Blog

The Best Insulation for Noise Reduction in South Florida Homes

When it comes to the best insulation for noise reduction, you're looking for a material that pulls double duty. It needs high density to physically block sound waves and a porous, open structure to absorb them. That's why materials like spray foam and mineral wool consistently come out on top.

The right choice really boils down to your specific problem. Are you trying to block the rumble of traffic from outside, or are you trying to kill the echo in your home theater? No matter the material, though, one thing is non-negotiable: a complete air seal is the single most critical factor for success.

How Insulation Actually Controls Noise

We all know insulation is great for keeping our homes cool, but its power to create acoustic comfort is just as important. Here in South Florida, we’re surrounded by noise—the constant drone of traffic on I-95, the neighbor's lawn crew firing up at 8 a.m., or even just loud conversations from the house next door. The right insulation acts as your first line of defense, turning your home into a peaceful sanctuary.

But effective sound control isn't about just stuffing any old material into your walls. It starts with understanding the two different types of sound you’re up against.

Airborne vs. Structure-Borne Sound

Airborne sounds are exactly what they sound like—noises that travel through the air. Think voices, music from a stereo, or a barking dog. Insulation with a soft, porous structure is fantastic at trapping and absorbing these sound waves, much like a thick sponge soaks up water.

On the other hand, structure-borne sounds are vibrations that move through the solid parts of your home—the studs, drywall, and floors. This is the thud of footsteps from upstairs, the hum of your air conditioner kicking on, or the jarring slam of a door. To stop these vibrations, you need a denser, more rigid insulation that can effectively dampen them before they can radiate into your living space.

To measure how well an insulation material handles these sounds, the industry uses two key metrics. Getting a handle on these ratings is the first step to picking the right material for the job.

Key Takeaway: The best noise reduction strategies tackle both airborne and structure-borne sound. The goal is to create a complete, uninterrupted barrier within your home’s envelope, leaving no gaps or weak points for sound to sneak through.

