Blog

A Homeowner’s Guide to Polyurethane Spray Foam Roofing

Imagine giving your building a seamless, custom-fitted, insulated jacket. That's essentially what polyurethane spray foam roofing does. It’s a liquid-applied system that expands on your roof, creating a single, solid, and incredibly durable layer of protection.

A Deeper Look into Polyurethane Spray Foam Roofing

Polyurethane spray foam roofing, or SPF roofing as we call it in the industry, is a completely different approach to protecting a commercial or residential property. Unlike traditional materials that come in rolls or sheets and have to be fastened down, SPF is manufactured right on your rooftop.

Here’s how it works: Two liquid components, a polyol and an isocyanate, are pumped from our truck through separate, heated hoses to a specialized spray gun. When these two liquids combine at the tip of the gun, a chemical reaction kicks off, and the mixture is sprayed directly onto the existing roof surface.

In just seconds, that liquid mixture expands up to 30 times its original volume. It’s an incredible process to watch. This rapid expansion allows the foam to flow into every crack, crevice, and around every pipe and vent, creating a truly monolithic—or seamless—layer. The end result is a rigid, tough, and fully adhered membrane that literally becomes one with your building.

Why It Excels in South Florida

For property owners here in South Florida, an SPF roof isn't just another option; it's a strategic defense against our relentless climate. That seamless quality I mentioned? It eliminates the single biggest failure point for leaks: the seams and fasteners found in every other roofing system. That's a huge deal during our torrential downpours and hurricane season.

On top of the foam, we apply a protective elastomeric coating. This top layer is usually a bright white, and its job is to reflect the sun's punishing UV rays instead of absorbing them.

This reflectivity dramatically lowers the roof's surface temperature, which takes a massive load off your building's air conditioning system. We’ve seen cases where an SPF roof can pay for itself in energy savings alone in as little as five years.

This powerful one-two punch of seamless waterproofing and best-in-class insulation makes polyurethane spray foam roofing an incredibly smart investment for anyone looking to fortify their property while cutting long-term operating costs.

A Growing Market Driven by Performance

The shift toward spray foam roofing isn’t just a local trend. It’s a nationwide movement driven by the need for more resilient and energy-efficient buildings. The global market for this technology is on a steep climb, projected to hit USD 3.96 billion by 2031.

This growth is being pushed by stricter building energy codes, like the International Energy Conservation Code, which increasingly recognize closed-cell spray foam as a top-tier air-barrier solution. Here in Florida, continuous updates to the Florida Building Code are accelerating the adoption of SPF as builders and property owners work to meet modern standards for both energy efficiency and storm durability. You can read more about these market trends to see where the future of roofing is headed.

To put it simply, here’s a quick rundown of why SPF roofing is such a game-changer for properties in our climate.

SPF Roofing At a Glance for South Florida Properties

This table breaks down the key advantages of SPF roofing and what they mean for a property facing the unique challenges of South Florida's sun, heat, and storms.

| Benefit | Why It Matters in South Florida | Impact on Your Property |

|---|---|---|

| Seamless Waterproofing | Eliminates seams, the most common source of leaks during heavy rain and storms. | Significantly reduces the risk of water intrusion, mold, and interior damage. |

| Superior Insulation | Provides one of the highest R-values per inch, keeping conditioned air in and heat out. | Lowers monthly energy bills and reduces strain on your HVAC system. |

| High Wind Resistance | Fully adheres to the roof deck, creating a solid layer with no edges for wind to lift. | Offers exceptional protection against hurricane-force winds, exceeding FBC requirements. |

| Lightweight & Durable | Adds minimal weight to the building's structure while being strong enough for foot traffic. | Preserves structural integrity and allows for easy maintenance of rooftop equipment. |

Each of these benefits directly addresses a major pain point for property owners in our area, making SPF a comprehensive solution for long-term protection and efficiency.

Choosing Between Open-Cell and Closed-Cell Foam

When you start looking into polyurethane spray foam roofing, you’ll quickly find out that not all foam is created equal. The two main players are open-cell and closed-cell, and knowing the difference isn't just a technical detail—it's absolutely critical for a roof that lasts. Picking the wrong one can lead to total, catastrophic failure.

Let's break it down with a simple analogy. Think of open-cell foam like a kitchen sponge. It’s soft, flexible, and full of tiny interconnected air pockets. That structure is great for soaking things up, like sound.

