Blog

A Guide to Spray Foam Insulation for Concrete Block Walls

Spray foam insulation isn’t just another option for concrete block walls; it’s the only one that creates a truly seamless, airtight barrier to stop energy loss. It gets into every last crack and pore in the masonry, expanding to transform a leaky, inefficient wall into a high-performance thermal shield. The result? A far more comfortable home and dramatically lower utility bills.

Why Spray Foam Is the Modern Choice for Block Walls

Think of an uninsulated concrete block wall as a giant sponge for temperature. Because it’s naturally porous, it soaks up the brutal South Florida heat all summer and lets your expensive conditioned air seep right out. This forces your HVAC system to run constantly just to keep up.

Older insulation methods, like batts or rigid boards, can help, but they almost always leave tiny gaps and seams—little highways for air to travel. This is where spray foam insulation for concrete block walls completely changes the game.

Instead of just sitting against the wall, spray foam actively bonds to it. As it expands, it creates a single, solid, custom-fit layer. This process doesn’t just reduce air leakage—it stops it cold, tackling the number one source of energy waste in homes with masonry walls.

The Core Strengths of Spray Foam

Spray foam’s power comes from a unique combination of benefits that old-school insulation just can’t deliver. It solves several problems at once, turning a simple structural wall into the cornerstone of your home’s efficiency.

Three key advantages make it the clear winner:

- Unmatched Thermal Resistance: It packs a high R-value into every inch, putting a dead stop to heat transfer.

- Complete Air Sealing: The expanding foam seals every possible gap, eliminating drafts and energy leaks for good.

- Robust Moisture Control: Closed-cell foam, in particular, acts as a powerful vapor barrier, which is critical in our humid climate.

By creating a truly continuous and seamless barrier, spray foam converts a standard block wall into a modern, high-performance building envelope. This comprehensive approach is why its popularity has soared.

Homeowners and builders are catching on fast. The global spray foam market hit USD 2.4 billion in 2023, and the United States made up roughly 75% of that demand, all driven by the push for real energy efficiency.

Thinking about your home as a complete system is key. Just like spray foam seals your walls, you have to consider other weak points. For instance, it’s just as important to seal existing air leaks in your home’s ductwork to get the full benefit. This holistic view is what delivers the biggest savings and the most comfort.

Open-Cell vs. Closed-Cell: Picking the Right Foam for Concrete Walls

When it comes to spray foam for concrete block walls, you’ll hear two terms thrown around: open-cell and closed-cell. Making the right call here isn’t a minor detail—it’s the single most important decision you’ll make, especially in South Florida’s punishing climate. The difference boils down to how the foam itself is structured at a microscopic level.

Think of open-cell foam like a dense kitchen sponge. Its tiny bubbles, or “cells,” are intentionally left open. This makes the foam soft, light, and flexible. It’s fantastic at absorbing sound, but just like a sponge, it can also soak up and hold onto water.

Now, picture closed-cell foam as the rigid, dense material inside a high-end cooler. Its cells are completely sealed off from each other and packed tight, trapping a special gas that boosts its insulating power. This creates a tough, waterproof barrier that air and moisture simply can’t get through.

Open-Cell Foam Explained

Open-cell spray foam expands like crazy when it’s applied, puffing up to fill every nook and cranny with a soft, spongy cushion. Because it’s so light and airy, you don’t need as much raw material to fill a space, which often gives it a lower upfront price tag.

Its main selling points are:

- Great Sound Dampening: That spongy structure is a natural at trapping sound waves, making your home noticeably quieter.

- Flexibility: It stays pliable after it cures, so it can move with your home’s natural settling without cracking.

- Leak Detection: Because it lets water vapor pass through, a roof leak will eventually show itself. The water can travel through the foam, making the problem visible so you can get it fixed.

But that sponge-like quality is its biggest downfall for concrete walls, particularly below-grade or on the ground floor. It has a lower R-value and, if a leak springs, it can wick moisture right up against your concrete block, trapping it there.

Closed-Cell Foam: The Clear Winner for Concrete

For insulating concrete block walls in our humid, storm-prone region, closed-cell foam is almost always the right—and necessary—choice. Its rigid, dense structure is a powerhouse, directly tackling every challenge masonry throws at it.

