Blog

Open Cell Vs Closed Cell Insulation Comparison Guide

Deciding between open cell and closed cell spray foam often comes down to what you need most: cost savings and sound control or top-tier insulation and moisture resistance. Open cell foam delivers an affordable, sound-dampening barrier. Closed cell foam, on the other hand, packs more R-value per inch and creates its own moisture shield.

Key Takeaways For Open Cell vs Closed Cell

Here’s a quick rundown of how these two foams compare across thermal performance, moisture control, and price.

- R-Value Per Inch: Open cell delivers about R-3.6–4, while closed cell ranges between R-6–7.

- Vapor Permeability: Open cell allows assemblies to dry out; closed cell forms a low-perm layer.

- Cost Per Board Foot: Expect roughly $0.30–0.50 for open cell versus $1.00–1.50 for closed cell.

- Best Applications: Open cell excels inside walls and in sound-sensitive areas; closed cell shines on roofs, foundations, and metal building shells.

Key Differences At A Glance

| Criterion | Open Cell | Closed Cell |

|---|---|---|

| R-Value Per Inch | R-3.6–4 | R-6–7 |

| Vapor Permeability | High | Low |

| Air Sealing | Good | Excellent |

| Cost Per Board Foot | Low | High |

| Best Uses | Interior, Sound | Exterior, Moisture |

Use this table to match your budget, performance goals, and South Florida conditions.