Decoding Acoustic Ratings: STC and NRC

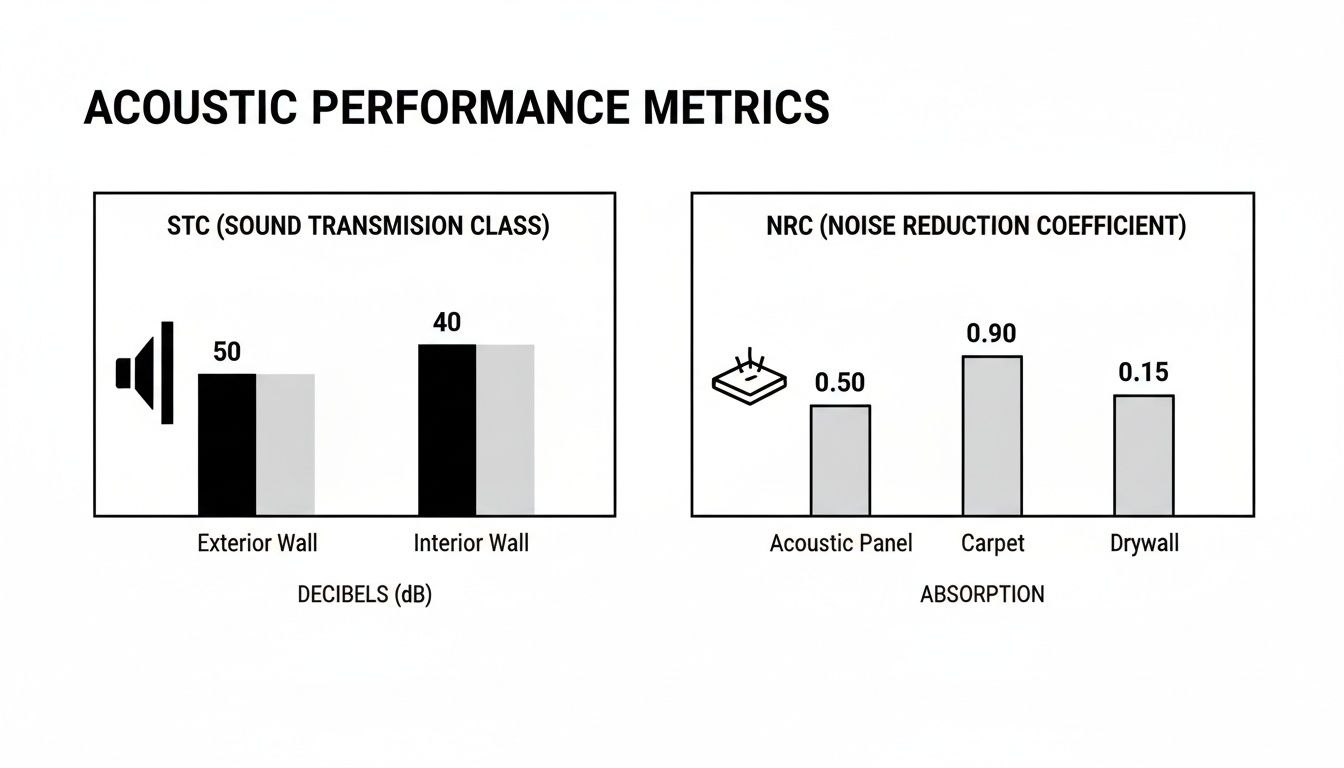

When you start comparing insulation, you’ll see two ratings pop up again and again: STC and NRC. They might sound similar, but they measure two very different aspects of sound control.

| Acoustic Metric | What It Measures | Higher is Better? | Ideal For |

|---|---|---|---|

| STC (Sound Transmission Class) | How well a barrier blocks airborne sound from passing through it. | Yes | Exterior walls, shared walls between apartments, and stopping traffic noise. |

| NRC (Noise Reduction Coefficient) | How well a material absorbs sound within a space to reduce echo. | Yes | Home theaters, offices, and open-concept living areas where sound clarity matters. |

A high STC rating means less sound makes it from one side of a wall to the other, making it crucial for privacy and blocking outside noise. A high NRC rating tells you how much sound gets soaked up when it hits a surface, which is all about improving the sound quality inside a room.

For a deeper look at how this all comes together, you can explore our detailed guide on insulation as a sound barrier. Ultimately, choosing the best insulation means finding a material with the right balance of STC and NRC to solve your specific noise problem.

Comparing Top Insulation Materials for Soundproofing

Picking the right insulation for noise reduction isn't just about grabbing the thickest material off the shelf. It’s about understanding how different materials actually perform in the real world. The usual suspects—fiberglass batts, mineral wool, cellulose, and spray foam—all have their own acoustic quirks, installation demands, and durability. A true head-to-head comparison shows which one really delivers for a quiet South Florida home.

To make an informed decision, you have to look past the sales pitches and get down to the hard numbers. This is where STC and NRC ratings come in. They are the two most critical metrics for measuring a material's ability to block and absorb sound.

Here's the key takeaway from that chart: STC tells you how well a barrier stops sound from punching through, while NRC measures how much echo it soaks up inside a room. For real soundproofing, you need an insulation that nails both.

Fiberglass Batts: A Budget-Friendly Starting Point

Fiberglass batts are everywhere, mostly because they're cheap and easy to find. They're made of fine glass fibers that trap air pockets, which slows down sound waves. For noise reduction, a standard fiberglass batt installation might get you an STC rating in the high 30s to low 40s—but only if it’s installed perfectly.

The problem is, "perfect installation" rarely happens. Any gap, any compression around a wire, and the acoustic performance plummets. In our humid South Florida climate, fiberglass is also notorious for absorbing moisture, causing it to sag and lose whatever sound-dampening ability it had.

Mineral Wool: The Dense Contender

Mineral wool, sometimes called rock wool, is a step up. It’s made from volcanic rock, and its dense, fibrous structure is naturally better at blocking sound than fiberglass. You’ll often see STC ratings in the mid-to-high 40s, which is why it’s a go-to for home theaters and shared walls where you really want to kill airborne noise.

But even with its density, mineral wool suffers from the same Achilles' heel as fiberglass: gaps. Research has shown that a tiny 1% gap in insulation coverage can slash its effectiveness by as much as 50%. While it’s more moisture-resistant than fiberglass, it isn't a true vapor barrier, which is still a major concern around here.

Crucial Insight: The biggest weakness of any batt insulation isn’t the material itself—it's the installation. Sound acts like water, finding the path of least resistance through every single crack and seam. That's why a complete, gap-free seal is the only way to achieve real soundproofing.

