Blog

Foam vs Fiberglass Insulation A Head-to-Head Comparison

When it comes to the foam vs fiberglass insulation debate, it boils down to one critical difference in how they function. Spray foam creates a monolithic, seamless barrier against both air and moisture. Fiberglass, on the other hand, works by trapping pockets of air to slow down heat transfer, but it doesn’t stop air or moisture from moving through it.

In a high-humidity climate like South Florida, spray foam’s ability to completely seal the building envelope makes it the undisputed long-term champion for both energy efficiency and moisture control. While fiberglass is still a viable, budget-friendly option for projects where upfront cost is the primary concern, it’s a different class of material altogether.

Making the Right Insulation Choice

Picking between spray foam and fiberglass isn’t just a line item on a construction budget—it’s a decision that will directly affect your home’s comfort, monthly energy bills, and even its structural health for years to come. While both materials are designed to resist heat flow (their R-value), their real-world performance couldn’t be more different.

To make a smart choice, you have to look past the price per square foot and dig into the key performance metrics that define an insulation’s true value, especially in our demanding South Florida climate.

Key Decision-Making Factors

- R-Value Per Inch: This is the standard measure of thermal resistance. A higher R-value means better insulating power, which is essential for keeping your home cool. Closed-cell spray foam offers the highest R-value, typically R-6.5 to R-7 per inch.

- Air Sealing Effectiveness: Air leakage is a massive source of energy waste and high humidity. One of these materials creates a true airtight seal as it’s installed, while the other requires a separate, meticulous air-sealing process to be even remotely effective.

- Moisture Management: In our humid environment, an insulation’s ability to manage moisture is non-negotiable. This is where you separate the products that prevent mold, mildew, and rot from those that can actually contribute to it.

- Long-Term Value: This isn’t just about the initial cost. It’s about the bigger picture: energy savings over decades, durability, and the overall lifespan of the insulation system.