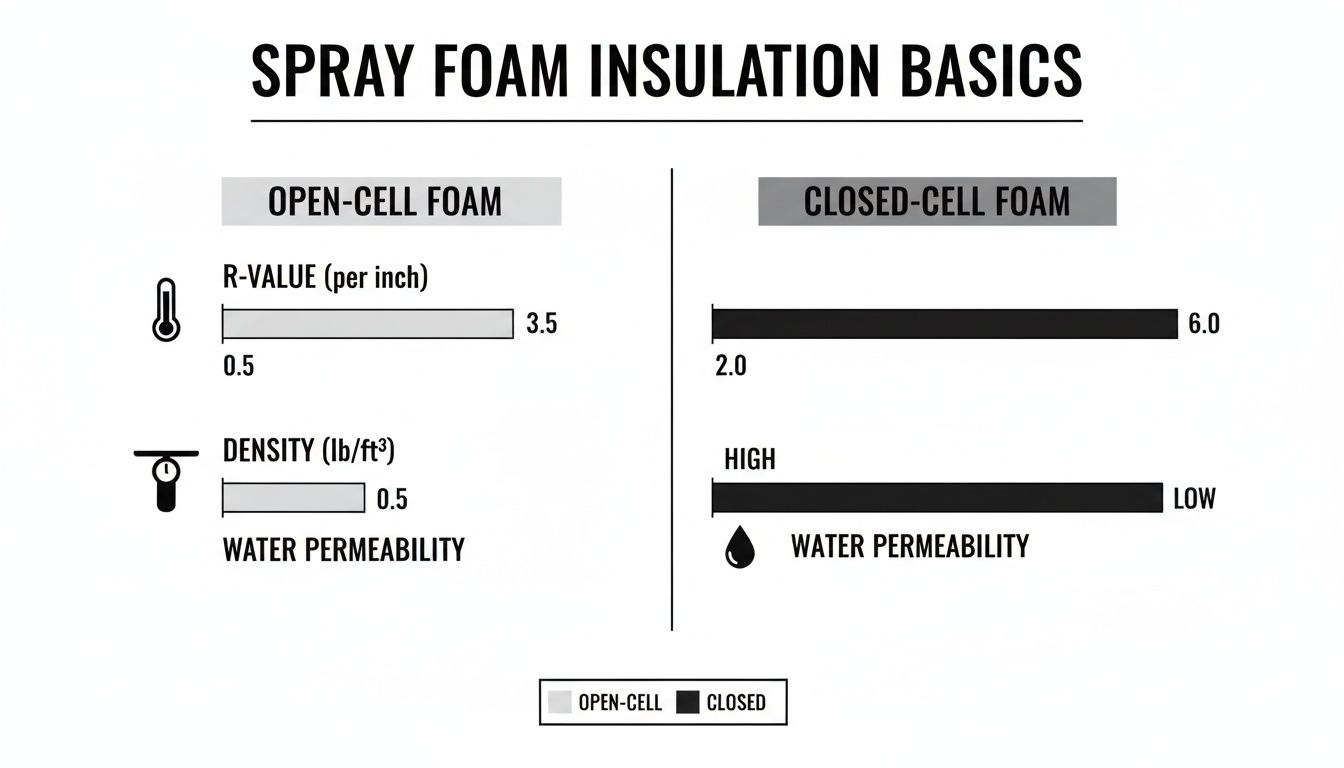

The diagram below from Wikipedia shows spray foam cell structure differences.

It clearly illustrates open cells’ interconnected web and closed cells’ dense, sealed pockets.

Choosing closed cell foam doesn’t just boost R-value. It also stiffens assemblies and keeps moisture out in high-humidity zones.

When To Choose Open Cell

If you’re tackling interior partitions or need to tame echoes in living spaces, open cell foam is hard to beat. It flexes to fill irregular cavities and wraps wiring and pipes snugly. Plus, the budget-friendly price tag makes it ideal when sound reduction matters more than a moisture barrier.

When To Choose Closed Cell

For roofs over garages, crawl spaces under homes, or metal buildings near the coast, closed cell foam is the go-to. Its high density creates a continuous vapor barrier that stops water intrusion and adds structural rigidity to roof decks and wall panels. In South Florida’s salt-air environment, that extra protection against corrosion is priceless.

Ready to seal and insulate with precision? Request a free quote from Airtight Spray Foam Insulation to align your project with the right foam type.

Matching Foam To Climate Conditions

South Florida’s combination of heat, humidity, and hurricanes demands an insulation system that handles moisture and solar gains. Closed cell foam’s vapor-tight seal reduces mold risk in unvented attics under tile roofs. Meanwhile, open cell foam supports attic venting strategies and helps maintain indoor humidity balance in living spaces.

Next Steps For Project

To move forward with confidence:

- Gather and compare quotes from qualified installers.

- Review product warranties and building-code compliance.

- Schedule a site assessment with Airtight Spray Foam Insulation.

Armed with these insights, you’ll choose the foam that delivers long-term comfort and energy savings.

Understanding The Basics Of Open Cell And Closed Cell Insulation

When I size up open-cell versus closed-cell spray foam, I start with how each one’s built. Open-cell feels almost sponge-like—light, breathable, and ready to flex into nooks and crannies. Closed-cell packs density, creating a tough, moisture-resistant shield in your walls.

Both formulations mix isocyanate and polyol, but the choice of blowing agents and catalysts drives differences in cell structure, material yield, and expansion behavior.

- R-Value Per Inch: Open-cell ~R-3.5 to R-4, Closed-cell ~R-6 to R-7

- Density: Open-cell <**0.5 lb/ft³**, Closed-cell >1.5 lb/ft³

- Curing Time: Open-cell sets up in seconds; Closed-cell often needs extra dwell and monitoring

Open-cell foam flexes to fill irregular cavities, while closed-cell locks up cells for a rigid, moisture-blocking layer.

Chemical Composition And Expansion Behavior

In open-cell spray foam, water or low-GWP agents cause a fast, frothy rise—often ballooning to 100× its original volume. That interconnected network traps air for sound dampening but still lets vapor flow.

Meanwhile, closed-cell uses specialized chemical blowing agents to expand more gradually (around 30×). Each cell seals itself, forming a continuous vapor barrier and boosting structural stiffness.

| Property | Open Cell | Closed Cell |

|---|---|---|

| Cell Integrity | Interconnected | Fully Sealed |

| Vapor Permeability | High | Low |

| Expansion Factor | ~100× | ~30× |

Installation Methods And Terminology

Most professional crews rely on plural-component rigs to meter iso and resin at precise ratios. DIY kits make foam accessible but often risk off-ratio batches that shrink, fuzz out, or lose R-value.

“Board foot” is simply one square foot covered at one inch thick—a quick way to estimate material needs. “Yield” is the real-world coverage you’ll get, which fluctuates with temperature, substrate, and spray technique.