Cellulose: The Recycled Sound Absorber

Cellulose is made from recycled paper and is usually blown into wall cavities. Because it's a loose-fill material, it does a much better job of conforming around pipes and wires than pre-cut batts, which helps minimize those performance-killing gaps.

Acoustically, cellulose is solid, with STC ratings that are often on par with or even slightly better than mineral wool. It’s particularly good at absorbing sound and cutting down echo. The deal-breaker? Moisture. If cellulose gets wet, it clumps, grows mold, and loses all its acoustic and thermal value. That makes it a huge gamble in South Florida without a bulletproof vapor barrier.

Airtight Spray Foam: The Uncompromising Seal

This is where spray foam insulation changes the game. It’s applied as a liquid that expands on contact, filling every single crack, crevice, and void to create a truly airtight, monolithic barrier. It completely eliminates the installation gaps that cripple other insulation types, giving you consistent, predictable performance.

Did you know that spray foam can cut noise transmission by up to 50%? For anyone living near I-95 or dealing with noisy lawn crews in Jupiter and Palm Beach Gardens, that’s a massive difference. The U.S. Department of Energy even points out how this air-sealing quality boosts acoustic comfort—a single 1-inch-square hole can drop a wall's sound-blocking ability by a staggering 10 points.

Because it creates such a rigid, seamless barrier, spray foam is often considered the best insulation for noise reduction. It attacks both airborne and structure-borne sound at the source. And for an extra layer of peace and quiet, pairing it with other soundproofing materials like the best noise reducing curtains can make your home an oasis.

To really put it all into perspective, let's look at how these materials stack up side-by-side.

Acoustic Performance of Common Insulation Materials

This table breaks down how the most common insulation types perform when it comes to noise reduction, cost, and suitability for different environments, especially our humid South Florida climate.

| Insulation Type | Typical STC Range | Typical NRC Range | Best For | Cost per Sq. Ft. | Moisture Resistance |

|---|---|---|---|---|---|

| Fiberglass Batts | 37 – 42 | 0.80 – 0.95 | Basic noise reduction on a tight budget. | $0.60 – $1.40 | Poor |

| Mineral Wool | 45 – 52 | 0.95 – 1.05 | Blocking airborne noise in dry, controlled environments. | $1.40 – $2.50 | Fair |

| Cellulose | 44 – 50 | 0.90 – 0.95 | Sound absorption in dry, sealed cavities. | $0.80 – $1.50 | Poor |

| Spray Foam | 37 – 50+ | 0.70 – 0.85 | Creating a complete air and sound seal; blocking all noise types. | $1.50 – $4.00 | Excellent |

As you can see, while some materials look good on paper, spray foam is the only one that delivers reliable, durable performance in a tough climate like ours. Its ability to form a perfect, airtight seal is what makes it so uniquely effective. To learn more, check out our deep dive on spray foam vs. blown-in insulation. At the end of the day, a truly quiet home depends on eliminating air gaps just as much as it depends on the material itself.

Why Spray Foam Is in a League of Its Own for Sound Dampening

While other insulation materials certainly help with noise control, spray foam is in a completely different class. This isn't just hype—it comes down to its unique liquid application and the physical barrier it creates. Unlike pre-cut batts or blown-in insulation that can leave tiny (but significant) gaps, spray foam starts as a liquid and expands, creating a single, seamless, airtight seal. This monolithic barrier is the real secret to its incredible sound-dampening power.

Think of sound like water—it will find any crack or crevice to get through. The small gaps and seams left behind by traditional insulation methods are basically superhighways for noise. Spray foam completely eliminates these pathways. The acoustic performance you're hoping for is the performance you actually get.

Open-Cell Foam: The Go-To for Absorbing Airborne Noise

For interior spaces where you want to absorb sound and reduce echo, open-cell spray foam is the top choice, hands down. It has a soft, almost sponge-like texture filled with millions of interconnected air pockets. When airborne sound waves—like conversations, TV noise, or music—hit this surface, they get trapped inside these pockets. The sound energy is converted into a tiny amount of heat, effectively killing the noise right where it starts.

This makes open-cell foam perfect for creating spaces that just feel quieter and more peaceful. Think about where it shines:

- Home Theaters: It soaks up echoes and reverberation, giving you that crisp, clear, and immersive audio you want.

