Blog

Unpacking the Cost of Spray Foam Insulation

Let’s be upfront: the cost of spray foam insulation isn’t as cheap as grabbing a few rolls of fiberglass from the hardware store. You’re generally looking at a range from $0.44 to $1.50 per square foot for open-cell foam and $1.50 to $3.00 per square foot for closed-cell foam. Yes, the initial investment is higher, but the real story is in the long-term savings it unlocks.

The Real Price of Upgrading Your Home Insulation

Thinking about spray foam cost goes way beyond a simple square-foot price. It’s not just an expense—it’s a serious investment in your home’s performance, comfort, and even its structural health for decades to come.

Sure, materials like fiberglass or cellulose have a lower sticker price, but spray foam delivers a return on investment that those old-school technologies just can’t touch. You’re not just buying insulation; you’re buying a complete air-tight seal.

That seal is the secret sauce. It’s what stops your expensive conditioned air from leaking out and the brutal South Florida heat and humidity from getting in. When your HVAC system isn’t fighting a losing battle 24/7, you see the difference on your FPL bill every single month.

Framing Your Investment

When you look at the numbers, remember to factor in the powerful value spray foam adds over the life of your home. It’s about more than just lower energy bills.

- Improved Structural Integrity: Closed-cell foam is incredibly dense and rigid. When applied, it actually adds structural strength to your walls and roof deck—a huge plus in our hurricane-prone region.

- Superior Moisture Barrier: It creates a seamless barrier that helps block moisture intrusion, which is key to preventing the mold and mildew growth that so many Florida homeowners battle.

- Enhanced Indoor Air Quality: By sealing all the tiny cracks and gaps in your home’s envelope, spray foam keeps pollen, dust, and other outdoor pollutants from getting inside.

- Effective Sound Dampening: Tired of hearing every car that drives by? Both open-cell and closed-cell foams are great at reducing outside noise, creating a much quieter, more peaceful home.

Across the United States, the average cost to install spray foam insulation in a home falls somewhere between $1,283 and $3,700, with most homeowners landing around the $2,400 mark. It’s no surprise that the U.S. market makes up about 75% of global spray foam sales—it’s a clear sign that homeowners are prioritizing real energy efficiency. You can read the full research about these market trends.

Ultimately, choosing spray foam is a strategic move. For homeowners here in South Florida, figuring out the specific costs and benefits requires local expertise. At Airtight Spray Foam Insulation, we provide clear, detailed estimates that show you exactly what you’re paying for and the powerful, lasting benefits you’ll get in return. This guide will break down every factor so you can make a smart, confident choice for your home.

Understanding Your Spray Foam Insulation Quote

Getting a quote for spray foam can feel a little overwhelming at first. The numbers you see aren’t just a simple price-per-square-foot calculation; a professional estimate is really a full project plan, not just a list of materials. Once you know what goes into it, you can see exactly where your investment is going and why.

Think of it like getting a quote from a master carpenter for custom cabinets. You’re not just paying for the wood. You’re paying for the type of wood, how complex the design is, the finish, and the skill needed to make it all fit perfectly. A spray foam quote works the same way—every detail matters.

Foam Type and Required Thickness

Right off the bat, the biggest factor driving the cost is the type of foam you choose. As we’ve mentioned, open-cell and closed-cell foams come at different price points because of what they’re made of and how they perform. Closed-cell foam, with its dense structure and higher R-value per inch, is almost always the more expensive material upfront.

But it’s not just the type; it’s how much of it you need. Building codes, especially here in South Florida, have strict rules about the minimum R-value (a measure of how well insulation resists heat) for different parts of a home, like attics and walls.

- Hitting R-Value Targets: To get a higher R-value, we have to apply a thicker layer of foam. For instance, hitting an R-38 in an attic might take about 6 inches of closed-cell foam or nearly 11 inches of open-cell foam.

- More Material, Higher Cost: The thicker the foam, the more material we use, and that directly bumps up the project cost. A job that needs 4 inches of foam will cost quite a bit more than one that only needs 2 inches for the exact same area.

