Blog

Best Way to Insulate Metal Building: best way to insulate metal building tips

For a metal building, your best bet is almost always closed-cell spray foam insulation. It goes on as a liquid and expands to create a solid, seamless layer that sticks directly to the metal panels. This process creates an airtight and moisture-proof barrier that stops condensation in its tracks, delivers a high R-value, and even adds a bit of structural strength to the building itself.

Why Insulating Your Metal Building Is a Non-Negotiable Step

A metal building gives you incredible durability, but without the right insulation, it’s not much more than a tin can fighting a losing battle with the Florida climate. Metal is a fantastic conductor, meaning it gets blazing hot under the sun and cools down just as fast when a storm rolls in. Trying to control the temperature inside is practically impossible, making it a miserable place for a workshop, garage, or commercial space.

Think of an uninsulated metal roof on a humid morning—it's just like a cold glass of sweet tea sitting on the porch. Condensation, or what we call "building sweat," is going to form all over the inside of those cool metal panels. This moisture isn't just annoying; it’s a destructive force that leads to rust, mold, and ruined tools, inventory, or stored belongings.

Sealing the Envelope Against Key Threats

The whole point of insulating your metal structure is to create a complete thermal and moisture barrier—what we in the industry call "sealing the envelope." This one step is what protects your investment from its two biggest enemies: runaway energy transfer and damaging condensation. An effective insulation system is the only way to turn your building from a simple shell into a truly functional, protected space.

Here’s what you gain with proper insulation:

- Stable Interior Temperatures: You’ll drastically cut down on the energy needed to heat or cool the space, which means real, significant savings on your FPL bill.

- Total Condensation Control: It stops humid air from ever touching the cool metal surfaces, putting an end to rust, mildew, and water damage.

- Protection for Valuables: Your tools, vehicles, inventory, and equipment are safe from the damage caused by extreme humidity and temperature swings.

- Enhanced Comfort and Usability: It creates a comfortable environment year-round, making your workshop, office, or storage area a place you actually want to be in.

Choosing the right insulation isn't just about feeling comfortable—it's about preserving the structural integrity and long-term value of your building. This is the critical upgrade that determines whether your metal structure serves its purpose for decades or starts rusting away in just a few years.

On top of all that, a well-sealed building does more than just control temperature and moisture. Many of our customers are surprised to find that good insulation is also a fantastic sound barrier. You can learn more about that in our guide on using insulation as a sound barrier.

This guide will walk you through the best options for your metal building so you can make the right call for your project.

Comparing the Top Metal Building Insulation Methods

Choosing the right insulation for a metal building is a lot like picking the right gear for a deep-sea dive. The wrong choice leaves you completely exposed to the elements, while the right one guarantees comfort, safety, and efficiency. Each of the top insulation methods offers a different level of protection, and understanding their true strengths is the secret to getting the best way to insulate metal building projects right here in South Florida.

We’re going to break down the four main contenders: spray foam, rigid foam board, fiberglass batts, and radiant barriers. This head-to-head comparison will show you how each one works, where it really shines, and which one is the undisputed champ for creating a climate-controlled, sweat-free space.

Spray Foam Insulation: The Airtight Champion

Spray polyurethane foam (SPF) is simply in a league of its own. It’s applied as a liquid that expands on contact, filling every single crack, seam, and pinhole as it bonds directly to the metal panels. The result is one solid, continuous barrier that’s totally airtight and waterproof. Think of it as a custom-molded wetsuit for your building—there are zero gaps for air or water to sneak through.

You’ll run into two main types of spray foam:

- Closed-Cell Spray Foam: This is the gold standard for metal buildings, hands down. Its dense, rigid structure is impermeable to moisture, making it an all-in-one insulator, air barrier, and vapor retarder. It even adds a surprising amount of structural strength to the metal panels and packs a punch with a high R-value of around R-6 to R-7 per inch.

- Open-Cell Spray Foam: Lighter and more sponge-like, open-cell foam is a fantastic air barrier and does a great job of deadening sound. But here’s the catch: it's vapor-permeable. That means it can hold moisture, making it a poor choice for direct application to metal in our humid climate unless you add a separate, perfectly installed vapor barrier. Its R-value is also lower, around R-3.5 to R-4 per inch.