- Home Offices: It dampens background chatter and other distractions, helping you stay focused.

- Bedrooms and Nurseries: It drastically cuts down on noise bleeding between rooms, creating a more restful atmosphere.

Open-cell is a champion at managing those mid-to-high frequency sounds. Its sound-absorbing capability is measured by its Noise Reduction Coefficient (NRC), and a higher number is better.

Open-cell spray foam boasts a Noise Reduction Coefficient (NRC) of around 0.70 to 0.75. That means it can absorb about 70-75% of the sound energy that hits it. This is exceptional performance, making it one of the best choices for controlling echo and chatter in garages, workshops, or new construction. You can dig into the technical specs on soundproofing with spray foam to see the data for yourself.

Closed-Cell Foam: The Ultimate Barrier for Low-Frequency Noise

When your goal is to block powerful, low-frequency sounds and stop structural vibrations, closed-cell spray foam is the heavy hitter you need. This stuff is far denser and more rigid than its open-cell cousin. As it cures, it forms a tight web of discrete, sealed cells, creating a formidable barrier that sound has a very hard time penetrating.

Its dense, rigid structure is incredibly effective at blocking the low-end rumble of traffic, the constant hum of an HVAC system, or the thud of footsteps from the floor above. Because it's so rigid, closed-cell foam also adds structural strength to whatever it's applied to, which helps dampen vibrations before they can travel through your home's frame.

Here are a few places where closed-cell foam is the clear winner:

- Exterior Walls: It creates a powerful shield against noise from busy streets or loud neighbors.

- Floors and Ceilings: It minimizes impact noise from foot traffic, keeping things peaceful between levels.

- Walls Next to Mechanical Rooms: It's great for containing the noise from furnaces, pumps, and other loud equipment.

The Airtight Advantage: Stopping Sound Flanking in Its Tracks

One of the biggest reasons soundproofing projects fail is something called sound flanking. This is when sound cleverly bypasses your insulated wall and travels through the building’s structure—the studs, joists, and even electrical outlets. Traditional batts do almost nothing to stop this because they don't seal the assembly.

This is where spray foam's biggest advantage comes into play. By adhering directly to the studs, sheathing, and everything in between, it creates a fully bonded, airtight assembly. It physically locks everything together, which dramatically reduces sound flanking and makes the entire wall act as a single, cohesive sound-blocking unit.

Critical Differentiator: In a perfect lab test, mineral wool might show a higher STC rating. But in the real world, installations are never perfect. Spray foam's ability to create a flawless air seal means it often outperforms other materials on the job site by completely eliminating the sound flanking that undermines their lab-tested performance.

At the end of the day, spray foam's unique ability to both absorb and block sound—while sealing every last air leak—makes it the most reliable and effective choice for serious noise reduction. Whether you’re using open-cell to fine-tune the acoustics inside or closed-cell to block out the world, the result is a quieter, more comfortable home.

Let's move past the technical specs and talk about where the rubber meets the road. Knowing the science behind spray foam is great, but seeing how it solves real-world noise problems here in South Florida is what really matters. The best insulation for noise reduction isn't just about what a lab test says; it’s about tangible results in your home or building.

Spray foam’s biggest advantage is its ability to create a completely seamless, monolithic seal. This makes it a game-changer for the unique and challenging noise situations we deal with every day in our region.

Here are four common scenarios where Airtight Spray Foam makes all the difference, turning a noisy, frustrating space into a quiet retreat.

Quieting a Dense Neighborhood Home

Picture a home in a tightly packed Jupiter neighborhood. You’ve got the constant hum of your neighbor’s AC unit, the lawn crew that shows up at 7 AM on a Saturday, and barking dogs at all hours. Trying to relax feels impossible when you're surrounded by airborne sounds coming from every direction.

This is a perfect job for closed-cell spray foam applied to the exterior walls. Its dense, rigid structure creates a serious barrier against those mid-to-high frequency noises. Unlike fiberglass batts that can leave tiny but significant gaps around outlets, pipes, and window frames, spray foam expands to seal every single crack and crevice. It leaves no path for sound to sneak through, effectively wrapping your home in a protective, quiet shield.