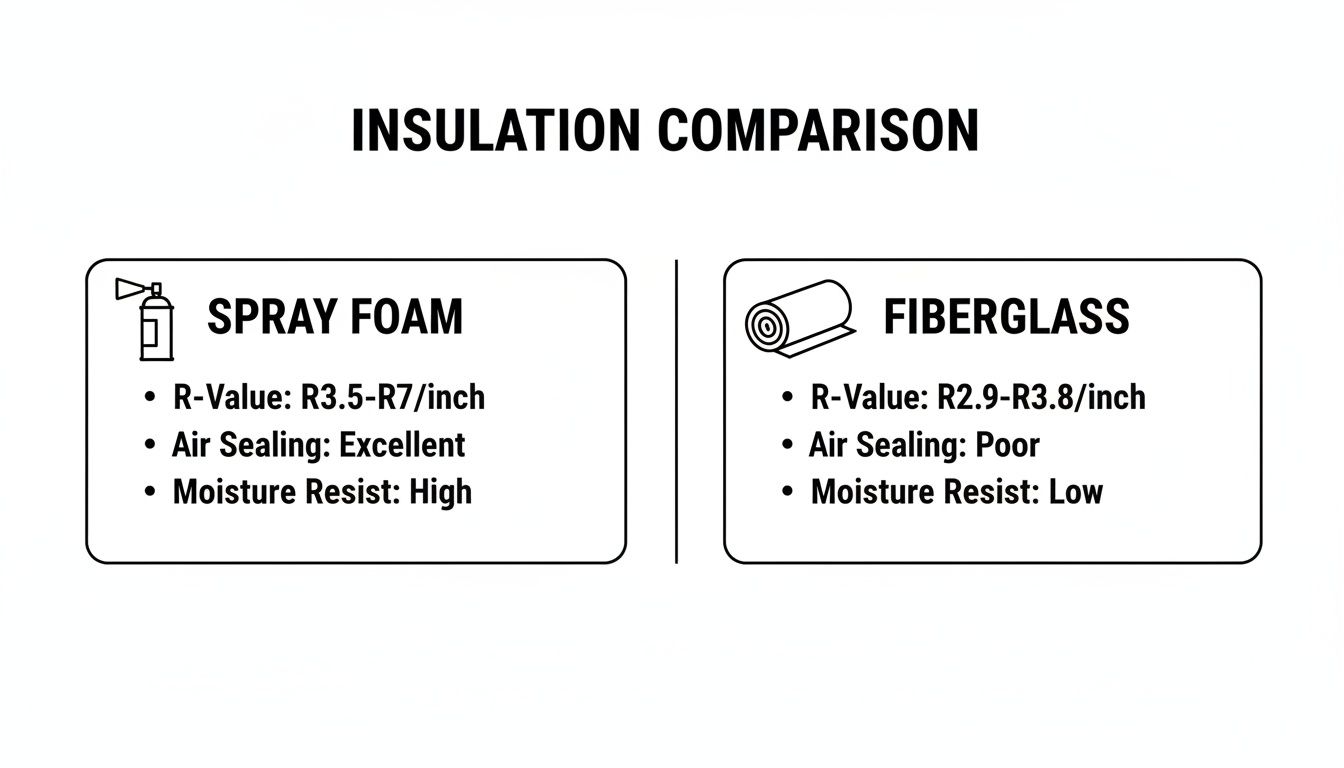

This image really drives home the core differences between the two materials.

As you can see, while both offer thermal resistance, spray foam is doing double duty by providing high R-value and an integrated air and moisture barrier. That’s a huge advantage.

Key Differences at a Glance

This table gives you a quick, side-by-side look at the most important distinctions between spray foam and fiberglass insulation.

| Performance Attribute | Spray Foam Insulation | Fiberglass Insulation |

|---|---|---|

| Air Sealing | Excellent. Creates a continuous air barrier. | Poor. Does not stop airflow on its own. |

| R-Value Per Inch | High (R-3.7 for open-cell, R-6.5+ for closed-cell). | Moderate (R-2.2 to R-3.8), degrades when compressed. |

| Moisture Resistance | Excellent. Closed-cell is a vapor barrier. | Poor. Can absorb moisture, lose R-value, and support mold. |

| Installation | Requires certified professionals and specialized equipment. | DIY-friendly (batts) or requires basic equipment (blown-in). |

| Upfront Cost | Higher. A premium, high-performance product. | Lower. Considered a budget-friendly option. |

| Lifespan | 30-80+ years. Does not sag or settle. | 15-25 years. Can sag, settle, and degrade over time. |

Ultimately, this comparison helps frame the conversation around performance. One product is an all-in-one building envelope solution, while the other is a single-function insulator.

Choosing the right insulation isn’t just about hitting a target R-value; it’s about creating a complete thermal boundary. In South Florida, an insulation that fails to control air and moisture movement is only doing half the job.

As we dive deeper into the foam vs. fiberglass insulation matchup, these foundational differences will show exactly why one material often provides a far greater return on investment through lower utility bills, a healthier home, and superior comfort.

Understanding Your Insulation Options

Before you can settle the foam vs. fiberglass insulation debate for your project, you have to get a feel for what these materials actually are. Both are designed to slow down heat, but how they’re made and how they work in the real world couldn’t be more different. Let’s break down the two main players you’ll be choosing between.

Traditional Fiberglass Insulation

You’ve seen it before. That pink or yellow fluffy stuff in most attics is fiberglass, the go-to insulation for decades. Made from incredibly fine glass fibers, its main job is to trap pockets of air to slow the transfer of heat. Simple and effective, right?

It typically comes in two forms:

- Batts and Rolls: These are the familiar pre-cut blankets, sized to fit between standard wall studs and ceiling joists. Many have a paper or foil face that’s meant to act as a vapor barrier.

- Blown-In (Loose-Fill): This is the same material but shredded into loose fibers. A machine blows it into attics or sealed wall cavities, which helps it settle around pipes and wires better than batts can.

Here’s the catch with fiberglass: its performance hinges entirely on a perfect installation. If it’s compressed, has gaps, or leaves any voids, its ability to trap air is shot. Those gaps become thermal bridges—superhighways for heat to move in and out of your home.

The key takeaway for fiberglass is this: it resists heat flow but does nothing to stop air movement. In a humid place like South Florida, uncontrolled airflow means uncontrolled moisture. That’s a critical distinction.

Advanced Spray Foam Insulation

Spray Polyurethane Foam (SPF), or just spray foam, is a totally different beast. It starts as a two-part liquid chemical that gets mixed and applied on-site with a sprayer. As soon as it hits a surface, a chemical reaction causes it to expand dramatically, hardening into a solid, seamless layer of insulation.