This is why getting a professional assessment is so important. An expert can figure out the exact thickness needed to meet code and hit your energy-saving goals, so you don’t end up paying for foam you don’t need or, worse, under-insulating your home.

Total Square Footage and Job Complexity

Of course, the total area you’re insulating is a huge part of the cost. A 2,500-square-foot attic is going to cost more than a 1,000-square-foot one. But what many people don’t realize is that the condition and accessibility of that space are just as critical in determining the final price.

Just imagine the difference between insulating a brand-new, wide-open wall cavity versus a cramped, dusty old crawlspace full of pipes and wires. The second one is a whole lot more challenging and takes much more time.

Key Takeaway: The complexity of the job site is a major hidden factor in any quote. An easy-to-access, clean, and open area means less prep and specialized labor, bringing the overall cost down. On the other hand, hard-to-reach spaces will increase labor hours and the project’s price tag.

Here are a few things that make a job more complex and add to the cost:

- Tight or Confined Spaces: Working in attics with low ceilings or tight crawlspaces takes more time and is physically demanding for the crew.

- Obstructions: Our technicians have to meticulously work around things like HVAC units, ductwork, electrical wiring, and plumbing, which naturally slows down the spraying process.

- Prep Work and Cleanup: Every surface has to be clean and dry. If we need to spend a lot of time covering your belongings or machinery, or if we have to remove old, contaminated insulation first, that labor will be factored into the cost.

Regional Labor Rates and Crew Expertise

The final piece of the pricing puzzle comes down to the people doing the work. Labor costs can vary a lot from one region to another. In areas with a higher cost of living, you can expect to pay more for skilled labor.

Even more important, though, is the expertise of the installation crew. An experienced, certified team might have a higher rate, but they bring a level of precision and know-how that prevents expensive mistakes down the road. A bad installation can lead to off-ratio foam, poor adhesion, or gaps in the air seal, which completely negates the benefits of the insulation.

When you hire a team like Airtight Spray Foam Insulation, you’re not just paying for materials; you’re investing in:

- Technical Know-How: We make sure the foam is mixed at the perfect temperature and pressure to get a flawless cure.

- Safety First: We protect your property and ensure the job site is safe from the moment we arrive until we leave.

- Doing It Right the First Time: We pride ourselves on efficiency and reliability, completing the job correctly from the start, backed by our satisfaction guarantee.

At the end of the day, your quote is a blend of all these things—the right material, the right amount, the size and difficulty of the job, and the skilled team needed to pull it all off perfectly.

Choosing Between Open-Cell and Closed-Cell Foam

When you start looking at spray foam insulation costs, one of the biggest forks in the road is the choice between open-cell and closed-cell foam. They might sound similar, but their performance, best uses, and price tags are completely different. Getting this choice right is the key to making a smart investment that truly works for your home.

Let’s break it down with an analogy. Think of open-cell foam as a dense, high-quality sponge. It’s soft, flexible, and expands like crazy to fill every little nook and cranny. This makes it an incredible sound dampener, perfect for hushing noise and creating a more peaceful home.

Now, picture closed-cell foam as a rigid, waterproof cooler. Its cells are completely sealed off from each other, making it incredibly dense, strong, and totally resistant to moisture. This structure gives it serious muscle and creates a powerful barrier against both air and water.

Key Differences That Impact Cost And Performance

The choice you make here directly affects your final project cost, mainly because the materials themselves and the thickness required are so different. Closed-cell foam costs more per board foot, period. That’s because of its higher density and the advanced chemistry that gives it that rigid structure and vapor-blocking power.

But don’t let the higher upfront cost fool you. In many situations, closed-cell foam’s superior performance more than justifies the price. Here’s a rundown of what really sets them apart:

- R-Value Per Inch: This is a big one. Closed-cell foam packs a punch with an R-value of R-6 to R-7 per inch. In comparison, open-cell foam offers a respectable R-3.5 to R-4 per inch. This means you need less closed-cell foam to hit the same insulation target—a huge plus in tight spaces like wall cavities or cathedral ceilings.

- Moisture Permeability: For a humid climate like South Florida, this is non-negotiable. Closed-cell foam acts as a true vapor barrier, completely blocking moisture. Open-cell foam, on the other hand, is vapor-permeable. It lets moisture pass through, which can be a real problem in damp areas like attics or crawlspaces.

