Blog

The Real Concrete Block Insulation Value for Florida Homes

Here in South Florida, concrete block is king. It’s tough, stands up to hurricanes, and termites hate it. But there’s a huge misconception that its sheer thickness and density make it a good insulator.

The truth is, it’s not. Not even close.

A standard, uninsulated concrete block wall is a surprisingly poor barrier against heat. Think of it like a single-pane window: it’ll stop the wind and rain, but it does very little to stop the relentless flow of heat.

This is a massive problem in our hot, humid climate. On a blistering summer day, that block wall soaks up the sun’s energy and radiates it straight into your home, forcing your AC to work overtime well into the night. It becomes a heat magnet, turning your home’s protective shell into a source of uncomfortable warmth and sky-high energy bills.

Breaking Down the Baseline R-Value

The term R-value is just a simple way to measure how well a material resists heat flow. The higher the number, the better the insulation.

And this is where concrete block really falls short. A standard 8-inch hollow concrete block—the kind used to build most homes around here—clocks in at a dismal R-value of about R-2.0. That’s a tiny fraction of the thermal resistance needed in a modern, energy-efficient home, where wall systems often aim for R-20 or higher. You can dig deeper into the thermal performance of CMU block insulation and why it’s so critical for construction.

Here’s a quick look at the starting point for common concrete blocks.

Baseline R-Values of Common 8-Inch Concrete Blocks

| Block Type (8-inch CMU) | Typical R-Value (US) | Primary Use Case |

|---|---|---|

| Hollow-Core (Unfilled) | R-1.9 to R-2.2 | Standard structural walls |

| Perlite/Vermiculite Filled | R-4.2 to R-5.0 | Lightly insulated block |

| Grout-Filled (Solid) | R-1.3 to R-1.5 | Reinforced structural walls |

As you can see, even filling the cores with a basic material like perlite doesn’t get you anywhere near the performance needed for real comfort and efficiency in Florida. Relying on the block alone just isn’t a winning strategy.

Think of it this way: An uninsulated concrete wall is like trying to keep a drink cold in a thin glass on a hot day. The glass gives it structure, but the ice melts in minutes. Proper insulation is the premium cooler that creates a real thermal barrier, keeping the heat out and the cool air in.

Why This Really Matters for Your Florida Home

Turning that heat magnet of a wall into an energy-efficient shield is the real challenge. Without good insulation, you’re essentially paying to cool down tons of concrete before you even start to cool the air inside your home.

The good news? There are powerful, proven strategies to dramatically boost the concrete block insulation value.

This guide will walk you through exactly why concrete struggles as an insulator and explore the practical, climate-specific solutions that work best right here in South Florida. We’ll cover everything from filling the block cores to wrapping the entire wall in a continuous thermal blanket, giving you the knowledge you need to make the right call for your property.

Here’s the rewritten section, crafted to sound like an experienced human expert writing for a South Florida audience.

Why Concrete Is a Better Heat Sponge Than a Shield

To really get why a concrete block wall does such a poor job of insulating, you have to stop thinking of it as a solid shield. It’s not. It’s great for strength, but when it comes to heat in a place like Florida, its properties work against us. Two big concepts are at play here: thermal bridging and thermal mass.

Most people picture a concrete block as a barrier. The reality is that it’s more like a complex network of pathways, and some of those paths are superhighways for heat to drive right into your house.

The Problem of Thermal Bridging

Ever dip a metal spoon into a hot cup of coffee? You know how the heat zips right up the handle and burns your fingers? The metal gives the heat an easy, direct path to travel. That’s exactly what thermal bridging does in your concrete block walls.

The solid parts of a CMU block—the “webs” connecting the front and back—are made of dense, solid concrete. Just like that metal spoon, these webs create a direct bridge for heat to move from the scorching hot exterior of your wall straight to the cooler interior. It completely bypasses the hollow air-filled cores that are supposed to provide a little bit of insulation.

A thermal bridge is a shortcut for heat. It completely undermines any insulating value the block’s hollow cores might have, letting heat pour through the solid concrete parts with almost nothing to stop it.

