Blog

Spray Foam Pros And Cons A Homeowner’s Unbiased Guide

Deciding on the right insulation for your home is a big deal, and when it comes to spray foam, there are some serious pros and cons to weigh. Let’s be clear: spray foam offers incredible energy efficiency and an airtight seal that old-school insulation just can’t touch. That often translates to a huge drop in your utility bills. But—and it’s a big but—that performance comes with a higher upfront cost and a non-negotiable need for professional installation to sidestep potential health risks or performance headaches.

An Honest Look At Spray Foam Insulation

Think of choosing insulation like picking the right coat for your house. Sure, a simple fleece blanket might get the job done, but a custom-fitted, windproof jacket gives you a totally different level of comfort and protection. Spray polyurethane foam (SPF) is that high-performance jacket. It’s a chemical product that expands right on site, filling every single crack, crevice, and odd-shaped corner.

This process creates a seamless, continuous barrier against both air leaks and heat transfer. Unlike traditional insulation like fiberglass batts or blown-in cellulose, which can leave gaps and sag over time, spray foam bonds directly to your home’s structure. That complete seal is the secret sauce that makes it so effective at keeping your home cool in the summer and warm in the winter.

Weighing The Benefits Against The Risks

The conversation around spray foam pros and cons is so important because the stakes are high. On the one hand, the benefits are really compelling.

- Exceptional Energy Savings: By creating that rock-solid airtight seal, spray foam can slash heating and cooling costs by up to 50%.

- Moisture and Mold Defense: Closed-cell spray foam acts as a powerful moisture barrier, which is a game-changer for preventing mold in humid climates like ours in South Florida.

- Enhanced Structural Integrity: The rigid structure of closed-cell foam can actually add strength to your walls and roof deck.

- Superior Sound Dampening: Both open-cell and closed-cell foams are great at hushing unwanted noise from the outside.

On the flip side, the drawbacks need a hard look. The initial investment is quite a bit higher than other types of insulation. And a botched installation can lead to a whole host of problems, from disappointing energy savings to lingering chemical odors that tank your indoor air quality. Because it’s permanent, it also makes future electrical or plumbing work a lot more complicated.

For a deeper dive into how it’s used, you can learn more about the different spray foam insulation categories and their specific jobs.

To help you sort through it all, here’s a simple at-a-glance comparison.

Quick Look At Spray Foam Insulation Pros And Cons

| Feature | Pros (Advantages) | Cons (Disadvantages) |

|---|---|---|

| Energy Efficiency | Unmatched thermal resistance (high R-value) and superior air sealing dramatically reduce energy bills. | Poor installation can create gaps, negating energy-saving benefits. |

| Upfront Cost | – | Significantly more expensive than fiberglass or cellulose, requiring a larger initial investment. |

| Installation | Creates a perfect, custom fit for any space, including irregular cavities. | Must be installed by certified professionals; DIY is not a safe or effective option. |

| Durability | Does not sag or settle over time, maintaining its R-value for the life of the building. | Difficult and costly to remove if renovations or repairs are needed. |

| Moisture Control | Closed-cell foam provides an excellent vapor barrier, preventing moisture intrusion and mold. | Can trap moisture within wall cavities if an external leak is not addressed. |

| Health & Safety | Once cured, it is inert and stable, improving indoor air quality by blocking pollutants. | Improper mixing or ventilation during installation can release harmful VOCs. |

Ultimately, weighing these factors will help you decide if spray foam’s powerful performance is the right fit for your home and budget.

The Advantages Of Choosing Spray Foam Insulation

When homeowners weigh the pros and cons of spray foam, the advantages tend to jump right off the page. The benefits aren’t just minor improvements; they represent a fundamental upgrade to a home’s performance and comfort.

Think of traditional insulation like a patchwork blanket—it covers you, but there are always gaps where cold air sneaks in. Spray foam, on the other hand, is like a seamless, custom-tailored winter coat for your house. It’s applied as a liquid that expands on contact, filling every tiny crack, odd-shaped cavity, and awkward corner to create a truly continuous barrier.