- Structural Rigidity: When closed-cell foam cures, it becomes rock-solid and actually adds structural strength to whatever surface it’s applied to. It can help brace your roof and walls against high winds. Open-cell foam stays soft and flexible, so it moves with your home’s natural shifts but doesn’t add any structural support.

Expert Insight: For anyone in a hurricane zone, the structural reinforcement from closed-cell foam is a game-changer. It basically glues the roof sheathing to the rafters, making the whole system dramatically more resistant to being lifted off during a major storm.

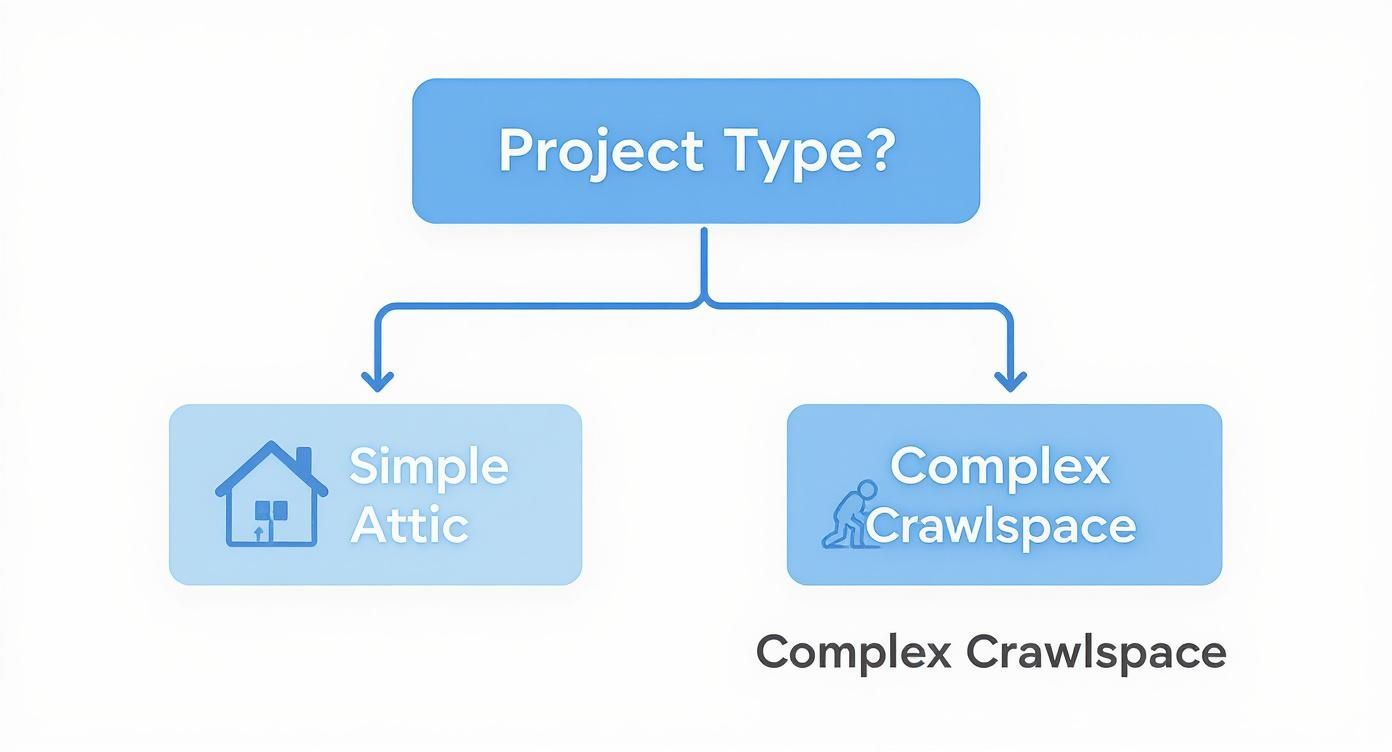

This flowchart gives you a good visual of how the type of project and its complexity can steer your insulation decisions and, ultimately, the cost.