This is an incredibly efficient way to move heat where you don’t want it. It means that even on a wall where the cores are filled with some basic insulation, the webs are still leaking heat into your home all day long, making your AC unit work overtime.

Concrete’s Heat Battery Effect

The second problem, and maybe the more frustrating one for us in South Florida, is thermal mass. This is just a term for a material’s ability to absorb, store, and then release heat. Concrete has a very high thermal mass. It acts less like a shield and more like a giant, slow-charging battery for heat.

Think of your home’s block walls like the asphalt in a Publix parking lot in the middle of August.

- Charging Up: All day, the relentless Florida sun beats down, and the concrete just soaks that solar energy up, storing it deep inside the block.

- Releasing Heat: Then, as the sun goes down and the air finally starts to cool off, that “heat battery” in your walls starts to discharge. All that stored warmth begins radiating slowly and steadily into your living space, right through the evening and into the night.

This “thermal lag” is why your house can feel stuffy and warm hours after sunset, even when it’s pleasant outside. Your AC isn’t just fighting the day’s heat—it’s also fighting the heat your walls saved up to release later. In a climate where we need to cool our homes almost year-round, high thermal mass is a massive liability.

How Humidity Makes Everything Worse

Finally, let’s talk about our constant companion: humidity. Concrete is porous, meaning it can absorb moisture right out of the thick Florida air. When concrete gets damp, its ability to conduct heat skyrockets.

Water is a much better heat conductor than air. As moisture seeps into the block, it fills up the tiny air pockets within the concrete mix. This makes the thermal bridging problem even worse, further tanking the wall’s insulation performance and making your home that much harder to keep cool and dry.

How Core-Fill Insulation Boosts CMU Performance

Since concrete blocks on their own are pretty terrible insulators, the most obvious place to start improving them is by tackling their biggest weakness: those big, empty hollow cores.

Filling these voids is the first and most fundamental strategy to slow down heat transfer. There are a few ways to do it, and each comes with different trade-offs in cost and real-world effectiveness.

Think of an uninsulated block wall as a row of empty glass jars. Air moves freely inside them, transferring heat with almost no resistance. Core-fill insulation is like filling those jars with a material that traps the air, stopping that heat flow dead in its tracks.

Common Core-Fill Insulation Materials

Not all core-fill materials are created equal, especially when you’re dealing with South Florida’s relentless heat and humidity. The material you pick directly impacts the final concrete block insulation value and, just as importantly, its ability to manage moisture.

- Loose-Fill Insulation (Perlite and Vermiculite): This is the classic, old-school choice. Perlite and vermiculite are lightweight, granular minerals that are simply poured into the block cores as the wall goes up. They trap air, which helps slow down heat transfer. Adding perlite can take a standard CMU from a measly R-2 up to a more respectable R-4 or R-5.

- Pre-Formed Foam Inserts: Think of these as custom-molded puzzle pieces made from expanded polystyrene (EPS) foam. They’re shaped to fit snugly inside the block’s cores and are installed as the masons build the wall. They offer a very consistent and predictable boost in R-value, but they don’t create an air seal, so you can still get some air movement inside the wall.

- Injectable Foam Insulation: This is the high-performance option. Specialty foams are injected into the block cores after the wall is built, expanding to fill every single crack and crevice. This method creates one solid, monolithic barrier that not only insulates but also provides an incredible air and moisture seal.

Why Injectable Closed-Cell Foam Excels in Florida

For our hot, humid climate, there’s no contest: injectable closed-cell spray foam is the clear winner.

Unlike loose-fill that can get damp or foam inserts that leave tiny gaps, closed-cell foam creates a seamless, non-permeable barrier. It becomes one with the block.

In South Florida, insulation isn’t just about stopping heat; it’s about controlling moisture. Injectable closed-cell foam is the only core-fill method that effectively does both, turning the block cores into a waterproof, airtight, and highly insulated barrier.

This dual-action performance is critical here. By stopping moisture from wicking through the block cores, it prevents the concrete from getting saturated—a condition that would otherwise tank its insulating ability. This makes the entire wall system stronger, more resilient, and far more efficient.

If you want to dive deeper into the numbers, check out our guide on the insulation value of concrete block.