This complete, gap-free coverage is the secret to its superior performance. Fiberglass batts can sag over time or leave small openings around pipes and electrical boxes, creating thermal weak spots. Spray foam eliminates these vulnerabilities by bonding directly to the structure, locking in its insulating power for the life of your home.

Unmatched Thermal Performance And Energy Savings

The number one reason people choose spray foam is its incredible ability to slash energy bills. It all comes down to its high R-value, the industry’s yardstick for measuring thermal resistance. The higher the R-value, the better a material is at stopping heat transfer.

Closed-cell spray foam is the undisputed champion here, often delivering an R-value between R-6 and R-7 per inch—one of the highest ratings you can get.

This powerful insulation, combined with its airtight seal, translates directly into major energy savings. Your HVAC system doesn’t have to work nearly as hard to keep your home comfortable when conditioned air isn’t escaping through a dozen hidden leaks. For many homeowners, this can cut heating and cooling costs by up to 50%.

It’s no surprise that demand is growing. The global spray foam insulation market is projected to climb from USD 3.12 billion in 2025 to USD 4.39 billion by 2032. That growth is largely driven by homeowners who make up 41% of the market share and are looking for real efficiency gains.

A Powerful Barrier Against Moisture And Sound

Beyond keeping your home comfortable, spray foam acts as a powerful line of defense against other common problems. Its seamless seal is a game-changer, especially in humid climates like we have here in South Florida.

- Moisture Control: Closed-cell spray foam is non-permeable, which means it blocks water vapor from seeping through your walls. This is crucial for preventing the kind of moisture buildup that leads to mold, mildew, and wood rot.

- Air Sealing: By sealing every last gap, spray foam not only stops drafts but also blocks airborne pollutants, allergens, and dust from getting inside. The result is cleaner, healthier indoor air.

- Noise Reduction: The dense, expansive nature of spray foam makes it an amazing sound dampener. It absorbs sound waves, significantly quieting noise from traffic, loud neighbors, or nearby airports.

That sound-dampening quality is a benefit people often don’t think about until they experience it. We actually have a whole guide explaining how insulation acts as a sound barrier if you’re curious to learn more.

By forming a complete air and moisture barrier, spray foam doesn’t just insulate—it actively protects your home’s structural integrity and improves the overall quality of your living environment.

Enhanced Structural Integrity And Durability

Here’s a unique benefit you only get with closed-cell foam: it actually makes your house stronger.

When closed-cell spray foam cures, it becomes a rigid, dense solid. It sticks tenaciously to whatever it’s sprayed on, like wall studs and roof sheathing, effectively gluing the structure together.

This process adds significant racking strength to your walls and can even reinforce your roof deck, helping it better withstand the high winds we see in storm-prone regions. This mirrors the benefits of insulated roofs in creating a more resilient and efficient home.

And unlike other types of insulation that might degrade or need replacing down the road, spray foam is a permanent solution. Once it’s in, it’s there for the entire lifetime of your property.

The Other Side of the Coin: Drawbacks and Potential Risks

While the benefits of spray foam are impressive, a fair look means giving equal weight to the potential downsides. To make a smart decision for your home, you have to understand the drawbacks—starting with the biggest one for most people: the price.

Let’s be direct: spray foam insulation is a premium product with a premium price tag. The upfront investment is significantly higher than traditional options like fiberglass batts or blown-in cellulose. That cost isn’t just for the material itself; it’s also paying for the specialized labor required to install it safely and effectively.

This is absolutely not a weekend DIY project. Installing spray foam is a complex chemical reaction on-site. It demands precise temperature control, sophisticated equipment, and an expert who knows exactly how to mix the two chemical components. This mandatory professional installation is a huge part of the final cost.

Why Professional Installation Isn’t Optional

The need for a certified professional goes way beyond just getting a good thermal seal—it’s a serious matter of health and safety. When the chemicals are mixed and sprayed, they release volatile organic compounds (VOCs) and other fumes. This “off-gassing” is a normal part of the curing process.

But if that chemical mix is even slightly off, or applied in the wrong conditions, the foam might not cure correctly. This can lead to prolonged off-gassing, leaving a lingering chemical odor that can tank your overall indoor air quality.