For a closer look at how different spray-applied insulations stack up, check out our detailed guide on spray foam vs. blown-in insulation to get deeper into the details.

Rigid Foam Board: The Precision Puzzle

Rigid foam board insulation comes in big, sturdy panels made from materials like polystyrene or polyisocyanurate. The idea is to cut these boards to fit perfectly between the building’s framing—the girts and purlins. While the boards themselves offer good thermal resistance, their success depends entirely on a flawless installation.

Imagine trying to build a waterproof box out of a stack of square panels. Every single seam, joint, and edge has to be meticulously taped and sealed. If you miss even one tiny spot, warm, humid air will hit that cold metal, and you’ll have condensation, defeating the whole point of the insulation.

The success of rigid foam board isn’t in the panels themselves, but in the perfection of the seal. It’s a puzzle where every piece must fit flawlessly, and one mistake can compromise the entire system.

These boards usually deliver an R-value between R-4 and R-6.5 per inch, depending on the material. They can work, but the intense labor needed to seal every seam leaves them wide open to installation errors that create major moisture headaches down the road.

Fiberglass Batts: The Traditional Budget Option

We all know fiberglass batts—the fluffy pink or yellow rolls you see in every big-box store. It’s the most familiar and cheapest option out there. You just unroll it and stuff it into the wall and ceiling cavities. While it provides some thermal resistance, fiberglass is basically just a loose, fluffy jacket for your building. It slows down heat, but it does almost nothing to stop air from moving right through it.

The biggest enemy of fiberglass in a metal building is moisture. The fibers themselves don’t absorb water, but the air pockets between them are perfect little traps for condensation. Once it gets damp, its insulating power plummets, and it becomes a breeding ground for mold and mildew. To even have a chance of working in a metal structure, it must be paired with a separate, perfectly installed vapor barrier.

Even then, any little rip, tear, or unsealed edge in that barrier will let moisture get trapped between it and the metal wall, causing hidden rust and rot. With an R-value of just R-3.1 to R-3.7 per inch, it’s one of the weakest performers on a per-inch basis.

Radiant Barriers: The Heat Reflector

Unlike the other insulators that slow down heat transfer, a radiant barrier—or reflective foil—works by reflecting it. It’s a thin, shiny material designed to block radiant heat, which is the kind you feel beaming down from the sun.

Think of it like that silver sunshade you put in your car's windshield. It doesn’t stop the air in your car from getting hot; it stops the sun's rays from baking your dashboard and seats. In a Florida metal building, a radiant barrier under the roof can reflect a huge amount of solar heat, keeping the inside much cooler.

However, radiant barriers have virtually no R-value and do nothing to stop heat transfer from conduction or convection. They are best used as a supplement to another insulation type. By itself, a radiant barrier is a great tool against the summer sun but offers almost zero protection when it gets cool and provides no air or moisture seal whatsoever.

Metal Building Insulation Methods at a Glance

To help you see the whole picture, we've put together a quick comparison of how these four insulation types perform in the areas that matter most for a metal building in our climate.

| Insulation Type | Typical R-Value (per inch) | Moisture and Air Seal | Installation Complexity | Best Use Case |

|---|---|---|---|---|

| Closed-Cell Spray Foam | R-6 to R-7 | Excellent (monolithic seal) | Professional Only | Climate-controlled workshops, garages, and commercial spaces where performance is critical. |

| Rigid Foam Board | R-4 to R-6.5 | Good (if perfectly sealed) | High (requires precision) | DIY projects where meticulous attention to detail can be guaranteed. |

| Fiberglass Batts | R-3.1 to R-3.7 | Poor (requires vapor barrier) | Moderate | Budget-conscious projects for unconditioned or semi-conditioned storage. |

| Radiant Barrier | Negligible | Poor (no inherent seal) | Low to Moderate | Supplementing other insulation in hot climates to reduce solar heat gain. |

When it comes down to it, the best way to insulate metal building applications is all about real-world performance. While options like fiberglass and rigid board can work under perfect conditions, closed-cell spray foam is the only method that inherently creates the seamless, impermeable barrier you need to truly protect a metal structure from Florida’s extreme temperatures and humidity.