The Measurable Impact of Core-Fill

Adding insulation to the cores isn’t just theoretical; it provides a real, measurable boost. Studies on modified concrete blocks confirm that introducing insulating additives is a proven way to reduce heat transfer. For instance, adding perlite has been shown to cut a block’s thermal conductivity by 30–33% compared to a standard, hollow block. You can read more about these research findings into self-insulating concrete blocks.

Here’s a quick breakdown of what you can expect from different core-fill options for a standard 8-inch CMU wall:

| Core-Fill Method | Typical R-Value Boost | Key Advantage | Best For |

|---|---|---|---|

| No Fill (Hollow) | R-0 | None | N/A |

| Loose-Fill (Perlite) | + R-2 to R-3 | Cost-effective and simple | Basic insulation on a tight budget |

| Foam Inserts | + R-4 to R-6 | Consistent, predictable performance | New construction aiming for moderate gains |

| Injectable Foam | + R-5 to R-8 | Highest R-value, air/moisture barrier | Maximum performance and humidity control |

While filling the cores is a fantastic first step, it’s not a silver bullet. It doesn’t solve the problem of thermal bridging through the solid concrete webs of the block. To get truly top-tier performance, core-fill is almost always paired with another insulation strategy.

Achieving Peak Performance with Continuous Insulation

So, you’ve filled the cores of your concrete blocks. That’s a huge step, but it doesn’t quite solve the whole puzzle. Why? Because the solid parts of the block—the concrete webs between the cores and the mortar joints holding everything together—are still there. These act like dozens of little highways for heat to travel, bypassing your brand-new insulation and streaming right into your home.

To truly get the most concrete block insulation value, you have to think bigger. You need to wrap the entire wall in an unbroken thermal blanket. This strategy is called continuous insulation (CI), and it’s the absolute gold standard for building high-performance walls.

Think of it like one of those high-end coolers. The good ones don’t just have insulated panels; they have a seamless, uninterrupted lining. That continuous layer is what keeps ice solid for days. Applying continuous insulation to your block walls works the exact same way. It creates a complete thermal break, stopping heat dead in its tracks before it can even touch the concrete.

How Continuous Insulation Eliminates Thermal Bridges

When you apply an unbroken layer of insulation over the entire face of the wall, you effectively sever all those heat highways. The intense South Florida sun can no longer find a direct path through the concrete webs or mortar. Instead, its energy hits the insulation first and gets stopped cold.

This completely transforms the wall’s performance. The concrete block is no longer a heat conductor but is instead protected inside the building’s thermal envelope.

Continuous insulation is the only method that addresses the entire wall system, not just the hollow parts. It neutralizes concrete’s biggest weaknesses—thermal bridging and thermal mass—by isolating it from the extreme Florida heat.

This total separation is what allows a CMU wall to finally hit the high R-values needed for modern building codes and deliver real, tangible energy savings. It’s a crucial part of creating what we call the Airtight Comfort System, where every piece of the puzzle works together to lock out heat and humidity for good.

Popular Strategies for South Florida Homes

In our climate, you have two main options for applying continuous insulation to a block wall: on the outside or on the inside. Each approach has its own set of advantages, depending on whether you’re building a new home or upgrading an existing one.

Exterior Continuous Insulation

Applying insulation to the exterior is often the most effective route, as it stops solar heat before the concrete can even think about absorbing it.

- Rigid Foam Boards: First, we fasten large sheets of rigid foam insulation, like extruded polystyrene (XPS) or polyisocyanurate (polyiso), to the outside of the CMU wall.

- Weather Barrier: Next, a weather-resistant barrier goes over the foam to keep moisture out.

- Final Cladding: Finally, the wall is finished with a new cladding. This could be traditional stucco, fiber cement siding, or a modern Exterior Insulation and Finish System (EIFS).

This approach is perfect for new construction or major renovations where the siding is being replaced anyway. It doesn’t just insulate; it adds a powerful layer of moisture protection.

Interior Continuous Insulation

For existing homes where tearing off the exterior finish isn’t an option, adding insulation to the inside is an excellent alternative.