The advantages are undeniable:

- Higher R-Value: You get far more insulating power per inch, which means maximum thermal performance without sacrificing interior space.

- True Moisture and Vapor Barrier: Closed-cell foam is completely non-permeable. It stops water vapor dead in its tracks, preventing condensation inside your walls and shutting down mold growth. This is non-negotiable in South Florida.

- Adds Structural Strength: When it cures, it acts like a super-strong glue, literally reinforcing your block walls and adding significant racking strength to the entire structure.

Concrete is naturally porous and a magnet for moisture. The waterproof, air-sealing power of closed-cell foam makes it the definitive solution for protecting your home. It doesn’t just insulate; it actively defends your walls against water intrusion.

The difference in performance is huge. On concrete block, closed-cell spray foam delivers an impressive R-6 to R-7 per inch. In contrast, open-cell foam only offers about R-3.5 to R-4 per inch. That efficiency boost is why retrofitting masonry walls with closed-cell foam can slash heating and cooling costs by 15% to 40%.

Open-Cell vs Closed-Cell Spray Foam for Concrete Walls

Choosing between open-cell and closed-cell isn’t just about R-value; it’s about matching the material’s properties to the unique demands of a concrete wall in a humid climate. This table breaks down the key differences to show why one is clearly better suited for the job.

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value | R-3.5 to R-4 per inch | R-6 to R-7 per inch |

| Moisture Barrier | No (Vapor Permeable) | Yes (Vapor Impermeable) |

| Air Barrier | Yes | Yes |

| Structure | Soft, flexible, spongy | Rigid, dense, strong |

| Sound Dampening | Excellent | Good |

| Structural Strength | None | Adds significant strength |

| Best For | Soundproofing interior walls | Exterior walls, basements, concrete |

For concrete block walls in South Florida, the table makes the choice clear. The rigidity, high R-value, and built-in vapor barrier of closed-cell foam provide the multi-layered protection that masonry requires.

Yes, closed-cell foam has a higher upfront cost. But it’s doing four jobs in one—insulator, air barrier, vapor barrier, and structural reinforcement. That multi-functionality delivers unmatched long-term value and protects the health and durability of your home. While deciding between insulation types can feel overwhelming, our detailed comparison of spray foam vs. blown-in insulation can offer more insight. But when it comes to concrete, the tough, moisture-proof nature of closed-cell foam makes it the undisputed champion.

What to Expect During a Professional Installation

So, what actually happens when a professional crew shows up to insulate your concrete block walls? It’s a lot more than just pointing a spray gun and calling it a day. A quality job is a precise, multi-step operation that puts safety and your property first.

Knowing the process helps you understand why hiring a certified team is so important. From the moment we arrive, our focus is on meticulous prep work, a controlled application, and leaving your space cleaner than we found it.

Meticulous Site Preparation

The first thing you’ll see our installation team do is thoroughly prepare the work area. This isn’t a step we rush; it’s the foundation for a flawless job and a non-negotiable part of our process.

Here’s what you can expect the crew to do:

- Covering Surfaces: We’ll lay down heavy-duty plastic sheeting to protect your floors, furniture, and anything else in the vicinity from overspray.

- Masking Fixtures: Windows, doors, electrical outlets, and plumbing fixtures get carefully masked off with tape and plastic to keep them completely clean.

- Establishing Ventilation: Proper ventilation is critical. Our team sets up powerful fans and exhaust systems to keep fresh air moving and manage fumes, ensuring a safe environment for everyone.

This careful preparation makes sure the foam only sticks where it’s supposed to—your concrete walls.

