Blog

Spray Foam vs Blown In Insulation A Homeowner’s Guide

Deciding between spray foam and blown-in insulation usually boils down to a simple trade-off: upfront investment versus long-term performance.

Closed-cell spray foam gives you a much higher R-value and creates an airtight moisture barrier, making it the heavyweight champion for our humid South Florida climate. On the other hand, blown-in insulation is a solid, budget-friendly thermal upgrade, especially for topping off existing attics. The right choice really depends on whether you’re prioritizing maximum, all-in-one efficiency or immediate cost-effectiveness.

Key Differences Spray Foam vs Blown In Insulation

When you’re looking at spray foam versus blown-in insulation, you have to see beyond the price tag and understand how each material actually performs inside your home. This decision doesn’t just affect your FPL bill; it impacts your home’s air quality, its structural integrity, and how well it stands up to moisture—a battle we fight every day here in South Florida.

Spray foam insulation starts as a liquid that expands on contact, creating a solid, seamless barrier. This is its superpower. It gets into every tiny crack and crevice, stopping air leakage cold.

Blown-in insulation is made of loose fibers—usually fiberglass or cellulose—that are blown into cavities. It settles around obstacles to create a thick, fluffy blanket. While it does a good job slowing down heat transfer, it simply doesn’t create that same impenetrable air seal.

Getting a handle on these basic differences is the first step. To make the right call for your home, you need a clear, side-by-side comparison of what each one brings to the table.

Quick Comparison Spray Foam vs Blown In Insulation

Here’s a quick-glance table to help you see the main distinctions between these two common insulation types.

| Feature | Spray Foam (Closed-Cell) | Blown-In Insulation (Fiberglass/Cellulose) |

|---|---|---|

| R-Value per Inch | R-6 to R-7 (Highest thermal resistance) | R-2.2 to R-3.8 (Good thermal resistance) |

| Air Sealing | Excellent. Creates a true air barrier. | Poor. Requires separate air sealing measures. |

| Moisture Barrier | Excellent. Acts as a vapor retarder. | Limited. Can absorb and hold moisture. |

| Installation | Professional installation is required. | Can be a DIY project but professional is best. |

| Upfront Cost | Higher initial investment. | Lower initial investment. |

| Lifespan | 80+ years. Rigid and does not settle. | 15-30 years. Can settle or compact over time. |

This table makes it clear that spray foam is more than just insulation; it’s a complete building envelope solution that air-seals and protects against moisture, all in one shot. This all-in-one approach is the foundation of a truly comfortable and efficient home.

To see how these elements work together as part of a complete home performance strategy, check out the principles behind the Airtight Comfort System. In the next sections, we’ll dive deeper into each of these features to give you the context you need for your project.

R-Value, Air Sealing, and Moisture Control: The Real Performance Metrics

When you’re comparing spray foam to blown-in insulation, performance is everything. Forget the marketing fluff—what matters is how a material actually performs inside your attic or walls to fight our intense South Florida heat, relentless humidity, and costly air leaks. The true test of any insulation is its real-world ability to keep your home comfortable and your FPL bills from spiraling out of control.

It’s About More Than Just R-Value

R-value is the industry standard for measuring thermal resistance, or how well an insulation stops heat from moving through it. It’s a good starting point, but the numbers on a spec sheet only tell you half the story.

Closed-cell spray foam is a powerhouse, delivering an impressive R-value between R-6 and R-7 per inch. Its high-density structure means you get a much stronger thermal break in the same amount of space compared to other materials.

On the other hand, blown-in insulation (both fiberglass and cellulose) typically comes in between R-2.2 and R-3.8 per inch. It’s effective at slowing down heat, but you need almost double the depth to get the same raw insulating power as closed-cell foam.

The superior performance of spray foam isn’t just a local observation; it’s a global trend. For the same installed thickness, closed-cell foam can deliver 40–100% more R-value than many blown-in products. It’s no wonder the market is expected to surpass USD 3 billion by 2025. You can read more about the growth of spray foam insulation.

This R-value gap is a huge deal here in South Florida, where the sun relentlessly hammers your roof all year. A higher R-value means less of that brutal heat radiates down into your attic and living space, giving your AC a much-needed break.