An improper installation can turn a high-performance upgrade into a significant health risk. Occupants must vacate the premises for at least 24-48 hours during and after application to allow the foam to fully cure and for harmful vapors to dissipate safely.

This is why vetting your installer is the single most important step you can take. A reputable contractor will have strict safety protocols, proper ventilation gear, and certified training to ensure the job is done right the first time, every time.

Potential Headaches Down the Road

Beyond the initial cost and installation risks, there are a few long-term things to keep in mind. The very permanence that makes spray foam so durable can also become a drawback in certain situations.

- Difficulty with Future Renovations: Once spray foam hardens, it sticks to everything it touches with incredible strength. This makes future electrical or plumbing work a lot harder and more expensive. Accessing wiring or pipes inside a foam-filled wall means cutting the rigid foam out.

- Moisture Trapping Risks: While closed-cell foam is an amazing moisture barrier, its inability to let anything pass through can sometimes hide problems. If a roof leak or a pipe bursts, the foam can trap water against your home’s wood structure, potentially leading to hidden rot that goes unnoticed until major damage is done.

- The Cost Hurdle: The high installation cost is a major con, often making spray foam 20-50% pricier than other common types of insulation. This price difference is a real barrier for many homeowners and builders, even as the market for spray foam is projected to hit USD 3,017.8 million by the end of 2025. You can get more insights on this growing but cost-sensitive market.

These challenges show why getting the full picture is so important. For homeowners weighing their options, our guide comparing spray foam vs. blown-in insulation takes a deeper dive into how it stacks up against another popular choice. When you weigh these potential risks against the powerful benefits, you can move forward with confidence.

Choosing Between Open-Cell And Closed-Cell Foam

When you start looking into spray foam, you quickly realize it’s not a simple one-size-fits-all product. There are two main players on the field: open-cell and closed-cell foam. They have completely different personalities and are designed for very different jobs in your home. Getting a handle on what makes them tick is the key to a smart investment.

Think of open-cell foam like a dense, high-quality sponge. It’s full of tiny, interconnected bubbles that allow air and moisture to move through. This structure makes it soft, flexible, and fantastic at dampening sound. It also expands like crazy when applied—sometimes swelling up to 100 times its liquid volume—making it perfect for filling big, awkward spaces in walls or attics without leaving any gaps.

Now, picture closed-cell foam as a solid, rigid shield. Its cells are completely sealed off from each other and packed tightly together, creating an incredibly dense material. This structure doesn’t just block air; it’s a powerful moisture barrier that stops water vapor in its tracks. It delivers more insulation power per inch and can even add structural strength to your walls and roof.

Key Differences That Matter

The right choice really boils down to what you’re trying to accomplish. Are you trying to soundproof a home office, or do you need to create an bulletproof moisture barrier in a crawl space? Each type of foam brings a unique set of skills to the job.

- R-Value and Thermal Muscle: Closed-cell foam is the undisputed champion here, delivering a hefty R-6 to R-7 per inch. Open-cell offers a respectable but lower R-3.5 to R-4 per inch. That means you get more insulation with less thickness from closed-cell foam.

- Moisture and Humidity Control: This is a big one for us in South Florida. Closed-cell foam is non-permeable, meaning it functions as a vapor barrier. Open-cell foam, on the other hand, is permeable and will let moisture pass through, which can be a problem in damp areas.

- Structural Strength: The dense, hard nature of closed-cell foam adds significant racking strength to walls, making the whole structure more rigid. Open-cell foam is soft and flexible and offers no structural backup.