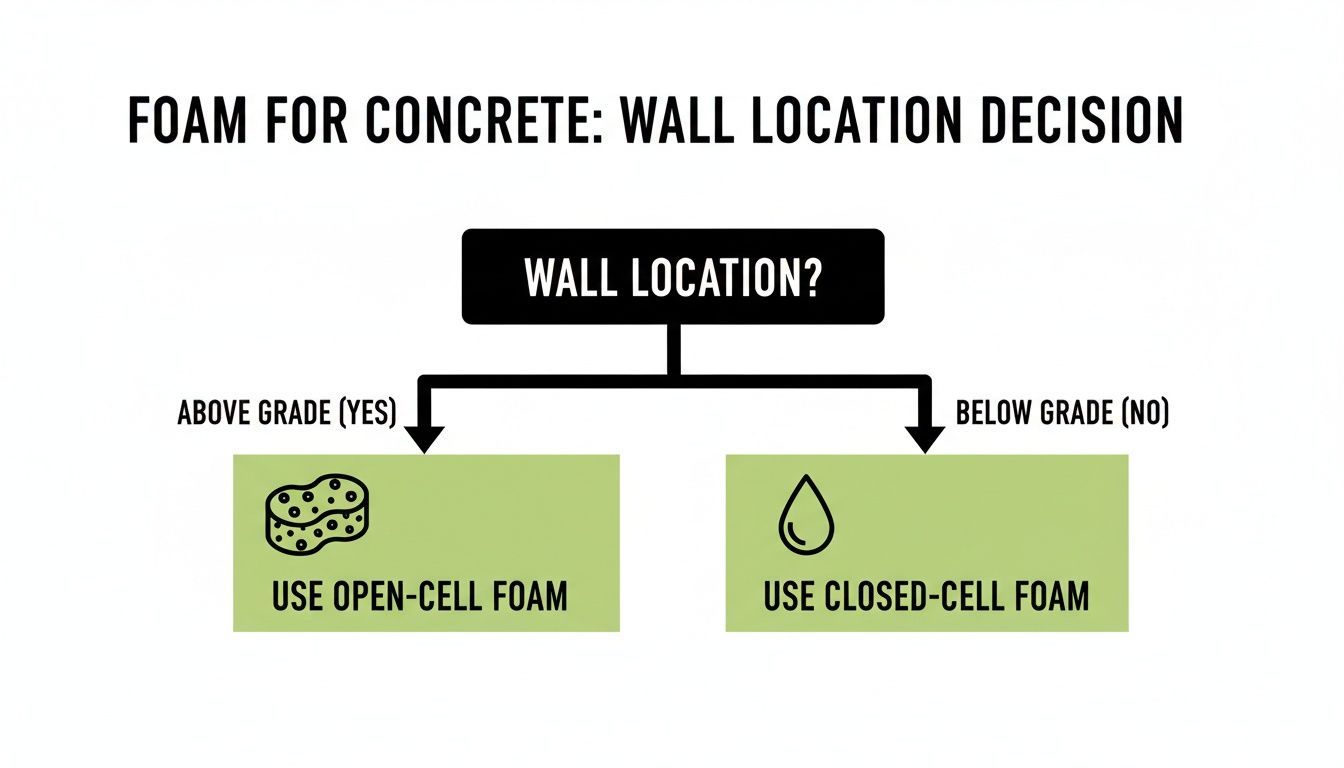

This handy visual helps show which type of foam we’d likely recommend depending on whether your wall is above or below ground.

As you can see, below-grade walls need the waterproof protection of closed-cell foam to stand up to ground moisture.

A professional installation isn’t just about applying foam; it’s a systematic process focused on safety, precision, and leaving your home better than we found it. Honestly, the quality of the prep work is almost always a direct reflection of the final result.

The Application and Curing Process

Once the site is fully prepped and secured, our certified technicians suit up. We’re talking full personal protective equipment (PPE)—respirators, coveralls, the works. This is essential because the chemical reaction that creates the foam releases vapors that should not be inhaled.

Next, the technician applies the foam in controlled, even layers, which we call “lifts.” This method is crucial. If you spray too much foam at once, it can trap heat from the chemical reaction and mess up the foam’s structure. By applying it in lifts of about 2 inches (for closed-cell), we ensure each layer cures properly, creating a solid, seamless barrier across the entire wall.

After application, the foam needs to cure and fully harden. This usually takes up to 24 hours, and during this time, the space needs to stay well-ventilated and unoccupied.

Final Trimming and Site Cleanup

After the foam has cured, you’ll notice it has expanded slightly beyond the wall studs. This is normal. To get the wall ready for drywall, we perform a few final, but critical, steps.

- Trimming the Excess: Our technicians use special tools to carefully shave down any over-expanded foam, making it perfectly flush with the framing. This gives you a smooth, flat surface so your drywall can be installed without any bumps or bulges.

