Blog

Insulation Fire Ratings: How to Compare Materials and Choose Safely

When you’re thinking about insulation, the first things that probably come to mind are keeping your home cool and your energy bills down. But there's another, equally critical job it does: protecting your home in a fire.

Insulation fire ratings are a standardized way to measure how a material will behave when things get hot. Think of it like a safety report card for your insulation. These ratings tell us how long a material can resist catching fire, how quickly flames will spread across it, and just how much smoke it will create. Getting this right isn’t just about checking a box for a building inspector; it’s about buying yourself and your family precious time to get out safely if the worst happens.

What Insulation Fire Ratings Mean for Your Home's Safety

When an insulation product has a fire rating, it means it's been through the wringer in a controlled lab setting. These aren't just guesses; they're the results of intense, standardized tests that simulate real-world fire scenarios. This process cuts through the marketing fluff and gives you a straight, reliable answer on safety.

For anyone building or renovating in South Florida, understanding these ratings is step one in creating a home that’s not only efficient but also fire-resilient. It’s about more than just numbers on a package—it's about the fundamental safety of the building and the people inside it.

Decoding the Core Classifications

Most insulation materials are graded using a simple A, B, or C classification. This system gives you a quick snapshot of its fire performance based on two critical metrics from those lab tests:

- Flame Spread Index (FSI): This tells you how fast fire will travel across the insulation's surface. Lower is always better. A low FSI means the material is doing its job and slowing the fire down.

- Smoke Developed Index (SDI): This number measures the amount of smoke produced when the material burns. Again, you want a low number here. Less smoke means better visibility and safer air during an evacuation.

A Class A rating is the best you can get and is what you should look for in your home. These materials have a flame spread index of 25 or less, which means they’re incredibly resistant to burning and won't act as fuel to help a fire grow.

A common misconception is that "fire-rated" means "fireproof." The reality is, almost nothing in a home is truly fireproof. A high fire rating means the insulation is engineered to resist heat and slow a fire's spread, giving you a critical window of time to escape.

To make it even clearer, here's a quick breakdown of what these classifications really mean.

Quick Guide to Common Fire Rating Classifications

This table breaks down the most common fire rating classifications found on insulation materials and explains what each class signifies in terms of fire spread and smoke development.

| Classification | Flame Spread Index (FSI) | Smoke Developed Index (SDI) | What It Means for Your Home |

|---|---|---|---|

| Class A | 0-25 | 0-450 | This is the highest level of fire resistance available for building materials. Insulation with a Class A rating offers the best protection, significantly slowing the spread of fire and minimizing its contribution to the blaze. It's the gold standard for residential safety. |

| Class B | 26-75 | 0-450 | Materials in this category offer moderate fire resistance. While still providing a level of protection, they will allow flames to spread more quickly than Class A materials. This rating is often found in commercial applications where other fire suppression systems are also in place. |

| Class C | 76-200 | 0-450 | This is the lowest level of fire resistance for rated materials. Class C insulation provides minimal protection against flame spread and is generally not recommended for areas where fire safety is a primary concern. It can contribute significantly to the growth of a fire compared to Class A or B options. |

Simply put, choosing a Class A-rated material is one of the most important decisions you can make for your home's fire safety.

Why This Matters in a Real Fire

In a house fire, seconds are everything. The insulation inside your walls and attic can be the difference between a small, containable incident and a fast-moving disaster. Insulation with a poor fire rating can literally add fuel to the fire, accelerating its spread and pumping out toxic smoke.

On the other hand, high-performance insulation with a Class A rating—like many professionally installed spray foam products—behaves very differently. Instead of melting, dripping, or fueling the flames, it tends to char in place. This charring helps contain the fire, keeping it from easily breaking through walls or ceilings and helping maintain your home's structural integrity for longer. Making an informed choice based on fire ratings isn't a minor detail; it's a fundamental part of building a safer home from the inside out.

How Fire Safety Tests Reveal What Really Matters

An insulation fire rating isn't just a letter on a spec sheet. It's a grade earned by surviving some of the toughest, most intense trials in the building industry.

These tests are designed to simulate the brutal reality of a fire, pushing materials to their absolute limits to see how they hold up under pressure. When you understand what these tests involve, you can look right past the marketing fluff and see the true safety profile of an insulation product.