- Spray Foam Application: Closed-cell spray foam can be applied directly to the interior face of the concrete blocks. This method is incredibly effective because it creates a perfect air, moisture, and vapor barrier all in one shot, sticking tight to the block’s surface without any gaps.

- Framing and Drywall: After the foam cures, a new stud wall is framed in front of it. We then hang drywall to create the new interior finish.

This method delivers a massive improvement in comfort and efficiency without changing your home’s curb appeal. And the big bonus of using closed-cell spray foam? It adds structural strength to the wall and is second to none at blocking moisture—a non-negotiable feature for any home in Florida’s humid climate.

CMU Walls vs. Insulated Concrete Forms: A Head-to-Head Comparison

So far, we’ve talked about adding insulation to a standard concrete block wall to make it perform better. But what if you could build a wall that was born to be insulated? That’s the whole idea behind Insulated Concrete Forms, or ICFs. For anyone building new in South Florida, ICFs offer a powerful alternative to traditional Concrete Masonry Unit (CMU) construction.

Forget about stacking heavy concrete blocks. ICFs are large, hollow forms, usually made of dense foam, that lock together like oversized LEGO bricks. Rebar is placed inside these forms, and then concrete is poured into the hollow core.

The result is a solid, steel-reinforced concrete wall sandwiched between two continuous layers of thick foam insulation. The structure and the insulation are created in one seamless step—it’s an all-in-one system.