Now, picture closed-cell foam as a high-end, hard-shell cooler. Its structure is made of countless individual cells, each one sealed off and filled with an insulating gas. This creates a rigid, dense, and completely impenetrable barrier.

That structural difference changes everything. The sponge-like nature of open-cell foam means it will absorb and hold water—the absolute last thing you want happening on your roof. Closed-cell foam, with its rigid and sealed structure, is completely waterproof and incredibly strong.

Why Closed-Cell Foam Is The Only Choice For Roofing

For roofing applications, especially here in the humid, hurricane-prone environment of South Florida, closed-cell foam is the undisputed champion. There's really no debate. It's the only option that can properly protect your property from the elements.

The dense structure of closed-cell foam actually adds significant structural strength to your roof deck. This rigidity helps the entire system stand up to high winds and flying debris during a hurricane.

Because its cells are completely sealed, closed-cell foam acts as a true air and vapor barrier. This is non-negotiable in South Florida, where high humidity can lead to moisture intrusion, mold growth, and wood rot within the roof structure. Closed-cell foam stops this moisture in its tracks.

This is a key point that many people miss. The foam doesn't just insulate; it creates a complete seal that protects the very integrity of your building.

To really see the difference, a side-by-side comparison makes it clear why one is for roofs and the other is for interior walls.

Open-Cell vs Closed-Cell Foam A Head-to-Head Comparison for Roofing

| Feature | Open-Cell Foam (The 'Sponge') | Closed-Cell Foam (The 'Hard Shell') |

|---|---|---|

| Structure | Soft, flexible, interconnected cells | Rigid, dense, sealed individual cells |

| Water Permeability | High – Absorbs and holds water | Very low – Waterproof barrier |

| Air Permeability | Permeable – Allows air to pass through | Impermeable – True air barrier |

| Vapor Permeability | Permeable – Allows moisture vapor through | Impermeable – True vapor barrier |

| Structural Strength | Low – No structural reinforcement | High – Adds significant rigidity to the roof |

| Best Application | Sound-dampening in interior walls | Roofing, exterior walls, and flood zones |

Looking at this, it's easy to see how the properties that make open-cell foam great for soundproofing inside a house would make it a disaster on a roof exposed to rain and humidity.

Understanding R-Value and Material Efficiency

Beyond strength and water resistance, the main job of any insulation is to resist heat flow, which we measure by its R-value. The higher the R-value, the better the insulation. This is another area where closed-cell foam really shines.

- Closed-Cell Foam: Delivers a very high R-value, typically ranging from R-6.0 to R-7.0 per inch.

- Open-Cell Foam: Offers a lower R-value, usually around R-3.5 to R-4.0 per inch.

What this means in the real world is that you'd need almost twice the thickness of open-cell foam to get the same insulating performance. For roofing, that's a huge deal. A thinner layer of high-performance closed-cell foam keeps your roof profile sleek, avoids adding unnecessary weight, and gets the job done right. You get top-tier energy efficiency without compromising the building's structure.

If you want to dig even deeper, you can learn more about the distinct properties of open-cell versus closed-cell foam in our detailed guide.

The Right Application for Open-Cell Foam

So, if open-cell foam is so bad for roofing, what is it actually for? Its soft, sponge-like structure makes it a fantastic sound-dampening material. We often use it in interior walls, between floors, and in home theaters to absorb noise and create much quieter spaces.

In those specific indoor situations, its lower cost and ability to let vapor pass through are actually benefits. But those are the very same properties that make it a total liability on the exterior of a building. For a tough, waterproof, and highly insulated roof, closed-cell foam is the only professional choice.

How a Spray Foam Roof Is Installed

Installing a spray foam roof isn't like nailing down shingles or rolling out membrane. It’s more like a science experiment performed right on top of your building, where we manufacture the roof directly on the existing surface. This process is all about precision and control—it’s what separates a flawless, leak-proof roof from a complete failure.

The whole system starts with two liquid components that, when combined, react and expand to form a solid, seamless, and incredibly durable layer. It’s a job that demands specialized equipment, and keeping that gear in top shape is non-negotiable. That's why we rely on things like reliable Graco sprayer components to ensure every application is perfect. This behind-the-scenes attention to detail is what makes all the difference.