It’s this rigorous process that separates professionally engineered materials from the ones that could fail when you need them most. The hard data from these controlled lab tests is what backs up a Class A, B, or C fire rating, giving you a reliable measure of how it will actually perform.

The Fire Tunnel Test: ASTM E84

One of the most foundational tests is ASTM E84, which most of us in the industry simply call the "Steiner Tunnel Test." Picture a long, controlled fire tunnel where a sample of insulation is mounted on the ceiling. A flame is lit at one end, and technicians measure two critical things.

- Flame Spread Index (FSI): This shows how quickly flames travel across the surface. A lower score is better—it means the insulation is actively resisting the fire's advance.

- Smoke Developed Index (SDI): This measures how much smoke the material kicks out when it burns. Less smoke means better visibility and safer conditions for anyone trying to get out.

To earn the gold standard Class A rating, a material needs a Flame Spread Index of 25 or less. This test is a big deal; it tells us how a material might contribute to a fire's growth in those critical first moments.

The Endurance Test: ASTM E119

While the tunnel test looks at how fire spreads across a surface, the ASTM E119 test asks a different question: how well can an entire wall or floor assembly contain a fire? This isn't just about the insulation anymore. It’s about how the insulation, drywall, studs, and everything else work together as a system.

For this test, a full-scale wall is built and then blasted with a furnace fire that follows a specific temperature curve to mimic a real building fire. To pass, the assembly has to do two crucial jobs:

- Stop the Flames: It absolutely cannot let fire burn through to the other side.

- Block the Heat: It has to keep the non-fire side cool enough that it won't spontaneously ignite other materials.

The rating is given in hours—like a 1-hour or 2-hour rating—which tells you how long that wall can hold back the fire and stay standing. This is what buys precious time for people to evacuate and for firefighters to do their jobs before a potential collapse.

The ASTM E119 test is less about the insulation itself and more about its role as a key player on a fire-resistant team. A wall's fire rating depends on every single component doing its job.

The Wall Assembly Test: NFPA 285

For modern buildings, especially commercial ones with foam plastic insulation, the NFPA 285 test is non-negotiable. This standard is all about stopping fire from climbing up the outside of a building. It's designed to make sure a fire on one floor doesn't just leapfrog up the exterior walls and ignite the floors above.

This is a critical safety measure across many industries. Just as insulation is tested, personal protective gear must also meet strict standards to be effective. For example, you can learn more about the requirements for NFPA 2112 standards for FR clothing to see how these principles apply elsewhere.

By hitting a multi-story wall mock-up with intense flames, the test proves that the entire exterior system—cladding, weather barriers, and insulation—won’t create a chimney for fire. Passing this test is often a code requirement, ensuring the entire building envelope is designed with safety as the top priority. These tests are the backbone of modern fire safety, turning abstract ratings into performance you can count on.