Soundproofing a Multi-Family Building

If you're a property manager in West Palm Beach, you've probably heard it all—literally. Noise complaints are a constant headache. Tenants can hear conversations, TVs, and footsteps from the units next to them and above them, which leads to unhappy residents and high turnover. The mission here is to stop both airborne sound and structure-borne vibrations.

You need a two-pronged attack for this one.

- For shared walls: Open-cell spray foam is the ticket. Its soft, almost spongy texture is fantastic at absorbing airborne sounds like voices and music, stopping them dead in their tracks before they pass through the wall.

- For floors and ceilings: Applying spray foam between the floor joists is the key to dampening structure-borne sound. It absorbs the vibrations from footsteps and impacts, so the downstairs neighbor doesn't have to hear every step the upstairs tenant takes.

By creating fully sealed and insulated assemblies between units, you dramatically improve privacy and comfort, making the building a place people actually want to stay.

Expert Insight: In multi-unit buildings, the biggest sound culprit is often "flanking"—noise that travels through shared joists and studs. Spray foam is uniquely effective at stopping this because it adheres directly to the framing, creating a break in the vibration path. Pre-cut batts just can't do that.

Dampening a Commercial Metal Building

Think of a business owner in Stuart with a big metal workshop. When it rains, the noise on that roof is deafening. On top of that, the sound from machinery inside can easily travel outside and bother the neighbors. You’re fighting impact noise from the rain and trying to contain the noise you’re creating.

Applying closed-cell spray foam directly to the underside of the metal roof and walls is completely transformative.

First, it acts as a vibration dampener. That deafening roar from a downpour becomes a gentle patter. Second, its rigidity helps contain the operational noise from machinery inside. Finally, it helps cut down on the echo and reverberation within that big open space, which makes for a safer and less exhausting work environment. It's a prime example of how the best insulation for noise reduction also delivers unmatched thermal and moisture control.

Building New Homes Near a Busy Road

Imagine you're a contractor developing new homes in Palm Beach Gardens, right near a major highway. That constant, low-frequency traffic rumble is one of the hardest sounds to block, and buyers are looking for a peaceful retreat, not a home that sounds like it's on the interstate.

For new construction, the most effective strategy is installing closed-cell spray foam in the exterior walls from the get-go. Its high density is exactly what you need to fight those tough, low-frequency sound waves from traffic. And since most homes in South Florida are built with concrete block, understanding how these two materials work together is crucial. You can learn more about the insulation value of concrete block walls and see how spray foam supercharges their performance.

By building with spray foam from the start, a contractor can offer homes that are a true sanctuary from road noise—a massive selling point for any homebuyer.

Choosing the Right Insulation for a Quieter Home

Deciding on the best insulation for noise reduction isn’t about picking the material with the highest rating on a chart. It’s about building a complete system that works for your home, especially here in South Florida where we battle relentless humidity and need serious energy efficiency all year long. The right choice is more than a quick fix; it’s a long-term investment in your home's comfort and durability.

Materials like mineral wool and fiberglass look good on paper, and they do offer decent sound dampening in a perfect lab setting. But our homes aren't labs. In the real world, their performance often falls short because of one simple thing: gaps. Sound travels like air and water—it will find and exploit every tiny crack and crevice in your home's defenses, making even high-STC materials far less effective.

Balancing Performance and Practicality

For homeowners from Jupiter to Palm Beach Gardens and Stuart, the equation is bigger than just sound. Your insulation has to be a rock-solid barrier against moisture to prevent mold and rot. This is where traditional materials really show their weakness. Batt and blown-in insulation can absorb ambient moisture, causing them to sag, compress, and lose both their acoustic and thermal integrity over time.

This is where Airtight Spray Foam, especially the closed-cell type, really shines. It doesn't just insulate; it creates a single, solid, seamless barrier. It blocks sound, stops air leaks completely, and acts as a powerful vapor barrier all in one shot. This integrated approach means your investment pays off on all fronts—giving you a quieter, healthier, and more energy-efficient home.

Decision-Making Framework: When you're weighing your options, ask yourself these three questions:

- Does it create a complete air seal to stop sound from flanking around the insulation?

- Will it hold up and perform in our high-humidity climate?

- Does it tackle both airborne noise (like traffic) and structure-borne noise (like vibrations)?