The Initial Inspection and Preparation

Before a single drop of foam is sprayed, we start with the most important part of the entire job: a deep clean and thorough inspection of your existing roof. Think of it like painting a car—you'd never spray new paint over dirt and rust. The foam needs a clean, dry, and stable surface to grab onto and form a permanent, watertight bond.

Our prep work is meticulous and includes a few key steps:

- Power Washing: We blast away years of accumulated dirt, grime, loose gravel, and anything else that could get in the way of perfect adhesion.

- Moisture Detection: We use infrared scanners to hunt down any hidden moisture trapped in your current roof. Spraying foam over a wet spot is a cardinal sin in this business and will lead to major problems down the road.

- Minor Repairs: We fix any underlying damage to the roof deck itself. You can't build a great new roof on a crumbling foundation.

We don't cut corners here. A rushed prep job will compromise the entire system, which is why our crews dedicate so much time to getting this stage absolutely right.

Primer and Foam Application

With the roof perfectly prepped, the next step is applying a specialized primer. This isn’t just a simple coat of paint; it acts like industrial-strength double-sided tape, chemically locking the foam to your roof deck. This bond is what gives the system its incredible strength against hurricane-force winds.

Then comes the main event. Our certified technicians use high-pressure spray equipment to apply the polyurethane foam in layers, or "lifts," usually about one to one-and-a-half inches thick at a time. This methodical layering isn't just for show—it allows our applicators to do three critical things:

- Build Uniform Thickness: We ensure the entire roof gets the right amount of foam to deliver a consistent R-value and insulation level across every square foot.

- Create Proper Drainage: This is where the real artistry comes in. We can build up the foam in low spots to eliminate areas where water ponds, actively contouring the roof to channel water directly to drains.

- Seal All Penetrations: We meticulously spray around every pipe, vent, and HVAC unit, creating a custom-molded, monolithic seal. It’s a truly seamless and self-flashing detail that’s impossible to replicate with traditional roofing materials.