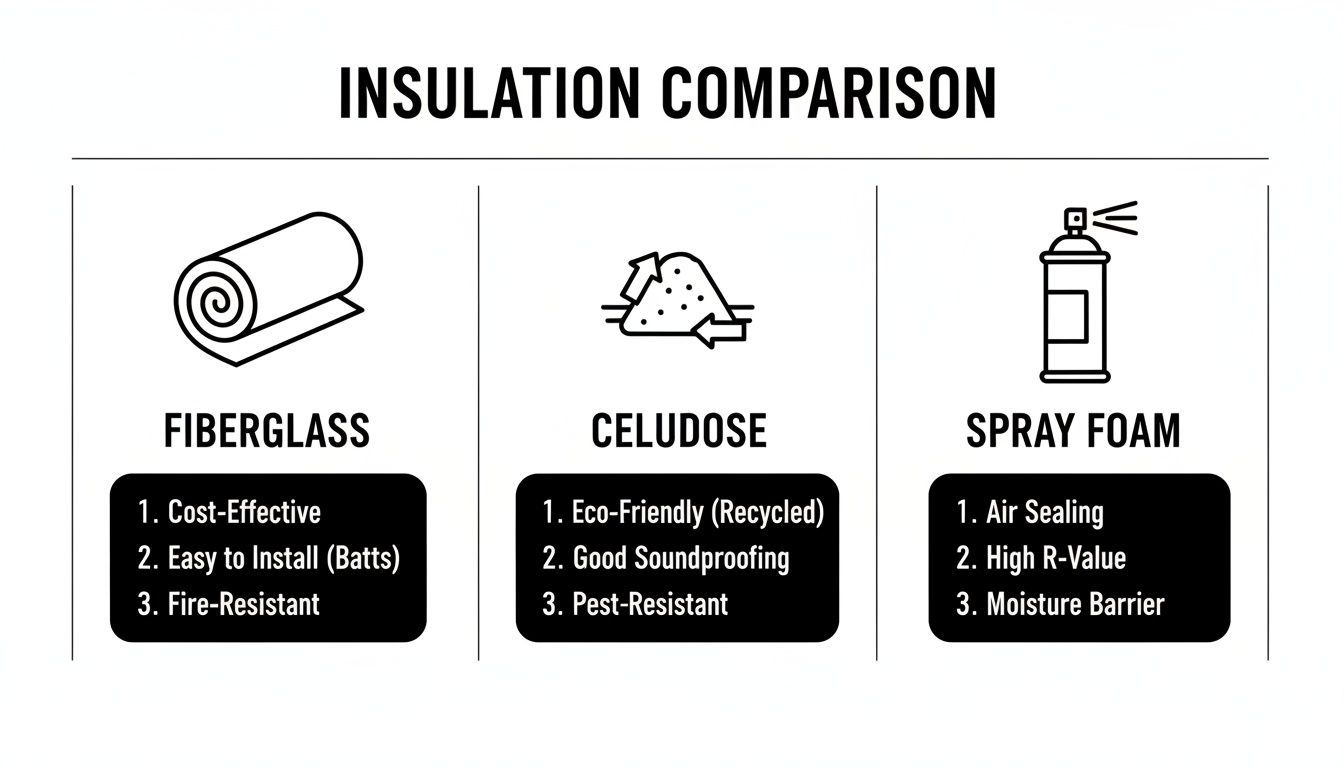

Comparing Fire Performance of Common Insulation Materials

When it comes to fire safety, not all insulation materials are cut from the same cloth. Their unique chemical and physical properties fundamentally change how they behave when things get hot—and understanding those differences is key to choosing an option that keeps a home safe without sacrificing performance.

Some materials, like mineral wool and fiberglass, are naturally fire-resistant. Mineral wool is literally made from molten rock spun into fibers, so it’s non-combustible right out of the gate. Fiberglass, being made of glass, also resists burning quite well.

Then you have products like cellulose and spray foam, which are derived from organic or plastic-based sources. To meet modern safety codes, they’re treated with fire-retardant additives. Don't let that fool you, though. With today's advanced formulations, these materials can achieve a top-tier Class A fire rating, making them incredibly safe when installed as part of a complete, code-compliant assembly.

Spray Foam Insulation Fire Performance

Spray polyurethane foam (SPF) is famous for its air-sealing and R-value, but its fire performance is just as impressive. Both open-cell and closed-cell spray foams are infused with fire retardants that help them earn that Class A rating. Specialized products, like a high-performance fire retardant polyurethane foam, take this protection even further.

Instead of bursting into flames, modern spray foams are engineered to char when exposed to fire. This char creates a protective carbon layer that insulates the material underneath, slowing down heat transfer and preventing the fire from finding more fuel to spread. It’s this self-extinguishing behavior that makes SPF a critical component in fire-resistant wall and roof systems, especially when paired with the required thermal barriers.

The demand for these advanced materials is skyrocketing. In 2023, the global fireproof insulation market was valued at an incredible USD 33.8 billion, and it's only expected to climb. This growth is largely driven by stringent building codes, which makes choosing a code-compliant material like spray foam a smart, long-term investment for any homeowner in South Florida.

Key Takeaway: The real goal of fire-rated insulation isn’t to be "fireproof," but to resist catching fire and, most importantly, slow a fire’s spread. Materials like spray foam that char in place are so effective because they don't add fuel to the fire, which buys precious, life-saving time for everyone to get out safely.