That expansion is its secret weapon. It lets the foam creep into every tiny crack, gap, and odd-shaped cavity, creating a perfect, custom-fit barrier. No gaps, no leaks. Spray foam is broken down into two main types, and each has its own unique strengths.

Open-Cell Spray Foam

Open-cell foam has a soft, sponge-like texture. Its cells aren’t completely sealed, which makes it flexible and vapor-permeable. This means it stops air dead in its tracks but still allows any trapped moisture to dry out.

- What it’s great for: Unbelievable sound dampening and creating a powerful air seal.

- Typical R-Value: Around R-3.7 per inch.

You’ll often find this used for interior walls to quiet down a house or on roof decks where its air-sealing abilities shine.

Closed-Cell Spray Foam

In sharp contrast, closed-cell foam cures into a hard, dense, and rigid material. Its cells are completely sealed and packed tightly, making it a true barrier to both air and moisture. As a bonus, its rigidity adds a surprising amount of structural strength to whatever it’s applied to.

- What it’s great for: The highest R-value, acting as a true vapor barrier, and adding structural reinforcement.

- Typical R-Value: Ranges from R-6.5 to R-7 per inch.

For South Florida, closed-cell is the heavy hitter. It’s the top choice for exterior walls, crawl spaces, and metal buildings, where its ability to block moisture is absolutely essential for preventing condensation and mold.

Now that you understand the core differences between these materials, you can really start to see why their performance in the real world is so dramatically different.

Diving Deep into Performance

When you get down to brass tacks, the choice between foam and fiberglass insulation really boils down to three critical factors, especially here in South Florida: thermal resistance (R-value), air sealing, and how it handles moisture. Both materials insulate, sure, but how they do it couldn’t be more different. Getting this right means the difference between a comfortable, efficient home and one that’s constantly fighting the climate.

Your insulation choice is a cornerstone of your overall home performance. To get the full picture, it helps to understand other effective home energy efficiency strategies and see how everything works together.

The R-Value Reality Check

Everyone talks about R-value—it’s the standard measure of how well insulation resists heat flow. Higher is better. But the number on the package doesn’t tell the whole story; it’s the “R-value per inch” that really dictates performance in a wall or attic with limited space.

Fiberglass batts offer a decent R-value, usually somewhere between R-2.9 to R-4.3 per inch. In a perfect world, that gets you about an R-13 in a standard 2×4 wall. The problem is, we don’t live in a perfect world. That R-13 rating assumes a flawless installation with zero gaps, no compression, and no air movement—a scenario that almost never happens on a real job site.

Spray foam, especially closed-cell, is in another league entirely, delivering R-6.5 to R-7 per inch. This means you can pack significantly more insulating power into the exact same space. In modern construction, where energy codes are only getting tougher, that extra performance is a massive advantage.

Air Sealing: The Game-Changer for Foam

This is where the debate almost ends. It’s the single biggest performance gap between foam and fiberglass.

Fiberglass is air-permeable. Period. Wind, drafts, and humid Florida air can blow right through it, which completely torpedoes its “rated” R-value. It slows heat down, but it does absolutely nothing to stop air leakage.

Spray foam, on the other hand, is both an insulator and an air barrier in one shot. As it’s applied, it expands to fill every single crack, gap, and crevice, creating a seamless, airtight seal. It’s a level of airtightness that fiberglass batts simply can’t achieve, no matter how meticulously they’re installed.

Studies have shown that a properly air-sealed building envelope can slash air leakage by as much as 24 times compared to traditional methods. That’s a direct hit on your energy bills, because your A/C isn’t constantly battling hot, humid air sneaking in from outside.

This airtight seal also pays huge dividends in noise reduction. The solid, dense barrier that foam creates is incredibly good at muffling traffic, neighbors, and other outside noise. If you’re looking for a quieter home, you can learn more about using insulation as a sound barrier in our detailed guide.

Moisture and Mold: A Clear Winner in a Humid Climate

In a place like South Florida, how your insulation handles moisture is just as critical as its R-value. This is another area where foam, particularly closed-cell, pulls far ahead.

Fiberglass acts like a sponge. It can absorb moisture right out of the humid air, and once it gets damp, its insulating power plummets. Worse, that damp fiberglass—especially the kind with a paper facing—becomes a perfect breeding ground for mold and mildew.

- Closed-cell spray foam is a different beast. It’s non-porous and acts as a Class II vapor retarder, meaning it repels water and resists moisture vapor. It won’t absorb water, its R-value stays put, and it doesn’t support mold growth.