Air Sealing: The Ultimate Performance Differentiator

This is where the debate between spray foam and blown-in gets really one-sided. An insulation’s R-value means very little if your expensive, conditioned air is just escaping through thousands of tiny gaps, cracks, and penetrations in your home’s structure.

Spray foam creates a seamless, monolithic air barrier. When applied, the liquid expands on contact, filling every single crevice, joint, and hole. It doesn’t just insulate; it completely seals the building envelope in one shot. This stops cool air from leaking out and, just as importantly, prevents hot, humid outdoor air from forcing its way in.

Blown-in insulation, by its very nature, is a loose-fill material that simply can’t stop air movement. It settles around joists and pipes, but it leaves countless microscopic pathways for air to pass right through. It slows heat, yes, but it does nothing to prevent air leakage on its own. To get a similar effect, you’d have to spend a ton of extra time and money meticulously air-sealing every single gap before the insulation is even installed.

Spray foam is fundamentally a two-in-one solution: insulation and air barrier. This dual function is the number one reason homeowners see such dramatic energy savings. And while its thermal performance is top-notch, spray foam’s ability to seal gaps also makes it a fantastic soundproofer. You can learn more about how insulation can serve as a sound barrier in our detailed guide on the topic.

Moisture Control in Our Humid Climate

Managing moisture isn’t just a “nice to have” in South Florida—it’s non-negotiable. The wrong insulation can trap humidity, which is a recipe for mold, mildew, and wood rot.

- Closed-Cell Spray Foam: This stuff is a true vapor barrier. Its dense, rigid structure is completely impermeable to both water and water vapor, blocking moisture from passing through. This makes it the go-to choice for areas with high moisture risk, like crawl spaces, concrete block walls, and the underside of roof decks.

- Open-Cell Spray Foam: Unlike its closed-cell cousin, open-cell foam is vapor-permeable. This means it allows moisture to pass through it, which lets the building materials around it breathe and dry out if they get wet. This is a big advantage in certain wall assemblies, but it requires a smart, system-wide approach to moisture management.

- Blown-In Insulation: Herein lies a major risk. Both fiberglass and cellulose act like sponges, readily absorbing and holding onto moisture. If you get a small roof leak or your attic humidity isn’t controlled, blown-in insulation can become saturated. Once wet, it loses its R-value, clumps together, and creates the perfect breeding ground for mold.

Understanding the Installation Process and Project Impact

The type of insulation you pick does more than just affect your power bill; it completely shapes the installation experience. The process for putting in spray foam versus blowing in loose-fill insulation couldn’t be more different, and each one has a real impact on your home, your schedule, and your day-to-day life while the work is being done. Knowing what to expect on-site is key to making the right call.

At their core, the two methods are worlds apart. One is a meticulous chemical application that creates a solid barrier, while the other is a mechanical process of distributing loose material. You’ll feel that difference in everything from prep work and project time to how much your household is disrupted.

The Spray Foam Installation Experience

Installing spray foam isn’t a weekend DIY project—it’s a precise, technical job for certified pros with specialized equipment. The chemical nature of the materials and the need for exact mixing ratios mean you absolutely need an experienced crew to ensure it’s done safely and performs correctly.

The whole thing kicks off with serious prep work. Our technicians meticulously mask and cover every surface that isn’t being insulated—windows, floors, furniture, you name it. We do this to protect everything from overspray, because once that foam hits a surface, it’s there for good.

Next, we set up powerful ventilation systems to handle fumes while we spray. Our crew gears up in full personal protective equipment (PPE), including respirators and hazmat suits, because the chemical components release volatile organic compounds (VOCs) before they cure.

A critical part of the spray foam process is the curing period. The home must be vacated by all occupants and pets, typically for a minimum of 24 hours. This allows the foam to fully harden and the off-gassing to dissipate completely. This safety step is non-negotiable and requires a bit of planning on your part.

Cleanup involves carefully removing all the protective coverings and making sure the work area is spotless. Because of the detailed prep and the mandatory curing time, a spray foam job is going to take longer than a blown-in installation.

The Blown-In Insulation Method

In contrast, installing blown-in insulation is a much faster and far less intrusive job. It’s a mechanical process, not a chemical one, which makes the whole project simpler and quicker from start to finish.