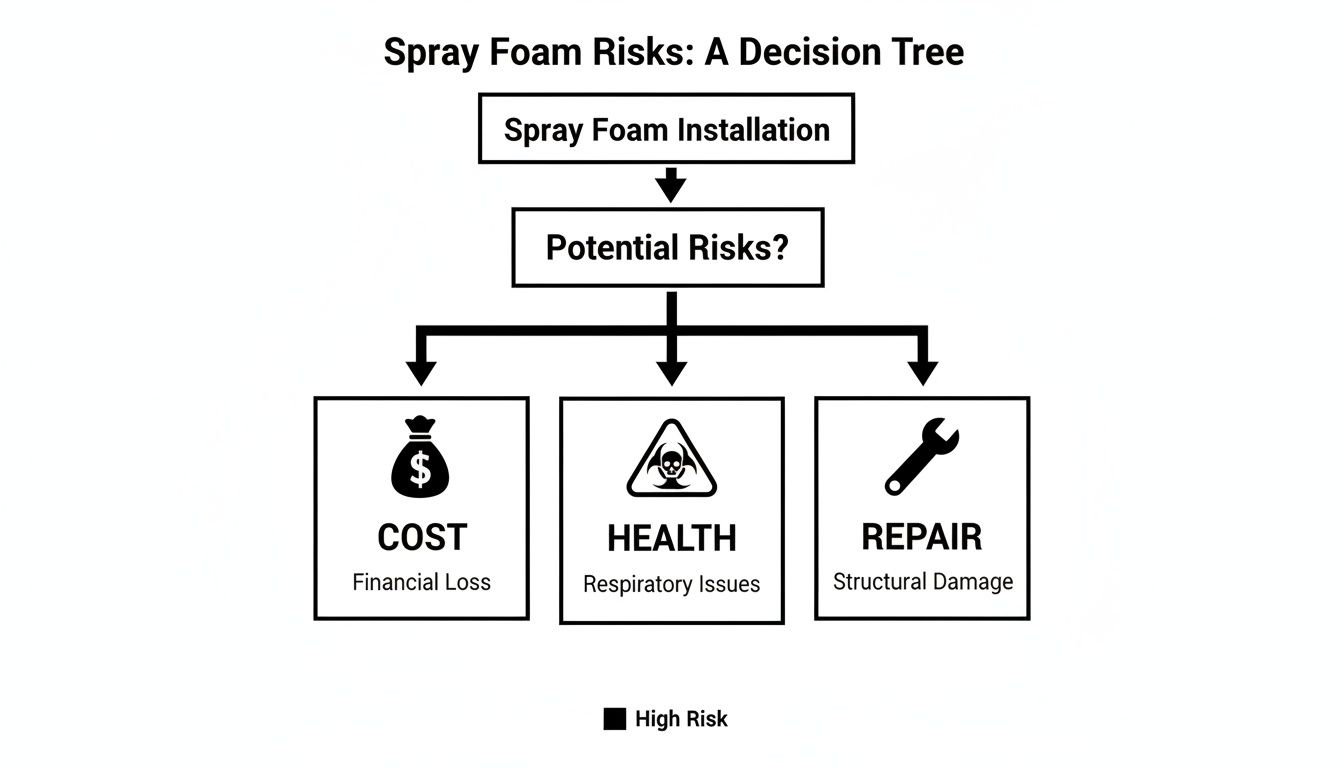

This chart helps break down the main decision points when you’re weighing the risks of a spray foam project, from the initial cost to potential health or repair issues down the road.

As you can see, every choice—from the foam type to the contractor you hire—is a balance between upfront cost, safety, and long-term performance.

Cost And Where To Use Each Type

Price is another major dividing line. Open-cell foam requires less raw material, so it’s generally the more affordable option. Closed-cell foam is much denser, uses more chemical product, and comes with a higher price tag.

The real question isn’t which foam is “better,” but which one is the right tool for the job. Often, the smartest strategy for a whole-home project is using a combination of both.

To make it simple, we’ve put together a table that lays out the core differences and best-use scenarios for each type of foam.

Comparing Open-Cell And Closed-Cell Spray Foam

| Characteristic | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value | R-3.5 to R-4 per inch | R-6 to R-7 per inch |

| Moisture Barrier | Permeable (lets moisture pass) | Impermeable (blocks moisture) |

| Sound Dampening | Excellent | Good |

| Structural Strength | None | Adds significant strength |

| Cost | Lower | Higher |

| Ideal Locations | Interior walls, attics, ceilings | Exterior walls, roofs, basements, foundations |

Seeing them side-by-side makes it easier to see how you could use them strategically. For example, you might install open-cell foam in the interior walls between a loud living room and a quiet bedroom for its top-notch soundproofing. At the same time, you’d use closed-cell foam on your exterior walls and under the roof deck to get the best R-value and a powerful defense against moisture.