- Open-cell spray foam doesn’t repel water like closed-cell, but it also doesn’t wick or hold it like fiberglass. Instead, it allows any moisture that gets in to pass through and dry out, preventing it from getting trapped in your walls.

This difference is everything in a region where we’re constantly fighting humidity. While the U.S. insulation market, valued at $9.7 billion, has historically been dominated by low-cost fiberglass, that tide is turning. Projections show a decline for fiberglass as high-performance foamed plastics gain market share, a shift driven by the demand for superior air sealing.

Here in South Florida, that trend is even more pronounced. The ability of spray foam to create a true air and moisture barrier offers an undeniable advantage, with some property managers reporting energy savings of 20-50% on cooling bills after upgrading from fiberglass.

Comparing Upfront Cost vs. Long-Term Value

Let’s talk money. It’s often the first—and sometimes only—thing people look at in the foam vs. fiberglass insulation debate. And yes, it’s an undeniable fact: fiberglass is cheaper upfront. The initial quote for materials and installation will almost always be lower, making it seem like the obvious choice for anyone on a tight budget.

But that initial invoice is just page one of a much longer financial story.

To really understand the cost, you have to look at the total cost of ownership. That means factoring in what you’ll save on energy bills year after year, how long the insulation will last, and what you might have to spend later on repairs or replacement. Spray foam demands a bigger investment on day one, but its performance often delivers a return on investment (ROI) that fiberglass just can’t compete with over the life of your home.

The Upfront Cost Breakdown

When the quotes come in, the difference can be jarring. You’ll typically see spray foam costing two to three times more per square foot than traditional fiberglass batts.

- Fiberglass: It’s mass-produced, easy to find, and cheap to make. Installation is also pretty straightforward, especially in new construction with wide-open walls, which helps keep labor costs in check.

- Spray Foam: This is a different animal altogether. It’s a premium product made from a two-part chemical formula, applied with expensive, specialized equipment, and requires certified professionals to install it correctly. All those factors drive up the price.

This initial cost difference often makes fiberglass the default for quick retrofits or projects where the immediate bottom line is the only priority. But that’s a shortsighted way to look at a long-term part of your home.

The most expensive insulation is the one you have to replace. While fiberglass is cheaper upfront, its susceptibility to moisture, sagging, and pest damage can lead to costly remediation and re-installation projects down the road.

Calculating Long-Term Return on Investment

The real financial story isn’t told in the first week; it unfolds over years. That higher upfront cost for spray foam is an investment in serious energy efficiency, and you start getting paid back the moment your first lower utility bill hits your inbox.

The biggest driver of this ROI is air sealing. Because spray foam expands to create a solid, monolithic air barrier, it dramatically cuts down the workload on your HVAC system. In a humid climate like South Florida’s, studies show that properly installed spray foam can slash HVAC loads by 30-50%. That’s a massive saving that you’ll see month after month.

For many homeowners, the energy savings alone are enough to pay back the initial investment in just three to five years. After that, the insulation just keeps putting money back in your pocket for the lifetime of the home. This long-term financial gain is a key reason why the global market for foamed plastics is growing at nearly double the rate of fiberglass. You can learn more about the insulation market’s projected growth and trends on coherentmarketinsights.com.

Lifecycle Costs and Durability

Durability is where the total cost of ownership really comes into focus. Insulation only works if it stays put and keeps its R-value.

Spray Foam Durability:

- It becomes part of your house. It adheres directly to studs and sheathing, creating a rigid, permanent bond.

- It doesn’t move. Spray foam will not sag, shrink, or settle over time. The thermal barrier you have on day one is the same one you’ll have decades later.

- It blocks water. Closed-cell foam is impermeable to moisture, preventing the kind of water damage that can completely ruin other insulation types.

Fiberglass Durability:

- It sags and shifts. Gravity is not fiberglass’s friend. Over time, batts can slump down in wall cavities, creating huge gaps in your thermal protection.

- It’s a sponge. If fiberglass gets wet, it’s game over. It compresses and can permanently lose up to 50% of its R-value.

- It needs a babysitter. Over the years, you might find yourself needing to add more blown-in insulation to a settled attic or replacing entire sections of sagging batts just to keep up.