How to Permanently Stop Condensation and Building Sweat

Condensation is the silent enemy of every metal building in South Florida. It’s that uninvited guest that shows up dripping from the ceiling and running down the walls, quietly kickstarting rust, nurturing mold, and causing serious structural damage over time.

This phenomenon, often called "building sweat," is way more than a minor annoyance—it's a flashing red light signaling a critical vulnerability in your building's defense system.

To get a clear picture of why your building sweats, just think about a cold can of soda on a hot, humid day. Almost instantly, beads of water form on its surface. Your metal building is doing the exact same thing. When the warm, moisture-rich Florida air hits the cooler surface of your metal panels, the air can't hold all that moisture anymore. It has to release it, and it does so as liquid condensation right onto your steel.

Why Insulation Is the Only Real Solution

This constant cycle of moisture creates a perfect storm for destruction. It corrodes metal fasteners, degrades the steel panels themselves, and soaks traditional insulation until it's completely useless. More importantly, it creates a damp, dark environment where mold and mildew can thrive, ruining air quality and damaging anything you store inside, from classic cars to valuable inventory.

The only way to permanently stop this cycle is to prevent that warm, humid air from ever touching the cool metal. This is where the right insulation becomes your most powerful weapon, acting as a complete thermal and vapor barrier. The effectiveness of this barrier, however, varies dramatically between the different types of insulation out there.