Answering these will point you toward a solution that delivers lasting value, not just a temporary patch.

The Critical Role of Professional Installation

The on-paper performance of any insulation is useless if it isn't installed correctly. A seasoned crew with deep, hands-on experience in South Florida's unique construction challenges is what makes the difference. They know how to ensure every gap is sealed and how to apply the material correctly around complex framing, pipes, and wiring without compromising the sound barrier.

This expertise is what turns a good material into a great soundproofing solution. In fact, recent lab benchmarks confirm spray foam’s superiority in fighting noise. While fiberglass and mineral wool might hit STC ratings of 43 or 45 in a lab, a real-world installation with unavoidable gaps can easily drop that performance by 10 points or more. Spray foam just doesn't have that problem. It consistently delivers STC ratings of 37-39 and provides a significant 48.8 dB reduction for common sounds like speech and traffic.

Beyond the walls and attic, you can create an even quieter space by adding other layers, like specialized noise-reducing window shades. Ultimately, the most effective path to a truly quiet home is a holistic one that combines superior materials, expert installation, and smart, complementary solutions.

Your Soundproofing Questions, Answered

When you start digging into soundproof insulation, a lot of practical questions pop up. It’s natural to wonder about the cost, the installation process, and which material is really the right fit for your situation. Getting straightforward answers is the key to feeling good about your decision.

Here, we'll tackle the most common questions we hear from homeowners trying to quiet things down, especially here in South Florida.

Is Spray Foam Really More Expensive Than Fiberglass for Soundproofing?

Looking at the initial price tag, yes, spray foam insulation usually costs more than fiberglass. But that’s only half the story. Fiberglass is cheap upfront, but it has a bad habit of sagging, absorbing moisture, and leaving gaps as it ages—all of which kill its ability to block sound over time. You might pay less, but you won't get the quiet you were hoping for.

Spray foam, on the other hand, is a one-and-done solution. It's a sound barrier, an air seal, and a moisture barrier that doesn't break down or settle. When you consider its permanent acoustic performance and the real-world energy savings it delivers, spray foam often ends up being the smarter financial choice over the life of your home. The best way to know for sure is to get a detailed estimate that breaks down the full picture.

Can You Install Spray Foam in an Existing Home?

Absolutely. Putting soundproofing insulation into an existing home is something we do all the time, and it's incredibly effective. A lot of people think it means tearing down drywall, but modern techniques are much less invasive than that.

For closed-off walls, our technicians use injection foam. We drill a few small, precise holes, install the foam, and then patch and paint them. It's a clean process with minimal disruption. For easier-to-reach spots like attics and crawl spaces, the job is even simpler. A quick professional assessment will tell us the best way to get it done for your home.

Key Insight: Retrofitting an existing home with spray foam isn't just doable—it's one of the single best upgrades you can make for acoustic comfort and energy efficiency. The airtight seal it forms can finally solve those persistent noise problems that other types of insulation just can't touch.

What’s the Best Insulation for a Home Theater?

For a space like a home theater or a media room, open-cell spray foam is the hands-down winner. In these rooms, the goal isn't just blocking outside noise; it's about controlling sound inside the room to stop echoes and reverberation. That’s what gives you that crisp, clear audio.

Open-cell foam has a soft, almost spongy structure that’s phenomenal at absorbing sound waves, especially the mid-to-high frequencies you get from dialogue and movie scores. It basically soaks up sound energy instead of letting it bounce off the walls. This creates the perfect acoustic environment for a truly immersive movie night.

How Does Humidity Affect Soundproofing Insulation?

Here in South Florida, humidity is a huge deal, and it’s a silent killer for traditional insulation. Materials like fiberglass and cellulose act like sponges, soaking up moisture from the air. Over time, this makes them heavy, causing them to compress and sag.

When that happens, you get air gaps inside your walls, which are like open highways for sound to travel through. Closed-cell spray foam, however, is completely different—it’s waterproof. It creates a solid vapor barrier that won't lose its shape or its ability to block sound, no matter how humid it gets. That’s why it's the best insulation for noise reduction in a climate like ours.

Ready to create a quieter, more comfortable space? The experts at Airtight Spray Foam Insulation have over 25 years of experience delivering superior sound dampening and energy efficiency to homes and businesses across South Florida. Request your free, no-obligation quote today!