When you start adding up the potential costs of fixing water damage, replacing failed insulation, and paying higher energy bills from degraded performance, that cheap upfront price for fiberglass starts to look a lot less attractive. Spray foam is truly a “set it and forget it” solution that gives you financial peace of mind and a far more resilient home for the long haul.

Best Use Cases for Each Insulation Type

Figuring out whether to use spray foam or fiberglass really comes down to the job at hand. It’s not about one being universally “better”—it’s about picking the right tool for the specific task. Each material has its own strengths, and knowing where they shine is the key to a smart investment.

Think about where you’re insulating and what you’re trying to achieve. That’s how you get the best performance and long-term value for your money. Let’s walk through some real-world scenarios to see which one makes the most sense.

When Spray Foam Insulation Is the Superior Choice

Spray foam’s biggest advantage is its one-two punch: it’s a high R-value insulator and an air and moisture barrier all in one. This makes it the clear winner for any application where performance is non-negotiable and you need a truly sealed building envelope.

You’ll want to use spray foam for these critical areas:

- Attics and Roof Decks: In South Florida, sealing an attic with spray foam on the underside of the roof deck is a complete game-changer. By moving the thermal boundary to the roofline, your attic stops being a super-heated oven that cooks your home from above. Your AC system breathes a huge sigh of relief.

- Metal Buildings and Warehouses: Metal structures are notorious for “sweating” with condensation. Closed-cell spray foam is the perfect fix. It bonds directly to the metal, stops air movement cold, and acts as a vapor barrier, which completely eliminates condensation problems while giving you great thermal control.

- Crawl Spaces and Rim Joists: These spots are magnets for dampness and air leaks. Closed-cell spray foam seals them off from ground moisture and drafts, which helps prevent mold, stops chilly floors, and improves the overall health of your home’s air.

- Exterior Walls in New Construction: For a high-performance home, nothing beats filling 2×6 wall cavities with spray foam. It creates a powerful, airtight seal, actually adds structural rigidity to the walls, and maxes out the R-value you can fit in the space. It’s also a crucial part of the puzzle when you’re looking at the insulation value of concrete block walls, where a perfect seal is just as important as the R-value itself.

When your main goal is to kill air leaks, block moisture, and squeeze every bit of R-value out of a space, spray foam is the definitive choice. It creates a single, unbroken seal that fiberglass just can’t replicate.

Scenarios Where Fiberglass Insulation Makes Sense

While spray foam dominates in performance-critical areas, fiberglass still has its place. It’s a practical and cost-effective choice when the budget is tight and the conditions aren’t as demanding. Its lower upfront cost keeps it in the running for certain projects.

Here’s where fiberglass can be a suitable option:

- Standard Interior Walls for Sound Control: If your main goal is just to quiet things down between rooms, fiberglass batts are an economical and effective way to do it. While open-cell spray foam is better at sound dampening, fiberglass provides a noticeable improvement for a fraction of the cost.

- Budget-Driven Attic Retrofits: For a homeowner who just wants to add more insulation to their attic floor without a complete overhaul, blowing in a thick layer of fiberglass is a common and affordable strategy. It can definitely boost the attic’s overall R-value, but this only works well if air sealing was already handled separately.

- Dry Climate Construction: In arid places like Arizona or Nevada, where high humidity isn’t a constant battle, the powerful air-sealing and vapor-blocking features of spray foam are less critical. In these specific environments, a meticulous fiberglass installation can provide adequate thermal performance for a much lower price.

- Accessible Wall Cavities with Separate Air Sealing: If you have a project where you can absolutely guarantee that a separate, thorough air-sealing plan is executed first, fiberglass batts can work just fine as a basic thermal insulator. But remember, this approach lives or dies by the quality of that initial air barrier installation. If it’s not perfect, the fiberglass won’t perform as it should.

How to Make the Right Choice for Your Home

Navigating the foam vs fiberglass insulation decision really comes down to weighing your priorities. There’s no single “best” insulation for every project, but there is always a right choice for your home, your budget, and what you’re trying to accomplish.

It helps to move past the initial sticker shock and think about the long-term value. This isn’t just about stuffing insulation in the walls; it’s about creating a high-performance barrier that can handle South Florida’s brutal climate year after year. The goal is to pick the solution that best aligns with your goals for comfort, efficiency, and home resilience.

Your Decision-Making Checklist

To cut through the noise, just walk through these key questions. Your answers will point you in the right direction.