Here’s what you can expect:

- Minimal Preparation: The crew just needs clear access to the attic or wall cavities. There’s no need to spend hours masking off your home.

- Quick Application: We run a large hose from a truck-mounted hopper filled with loose-fill fiberglass or cellulose. A technician directs the hose, blowing the material into place until we hit the perfect depth for the R-value you need.

- No Curing Time: Since there’s no chemical reaction, there’s no off-gassing or waiting period. You don’t have to leave your home, and the area is safe the moment we’re done.

- Simple Cleanup: The process can create some dust, but cleanup is quick and usually confined to the immediate work area. We can often insulate an entire attic in just a few hours.

This huge difference in project impact makes blown-in insulation a great choice for homeowners who want a fast, low-disruption upgrade. But for those who are after the superior, all-in-one performance of spray foam—the air sealing, moisture barrier, and high R-value—the more involved installation and temporary move-out are a worthwhile trade-off for decades of performance.

Analyzing the True Cost and Return on Investment

When you’re weighing spray foam vs. blown-in insulation, the quote you get is just the starting line, not the finish line. Blown-in insulation almost always has a lower upfront cost, but a real-world analysis means looking at the return on investment (ROI) you’ll get over the entire life of your home. It’s the classic standoff: initial expense versus lifetime value.

The higher price of spray foam isn’t arbitrary. It’s a mix of complex chemical components, specialized high-pressure equipment, and the need for certified professionals who know how to apply it safely and correctly. That combination of advanced material science and skilled labor naturally costs more than the relatively simple and quick installation of blown-in products.

But looking at that initial cost in a vacuum is a huge mistake. The real financial story unfolds when you start looking at the returns.

Modeling Long-Term Energy Savings

The single biggest ROI driver for any insulation is how much it cuts your monthly power bill. This is where spray foam really pulls ahead, especially in South Florida’s brutal climate.

- The Power of an Air Seal: Spray foam’s biggest financial superpower is its ability to create a nearly perfect air seal. By stopping your expensive conditioned air from leaking out—and keeping hot, humid air from sneaking in—it can slash your HVAC runtime by up to 40% or even more.

- More R-Value Per Inch: Closed-cell spray foam packs more insulating punch into less space, delivering an R-value of R-6 to R-7 per inch. This means less heat getting through your roof and walls, which translates directly into lower cooling costs every single month.

Blown-in insulation does a decent job of slowing down heat transfer, but it does absolutely nothing to stop air leaks. That means even with a thick blanket of insulation, your home is still losing energy through countless tiny gaps. You’ll definitely see savings with blown-in, but they’re typically more modest—often in the 15-25% range—and you’ll need to pay for separate air-sealing work to get the most out of it.

Beyond the FPL Bill: Other Ways Spray Foam Adds Value

The financial perks of spray foam go way beyond just a lower utility bill. Its physical properties add real, tangible value to your home in ways loose-fill materials just can’t match.

One of the biggest is structural strength. When closed-cell spray foam hardens on the underside of your roof deck, it basically glues the sheathing to your trusses. This added rigidity can seriously increase your roof’s resistance to uplift during a hurricane—a massive plus for any property in South Florida.

Think of spray foam not just as insulation, but as a long-term investment in your home’s resilience, energy performance, and health. Blown-in gives you a quick payback on thermal performance, while spray foam provides a deeper, multi-layered return that protects and strengthens your entire home.

That structural boost might even help you qualify for home insurance discounts, adding another financial win. On top of that, its ability to block moisture saves you from the potentially massive costs of mold remediation and wood rot repairs—expenses that can easily make the initial cost difference between the two insulation types look tiny.

A Look at Market Trends and What Contractors are Choosing

You can see the growing demand for high-performance building solutions in the market data. The U.S. spray foam market is valued at around USD 750 million in 2024 and is expected to hit about USD 1.01 billion by 2030. At the same time, blown-in fiberglass and cellulose are often quoted as being 20–60% cheaper for a standard attic job. You can dig deeper into these market dynamics and forecasts.

This tells us something important about how pros make decisions. Contractors often recommend blown-in insulation for straightforward thermal upgrades where air sealing is being handled separately. But they’ll specify spray foam when the job requires one product to be the insulation, the air barrier, and the moisture barrier all at once.