By applying each type of foam where it shines, you get the best of both worlds—peak performance and real value for your money.

When you start digging into the pros and cons of spray foam, the environmental side of things can get a little complicated. It’s not a simple good-vs-bad story. It’s really a trade-off between how it’s made and the incredible energy savings it delivers over decades.

On one hand, spray foam is a powerhouse for sustainability. By creating a nearly perfect airtight seal, it dramatically cuts down on the energy a building needs for heating and cooling. Over the life of a home—which can easily be 80 years or more—that reduction in energy use adds up to a massive drop in the building’s carbon footprint.

Think of it like buying a super-efficient car. It takes energy to manufacture it, sure, but its amazing fuel economy saves far more fossil fuels over its lifetime than a gas-guzzler. Spray foam works the same way, offering decades of energy conservation that can easily outweigh the initial environmental cost of making it.

The Manufacturing and Material Story

But you have to look at the other side of the coin. Traditional spray foam formulas are petrochemical products, meaning they’re made from non-renewable fossil fuels. The manufacturing process itself is energy-intensive and does contribute to greenhouse gas emissions.

A big concern, especially with older closed-cell foams, was the use of hydrofluorocarbons (HFCs) as blowing agents. These are the chemicals that make the foam expand. While they work well, HFCs have a very high Global Warming Potential (GWP), which is just a way of measuring how much heat a gas traps in the atmosphere.

This is where the environmental drawback becomes obvious. Some HFCs are over 1,400 times more potent than carbon dioxide at trapping heat. That staggering number has pushed the entire industry to find much better, more responsible alternatives.

The Rise of Eco-Friendly Alternatives

Fortunately, the insulation industry hasn’t been standing still. Responding to these environmental concerns, manufacturers have come up with newer, greener formulas that seriously reduce the impact.

- Water-Blown Agents: A lot of modern open-cell foams now use plain old water as the main blowing agent. The chemical reaction creates CO2 to expand the foam, which gives it a GWP of just 1.

- HFO Blowing Agents: For closed-cell foams, new hydrofluoroolefin (HFO) agents have taken the place of those high-GWP HFCs. These next-gen chemicals break down in the atmosphere in days, not centuries, and have an ultra-low GWP.

- Bio-Based Materials: Some foams even incorporate renewable materials like soy or sucrose right into their chemical mix, cutting back on the need for petroleum.

This shift isn’t just a marketing trend; it’s a direct response to a growing global demand for building materials that make sense for our planet. In fact, market forecasts predict the eco-friendly spray foam sector will grow from USD 3,369 million in 2025 to USD 4,352 million by 2031, all driven by this demand for better, bio-based solutions. You can read more about this shift toward sustainable insulation.

While the environmental cons of old-school spray foam are real, the industry’s rapid innovation means homeowners today can get a high-performance product with a much, much smaller ecological footprint.

One last thing to consider is what happens at the end of its life. Spray foam isn’t recyclable and has to go to a landfill. But since it’s designed to last for the entire life of the building, this isn’t a frequent problem like it is with other materials. By choosing modern, low-GWP formulas, you get to maximize the energy-saving benefits while keeping the environmental drawbacks to a minimum.

How To Hire The Right Insulation Professional

Let’s be perfectly clear: spray foam insulation is a complex chemical process that happens right inside your home. It is absolutely not a weekend DIY project.

The difference between a successful, high-performance insulation job and a costly, permanent failure comes down to one thing: the skill of the installer. Finding the right professional isn’t just a good idea—it’s the most critical step you’ll take.

An experienced crew knows the precise chemical ratios, the exact temperature and humidity requirements, and the specific application techniques needed for the foam to cure properly. They know how to prep your home, protect your belongings, and manage the critical ventilation needed for a safe job. When you hire a pro, this is the expertise you’re paying for.