Fire Performance of Common Insulation Materials

Let's break down how different insulation types stack up against each other when it comes to fire. This table gives a quick, side-by-side look at their typical ratings and behaviors.

| Insulation Type | Typical Fire Rating (Class) | Behavior in Fire | Key Benefits |

|---|---|---|---|

| Spray Foam | Class A (with barrier) | Chars and self-extinguishes; does not melt or drip. | Excellent at slowing flame spread; forms a tight air seal. |

| Fiberglass | Class A (non-combustible) | Resists burning but can melt at high temperatures. | Naturally non-combustible; cost-effective. |

| Mineral Wool | Class A (non-combustible) | Withstands extreme heat (over 2,000°F) without melting. | Superior fire resistance; great for fire-blocking applications. |

| Cellulose | Class B or C (treated) | Heavily treated with fire retardants to smolder and resist ignition. | Made from recycled materials; good sound dampening. |

As you can see, while materials like mineral wool are inherently non-combustible, professionally installed spray foam offers a unique advantage by charring in place, effectively starving the fire of fuel.

Open-Cell vs. Closed-Cell Spray Foam

While both major types of spray foam deliver excellent fire resistance, their core differences in density and cell structure create a noticeable gap in performance. You can get a deeper dive into their makeup in our guide to the types of spray foam insulation.

Open-Cell Spray Foam: This is the lighter, softer version, with a density of around 0.5 pounds per cubic foot. Its open-celled structure makes it a fantastic sound absorber. While it contains fire retardants and performs well, its lower density means it doesn't resist heat transfer as robustly as its denser cousin.

Closed-Cell Spray Foam: This stuff is tough. At a density of roughly 2.0 pounds per cubic foot, it’s rigid, strong, and creates an incredible barrier against air and moisture. That dense, closed-cell structure is also far better at resisting heat transfer, which means it slows the progression of a fire much more effectively.

For homeowners in South Florida dealing with our unique climate challenges, the tough, dense nature of closed-cell foam is the clear winner. It delivers an unbeatable package of thermal performance, moisture control, structural strength, and superior fire resistance.

Why Thermal and Ignition Barriers Are Non-Negotiable

Spray foam is a beast when it comes to thermal performance, but its raw power is only half the story. To be truly safe and effective, it has to work as part of a system—and that means partnering it with crucial protective layers called thermal and ignition barriers.

Without them, the installation is incomplete, a code violation, and frankly, a serious safety risk.

The Critical Role of a Thermal Barrier

Think of a thermal barrier as a firefighter standing guard over the insulation. Its job is to shield the foam from the intense heat of a fire, buying precious time before the insulation itself is exposed to dangerous temperatures.

This isn’t just a friendly suggestion; it’s a non-negotiable safety mandate.

A thermal barrier is a material that gets applied over spray foam in any habitable space—think living rooms, bedrooms, or finished basements. The most common, go-to thermal barrier is 1/2-inch thick drywall, though other approved materials like certain wood panels or plaster can also do the job.

The code defines its mission with a very specific, time-based standard. It must prevent the foam's surface from heating up by more than 250°F (121°C) for at least 15 minutes when one side of the wall is exposed to fire. That 15-minute window is everything. It provides the invaluable time people need to get out of the house safely.

A thermal barrier isn't meant to make a wall "fireproof." Its real purpose is to create a time delay. It keeps the heat at bay just long enough for people to escape and for first responders to show up. It’s a life-safety layer, pure and simple.

The chart below gives you a quick look at how different insulation materials stack up in a few key areas.

It’s a good reminder that while all materials have their own properties, spray foam's safety profile is only complete once these essential barriers are in place.

Understanding Ignition Barriers

While a thermal barrier provides heavy-duty, timed protection for living spaces, a less robust layer called an ignition barrier is required for unoccupied areas. We're talking about places like attics or crawl spaces that aren't used for storage.

An ignition barrier has a simpler, but still important, job: to stop the foam from catching fire from a brief, direct exposure to a flame or spark—like a stray ember or a quick slip-up with a maintenance torch.

Some common materials used as ignition barriers include:

- Plywood or oriented strand board (OSB) at least 3/8-inch thick.

- Special fire-retardant paints called intumescent coatings, which puff up when heated to form a protective char layer.

- Gypsum wallboard that is at least 3/8-inch thick.

Knowing which barrier to use and where is the key to a safe, code-compliant job that will fly through inspection. While spray foam is an incredible insulator, its fire safety is all about this system-based approach. If you’re curious about the foam itself, you can learn more about how spray foam insulation is tested for fire safety in our other guide.

The push for safer, high-performance insulation is clear in the market. The fireproof insulation market is expected to hit USD 30.5 billion in 2025 and grow to USD 43.0 billion by 2035. This shows just how focused the industry is on materials that deliver on both fire safety and energy efficiency—a combo where spray foam, when installed correctly in attics, walls, and roofs, really shines. You can read more about the future of fireproof insulation on futuremarketinsights.com.