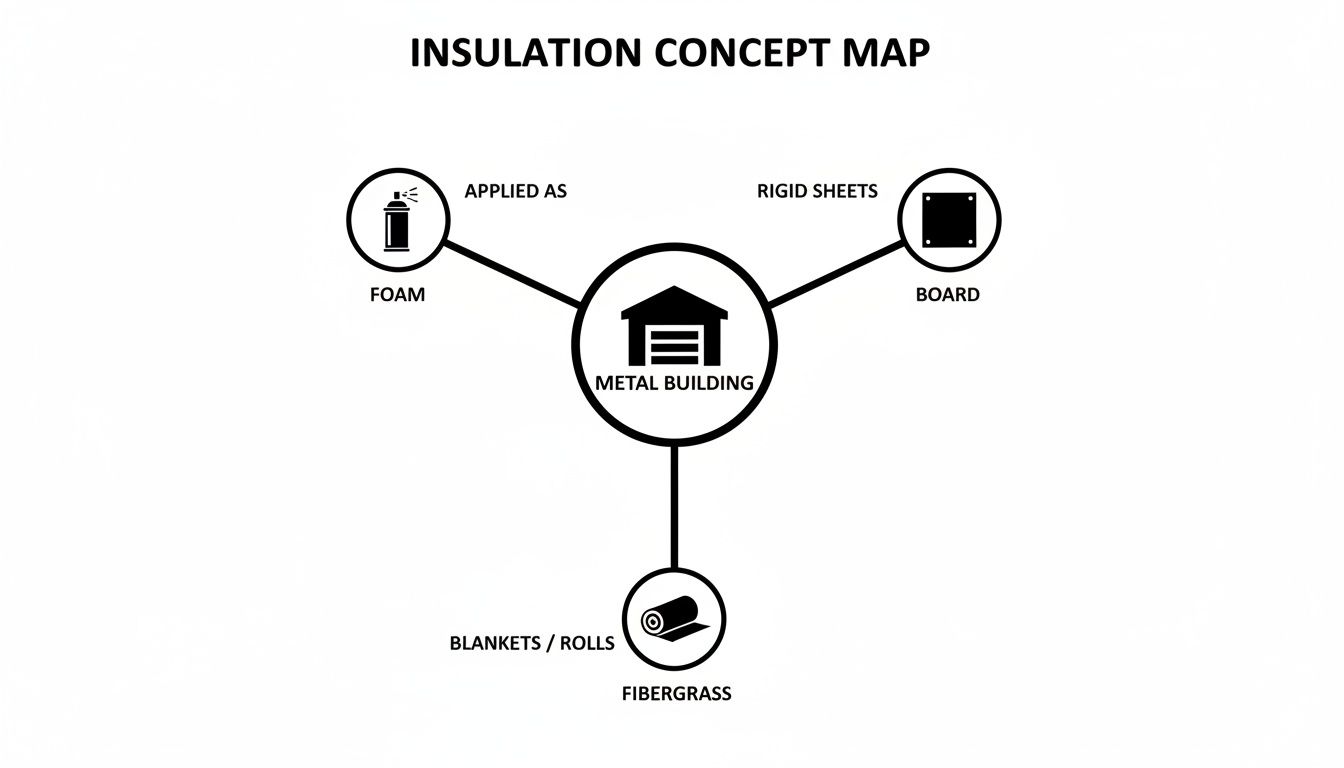

This map gives a quick overview of the main insulation categories for metal buildings.

As you can see, each method takes a fundamentally different approach, from foams that are sprayed on to pre-made boards and classic fibrous rolls.

Comparing Vapor Barrier Performance

Putting an end to building sweat really comes down to one critical factor: how well your insulation system works as a vapor barrier. A true vapor barrier is a material that stops water vapor dead in its tracks. Some insulation types have this built-in, while others need a separate layer that has to be installed perfectly.

Let’s see how the main contenders stack up in this crucial battle against moisture:

- Fiberglass Batts: On its own, fiberglass offers zero resistance to moisture vapor. In fact, its fluffy structure is a pro at trapping humid air right against the metal, which actually makes condensation worse. It absolutely needs a separate plastic vapor barrier, but any tiny tear, unsealed seam, or staple hole in that sheet becomes a gateway for moisture to get in and get trapped.

- Rigid Foam Board: The foam panels themselves are pretty good at blocking moisture. The problem? The system is only as strong as its weakest link—the seams. Every single joint between the boards has to be perfectly taped and sealed. An imperfect seal, which is incredibly common on complex jobs, creates a direct channel for moisture-filled air to find its way to the metal.

- Closed-Cell Spray Foam: This is where the game completely changes. Closed-cell spray foam is in a league of its own because it's an all-in-one insulator, air barrier, and true vapor retarder in a single, seamless application. It sticks directly to the metal, creating one solid, monolithic seal with no joints, gaps, or fasteners to worry about.

Because closed-cell spray foam forms a direct, airtight bond with the metal substrate, it physically separates the warm interior air from the cooler exterior panels. This eliminates the temperature difference that causes condensation in the first place, stopping building sweat at its source.

Ultimately, choosing the best way to insulate a metal building is about more than just R-value; it’s about creating an unbreakable shield against moisture. While other methods depend on extra layers and flawless sealing jobs, closed-cell spray foam delivers this protection as part of its very nature. It creates a seamless, waterproof, and airtight barrier that permanently solves the condensation problem, protecting your structure's integrity and value for decades to come.

Why Spray Foam Is the Ultimate Fix for Metal Buildings

While other insulation types have their uses, when it comes to a metal building, closed-cell spray foam is in a league of its own. It’s not just insulation; it’s a complete upgrade that reinforces the structure and seals the environment. It’s simply the best way to insulate a metal building because it solves multiple problems in a single application, making it a powerful, long-term investment.

Unlike insulation that's cut, stuffed, or taped into place, spray foam starts as a liquid. It gets sprayed directly onto the metal panels, where it expands to fill every single crack, seam, and void before hardening. This creates a solid, monolithic shield that’s bonded directly to the building itself. The result is three game-changing advantages that no other system can truly match.

The Triple-Threat Advantage of Spray Foam

First, its air-sealing power is unbelievable. Because it creates a continuous, gap-free barrier, it completely stops drafts and air leaks in their tracks. This airtight seal is the secret to massive energy savings and a stable interior climate—your HVAC system no longer has to fight a constant battle against hot, humid air sneaking in from outside.