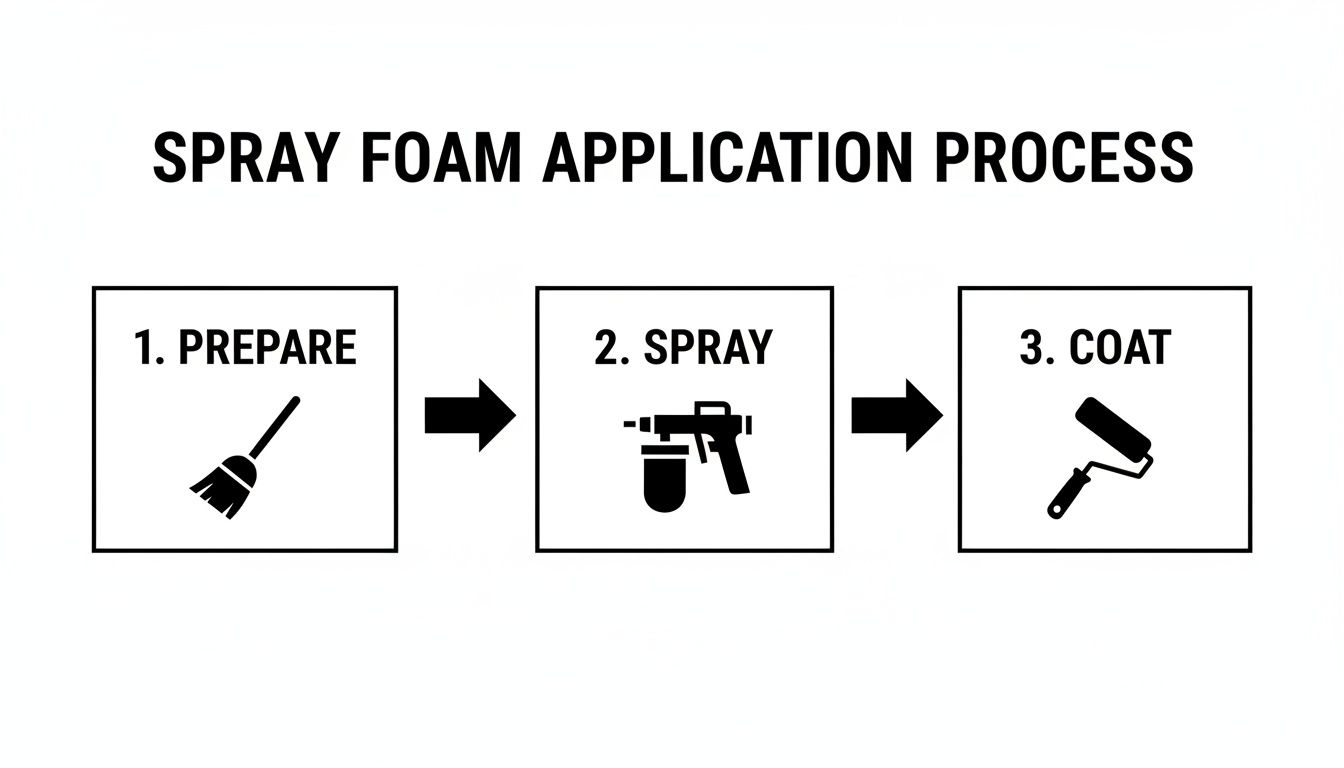

This graphic breaks down the basic flow of the job.

It really is that straightforward when done by an expert crew: prepare the surface, spray the foam, and apply the protective coat.

Protective Coating and Final Walkthrough

As tough as polyurethane foam is, it has one weakness: the sun. UV rays will degrade the foam over time. To protect it, we apply a thick, durable elastomeric coating—usually a high-solids silicone—over the entire roof. We almost always use a bright white coating to reflect the brutal Florida sun and dramatically lower your building’s cooling costs.

This topcoat is the roof’s armor. It shields the foam from UV damage, adds another layer of waterproofing, and makes the surface tough enough to walk on. It’s also the key to the system's incredible lifespan. With simple maintenance, this coating can be cleaned and reapplied every 15-20 years, effectively resetting the clock on your roof's warranty and making it last indefinitely.

The very last step is a rigorous final walkthrough. Our project manager inspects every inch of the new roof, verifying foam thickness, coating consistency, and the integrity of the seals around every penetration. This final check ensures our work meets our high standards and that you have a high-performance roof you can count on for decades.

Breaking Down the Cost and ROI of an SPF Roof

When you’re looking at any major upgrade for your property, the conversation always lands on the numbers. Let's be upfront: a polyurethane spray foam roof is a premium system. The initial ticket price can sometimes be higher than conventional options like TPO or modified bitumen. But if you stop there, you’re missing the whole story—the incredible long-term value and return on investment (ROI) that an SPF roof delivers.

Think of it less as a typical expense and more as a capital investment in your building’s future. The real financial narrative of an SPF roof isn't written on installation day; it unfolds over years of performance, efficiency, and durability. While the initial investment might be more, the savings it generates often mean the roof pays for itself over time.

Key Factors That Influence the Initial Cost

No two roofs are the same, so there's no one-size-fits-all price tag for a polyurethane spray foam roofing system. A few key variables will shape the final quote, and understanding them helps you see exactly where your money is going.

- Roof Size and Complexity: This one is pretty straightforward. A massive, wide-open commercial roof is simpler to spray than a smaller, residential one cluttered with vents, pipes, HVAC units, and skylights. The more detail work and maneuvering around obstacles, the more time and precision it takes.

- Existing Roof Condition: The state of your current roof is a huge factor. If the underlying substrate is in good shape—structurally sound and dry—we can often spray the foam directly over it. This saves you the huge expense and messy disruption of a full tear-off. But if we find widespread water damage or rot, that old roof has to go, which will add to the project's bottom line.

- Required Insulation Level (R-Value): The thickness of the foam directly translates to its insulating power, or R-value. To hit the numbers required by modern building codes and meet your energy efficiency goals, we might need to apply a thicker layer of foam. More material means a higher cost, but it also means more powerful insulation.

The bottom line is that an SPF roof’s cost is directly tied to the value it provides. A thicker application costs more but delivers greater energy savings. Prepping a damaged roof adds expense but ensures the system will perform flawlessly for decades to come.

The Real Story: Your Return on Investment

This is where spray foam roofing truly leaves other systems behind. The ROI isn’t some abstract idea; it's a tangible financial benefit you’ll see for the life of the roof. For many property owners, the energy savings alone are enough to cover the cost of the roof in as little as five to seven years.

