from start to finish.

How Does Insulation Affect Home Resale Value?

High-performance insulation is a huge selling point, especially here in South Florida, where everyone is worried about cooling costs. When a potential buyer sees a home insulated with spray foam, it signals top-tier energy efficiency, comfort, and durability.

Being able to document that your home has an air-sealed thermal envelope makes it stand out in a crowded market. It gives you a real justification for a higher valuation and catches the eye of smart buyers who want a home that’s built to last and is cheap to keep cool.

Finally, while both insulation types help muffle sound, spray foam’s dense, gap-filling nature provides truly exceptional noise reduction. You can learn more about how to use insulation as a sound barrier to create a quieter, more peaceful home. It’s just another valuable feature that adds to your property’s overall appeal.

Ready to upgrade your property with high-performance insulation that delivers lasting comfort and energy savings? The experts at Airtight Spray Foam Insulation provide professional installation and tailored solutions for homeowners and contractors across South Florida.

Homeowners in Jupiter, FL can learn more about our spray foam insulation services designed to improve comfort, control moisture, and increase energy efficiency in South Florida homes.