- Thorough Cleanup: Then, it’s time to clean up. The crew removes all the protective plastic and masking tape. We sweep up, bag all the trimmed foam debris, and leave your space tidy.

- Final Walkthrough: Before we consider a job done, a reputable company will do a final walkthrough with you. We’ll inspect the work together, answer any last-minute questions, and make sure you are 100% satisfied.

This systematic approach—from obsessive prep to meticulous cleanup—is the hallmark of a true professional. It’s how we guarantee your investment in spray foam insulation for concrete block walls not only performs at its best but is also installed safely and cleanly.

The Hidden Benefits Beyond Better Insulation

Thinking of spray foam insulation for concrete block walls only for temperature control is like buying a smartphone just to make calls. You’re missing out on some of the best features. While its ability to stop heat transfer is absolutely top-notch, spray foam delivers a whole package of benefits that can transform your home’s performance, comfort, and even its durability.

These “hidden” advantages all work together to create a space that’s healthier, quieter, and more resilient. Once you see the full picture, you’ll understand why we consider it a complete upgrade to your home’s envelope, not just another layer of insulation.

Creating an Impenetrable Air Barrier

Concrete block walls might look solid, but on a microscopic level, they’re surprisingly porous. Tiny cracks in the mortar and the natural texture of the blocks create thousands of little pathways for air to leak in and out. That constant, uncontrolled air exchange is what causes drafts, wastes energy, and leads to those frustratingly inconsistent room temperatures.

Spray foam creates a truly monolithic air barrier. It doesn’t just sit next to the wall; it expands and bonds to every single surface, sealing every pinhole, crack, and joint. This stops air leakage far more effectively than any other insulation out there, putting an end to drafts for good and stabilizing your indoor climate.

A Powerful Defense Against Moisture and Mold

Here in South Florida, moisture is a constant battle. The humidity outside is always trying to push its way into your cooler, conditioned home. When that warm, moist air hits a cool concrete block wall, you get condensation—the perfect breeding ground for mold and mildew.

This is where closed-cell spray foam really shines. It acts as a true vapor barrier, meaning it’s impermeable to water vapor. It stops moisture from passing through the wall and prevents condensation from ever forming on the inside surface.

By blocking moisture right at the source, closed-cell spray foam shuts down the conditions mold needs to grow. It’s not just insulating your wall; it’s protecting your home’s structure and your family’s health from the damage humidity can cause.

This is a game-changing feature for any concrete block home, but it’s especially critical for basements or any below-grade space where ground moisture is a constant threat.

Adding Surprising Structural Strength

Another remarkable benefit, unique to closed-cell spray foam, is its ability to actually reinforce your walls. As the foam cures, it becomes incredibly dense and rigid. Its powerful adhesion means it essentially “glues” the entire wall assembly together.

Think of it like this: the foam not only fills the empty spaces but also acts as a structural adhesive, connecting the individual blocks and mortar joints into a single, unified panel. This process adds significant racking strength to the wall, helping it better resist lateral forces from high winds—a crucial benefit in our hurricane-prone region. That added rigidity enhances the durability of the entire building.

Turning Down the Volume on Outside Noise

The benefits don’t stop with performance; they make your home more comfortable, too. Both types of spray foam offer excellent sound-dampening qualities, helping to create a quieter and more peaceful home.

The foam’s cellular structure is highly effective at absorbing and deadening sound waves. You’ll really notice this with concrete block walls, which can otherwise transmit outside noise from traffic, neighbors, or lawn equipment right into your living space.

- Open-cell foam, with its softer, more flexible structure, is an exceptional sound absorber.

- Closed-cell foam, while primarily chosen for its thermal and moisture control, still provides a significant reduction in noise transmission thanks to its density.

By insulating your concrete walls, you’re also soundproofing them. You get a serene interior sanctuary, shielded from the disturbances of the outside world. If you want to dive deeper into this specific advantage, our guide on using insulation as a sound barrier provides a more detailed look.

Breaking Down the Cost and Long-Term ROI

Let’s talk numbers. The performance benefits of spray foam insulation are clear, but I know the final decision almost always comes down to budget. It’s critical to see this as a long-term investment in your home’s performance and comfort, not just another line-item expense.