Interestingly, open-cell SPF has led global residential markets. MarketsandMarkets forecasts growth from USD 2.4 billion in 2022 to USD 4.6 billion by 2030 (CAGR ~8.3%). You can explore the full forecast in the MarketsandMarkets spray foam market outlook.

Keeping temperature and pressure dialed in is critical. Off-ratio foam can lead to gaps, poor adhesion, or even health concerns. Likewise, your pass speed and gun distance directly affect cell integrity and final yield.

Key Terms Explained

Even experienced homeowners and pros mix up “board foot” and “yield.” Here’s a simple checklist:

- Calculate your target R-value based on South Florida’s code and climate.

- Verify substrate temperature, humidity, and airflow.

- Choose open-cell for acoustic damping and cost savings—or closed-cell for moisture resistance and extra rigidity.

Board foot yield can vary by up to 10% depending on jobsite conditions.

Before a full spray, contractors often test a small patch to confirm proper ratio and coverage. They watch for color shifts, expansion rate, and tackiness—early indicators of off-ratio foam.

With these basics under your belt, you’ll head into quotes and installations ready to ask the right questions. Next, we’ll dive into performance criteria and cost considerations that matter most.

Comparing Performance Criteria

Picking the right spray foam comes down to several factors that directly influence comfort, energy bills, and durability in South Florida’s humid climate.

Below, we unpack thermal performance, air sealing, moisture behavior, sound control, and structural impact—so you can choose the right foam for your project.

R-Value And Energy Impact

Open-cell spray foam delivers about R-3.5 to R-4 per inch, while closed-cell foam pushes that up to R-6 to R-7 per inch. That extra thermal resistance means less work for your air conditioner. In real-world tests, unvented attics insulated with closed-cell foam ran the A/C up to 20% less than those using open-cell.

Closed-cell foam’s higher R-value per inch drives measurable savings in hot, humid climates.

Below is a quick look at how these two foams stack up on core performance metrics:

Performance Criteria Comparison

The table below highlights key differences in R-value, density, vapor permeability and cost for open-cell and closed-cell spray foam.

| Metric | Open Cell | Closed Cell |

|---|---|---|

| R-Value Per Inch | R-3.5 to R-4 | R-6 to R-7 |

| Density | 0.4–0.5 lb/ft³ | ~2.0 lb/ft³ |

| Vapor Permeability | High (≈10 perms) | Low (<1 perm) |

| Cost (per board-ft) | $0.44–$0.65 | $1.00–$1.50 |

Both foams offer energy-saving benefits, but closed-cell’s higher density and R-value often justify the extra investment for projects focused on maximum insulation.

This infographic breaks down R-value, density and permeability—showing why closed-cell creates a tighter thermal envelope, while open-cell allows more vapor flow.

Air Sealing And Moisture Control

Closed-cell foam doubles as a vapor retarder, stopping moisture in its tracks and lowering mold risk in unvented assemblies. Open-cell, by contrast, remains vapor-open—letting assemblies dry naturally, which can help avoid trapped condensation in roof decks.

Key moisture management tips:

- Verify drainage plane integrity around roof penetrations

- Adjust ventilation when using open-cell in vented or semi-conditioned spaces

- Follow Florida Building Code rules on vapor barriers for ceilings and walls

In blower-door tests, closed-cell installations often record air leakage below 0.5 ACH, while open-cell generally measures around 1.5 ACH. Pair your foam choice with proper ventilation layout, and validate results using blower-door and moisture sensors at completion.

Sound Dampening And Structural Reinforcement

Open-cell’s soft, cellular structure soaks up noise, achieving up to 40% noise reduction between rooms. Closed-cell’s rigidity, on the other hand, adds stiffness to roof decks and wall panels—a real plus in hurricane-prone areas where wind uplift is a concern.

For metal buildings, many installers apply open-cell on interior walls and closed-cell on roofs. The outcome? A 50% drop in sound transfer and more stable interior temperatures.

Check out our guide on spray foam as a sound barrier for more acoustic best practices: Learn more in our sound barrier article

Structural perks of closed-cell foam include:

- Boosted racking strength in wall assemblies

- Superior resistance to air infiltration under pressure

- Added support that can extend roof-deck lifespan

Project Scenarios And Recommendations

If your attic sees occasional flooding or high humidity swings, open-cell foam shines by allowing moisture to escape quickly. For metal buildings, warehouses or any project demanding a continuous moisture barrier, closed-cell foam holds the edge.