Let’s break down the dollars and cents.

Cost and ROI Breakdown: Spray Foam vs. Blown-In

While the upfront numbers tell part of the story, the long-term value is where the real comparison lies. This table puts the financial metrics side-by-side to help you see the bigger picture.

| Financial Metric | Spray Foam (Closed-Cell) | Blown-In Insulation | Notes for Homeowners |

|---|---|---|---|

| Upfront Cost (per sq. ft.) | $1.50 – $4.50+ | $1.00 – $2.50 | Spray foam requires specialized labor and equipment, driving up initial costs. |

| Typical Energy Savings | 25% – 40%+ | 15% – 25% | The air-sealing properties of spray foam are the primary driver of higher savings. |

| Payback Period | 5 – 10 Years | 3 – 7 Years | Blown-in pays for itself faster due to lower initial investment. |

| Structural Reinforcement | Yes (Significant) | No | Adds hurricane resistance, a major value-add in South Florida. |

| Moisture Barrier | Yes (Vapor Impermeable) | No | Prevents costly mold and rot repairs, a common issue in our humid climate. |

| Lifespan / Durability | 50+ Years | 15-30 Years (can settle) | Spray foam is a one-and-done solution; blown-in may require “topping off.” |

| Added Home Value | Higher | Moderate | High-performance features are attractive to buyers focused on efficiency and resilience. |

Ultimately, the best choice really comes down to your priorities. Blown-in insulation offers a faster and more affordable return on improving thermal performance. Spray foam requires a larger investment upfront but pays you back for decades with superior energy savings, stronger structural integrity, and unbeatable moisture protection.

Matching the Insulation to the Application

The debate over spray foam versus blown-in insulation isn’t about which one is universally “better.” It’s about which one is the right tool for the job. You wouldn’t use a hammer to drive a screw, and the same logic applies here. The best choice depends entirely on what you’re trying to accomplish, from sealing a humid crawl space to simply topping up an attic.