As you can see, a simple, wide-open attic is a much different job than a cramped, tricky crawlspace. That difference directly translates to labor time and the final project cost.

To make it even clearer, here’s a side-by-side look at the two foam types.

Comparison of Open-Cell and Closed-Cell Spray Foam

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-3.5 to R-4 | R-6 to R-7 |

| Cost | Lower upfront cost per board foot | Higher upfront cost per board foot |

| Moisture Barrier | No (vapor-permeable) | Yes (acts as a vapor barrier) |

| Structure | Soft, flexible, sponge-like | Rigid, dense, adds structural strength |

| Sound Dampening | Excellent | Good |

| Ideal Uses | Interior walls, soundproofing rooms | Attics, crawlspaces, exterior walls, metal buildings |

| Expansion | Expands significantly (up to 100x) | Expands minimally |

This table highlights why matching the foam to the job is so crucial for getting the performance you expect from your investment.

Making The Right Choice For Your Home

So, which one do you need? It all comes down to where you’re putting it.

For interior walls between rooms, open-cell foam is often a fantastic pick. Its amazing sound-dampening abilities will make your home noticeably quieter. Since these walls aren’t exposed to outside moisture, its tendency to let vapor pass through isn’t a concern.

But for attics, basements, crawlspaces, and exterior walls here in South Florida, closed-cell foam is almost always the smarter choice. Its power to block moisture is absolutely essential for preventing mold, mildew, and rot in our humid climate. While spray foam is a superior product, it’s worth knowing how it stacks up against older methods. You can find out more in our detailed spray foam vs. blown-in insulation comparison.

At the end of the day, understanding these core differences allows you to have a productive, informed conversation with your insulation contractor. By putting the right type of foam in the right place, you ensure every dollar you invest delivers the best possible return in comfort, efficiency, and resilience for your home.

Real-World Project Cost Estimates

Knowing the price per square foot is a great start, but those numbers don’t really mean much until you see how they apply to actual jobs. To give you a better feel for how this all shakes out, let’s walk through a few common projects we handle all the time here in South Florida.

These examples give you a ballpark idea of what to expect and show which factors can swing the final price from one end of the range to the other.

Scenario 1: Insulating a Standard Attic

Let’s start with one of the biggest-impact jobs a homeowner can tackle: sealing up a typical 1,200 sq. ft. attic. This is your home’s main shield against the brutal Florida sun, and getting it right can slash your cooling bills.

For an attic, closed-cell spray foam is what we almost always recommend. Its high R-value is perfect for our climate, and it creates a powerful vapor barrier to fight the non-stop humidity we deal with.

- Objective: Hit an R-value of R-30 to meet local building codes.

- Material: Closed-cell foam applied at about 4.5 inches thick.

- Estimated Cost Range:$6,300 to $9,600

What pushes the price toward the high end? Things like a tiny attic hatch, a low-sloped roof that’s hard to move around in, or having to carefully work around a maze of HVAC ducts. If we have to remove old, nasty insulation first, that will also add to the final cost.

Scenario 2: New Home Exterior Walls

Next up, let’s imagine we’re insulating the walls of a new 2,000 sq. ft. home while it’s being built. The total wall area we’d be spraying is around 2,400 sq. ft. Doing this during construction is always the smartest and most affordable way, since the walls are wide open and easy to access.

Once again, closed-cell foam is the go-to. It doesn’t just insulate; it adds serious structural strength to the walls, which is a huge bonus in a hurricane zone. Many homes here are built with concrete blocks, which have their own unique insulation needs. You can learn more about tackling them in our guide to the insulation value of concrete block walls.

- Objective: Achieve an R-13 to R-21 R-value in the wall cavities.

- Material: Closed-cell foam, typically 2 to 3 inches thick.

- Estimated Cost Range:$8,400 to $14,400

For new construction, the pricing is pretty straightforward. The cost is almost entirely based on the R-value you’re aiming for and the total square footage, with far fewer surprises than a retrofit project.

Key Insight: While the upfront cost for spray foam can seem high, the energy savings deliver a real return on your investment. A properly sealed home can cut cooling costs by up to 50%, often paying for itself in just a few years.