Local case studies reveal:

- 25% energy-bill reduction after retrofitting unvented roof decks with closed-cell

- 15% indoor humidity drop when open-cell lined a second-floor ceiling

Before you pick, confirm local code on minimum thickness, fire barriers and documented R-value for insurance purposes. Ultimately, your choice hinges on whether you need drying potential or peak insulating power.

For attics, roofs, walls or metal structures in South Florida:

- Choose open-cell when drying capacity and sound absorption top your list

- Opt for closed-cell when maximum R-value and moisture blocking are must-haves

Ready to get started? Request a free quote from Airtight Spray Foam Insulation and match your climate-driven priorities with the best foam solution.

Prioritize your project’s climate and moisture profile to pick the foam type that aligns energy efficiency with durability.

South Florida Insulation Use Cases

South Florida’s combination of high humidity, intense solar heat, and coastal moisture demands a tailored approach to insulation. Deciding between open-cell and closed-cell spray foam here really comes down to moisture control, airtightness, and overall energy performance.

Below are real-life scenarios, tips, and mini case studies demonstrating 20–30% energy savings and noticeable comfort improvements.

- Attic assemblies: use open cell in vented setups for enhanced drying or closed cell in unvented roofs for stricter vapor control.

- Wall cavities: closed-cell foam stops mold at the source, while open cell allows assemblies to breathe and cuts condensation risk.

- Metal buildings: closed cell adds structural rigidity and corrosion resistance; open cell tames interior noise.

Attic Strategies

In an unvented attic, closed-cell foam seals every nook and resists moisture infiltration—ideal under sun-baked tile roofs. It forms a continuous barrier that keeps hot, humid air from sneaking in.

On the flip side, open-cell foam shines in vented attics. Its permeable nature lets vapor escape, preventing condensation buildup on roof sheathing.

Expert Tip South Florida code allows unvented roofs with closed cell foam when paired with reflective coatings to cut solar gain.

Wall Cavity Sealing

Southern heat drives moisture into wall assemblies, creating prime conditions for mold if left unchecked. Applying closed-cell foam introduces a low-perm layer that blocks vapor entirely. Meanwhile, open-cell foam functions as a smart secondary drainage plane, catching any stray moisture.

Before you spray:

- Test moisture levels in studs to avoid trapping hidden dampness.

- Use foam-compatible primers on aged wood studs to boost adhesion and prevent delamination.

- Inspect for voids and seal around electrical boxes to ensure total coverage.

Metal Building Solutions

Metal structures face two big challenges: thermal bridging and salt-air corrosion. A hybrid foam system tackles both head-on.

Step one: apply closed-cell foam to exterior panels for stiffness and a moisture shield. Step two: finish interior cavities with open-cell foam for sound dampening and stable indoor temps.

For alternate methods on metal buildings, see our detailed guide on spray foam vs blown-in insulation.

Moisture management is critical; closed cell foam can lower wall moisture by 40% compared to traditional batts.

In older homes, retrofit crews often remove siding in select areas, remediate any damp spots, and choose foam types based on assembly function. One case study from Miami Shores showed that closed cell under roof sheathing paired with open cell in vents delivered 25% energy-bill drops and stabilized attic humidity.

- Combine foam with reflective roof coatings to slash solar heat gain by up to 15%.

- Schedule post-storm inspections on coastal properties to check foam integrity.

- Pair spray foam with ridge ventilation to keep air and moisture flows in balance.

- Always partner with licensed installers who follow strict prep and application protocols.

Next Steps

- Schedule an on-site assessment with Airtight to map out foam types, thicknesses, and installation order.

- Review before-and-after energy bills and humidity readings to measure real-world impact.

- Explore compatible reflective coatings that boost foam performance and lower cooling loads.

- Set up regular maintenance inspections to preserve foam condition and honor warranties.

Ready to upgrade your South Florida home? Contact Airtight Spray Foam Insulation today for a detailed estimate, ROI comparison, and installation timeline—then enjoy greater comfort and lower utility costs.