A Tale of Two Walls

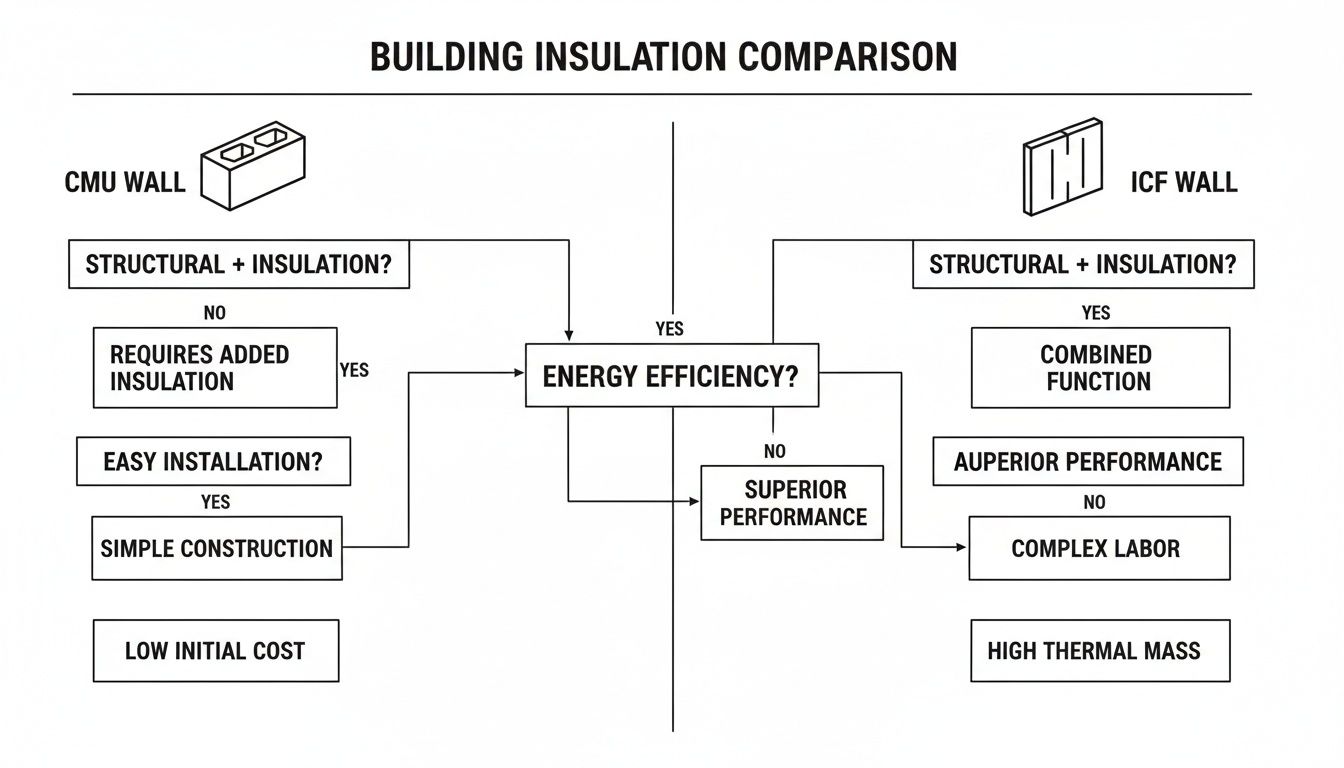

When you put an insulated CMU wall next to an ICF wall, you’re really looking at two different philosophies. An insulated CMU wall is a retrofitted system. You take a strong but thermally weak material and add layers to fix its flaws. An ICF wall, on the other hand, is an inherently high-performance system from day one.

With ICF, the foam forms don’t go anywhere. They become a permanent part of the wall, giving you continuous insulation on both the inside and the outside of the concrete. This design completely wipes out thermal bridging and creates an incredibly airtight building envelope.

Think of it like a concrete sandwich. With ICFs, the concrete core is the filling, and the thick foam insulation is the bread on both sides, protecting it from the outside world. This design guarantees top-tier thermal performance with no interruptions.

Whole-Wall R-Values and Real-World Savings

This integrated design delivers thermal performance that a standard block wall just can’t touch. A well-insulated CMU wall might get you an effective R-value in the teens, but a typical ICF wall system often starts at R-22 or higher. Even more importantly, that R-value is consistent across the entire wall—no weak spots from mortar joints or concrete webs.

The research backs this up. Study after study shows that Insulated Concrete Forms have far higher whole-wall thermal performance than uninsulated concrete block walls. One comparative study found that homes built with ICF systems used about 20% less energy for heating and cooling than a typical wood-frame house. You can dig into these comparative energy findings from the NAHB/HUD research yourself to see the proof.

A head-to-head comparison really drives home the differences in how these two systems approach performance.

Insulated CMU vs. ICF Wall System Performance

| Performance Metric | Insulated Concrete Block Wall | ICF Wall System |

|---|---|---|

| Effective R-Value | R-10 to R-15 (with injected foam & exterior insulation) | R-22+ (standard, can be higher) |

| Airtightness | Good, but depends heavily on sealant quality and stucco | Excellent, monolithic core and continuous foam create a superior air barrier |

| Thermal Bridging | Present at mortar joints and webs, reducing whole-wall R-value | Eliminated, thanks to continuous interior and exterior foam layers |

| Installation | Multi-step process: block laying, core filling, interior/exterior insulation | Integrated process: stack forms, add rebar, pour concrete |

| Structure | Segmented block construction | Monolithic, steel-reinforced concrete core |

Ultimately, choosing between these two systems for a new build in South Florida comes down to priorities. Insulating a traditional CMU wall is a proven, reliable strategy. But building with ICFs from the start offers a level of airtightness and thermal consistency that is simply in a different league. It’s a move beyond just improving concrete block insulation value—it’s creating an entirely different class of high-performance building.

Choosing the Smartest Strategy for South Florida Homes

Trying to translate technical R-values into a real-world decision can feel overwhelming. But for South Florida homeowners, it really boils down to two simple goals: blocking our intense solar heat and controlling our relentless humidity. Your insulation strategy has to nail both.

In our hot, humid climate, the best defense is a great offense. That means stopping heat before it has a chance to soak into your concrete block walls. Once that thermal battery gets charged up, your air conditioner is stuck fighting a losing battle all night long.

This is exactly why exterior continuous insulation is often the most powerful strategy, especially for new construction or major renovations.

Why Insulating From the Outside Wins in Florida

Wrapping your home’s exterior with a continuous layer of rigid foam or spray foam insulation under the stucco creates a true thermal break. Think of it like parking your car under a shady tree instead of in the direct sun—the inside never gets a chance to bake in the first place.