Yes, the upfront cost of spray foam is higher than old-school insulation like fiberglass batts. But that price reflects a far superior product that does three jobs in one—it insulates, creates an air barrier, and acts as a vapor barrier, all in a single application. You’re paying for a complete system.

Several key factors determine the final price tag for a project. Understanding these variables helps you see exactly where your money is going and why quotes can differ from one company to the next.

What Determines the Final Price

The cost of a professional installation isn’t just a number we pull out of thin air. It’s calculated based on a few core components that directly impact the amount of material and labor the job requires.

- Type of Foam: As we’ve covered, closed-cell spray foam is the only real choice for concrete block walls, especially here in South Florida. Its density, rigidity, and moisture-blocking properties make it a premium product, so it naturally has a higher material cost than open-cell foam.

- Total Square Footage: This one is pretty straightforward—the bigger the area you need to insulate, the more material and time the project will take, which is reflected in the final cost.

- Required Thickness: To create a truly effective thermal and air barrier on concrete, closed-cell foam is typically applied at a minimum thickness of 2 to 3 inches. The exact depth needed depends on your energy-saving goals and what local building codes require.

- Project Complexity: Not all walls are created equal. A simple, wide-open basement wall is much easier to spray than a finished room that requires extensive prep work, masking off windows and floors, and detailed cleanup. Those factors will influence the labor costs.

Investing in spray foam isn’t just about spending money; it’s about reallocating it. The funds you put into upgrading your home’s envelope are funds you’ll stop sending to the utility company, month after month.

To give you a clearer picture, here’s a breakdown of the main factors that influence the final price and your long-term payback.

Estimated Project Cost and ROI Factors

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Foam Type | Closed-cell foam is denser and offers superior moisture resistance, making it more expensive than open-cell. | Higher |

| Job Size | The total square footage of the walls being insulated directly affects material and labor time. | Proportional |

| Foam Thickness | Applying foam at the required 2-3 inches (or more) uses more material than a thinner application. | Higher |

| Prep & Labor | Complex areas with obstacles, existing finishes, or difficult access require more prep and cleanup time. | Variable |

| Energy Savings | Creating an air seal can reduce HVAC costs by 15-40%, delivering immediate monthly savings. | High ROI |

| Home Value | An energy-efficient home is a major selling point, potentially increasing its market value. | High ROI |

| Incentives | Government or utility rebates for energy-efficient upgrades can offset a portion of the initial cost. | High ROI |

As you can see, the initial cost is just one part of the story. The real value comes from what you get back over time.

Calculating Your Return on Investment

While the initial price is one piece of the puzzle, the real financial story is the return on investment (ROI). This is where spray foam truly leaves other options in the dust, paying for itself over time through substantial savings and added property value.

1. Drastic Reductions in Energy Bills

This is the most immediate and tangible return you’ll see. By creating a nearly perfect air seal, spray foam can slash your heating and cooling costs by 15% to 40%. For a typical South Florida home, that translates to hundreds, if not thousands, of dollars in your pocket each year instead of FPL’s.

2. Increased Home Resale Value

Energy efficiency is a huge selling point for homebuyers today. A home with professionally installed spray foam isn’t just more comfortable; it’s cheaper to own and operate. This makes your property far more attractive on the market and can lead to a higher final sale price.

3. Potential for Rebates and Tax Credits

Many utility companies and government programs offer financial incentives for making energy-efficient upgrades to your home. We stay on top of these programs and can help you identify and apply for any available rebates that can help offset the initial installation cost, making your payback period even shorter.

When you factor in these long-term financial benefits, the value proposition becomes crystal clear. To dive deeper into how these principles apply specifically to masonry, you can learn more about the insulation value of concrete block walls in our detailed guide.

Key Considerations Before You Insulate

Deciding on spray foam is a major step toward a better-performing home, but like any big project, getting it right comes down to planning. The benefits are huge, but there are a few critical things every homeowner needs to know before a single drop of foam is sprayed. Thinking through these points ahead of time is the key to a smooth, safe, and successful installation.