Cost Analysis And Return On Investment

Knowing upfront costs is the first step toward deciding if open-cell or closed-cell spray foam works for your budget—and for your long-term energy bills. Every project has its nuances, so breaking down the numbers early on pays off.

Open-cell spray foam typically runs $0.30–$0.50 per board foot, whereas closed-cell comes in at $1.00–$1.50 per board foot, based on density.

- Material: Isocyanate, polyol blends, and other raw chemicals

- Labor: Spray time, trimming overspray, and job-site cleanup

- Equipment: Rig mobilization, maintenance, and travel fees

Board Foot Pricing And Equipment Fees

Open-cell’s lighter density means you cover more square footage per kit—often trimming material costs by 35%. Its softer foam also speeds up application, cutting down on labor.

Closed-cell, with its precise chemical ratios and thicker beads, usually tacks on about 10% more installation time. That extra attention shows up in your labor line item.

Mobilization fees typically sit between $200 and $400, though tight access or off-hour work can push that range higher.

| Cost Component | Open Cell Range | Closed Cell Range |

|---|---|---|

| Material Per Board Ft | $0.30–$0.50 | $1.00–$1.50 |

| Labor Per Board Ft | $0.18–$0.28 | $0.24–$0.34 |

| Mobilization Fees | $200–$300 | $250–$400 |

Modeling Payback Periods

Consider a 2,000 sq ft attic as an example. Four inches of closed-cell foam runs about $10,000 installed.

To get the same R-value with open-cell, you’d need six inches—totaling roughly $6,000.

At an average rate of $0.14/kWh, homeowners often see cooling bills drop by 15% with closed-cell and 10% with open-cell.

“Closed cell foam’s moisture control can cut HVAC runtime by up to 20% annually,” says a South Florida building science expert.

With those savings, closed-cell pays back in about 7–8 years, while open-cell reaches breakeven in 4–5 years under moderate humidity. Along the coast, closed-cell’s superior moisture barrier can shave another year off your ROI.

Incentives And Rebate Programs

South Florida homeowners can stack several incentives:

- Federal Tax Credit (Residential Energy Efficiency): 10% of installation cost, up to $500

- Local Utility Rebates: $0.20–$0.30 per board foot for certified spray foam systems

- State Hurricane Mitigation Grants: Up to $1,000 toward foam insulation

Combining these with lower utility bills often shortens your payback by 1–2 years.

The North American spray-foam insulation market is set to hit USD 2.2 billion by 2030 at a 5.4% CAGR, and the U.S. segment may grow from USD 750.02 million in 2024 to USD 1.01 billion by 2030 (CAGR ≈ 5.09%). Learn more on North American Spray-Foam Insulation Market.

Feel free to plug in your local rates, project specs, and incentives into a spreadsheet or ROI calculator. It’s the best way to compare open-cell versus closed-cell breakeven timelines and long-term savings.

Ready to nail down your project’s ROI and get a detailed cost breakdown? Contact Airtight Spray Foam Insulation today.

Request a custom report complete with cost charts and timeline estimates tailored to your home or building.

Installation Requirements And Decision Checklist

When you’re comparing open-cell versus closed-cell spray foam, South Florida’s building codes and your budget details can’t be an afterthought. Getting these requirements right upfront keeps your project on track.

Code And Safety Requirements

Before any foam hits your walls or attic, the Florida Building Code (FBC) lays out strict fire and vapor barrier rules. Missing these can push your inspection back—and nobody wants delays.

- Minimum 3.5-inch thickness of open-cell foam to qualify as a vapor retarder under FBC R806.5

- Closed-cell foam needs at least 2-inch application to serve as a vapor barrier and reach its rated R-value

- Ignition Barrier: Cover all spray foam with a ⅛-inch wood-based panel, ⅜-inch gypsum board, or equivalent

- Thermal Barrier: In occupied spaces, shield foam with a ½-inch gypsum board or approved coating

- Installer Licensing: Contractors must hold a Florida building contractor license with a foam insulation endorsement and complete annual continuing education

“Meeting these FBC standards not only enhances safety but also smooths out your inspection process.”