Navigating South Florida's Building Codes for Insulation

Meeting fire safety standards isn't just a good idea—it's the law. Here in South Florida, the Florida Building Code (FBC) governs everything, from new homes going up in Palm Beach Gardens to remodels in Wellington. These aren't just arbitrary rules; they are the bedrock of a safe structure, designed to protect your property and, more importantly, save lives.

For anyone installing insulation, understanding these codes is non-negotiable. The FBC doesn't just list required insulation fire ratings; it gets into the nitty-gritty of how materials must be installed, including the absolute necessity of thermal and ignition barriers. A project that cuts corners here won't just fail an inspection—it creates a genuine safety hazard for the entire building.

What Inspectors Look for During an Inspection

When a building inspector shows up on your job site in Jupiter or Stuart, they're not just there for a quick once-over. They are there to scrutinize the entire insulation system, making sure it lines up perfectly with the approved plans and every letter of the FBC. Their checklist is detailed for a reason.

Here’s what’s on their radar:

- Correct Material Usage: Is the insulation that was actually installed the same product specified in the plans, with the right fire rating for that specific wall or ceiling?

- Proper Barrier Installation: They will meticulously check that the code-approved thermal or ignition barrier is installed correctly over the spray foam. No gaps, no unsealed joints, no excuses.

- Sufficient Application Depth: The foam must be applied at the right thickness to meet both the thermal (R-value) and fire code requirements. Too thin is an automatic fail.

- Sealed Penetrations: Every gap around pipes, vents, and electrical boxes needs to be sealed with the right fire-rated materials. This is crucial for stopping a fire from racing through the walls.

An experienced, professional installer knows this process like the back of their hand. They understand that a successful inspection isn't about "passing a test." It's about proving the job was done right from the start, locking in both safety and compliance.

The Critical Importance of Professional Installation

Trying to navigate the complexities of the Florida Building Code is not a weekend DIY project. One small mistake—using the wrong fastener for the drywall or leaving a tiny gap in an ignition barrier—can snowball into a failed inspection, expensive rework, and massive project delays. This is exactly why a professional installation team is your most critical partner.

An expert installer sees the bigger picture. They understand the building science required to create a continuous, sealed envelope that manages airflow, moisture, and fire risk all at once. Proper installation is also a cornerstone of any effective moisture management strategy, which is critical for preventing the mold and rot we see all too often. You can learn more about how insulation and moisture control go hand-in-hand in our guide on vapor barriers and insulation.

The demand for high-performance, fire-resistant insulation is skyrocketing for a reason. The global market, valued at USD 28.01 million in 2022, is expected to climb to USD 35.09 million by 2030, according to market research. This isn't just a trend; it's a direct response to stricter building codes designed to protect lives and property. For contractors here in South Florida, it underscores why proven systems like spray foam are the go-to choice, especially in places like metal buildings and garages where fire safety is a top priority.

Putting It All Together for a Safe, Airtight Home

When you're building or renovating, choosing the right insulation is one of the most fundamental investments you can make in your home's safety and long-term value. As we've covered, those insulation fire ratings aren't just technical jargon on a product sheet. They represent a material's real-world ability to resist heat, slow down a fire, and most importantly, buy you and your family precious time if the worst happens. Starting with that commitment to safety is the first step in creating a high-performance home.

But even the best materials in the world are only as good as their installation. A meticulous, professional job is what turns a great product into a complete, protective system. It’s about making sure every nook and cranny is sealed, every thermal barrier is installed perfectly, and every building code is met without question. This is the kind of attention to detail that separates an average house from a truly safe and efficient one.

More Than Just Fire Safety

When you commit to meeting South Florida's tough fire codes with advanced materials like spray foam, you get a whole host of benefits that go way beyond just fire resistance. A professionally installed spray foam system creates an incredible airtight seal, which delivers a powerful punch of advantages:

- Lower Energy Bills: By stopping air from leaking in or out, spray foam takes a massive load off your HVAC system. That means real, noticeable savings on your cooling costs month after month.

- Better Indoor Air Quality: A truly sealed home blocks all the junk you don't want inside—pollutants, allergens, and that famous Florida humidity. The result is a healthier, more comfortable place to live.