- What’s my main financial goal? If the absolute lowest upfront cost is the top priority for a simple job, fiberglass is the obvious budget choice. But if you’re focused on the biggest long-term energy savings and getting the best return on your investment over the life of your home, spray foam is the clear financial winner.

- How big of a deal is air sealing? For homes plagued by drafts, air leaks, and high humidity, spray foam isn’t just an option—it’s a necessity. Its ability to create a seamless, monolithic air barrier is its superpower. If your home is already pretty tight and you’re just adding a little more insulation to a dry attic, fiberglass can work as a basic thermal buffer.

- Is moisture or humidity a major concern? Here in South Florida, the answer is almost always a resounding yes. For crawl spaces, metal buildings, or any spot that gets damp, closed-cell spray foam is the only reliable choice. It functions as a true vapor barrier, blocking moisture completely. Fiberglass, on the other hand, can absorb moisture like a sponge, which kills its performance and opens the door to mold.

Your home’s unique quirks will dictate the best solution. A historic home with old, irregular framing gets a massive benefit from spray foam’s gap-filling ability. A brand-new build on a tight budget might strategically use fiberglass in less critical areas to save money.

If you really want to know where your home is losing energy, consider conducting a home energy audit. A professional assessment gives you a detailed roadmap, showing you exactly where your money is best spent for the biggest impact on comfort and your power bill.

The Final Step: A Professional Consultation

Ultimately, the best way to feel confident in your choice is to talk to an expert. A professional insulation contractor can do an on-site evaluation, spot problem areas you might have missed, and give you a detailed breakdown of the costs and benefits of each option.

This personalized approach ensures your final decision is perfectly matched to your home’s construction and your specific goals. And if you’re curious about other loose-fill materials, our detailed guide on spray foam vs. blown-in insulation offers even more clarity.

Frequently Asked Questions About Insulation

Even with the numbers crunched and the benefits laid out, you probably still have a few questions. That’s normal. Getting the details right is what separates a smart investment from a costly mistake.

Let’s clear up some of the most common questions we hear from homeowners every day.

Is Spray Foam Insulation a Fire Hazard?

This is a big one, and the answer is no—when it’s installed correctly. Professional-grade spray foam contains fire retardants and is engineered to meet strict fire safety building codes.

The key is proper installation by a certified pro, which includes covering the foam with a thermal barrier like drywall. This creates a safe, code-compliant system. The process has to be done by the book to ensure that protection is effective.

Can I Install Spray Foam Insulation Myself?

Absolutely not. This isn’t a weekend DIY project. Spray foam involves mixing chemicals at precise temperatures and pressures, and that requires specialized equipment and serious safety protocols, including full respiratory protection.

Trying to do it yourself can lead to a mess of problems: poor R-value, improper curing, dangerous off-gassing, and major safety risks.

The precision needed for a proper spray foam application can’t be overstated. With fiberglass, a mistake might cost you on your energy bill. With spray foam, a mistake can create chemical hazards and render the material totally useless. Professional installation is non-negotiable.

Does Fiberglass Insulation Cause Mold Growth?

While fiberglass itself is inorganic and won’t grow mold, it can definitely help create a mold-friendly environment. The paper or foil backing on many batts is a food source for mold once it gets wet.

More importantly, fiberglass is air-permeable. Humid South Florida air passes right through it, gets trapped, and condenses inside your walls. This creates the damp conditions needed for mold to thrive on your home’s wood framing and drywall, which can ruin your air quality and rot your home from the inside out.

Which Insulation Lasts Longer: Spray Foam or Fiberglass?

There’s no contest here. Spray foam is designed to last for the life of your building, often 80 years or more. It creates a rigid, permanent bond with the structure that doesn’t sag, settle, or break down. The R-value you have on day one is the same R-value you’ll have decades from now.

Fiberglass, on the other hand, has a much shorter effective lifespan—typically 15 to 25 years. Over time, it compresses, settles, or just falls out of place, creating gaps that bleed energy. If it ever gets wet, it’s ruined and needs a full replacement. For durability and long-term performance, spray foam is the clear winner.

Ready to make your home more comfortable and energy-efficient with the right insulation? The team at Airtight Spray Foam Insulation brings over 25 years of experience sealing homes across South Florida. Request your free, no-obligation quote today!

Homeowners in Jupiter, FL can learn more about our spray foam insulation services designed to improve comfort, control moisture, and increase energy efficiency in South Florida homes.