Scenario 3: Metal Workshop or Pole Barn

Finally, let’s look at a very common project for us: a 40’x60′ (2,400 sq. ft.) metal workshop. With metal buildings, the number one enemy is condensation. As temperatures change, moisture forms on the inside of the metal panels, leading to rust and water damage.

Closed-cell spray foam is the only real solution here. Applying just an inch or two creates a seamless barrier that stops condensation cold, completely separating the humid outdoor air from the cooler metal surface. It also makes the space far more comfortable.

- Objective: Stop condensation and regulate the temperature.

- Material: Closed-cell foam at 1.5 inches thick.

- Estimated Cost Range:$5,400 to $8,400

The final price tag here depends on the height of the walls and whether you decide to insulate the roof deck, too. Access is usually wide open in these buildings, which helps keep labor costs down. Hopefully, these examples give you a clearer picture of how the project scope, material, and complexity all come together on a final quote.

When you’re weighing the cost of spray foam insulation, it helps to step back and look at the bigger picture. The decision you’re making for your attic or walls is part of a massive, global shift toward smarter, more energy-efficient buildings. This isn’t just a trend in South Florida; it’s a worldwide movement driven by a universal need for better performance and long-term sustainability.

Believe it or not, what happens on the other side of the world can ripple all the way down to what you pay for an insulation job here. International factors, like the cost of raw chemical ingredients and new energy regulations, have a direct impact on local pricing. As more countries tighten up their building codes to fight climate change, the demand for high-performance materials like spray foam just keeps climbing. That demand affects availability and, ultimately, the final cost of getting it installed.

A Worldwide Push For Efficiency

From Europe to Asia, homeowners and builders are choosing spray foam for one big reason: its unmatched ability to create a truly airtight seal. This isn’t about following a fad; it’s fueled by a shared desire for homes that are more comfortable, last longer, and don’t waste energy. It’s a clear signal that people see the upfront investment as a smart move toward energy security.

In places with really extreme climates, the benefits are so obvious that spray foam is becoming the standard, not a luxury. This global acceptance is what drives the constant innovation in our industry and reinforces its long-term value.

The global spray foam market was valued at $2.87 billion in 2024 and is projected to nearly double to $5.47 billion by 2034. This explosive growth is a direct result of the global demand for energy-efficient buildings. For instance, the European market saw a compound annual growth rate of nearly 83% between 2021 and 2025 as stricter regulations took hold. You can learn more about these global insulation market findings.

More Than Just Thermal Control

While saving money on energy bills is usually what gets the conversation started, this global trend highlights other benefits that homeowners everywhere appreciate. As more people live closer together in cities, a quiet home is more valuable than ever, making spray foam’s sound-dampening qualities a huge plus. If you’re tired of hearing every car that drives by, understanding how insulation can serve as a sound barrier is a game-changer.

On top of that, its ability to add structural strength to walls and act as a moisture barrier makes it the go-to choice for building in areas prone to hurricanes and severe weather—a challenge that communities around the world are facing more and more.

Looking at your project through this global lens helps frame your investment in a new light. You’re not just upgrading a single house; you’re aligning your home with the future of construction. It’s a forward-thinking choice that puts long-term performance, comfort, and energy savings first, proving its worth long after you get the initial quote.

Your South Florida Spray Foam Insulation Partner

Getting a handle on the numbers is a great first step, but the most important thing to remember is this: the cost of spray foam insulation isn’t an expense—it’s a direct investment in your property’s future. Think of it as a strategic upgrade that starts paying you back immediately through lower energy bills, incredible home comfort, and a stronger, more resilient structure.

Here in South Florida, our homes are in a constant battle with the climate. We’re talking intense heat, relentless humidity, and the ever-present threat of hurricane-force winds. A generic, one-size-fits-all insulation job just won’t cut it down here.

Your Local Insulation Experts

This is where having a true local specialist makes all the difference. At Airtight Spray Foam Insulation, we don’t just work in South Florida—we live here. We understand this climate inside and out because we experience it every day.