1. Massive Energy Savings

The biggest driver of your ROI is the dramatic cut in cooling costs. You get a powerful one-two punch: high R-value insulation from the foam and a bright white, reflective topcoat that bounces sunlight away. This combination can drop a roof's surface temperature by up to 75 degrees. Your HVAC units suddenly don't have to battle the South Florida sun all day, which translates directly to lower utility bills—often reducing energy use by 30% or more. For a deeper dive, check out our guide on the costs and benefits of spray foam insulation.

2. Drastically Reduced Maintenance and Repair Costs

Because an SPF roof is one continuous, seamless surface, it has none of the joints, seams, or fasteners where traditional roofs fail and leaks begin. The durable, waterproof foam and its protective coating need very little upkeep. And if a repair is ever needed—say, from a fallen tree branch—it’s usually simple and inexpensive. We can cut out the small damaged area, fill it, and recoat it without compromising the rest of the roof.

3. Unmatched Longevity

A typical roof might give you 15-20 years before it needs a complete—and completely expensive—tear-off and replacement. An SPF roof, on the other hand, is a renewable system. With a simple and affordable recoat every 15-20 years, its life can be extended indefinitely. This sustainable approach lets you avoid the massive capital expense of future roof replacements, giving you predictable, low-cost maintenance for 50 years or more. That long-term durability is the cornerstone of its financial value.

Meeting Florida's Strict Building Codes

Roofing in South Florida is a whole different ballgame. We’re not just trying to keep the rain out; we’re fortifying buildings against some of the most powerful weather on Earth. It's why the Florida Building Code (FBC) is one of the toughest in the country, with a massive focus on preventing roofs from failing during a hurricane.

For any roofing system to last here, it has to do more than just waterproof. It has to prove it can handle extreme forces. A polyurethane spray foam roofing system doesn’t just meet these codes—it was practically made for them, outperforming traditional materials in ways they simply can’t.

Its completely seamless, fully bonded nature makes it a beast against both wind and water. This makes an SPF roof less of an alternative and more of a strategic decision for any property owner who's serious about long-term survival in our coastal climate.

Engineered for Hurricane-Force Wind Uplift

During a hurricane, the single biggest threat to your roof is wind uplift. This is the intense suction force created when high-speed winds whip over the top of a building. Traditional roofs, with all their seams, shingles, and fasteners, give the wind thousands of little edges to grab onto.

A spray foam roof gives the wind nothing to hold.

Since the foam is sprayed on as a liquid, it bonds directly to the roof deck, creating a single, solid surface. There are no seams to split, no shingles to tear off, and no fasteners to pull out. The roof literally becomes one solid piece, fused to the structure of the building.

This monolithic structure gives the roof incredible tensile strength. Wind tunnel testing has proven that SPF roofs can handle sustained wind speeds far beyond what's required for even the most intense hurricane categories. When the wind has no edge to grab, its power to rip a roof off is almost completely neutralized.

An Impenetrable Defense Against Humidity and Moisture

Beyond the obvious threat of hurricanes, we’re fighting a constant, silent war against humidity in South Florida. The air is thick with moisture, always trying to work its way into building materials, which leads to mold, mildew, and rot.

This is where the closed-cell structure of a spray foam roof is a game-changer. Unlike other materials that can absorb or trap moisture, closed-cell polyurethane foam is a true air and vapor barrier.

- No Water Intrusion: With a permeability rating near zero, water and water vapor just can’t get through. This stops the slow, hidden damage that rots out insulation and structural wood over the years.

- Self-Flashing Protection: The foam naturally forms a perfect seal around every vent, pipe, and curb on the roof. These are the classic weak spots for leaks in other systems, but with SPF, they become completely waterproof.

This is absolutely critical for maintaining healthy indoor air quality and stopping that musty smell that comes with mold growth. On top of that, many modern SPF systems have fire-retardant properties. If you want to dig into the details, you can learn more about the various insulation fire ratings and how they contribute to a safer building.

By creating a genuinely airtight and watertight seal, a polyurethane spray foam roof doesn't just pass inspection—it creates a healthier, more resilient building envelope perfectly designed for the demands of life in South Florida.

How to Select the Right Roofing Contractor

Let’s be honest: the most advanced polyurethane spray foam roofing system in the world is only as good as the crew putting it down. This isn't just slapping on a coat of paint; it's a precise chemical process. The difference between a roof that lasts 50 years and one that fails in five often boils down to the contractor's experience.