Vapor barrier performance is crucial in our humid climate:

| Foam Type | Perm Rating |

|---|---|

| Open Cell | ~10 perms |

| Closed Cell | <1 perm |

Pre Installation Checklist

A solid pre-installation walkthrough saves headaches later. Confirming site conditions and coordinating with other trades means you avoid costly rework.

- Moisture Survey: Verify substrate moisture is below 15% with a calibrated meter.

- Surface Prep: Clean, dry, and prime areas to promote proper foam adhesion and prevent off-ratio sections.

- HVAC Coordination: Shut off HVAC during spraying, then plan a staged restart to vent curing byproducts safely.

- Protective Measures: Shield windows, vents, and landscaping from overspray and drifting particles.

- Scheduling: Aim for dry days between 60–85°F to optimize foam expansion and cure times.

Check out our detailed overview of insulation value for concrete block assemblies.

Decision Checklist For Foam Selection

Choosing between open-cell and closed-cell comes down to the space you’re insulating and the performance you need:

- Project Scope: Attics or interior partitions focused on sound control? Open-cell foam often wins here.

- Moisture Profile: Unvented attics, crawl spaces, or areas prone to flooding call for closed-cell foam.

- R-Value Goals: When you need R-6+ per inch and space is tight, closed-cell is the answer.

- Budget Constraints: Open-cell foam runs about 30–50% less per board foot—ideal for broader coverage.

- Structural Benefits: Closed-cell adds rigidity and bolsters wind uplift resistance in roofs and metal buildings.

- Code Thickness: Double-check that your chosen foam meets minimum thickness for vapor control and fire barriers.

- Installer Credentials: Always confirm your contractor holds a valid Florida foam insulation license with the proper endorsement.

- Warranty & Maintenance: Review warranty details and schedule yearly inspections for moisture or damage concerns.

Ready to get started? Request a free estimate from Airtight Spray Foam Insulation today and make sure your South Florida project ticks every box.

These steps lock in compliance, protect your investment, and keep your timeline on point.

Frequently Asked Questions

Homeowners often wonder how open-cell and closed-cell spray foam stack up. This FAQ delves into R-value, moisture behavior, installation methods, and upkeep to help you choose the right solution.

Performance Expectations

What R-Value Can I Expect From Open-Cell And Closed-Cell Foam?

Open-cell spray foam typically provides R-3.5 to R-4 per inch, making it a solid choice when you have extra cavity space. Closed-cell foam packs more punch—R-6 to R-7 per inch—so it’s perfect for tight areas where maximum insulation matters.

Moisture Management

How Does Moisture Affect Foam Performance Over Time?

Closed-cell foam’s dense makeup yields a permeability of <1 perm, effectively blocking water vapor and acting as its own vapor barrier. That helps curb mold growth in South Florida’s humid environment. Open-cell foam, on the other hand, has a permeability of about 10 perms, so it relies on additional vapor-control strategies to keep condensation from building up.

Installation And Maintenance

Can I Install Spray Foam In An Existing Home Without Major Demolition?

Yes. Both open-cell and closed-cell foams can be injected through small ports or applied via minimal-access openings. Licensed installers craft tiny access points, fill the cavity, then seamlessly patch the surface—no gutting required.

What Maintenance Or Inspection Is Needed After Spray Foam Installation?

Plan on a yearly checkup to spot:

- Soft spots or areas where foam may have settled

- Discoloration, which can signal moisture intrusion

- Any delamination or shrinkage along seams

Keep vents and eaves clear, then grab moisture readings. Early detection preserves performance and comfort.

“A quick annual inspection can catch issues before they impact comfort and energy bills,” says a building-science specialist.

Quick Comparison

| FAQ Topic | Open Cell Foam | Closed Cell Foam |

|---|---|---|

| R-Value | R-3.5 to R-4 | R-6 to R-7 |

| Vapor Permeability | High (≈10 perms) | Low (<1 perm) |

| Installation Disturbance | Minimal | Minimal |

| Maintenance Focus | Vapor-control checks | Barrier-integrity checks |

Before You Start

- Confirm your installer’s license and insurance for South Florida projects

- Review manufacturer warranty terms each year to keep coverage active

- Conduct a blower-door test post-installation to verify airtightness

Ready to lock in comfort and savings? Request a free quote from Airtight Spray Foam Insulation today and see how precision sealing transforms your home.