- A Quieter Home: The dense, solid nature of spray foam insulation is a fantastic sound dampener. It hushes noise from outside, giving you a more peaceful and quiet indoor space.

It's a holistic approach. You're not just investing in one thing (safety); you're upgrading your home's entire performance and making it a better place to be every single day.

Your Next Step Toward a Better Home

For homeowners and builders here in South Florida, from Jupiter down to West Palm Beach, the takeaway is clear. Making a professionally installed, high-performance insulation system a priority is one of the most impactful decisions you can make. It's an investment that pays you back in peace of mind, lower utility bills, and a stronger, more resilient home for decades.

It all comes down to focusing on the complete system—the right material with a solid fire rating, a code-compliant installation, and a meticulous air seal. When you do that, you create a home that isn't just built to code, but built for life. This integrated approach ensures every part works together to protect your family and your investment.

At Airtight Spray Foam Insulation, this is the standard we live by. Our team has hands-on experience with the unique demands of our local climate and building codes. We bring a precise, step-by-step process to every job to guarantee your home is safe, airtight, and as efficient as it can possibly be.

A Few Common Questions About Fire Ratings

Let's be honest, navigating the technical side of insulation and fire safety can feel a bit overwhelming. When you're trying to make the best decision for your home or project in South Florida, a lot of questions pop up. We get it. Here are some of the most common ones we hear, with clear, straightforward answers.

"I've Heard Spray Foam is Flammable. Is it a Fire Hazard?"

This is a big one, and the short answer is no—not when it's installed correctly by professionals who follow the building code. Modern spray foams, the kind we use every day, are specifically engineered with fire retardants built right in. This allows them to achieve a Class A fire rating, the highest classification for flame spread.

But the real key to its safety isn't just the foam itself; it's the entire system. This means applying the foam at the right thickness and, crucially, covering it with a code-mandated protective layer called a thermal or ignition barrier. This barrier is what ensures the foam is safely encapsulated and won't contribute fuel to a fire, making it a perfectly safe part of a fire-resistant home.

What’s the Difference Between a Thermal Barrier and an Ignition Barrier?

Great question. While they both exist to protect the spray foam, they serve different purposes and are required in different areas of a home. Think of it as a difference in the level of protection needed based on who (or what) is in that space.

A thermal barrier is the heavyweight champ of protection. It's almost always 1/2-inch drywall and is mandatory anywhere the foam is adjacent to a habitable or "lived-in" space—like your living room or bedrooms. Its job is serious: to shield the foam from the intense heat of a fire for at least 15 minutes, preventing it from reaching a critical temperature.

An ignition barrier is a lighter-duty covering used in unoccupied areas like attics and crawl spaces. Its goal is much simpler: to stop the foam from igniting from a quick, direct exposure to flame, like a stray spark from an electrician's tool.

Can I Have Fire-Rated Insulation Installed in My Existing Home?

Absolutely. In fact, retrofitting an older home with modern, fire-rated insulation is one of the single best upgrades you can make. It's a huge boost for both safety and energy efficiency, and it's a project we handle all the time for South Florida homeowners.

For example, we can go into an existing attic and apply closed-cell spray foam directly to the underside of the roof deck. Once the foam is in place, we install the required ignition barrier over it. The result? You've not only dramatically improved your home's fire resilience but also created an airtight seal that will slash your cooling costs for years to come.

Upgrading your home's insulation isn't just about comfort; it's a direct investment in your property's safety and resilience. By bringing an older home up to modern fire code standards, you are adding a crucial layer of protection for your family and your investment.

Can Better Fire-Rated Insulation Actually Lower My Homeowners Insurance?

It often can. Insurance companies love to see homeowners take proactive steps to reduce risk, and installing certified, fire-resistant building materials is a major plus in their book. A professionally installed, code-compliant insulation system is a significant safety upgrade, and many carriers will reward you for it.

Our advice is always to call your insurance agent once the job is done. Show them the documentation for the high-performance, fire-rated products we used. They'll be able to tell you exactly what kind of discount you might qualify for. It's a fantastic way to get a return on an investment that's already protecting your home.

Ready to enhance your home's safety and efficiency with a professionally installed, fire-rated insulation system? The experts at Airtight Spray Foam Insulation have the hands-on experience to ensure your project meets the highest standards for performance and code compliance in South Florida. Request your free, no-obligation estimate today.