First up is air quality. When spray foam is applied, the chemical reaction releases vapors in a process called off-gassing. This is perfectly normal, but it has to be managed correctly. A professional crew will use powerful fans and ventilation systems to clear the air during the job and will tell you to stay out of the area for about 24 hours. This gives the foam time to fully cure and become stable. For your safety, proper ventilation is an absolute must.

Staying Safe and Code-Compliant

Beyond ventilation, your project has to follow local building codes. These aren’t just suggestions—they’re legal requirements put in place to keep you safe, especially when it comes to fire.

- Mandatory Thermal Barrier: Spray foam is a type of plastic, and it can burn. Because of this, building codes across the board require it to be covered by an approved 15-minute thermal barrier. For most homes, that simply means putting up half-inch drywall over the foam once it’s cured.

- Electrical and Plumbing Access: Spray foam is permanent. Once it hardens, it’s not going anywhere. It’s essential to make sure any electrical wiring or plumbing you might want in that wall is installed before the foam goes in. Trying to add it later means cutting into the insulation and breaking that perfect airtight seal.

Here’s a pro tip: Always plan for the future. It’s a hundred times easier to run an extra electrical conduit before the wall is sealed up than it is to deal with it years down the road.

Planning for the Long Term

Finally, it pays to look at the bigger picture. When you’re considering your project, it’s a good idea to research various insulation options like spray foam and rigid board to see how they stack up for different types of buildings. While closed-cell foam is the hands-down winner for concrete walls in our climate, understanding all the materials out there helps confirm you’re making the smartest choice for your home.

Nailing down these details—ventilation safety, code compliance, and future-proofing your walls—is what separates a good job from a great one. Any professional contractor will walk you through these steps to make sure your investment in spray foam insulation for concrete block walls pays off in comfort, safety, and long-term home value. A quick chat with your installer about these points beforehand is the best way to make sure there are no surprises.

Common Questions About Spray Foam on Concrete Walls

When you’re considering an upgrade like spray foam insulation, asking questions is the smartest thing you can do. It means you’re thinking like a homeowner who wants the job done right. Here are some of the most common questions we get, with the straightforward answers you deserve.

Can You Spray the Inside and Outside of Block Walls?

We hear this one a lot. The short answer is yes, but they are two completely different animals.

For almost every home in South Florida, spraying the interior of the block walls is the way to go. It’s the most practical and cost-effective method, and it works perfectly with both open-cell and closed-cell foam.

Spraying the exterior is a highly specialized commercial application. It demands an extremely dense closed-cell foam that can stand up to the elements, and it must be covered with a tough, UV-protective coating to shield it from our relentless sun.

Will Spray Foam Fix My Leaky Basement Walls?

This is a critical point to understand: closed-cell spray foam is an excellent moisture barrier, but it is not a waterproofing product.

What does that mean? It means it will stop water vapor—the humid, sticky air that causes condensation and mold—dead in its tracks. But it will not stop a stream of water from a foundation crack or from water pressure pushing through the wall.

You absolutely have to fix any and all active water leaks before we insulate. Think of spray foam as the final seal on a dry wall, not a patch for a wet one.

Spray foam is designed to keep a dry wall dry. It is not designed to make a wet wall dry. Resolving leaks first is a non-negotiable step for a successful and long-lasting installation.

How Long Does It Really Last on Concrete?

Once it’s on your wall, how long is it good for? When installed correctly by a professional crew and kept out of direct sunlight, spray foam is basically permanent.

It’s an inert plastic that’s engineered to last for the entire lifespan of your home. It won’t sag, shrink, or crumble over time like other materials. It’s a one-and-done investment.

What About Smells and Safety During the Job?

Your family’s safety is our top priority, period. During the application process, there is a noticeable odor as the two liquid components mix and react to form the foam. This is exactly why our installers wear full-body protective gear, including respirators.

We require the house to be empty during the installation and for a brief window afterward. Once the foam has fully cured—usually within 24 hours—it becomes a completely stable, odorless, and non-toxic solid. We only use modern, low-VOC (Volatile Organic Compound) formulas and stick to strict safety protocols to ensure the air in your home is perfectly safe for your return.

Ready to see how Airtight Spray Foam Insulation can transform the comfort and efficiency of your concrete block walls? We provide expert guidance and flawless installation to protect your home from South Florida’s heat and humidity. Request your free, no-obligation quote today!