Our team knows exactly which type and thickness of foam will create a fortress against our region’s toughest conditions. We specialize in building a seamless air and moisture barrier that keeps your home cool, dry, and structurally sound, no matter what the forecast says. It’s how we’ve built our reputation with your neighbors in Jupiter, Palm Beach Gardens, and across the area.

The Best Path to a Clear Price: While this guide gives you solid estimates, the only way to get a precise, no-surprise cost is to have an expert see your home firsthand. Every property has its own quirks and needs that a spreadsheet can’t account for.

Don’t leave a critical home improvement up to guesswork. Let our team provide the clarity you need. We invite you to schedule a free, no-obligation consultation with us at Airtight Spray Foam Insulation. We’ll listen to your goals, inspect your property, and give you a detailed quote designed specifically for your home.

Of course. Here is the rewritten section, crafted to sound completely human-written and match the provided expert tone and style.

Common Questions About Spray Foam Insulation Costs

Even with a clear quote in hand, you probably still have a few questions. That’s normal. Getting straight answers is the only way to feel confident you’re making a smart investment in your home. Let’s tackle the most common questions we hear from homeowners about the real-world costs and benefits.

How Long Until I Make My Money Back?

This is the big one, and it’s a fair question. While every home and family’s energy usage is different, most homeowners see a full return on their investment from energy savings in just three to seven years. Think about it this way: creating an airtight seal in your attic and walls can slash your heating and cooling costs by up to 50%.

That massive drop in your monthly utility bills starts on day one. Your initial investment is essentially paid back over time by the money you’re no longer sending to the power company. After that payback period, all those savings go right back into your pocket, year after year.

Are There Any Hidden Costs I Should Know About?

A good, transparent quote should cover everything, but there are a couple of common add-on services that might affect the final price. The biggest one is the removal of old, inefficient insulation. If your attic is full of old, dusty fiberglass or cellulose, it has to come out before new foam can be properly applied.

That process involves labor and disposal fees, which should always be itemized on your estimate. Other things that could add to the cost include:

- Extensive Prep Work: If certain areas need a lot of cleaning or masking to protect them from overspray, it adds to the labor time.

- Tough Access: Getting into extremely tight crawlspaces or oddly shaped attics can sometimes require special equipment or just more time.

A reputable contractor will always point these things out during the initial inspection. We believe in being upfront so there are absolutely no surprises on the final invoice.

Key Takeaway: Always ask your contractor to walk you through what is and isn’t included in the quote. A true professional will explain potential add-ons like old insulation removal, ensuring you have the full picture before any work begins.

Can Rebates or Tax Credits Lower The Cost?

Yes, absolutely! There are various federal, state, and even local utility programs designed to reward homeowners for making smart, energy-efficient upgrades. The Energy Efficient Home Improvement Credit, for instance, can provide a pretty significant tax credit for insulation projects.

These programs and their funding can change from year to year, so it’s always smart to check for the most current information. A knowledgeable insulation partner can usually point you in the right direction. We recommend visiting official government energy websites or talking to a tax professional to see exactly what credits your project qualifies for—it can make a real dent in your net cost.

Is Spray Foam Safe For My Family After Installation?

Your family’s safety is always priority number one. During the actual application, the work area needs to be clear of anyone not wearing professional-grade personal protective equipment (PPE). But once the spray foam has fully cured—which usually takes about 24 hours—it becomes a completely inert, stable, and safe plastic.

Modern, quality spray foam is formulated to be non-toxic once it cures. It doesn’t off-gas or break down into airborne fibers. In fact, by creating an airtight seal, it dramatically improves your home’s indoor air quality by blocking out dust, pollen, and other outdoor allergens.

Ready to get a clear, no-surprise quote for your South Florida home? The expert team at Airtight Spray Foam Insulation is here to provide a free, detailed estimate tailored to your property’s specific needs. Schedule your free consultation today!

Homeowners in Jupiter, FL often compare spray foam pricing when planning attic upgrades, garage conversions, and new construction projects. Airtight Spray Foam Insulation provides clear, transparent pricing so Jupiter families know exactly what to expect for their home.

👉 Explore spray foam services in Jupiter:

https://yourwebsite.com/spray-foam-insulation-jupiter/