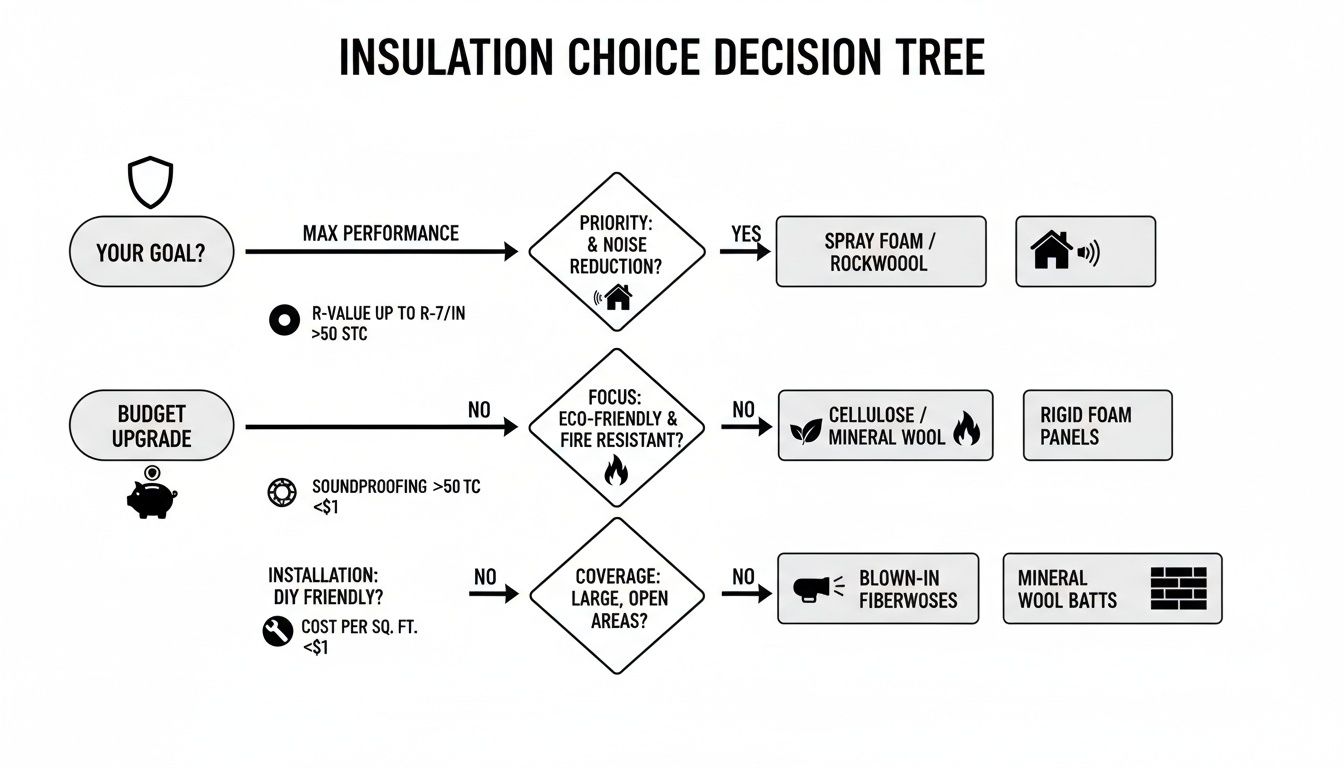

Making the right match means you get the performance you paid for without overspending on features you don’t need. This decision tree is a great starting point for figuring out where your project lands.

As the guide shows, if your project demands an all-in-one air, moisture, and thermal barrier, spray foam is the clear answer. But if you’re focused on a cost-effective R-value boost, blown-in solutions are probably your best bet.

When Spray Foam is the Clear Winner

Spray foam’s ability to create a seamless, airtight, and moisture-proof barrier makes it the undisputed champion for critical areas of a home—especially here in South Florida.

- Unvented (Sealed) Attics: This is the number one reason we use closed-cell spray foam. By applying it directly to the underside of the roof deck, we turn the attic into a conditioned or semi-conditioned space. This is a game-changer for any home with HVAC equipment or ductwork in the attic, as it brings those components inside the building envelope, drastically cutting energy loss and making your AC system work smarter, not harder.

- Crawl Spaces and Subfloors: The damp, musty environment of a typical Florida crawl space is a breeding ground for mold and pests. Closed-cell spray foam completely seals out ground moisture and humid air, protecting your subfloor from rot and improving the air quality for the entire home.

- Concrete Block Walls: Our region’s standard concrete block (CBS) construction is notoriously porous. Moisture wicks right through it. Spray foam is the only product that both insulates and creates a true vapor barrier in a single step. Understanding the proper insulation value for concrete block walls is key to keeping a home dry and comfortable for the long haul.

In these situations, the higher upfront cost of spray foam is more than justified. It’s not just insulation; it’s a complete solution that tackles thermal performance, air leaks, and moisture intrusion all at once.

For any job where stopping air and moisture is just as important as stopping heat, spray foam is the most effective long-term solution. It stops being just an insulation product and becomes a critical part of the building’s high-performance envelope.

Where Blown-In Insulation Shines

Blown-in insulation is still a fantastic and practical choice, mainly because it’s so cost-effective and easy to install in the right places. It really excels when a simple thermal upgrade is the only goal.

The most common and effective use for blown-in insulation is in a traditional vented attic. If your only goal is to increase the R-value over your ceiling, blowing a deep blanket of fiberglass or cellulose is an incredibly efficient and affordable way to do it. It’s the perfect fix for “topping up” old, compressed insulation to meet today’s energy codes.

It’s also a go-to for filling empty wall cavities in new construction. In these scenarios, the builder typically uses a separate air and vapor barrier on the exterior sheathing, so the insulation’s only job is to provide thermal resistance. It’s fast, low-cost, and keeps the construction budget in line without sacrificing basic thermal performance.

Ultimately, blown-in is the workhorse for straightforward, large-area insulation jobs where air and moisture control are already being handled by other parts of the building assembly.

Making Your Final Decision

So, how do you choose? When it comes down to spray foam versus blown-in insulation, the right answer really depends on your main goals, the specific problems your home is facing, and what you’re willing to invest for long-term results. This isn’t just about picking the highest R-value; it’s about matching a complete insulation system to your property’s needs here in South Florida.