Second, it adds incredible structural strength. As closed-cell spray foam cures, it becomes extremely dense and rigid. It literally glues the metal panels to the building's frame, which helps the whole structure resist flexing and vibration from high winds—a non-negotiable benefit here in South Florida.

Finally, it boasts an incredible thermal resistance, with an R-value of up to R-7 per inch. This means you get a much higher level of insulation with less thickness compared to other materials. You get superior performance while saving precious interior space.

Spray foam doesn’t just insulate your building; it transforms it. By creating an airtight, waterproof, and structurally reinforced envelope, it addresses the core weaknesses of a metal structure in one decisive step.

Real-World Performance: A Tale of Two Workshops

To see the difference this makes, let's imagine two identical 30×40 metal workshops in West Palm Beach going through a typical summer.

- Workshop A (Traditional Insulation): It’s insulated with fiberglass batts and a separate vapor barrier. On humid mornings, the owner is constantly wiping up condensation. The AC unit runs almost non-stop, but by mid-afternoon, it's still uncomfortably hot inside. The energy bills are brutal.

- Workshop B (Spray Foam Insulation): This one is insulated with closed-cell spray foam. The interior is bone-dry year-round, with zero building sweat on the walls or ceiling. A smaller, more efficient AC unit cycles on and off, easily keeping the shop cool and comfortable. The owner’s energy bills are nearly 40% lower than the other workshop.

The difference is night and day. Workshop B isn't just more comfortable and cheaper to run; its metal structure is actively protected from the long-term rust and damage that moisture causes.

What About Sound? A Role for Open-Cell Foam

While closed-cell is the champion for most metal building applications, its cousin, open-cell spray foam, has a specific talent: sound dampening.

Its softer, sponge-like texture makes it an exceptional sound absorber. If your metal building is a workshop filled with loud machinery or a space where you need acoustic control, open-cell foam can dramatically cut down on noise transfer. Just remember, because it’s permeable to moisture, it absolutely must be paired with a carefully installed vapor barrier in our humid climate.

To get into the technical specifics, you can explore more about different types of spray foam insulation in our guides. Whether you need the ultimate thermal shield or superior sound control, there’s a high-performance spray foam solution that’s right for the job.

The Insulation Installation Process From Start to Finish

Even the best insulation material on the market will fail if it’s installed poorly. Picking the right insulation for your metal building is only half the battle; getting it applied correctly is what actually delivers the performance you're paying for.

A professional installation isn't just about spraying foam on a wall. It’s a precise process, and understanding it helps you know what to look for and ensures you get the results you expect.

It all starts with one absolutely critical step: surface preparation. Spray foam is applied as a liquid, and for it to create that powerful, permanent bond, it needs a perfectly clean and dry surface. Any dust, grease, or leftover moisture on those metal panels will get in the way of proper adhesion, leading to gaps and a failed seal.

A true pro won't even think about pulling the trigger on their spray gun until every square inch is meticulously cleaned and prepped. This isn’t a corner you can cut—it’s the foundation for the entire system.

Don't Forget to Ventilate

Sealing your building up tight is great for energy bills, but you can't just trap all the air inside. An airtight building needs a smart ventilation strategy to manage indoor moisture and keep the air fresh. Without it, humidity from daily activities has nowhere to go.

This is why a professional plan is about more than just insulation. It's about creating a complete system where the sealed envelope and mechanical ventilation work together. This balance is what creates a healthy, comfortable, and efficient space.

Common ventilation solutions include:

- Ridge Vents: Installed along the peak of the roof, these let hot, humid air rise and escape naturally.

- Exhaust Fans: These are perfect for pulling stale, moist air out of specific areas like workshops or bathrooms.

- HVAC Systems: A modern, correctly sized HVAC system is designed to handle the air exchange needed in a well-sealed building.

Combining a tight seal with active ventilation is the secret to getting the best of both worlds: unbeatable energy efficiency and great indoor air quality.

Codes, Compliance, and Hiring the Right Pro

Every insulation project has to meet local building codes. These rules often dictate minimum R-values and specify important fire safety requirements.

Professional installers live and breathe these codes. They’ll make sure your project is 100% compliant, especially when it comes to things like using fire-retardant coatings (called intumescent coatings) over spray foam where required.