Your Contractor Vetting Checklist

When you start getting quotes, you need to ask the right questions to separate the seasoned experts from the risky amateurs. A true professional will welcome your questions and have confident, clear answers. Use this checklist as your guide.

- Certifications and Training: Ask if their team holds certifications from an organization like the Spray Polyurethane Foam Alliance (SPFA). It’s a great sign that they’re committed to industry standards and ongoing education.

- Insurance and Licensing: Don’t even think about skipping this. Verify that they carry both general liability and worker’s compensation insurance. This protects you, your home, and their crew if an accident happens.

- Experience and Specialization: How many years have they been installing spray foam specifically? Don’t be shy about asking to see a portfolio of projects similar to yours, whether it’s a tricky attic in a historic home or a large new construction build.

- Safety Protocols: What’s their plan for ventilation during and after the job? How long do they require you and your family to be out of the house? A pro will have a detailed, written safety plan ready to share.

A rock-bottom quote is almost always the biggest red flag. It can signal they’re cutting corners on material quality, using inexperienced labor, or skipping out on proper insurance and safety gear. In the world of spray foam, you truly get what you pay for.

Recognizing Red Flags And Ensuring Quality

Beyond the checklist, trust your gut. Keep an eye out for warning signs that might indicate a less-than-professional operation. Be wary of any contractor who seems evasive, rushes through the estimate, or uses high-pressure sales tactics to get you to sign on the spot.

A quality installation should feel thorough and transparent from the get-go. The crew should meticulously prep the area by covering floors, windows, and furniture. Once the foam is applied and cured, they should handle all the trimming of any excess and perform a complete cleanup.

They should leave your space better than they found it. By taking the time to hire a qualified, insured, and experienced professional, you ensure the job is done safely and correctly, locking in the long-term benefits of your new insulation for decades to come.

Your Top Spray Foam Questions Answered

Even after learning about the pros and cons, most people still have a few lingering questions. That’s perfectly normal. Getting straight answers is the best way to feel confident about your decision, so let’s tackle the ones we hear most often.

One of the biggest concerns? Longevity. It’s a significant investment, and you want to know it will last.

How Long Does Spray Foam Insulation Actually Last?

This is one of the best parts about spray foam. When it’s installed correctly by a real professional, it’s designed to last for the entire life of your house—we’re talking 80 years or more.

Unlike old-school insulation like fiberglass that can get compressed, sag, or just break down over the decades, spray foam chemically bonds to your home’s structure. It becomes a permanent, solid part of your attic or walls. That means it never loses its R-value or its air-sealing power, making it a true install-it-once-and-forget-it upgrade.

Is Spray Foam Safe After It Cures?

Absolutely, yes. Once spray foam has fully cured, it hardens into a completely inert, stable plastic. It’s no different than the other plastics you have all over your home. At this stage, it’s completely safe for everyone, including your kids and pets.

The only time for caution is during the installation and the brief curing period, which usually takes about 24 to 48 hours.

During this window, the area needs to be off-limits to people and pets. This is when the chemical reaction releases volatile organic compounds (VOCs). Any professional crew worth their salt will have powerful ventilation systems running to manage this process safely. After it’s cured, the foam is stable and stops off-gassing.

Can You Just Install Spray Foam Over My Old Insulation?

The answer is… it depends. In certain attic situations, we can apply a layer of spray foam directly over existing loose-fill insulation. It’s a hybrid method that can boost the R-value and dramatically improve the air seal.

However, for walls, crawl spaces, and most roof decks, the answer is almost always no. You have to get the old stuff out first. Removing the underperforming insulation is a critical step because it allows the foam to get a direct grip on the sheathing. That direct bond is what creates the seamless air and moisture barrier that gives spray foam its superpower performance. A good contractor will tell you what’s right for your home, not just what’s easiest.

Ready to feel the difference a properly sealed and insulated home can make? The team at Airtight Spray Foam Insulation has the hands-on experience to guide you through the whole process. We ensure every installation is safe, effective, and perfectly suited for our unique South Florida climate. Request your free, no-obligation quote today.