This approach gives you a few key advantages perfectly suited for our climate:

- Blocks Solar Gain: It stops the sun’s radiant energy right on the outside, keeping the concrete block itself cool. This prevents it from storing and slowly releasing that heat into your home later.

- Enhances Moisture Control: A properly installed exterior system is your first line of defense against weather. It acts as a primary moisture barrier, protecting the block from driving rain and humidity.

- Improves Durability: It shields the concrete structure from extreme temperature swings, which reduces stress and the potential for cracking over time.

When you pair this strategy with a light-colored, reflective finish, you get a one-two punch that can dramatically lower your cooling costs and make your home way more comfortable.

Aligning Your Choice With Cost and Building Codes

For existing homes where gutting the exterior isn’t practical, interior insulation is a fantastic alternative. Applying closed-cell spray foam directly to the inside face of the block walls gives you an exceptional air, moisture, and thermal barrier all in one.

While it doesn’t stop the block itself from heating up, it does an incredible job of preventing that stored heat from ever getting into your living space. You can check out a detailed comparison to see if a spray foam vs blown-in solution makes the most sense for your project.

The South Florida Rule of Thumb: Always prioritize strategies that create a continuous, uninterrupted insulation layer. Whether it’s inside or out, eliminating those thermal bridges is the key to unlocking the true performance of your concrete block walls and meeting the tough requirements of the Florida Building Code.

This infographic gives you a simple visual comparison between building with traditional insulated Concrete Masonry Units (CMU) and using Insulated Concrete Forms (ICF).

As you can see, ICF systems integrate continuous insulation right from the start, while CMU walls need extra layers to get to that same high-performance level.

Ultimately, the smartest choice is the one that fits your project’s scope and budget while delivering a robust, seamless barrier against the unique challenges our region throws at it.

Got Questions? We’ve Got Answers.

When you start digging into the details of insulating concrete block walls, a few questions always pop up. Here are the straight-up answers to some of the most common things we hear from South Florida homeowners.

Does Painting a Block Wall Add R-Value?

Nope. Standard paint is just a coating; it adds no meaningful insulation or R-value to a concrete wall.

Some companies push special “insulating” or reflective paints, claiming they bounce sunlight off the wall. While there’s a tiny bit of truth to that for reflecting solar heat, the effect is minimal. It does absolutely nothing to stop the conductive heat that bleeds right through the concrete itself. Paint is for looks and a bit of weather protection, not thermal performance.

To actually stop heat transfer, you need something that traps air, like spray foam or rigid foam boards. That’s real insulation.

What Is the Best Insulation for an Existing Block Home?

For an existing block home in South Florida, the hands-down best choice is typically closed-cell spray foam, which we apply to the interior side of your exterior walls.

The beauty of this method is that it’s incredibly effective without touching the outside of your house. We spray the foam directly onto the inner face of the concrete blocks, creating one solid, seamless barrier.

It’s the perfect all-in-one solution for our climate because you get three massive benefits in a single application: a high R-value, a powerful air barrier, and a rock-solid moisture barrier. Down here, stopping moisture is just as critical as stopping heat.

Once the foam is in, we frame a new stud wall right in front of it and hang fresh drywall. The result is a super-efficient, comfortable, and dry living space.

Can You Over-Insulate a Concrete Wall in Florida?

From a performance standpoint, it’s pretty much impossible to “over-insulate” a concrete wall in our climate. More insulation simply means less heat getting through, which translates to lower AC bills and a more comfortable home. There’s really no such thing as too high an R-value when you’re fighting off Florida heat.

The real concern isn’t too much insulation, but the wrong kind of installation that ends up trapping moisture. A wall assembly has to be able to dry out if it gets wet. This is another reason we lean on closed-cell spray foam—it’s waterproof. It doesn’t act like a sponge; it acts like a shield, preventing moisture from ever getting into the wall cavity to begin with.

So, the key isn’t to use less insulation. It’s to use the right insulation system designed for our humid environment.

Ready to stop your concrete block home from feeling like an oven? The team at Airtight Spray Foam Insulation has the expertise and the right high-performance materials to get the job done. We deliver custom spray foam solutions built to conquer South Florida’s brutal heat and humidity.

Request your free, no-obligation quote today!