When you’re ready to hire a contractor, asking the right questions is key. A real expert will have confident, detailed answers.

Your goal is to find a partner who understands building science, not just a technician who knows how to operate a spray gun. How they talk about preparation, sealing, and ventilation will tell you everything you need to know about their commitment to quality.

Use this checklist when you're talking to potential installers:

- “How do you prepare the metal surfaces before you start spraying?” You want to hear them talk about cleaning, degreasing, and ensuring the surface is completely dry.

- “What’s your technique for getting a complete, gap-free seal?” They should mention how they handle tricky spots like corners, joints, and around structural beams.

- “Are you licensed, insured, and certified by the spray foam manufacturer?” If the answer isn't a clear "yes" to all three, walk away.

- “How will you protect my property from overspray?” A professional will have a clear plan for masking off windows, doors, floors, and equipment.

Of course. Here is the rewritten section, adopting the voice, tone, and style of the provided examples to sound like an experienced, local human expert.

Your Metal Building Insulation Questions, Answered

Even after weighing the options, it’s smart to have a few questions before you kick off a project. Choosing the right insulation for a metal building is a big deal, and getting straight answers helps you move forward with confidence.

Here are a few of the most common questions our team gets from property owners right here in South Florida.

What’s the Ballpark Cost for Spray Foam Insulation?

Every job is a bit different, but having a general number helps you plan. For a professional installation, you can expect closed-cell spray foam to run between $2.00 to $3.00 per board foot. A board foot is just a simple way to measure volume—it’s a one-foot by one-foot square area, insulated one inch deep.

So, for a typical 30×40 metal building, you’re likely looking at a total project cost between $6,000 and $12,000. The final price tag really hinges on how much R-value you need (which dictates the foam’s thickness) and the complexity of the building itself.

While the initial investment is higher than something like fiberglass, the payback is huge. The airtight seal from spray foam can seriously slash your heating and cooling costs—often by 30-50%. That means the system can pay for itself in as little as 5 to 7 years, all while saving you the headache of expensive moisture repairs later on.

Can I Just Install This Stuff Myself?

The honest answer? It really depends on what insulation you’re using.

- DIY-Friendly Options: If you have some solid construction experience, you might be able to tackle fiberglass batts or rigid foam boards. But let me be clear: this requires meticulous attention to detail. Every single seam, joint, and edge has to be perfectly sealed to create a proper vapor barrier. Just one small gap, and you’ve opened the door for condensation to ruin the whole job.

- Professional-Only Installation: Spray foam is 100% not a DIY project. This is a job for certified professionals, period. The application involves mixing chemicals at very specific ratios, temperatures, and pressures. It takes specialized equipment and serious safety training to get it right.

When it comes to spray foam, professional installation is non-negotiable. It guarantees performance, safety, and a truly airtight seal. Trying to do it yourself is a recipe for poor results, wasted money, and serious safety risks.

How Much R-Value Does My Metal Building Really Need?

There’s no magic R-value that works for everyone. The right number depends on our South Florida climate and what you’re using the building for. The goal is to hit that sweet spot where you get the performance you need without paying for extra insulation you don't.

Up north in a cold climate like Minnesota (U.S. Climate Zone 6), a workshop might need a hefty R-20 in the walls and R-49 in the roof just to meet energy codes.

But down here in our hot, humid South Florida climate (Zone 1), that’s overkill. A similar building might only need R-13 in the walls and R-30 in the roof to stay comfortable and efficient. If you’re just using the structure for basic storage and not conditioning the air, an even lower R-value might be all you need to control condensation and keep your stuff from baking in the summer heat.

Your best bet is to talk to a professional insulation contractor. We can give you a precise recommendation based on local building codes, how you plan to use the space, and what your energy-saving goals are. That way, you invest in exactly the right amount of insulation to get the job done right the first time.

Ready to stop your building from sweating and start saving on energy costs? The team at Airtight Spray Foam Insulation has the hands-on experience to deliver the ultimate insulation solution for your metal building. Request a free quote today and find out how our Airtight Comfort System can completely transform your space.