It’s tempting to just go with the lowest bid, but that can be a truly costly mistake. A quality contractor has serious money invested in high-end equipment, ongoing training for their crew, and the right insurance to protect everyone involved. A price that seems too good to be true is usually a huge red flag—it often means cut corners, cheap materials, or an inexperienced team.

Instead of just shopping for a price, think of this as a vetting process. You're looking for a true professional with a track record of quality work. This isn't just about buying a service; it's about investing in a long-term asset for your building.

Verifying Credentials and Experience

Before you even start talking about your specific project, you need to check the basics. Any legitimate contractor will have this information ready and won't hesitate to show you. Don't be afraid to ask for these non-negotiables:

- State Licensing and Insurance: First things first, make sure they have a current, valid license to operate in Florida. Just as important, confirm they carry both general liability and worker's compensation insurance. This is what protects you from any liability if an accident happens on your property.

- Manufacturer Certifications: The best spray foam manufacturers don't just sell their products to anyone. They certify applicators who have gone through rigorous training. This certification is your peace of mind that the crew knows exactly how to apply the product to meet warranty standards.

- A Portfolio of Local Work: Ask to see their work. A good contractor will be proud to show you completed projects, especially ones here in South Florida that are similar to yours. A deep portfolio proves they have a history of success and know how to handle our unique climate.

Asking the Right Questions

Once you’ve confirmed they’re legitimate, it's time to dig a little deeper into how they actually operate. Choosing a contractor involves understanding contractor management and how they run their business, as it speaks volumes about their reliability and commitment to a job well done.

A professional contractor isn't just an installer; they are a long-term partner in protecting your investment. Their role extends from the initial estimate through installation and beyond, offering tailored solutions and ensuring your peace of mind.

Here are a few critical questions you should ask every potential contractor:

- What kind of equipment are you running? They should be able to tell you about their high-pressure spray rigs and how they maintain them. Properly maintained equipment is crucial for mixing the foam chemicals at the perfect ratio and temperature. Anything less can lead to big problems.

- How do you prep the roof before you spray? A good answer will involve details like power washing, using moisture detection tools to find hidden water, and applying the right primer. A detailed prep plan is the sign of a meticulous, professional team.

- What's your safety plan? A reputable company will have a clear plan for protecting your building, landscaping, and cars from overspray. They'll also ensure their crew uses the proper personal protective equipment (PPE).

Putting in this diligence upfront ensures you find a true professional who will deliver a flawless roof that protects your building for decades.

Got Questions About Spray Foam Roofing? We've Got Answers.

When you're looking into a new roofing system, the practical, day-to-day questions are often the most important. How will it hold up? What happens if it gets damaged? Let’s get straight to the most common questions we hear from property owners just like you.

Can You Walk on a Spray Foam Roof?

Yes, you absolutely can. A professionally installed closed-cell spray foam roof is remarkably durable and easily handles the foot traffic needed for routine maintenance on rooftop equipment like HVAC units.

The foam itself has a high compressive strength, kind of like the dense foam in a heavy-duty cooler, and the protective topcoat adds another tough layer. For areas that see constant, heavy traffic, we can even install dedicated walkway pads for an extra measure of protection.

How Are Spray Foam Roofs Repaired?

This is one of the best parts—repairs are incredibly straightforward and don't break the bank. If a tool gets dropped or a piece of storm debris causes a gouge, the process is simple. We just cut out the small damaged section, make sure it's dry, fill it with new foam, and re-apply the protective coating over the top.

The real magic is in the closed-cell structure. If you get a small puncture, water can't travel sideways through the foam. This means a minor issue stays a minor issue, preventing it from turning into a widespread leak that compromises your entire roof deck.

Is Spray Foam Roofing an Eco-Friendly Option?

It’s one of the best green roofing options on the market, and for a few key reasons. First, its incredible insulating power dramatically cuts down on your building's energy use, which in turn shrinks your carbon footprint.

Second, these roofs are built for the long haul. Instead of a full tear-off and replacement that sends tons of material to the landfill, we can simply recoat the roof every 15-20 years to extend its life indefinitely. On top of that, many modern foam systems have zero ozone-depleting potential, making them a truly responsible choice. It's a win for your energy bills and a win for the environment.

Ready to see how a polyurethane spray foam roofing system can protect your South Florida property while drastically cutting your energy bills? The team at Airtight Spray Foam Insulation brings over 25 years of hands-on experience to every project, ensuring a flawless installation from start to finish. Request your free, no-obligation quote today!