The best place to start is with one simple question: are you looking for the absolute best performance money can buy, or are you focused on a smart, cost-effective thermal upgrade? Your answer will almost always point you in the right direction.

Maximum Performance vs. a Sensible Budget

If your top priority is achieving the absolute best energy efficiency, a complete air seal, and serious moisture control, then spray foam is, without a doubt, the superior choice. Its ability to expand and create a single, seamless barrier is unmatched for stopping the two biggest enemies of comfort in South Florida: air leaks and humidity. The higher upfront cost is a direct investment in lower energy bills and a more resilient, comfortable home for years to come.

On the other hand, if you’re looking for a budget-friendly way to boost your home’s thermal performance—especially in a standard, vented attic—blown-in insulation is a fantastic, practical solution. It delivers a solid R-value increase for a much lower initial investment, meaning you’ll see a quicker payback from your energy savings.

Here’s a good way to think about it: Blown-in insulation is like putting a thicker, cozier blanket over your house. Spray foam is like wrapping your house in a high-tech, waterproof windbreaker—it doesn’t just insulate, it completely blocks wind and water from getting in.

Matching the Right Insulation to the Right Problem

Think about the specific issues you’re dealing with. Are you constantly battling humidity, finding condensation on your ductwork, or dealing with musty smells? Are your cooling bills through the roof because your attic is basically an oven that leaks hot air into your living space?

- For homes with nagging moisture problems or complex air leaks: Closed-cell spray foam is the only product that does it all—insulating, air sealing, and providing a moisture barrier in one shot. It’s a problem-solver.

- For straightforward thermal upgrades in a relatively healthy attic: Blown-in insulation is the reliable workhorse. It’s perfect for topping off what you already have and making your home more comfortable without the higher cost of a full spray foam job.

Ultimately, the winner in the spray foam vs blown in insulation debate is the one that solves your specific problems. Once you weigh your home’s needs against your budget and long-term goals, you’ll be ready to have a truly productive conversation with your contractor and pick the system that will deliver real comfort and value for decades.

Common Questions We Hear From Homeowners

When you’re weighing spray foam against blown-in insulation, a few questions always come up. Getting straight answers is the only way to feel confident you’re making the right call for your home’s comfort and efficiency for years to come. Here are some of the most common things we get asked.

Are There Any Health Concerns With Spray Foam Insulation?

Once it’s fully cured, modern spray foam is completely inert and safe for your home. The critical window is the application and curing period, which typically lasts 24 hours. During this time, the area must be completely clear of anyone who isn’t wearing professional-grade personal protective equipment (PPE) because of chemical off-gassing.

This is a non-negotiable safety protocol that any reputable installer follows to the letter. If you ever hear about lingering odors or issues, it’s almost always a sign of an amateur job where the foam was mixed or applied incorrectly—which is exactly why hiring a certified professional is so important.

Can I Just Put New Blown-In Insulation Over My Old Stuff?

Yes, and in most situations, it’s a smart, budget-friendly way to improve your home’s insulation. One of the biggest perks of blown-in insulation is that you can add a fresh layer right on top of what’s already there. This process, known as “capping,” gives your attic’s total R-value a serious boost.

But first, a professional needs to inspect the old insulation. If the existing layer is damp, heavily compressed, or has any signs of mold or pest contamination, it absolutely has to be removed. You can’t build an effective thermal barrier on a compromised foundation.

This quick inspection makes sure the new layer can do its job right.

Does Spray Foam Do More Than Just Insulate?

Absolutely. Closed-cell spray foam, in particular, delivers some major extra benefits that add a ton of value to your property. When we apply it to the underside of a roof deck, it basically acts like a high-strength glue, locking the roof sheathing to the trusses.

In a place like South Florida, this can make a huge difference in your roof’s ability to resist uplift during a hurricane or major storm. It also creates a powerful air and moisture barrier, which stops condensation in its tracks and takes a massive strain off your HVAC system by sealing up all those costly air leaks.

Ready to make your home more comfortable and efficient with an insulation solution that actually works for our climate? The team at Airtight Spray Foam Insulation has the local expertise to guide you every step of the way. Request your free, no-obligation quote today!