Blog

Boosting Insulation Value Concrete Block Walls

Let’s be blunt: a standard concrete block wall offers surprisingly little insulation on its own. The typical insulation value of a concrete block is only around R-2, which is nowhere near what modern energy standards demand for a home that’s both comfortable and affordable to run.

What Is the Real Insulation Value of a Concrete Block?

When we talk about a material’s insulation performance, the key metric is its R-value. Think of it as a measure of thermal resistance—the material’s ability to stop heat from passing through it.

A thin cotton t-shirt has a very low R-value. It won’t do you much good on a cold day. A thick, down-filled winter coat, on the other hand, has a high R-value, trapping your body heat and keeping you warm.

Unfortunately, when it comes to insulation, a standard concrete block wall is definitely more t-shirt than winter coat.

Understanding Baseline R-Values

So, what are we really working with? An average 8-inch hollow concrete block has an R-value of just R-1.9 to R-2.5. While concrete is an absolute beast for structural strength and durability, its dense nature lets heat pass right through it with ease.

This is a huge reason why uninsulated block homes often feel drafty and cold in the winter and become sweltering hot boxes during South Florida’s brutal summers.

This isn’t a new problem. For decades, builders understood this was a major challenge that led to sky-high energy bills and uncomfortable homes. That knowledge pushed the industry to start integrating insulation directly with the block wall, rather than treating it as an afterthought. You can find more details on how this led to the rise of insulated concrete forms and their market growth.

To get a clearer picture, here’s a quick look at the numbers for standard concrete blocks.

Typical R-Values Of Standard Concrete Masonry Units (CMUs)

This table gives a quick reference for the approximate thermal resistance you can expect from standard 8-inch concrete blocks.

| Block Type | Nominal Thickness | Typical R-Value Range |

|---|---|---|

| Hollow Concrete Block | 8 inches | R-1.9 – R-2.5 |

| Solid Concrete Block | 8 inches | R-1.1 – R-1.5 |

As you can see, whether hollow or solid, the baseline performance is quite low and not sufficient for modern building codes or comfort expectations.

The bottom line is that while concrete is a fantastic structural material, it cannot be relied upon for thermal protection. To create an energy-efficient building, you must treat the block wall as a starting point that requires a significant insulation upgrade.

This basic understanding is critical because it sets the stage for everything else we’re going to cover. We aren’t trying to slightly improve an already decent insulator; we are working to transform a fundamentally poor one into a high-performance thermal barrier.

Recognizing this weakness is the first step. Now, we can explore the effective solutions that will dramatically boost the insulation value of concrete block walls, making your home a more comfortable and affordable place to live.

Why Concrete Blocks Lose Heat So Easily

To pick the right insulation upgrade, you first have to understand why a standard concrete block wall is so bad at stopping heat. It’s not just one thing—it’s a combination of four core weaknesses that turn a seemingly solid wall into a thermal superhighway.

The Problem of Density

First, let’s look at the material itself. Concrete is incredibly dense. Imagine the difference between a solid chunk of rock and a light, airy sponge. Heat one end of the rock, and that warmth travels straight through it almost instantly. The sponge, with all its tiny air pockets, would slow that heat transfer way down.

Concrete acts a lot more like that rock. Its tightly packed particles create a direct, easy path for heat to move from one side of the wall to the other. This process, called conduction, is the main reason a solid concrete block offers a dismal R-value of only R-1.1.

Hollow Cores and Convection Currents

You’d think the hollow cores in a CMU would help by adding air space, right? Unfortunately, they create a whole new problem: convection. The air trapped inside those cavities doesn’t just sit still. As the Florida sun beats down on your wall, the air inside heats up, gets lighter, and rises.

Once it hits the top of the core, it transfers heat to the cooler side of the block, cools down, and sinks—only to start the cycle all over again. This creates a constant, invisible circular current that actively moves heat right through your wall.

Think of it as a tiny conveyor belt for heat, continuously carrying energy from the hot side of your wall to the cool, air-conditioned side. It’s the exact opposite of what you want.

The Impact of Moisture

Moisture is insulation’s worst enemy, and concrete is naturally porous. In a humid climate like South Florida’s, it will absorb water from rain and the air itself. When a concrete block gets damp, it becomes incredibly effective at conducting heat.

Water is a far better conductor than dry concrete. A wet wall can lose almost all its insulating ability, letting your cool, conditioned air escape right outside.

Understanding Thermal Bridging

Finally, we have thermal bridging. Ever stir a hot cup of coffee with a metal spoon? Even if you’re just holding the handle, the heat travels right up the spoon and burns your fingers. The spoon acts as a “bridge” for the heat.

In a concrete block wall, the solid parts of the block—the webs connecting the front and back faces—act just like that spoon. They create direct bridges that allow heat to completely bypass any insulation you might have in the hollow cores. This is a massive flaw that guts the overall insulation value of the concrete block wall system.

Getting a handle on these four weaknesses—density, convection, moisture, and thermal bridging—is the first step. It shows you exactly what problems we need to solve to turn that leaky concrete wall into a truly energy-efficient barrier.

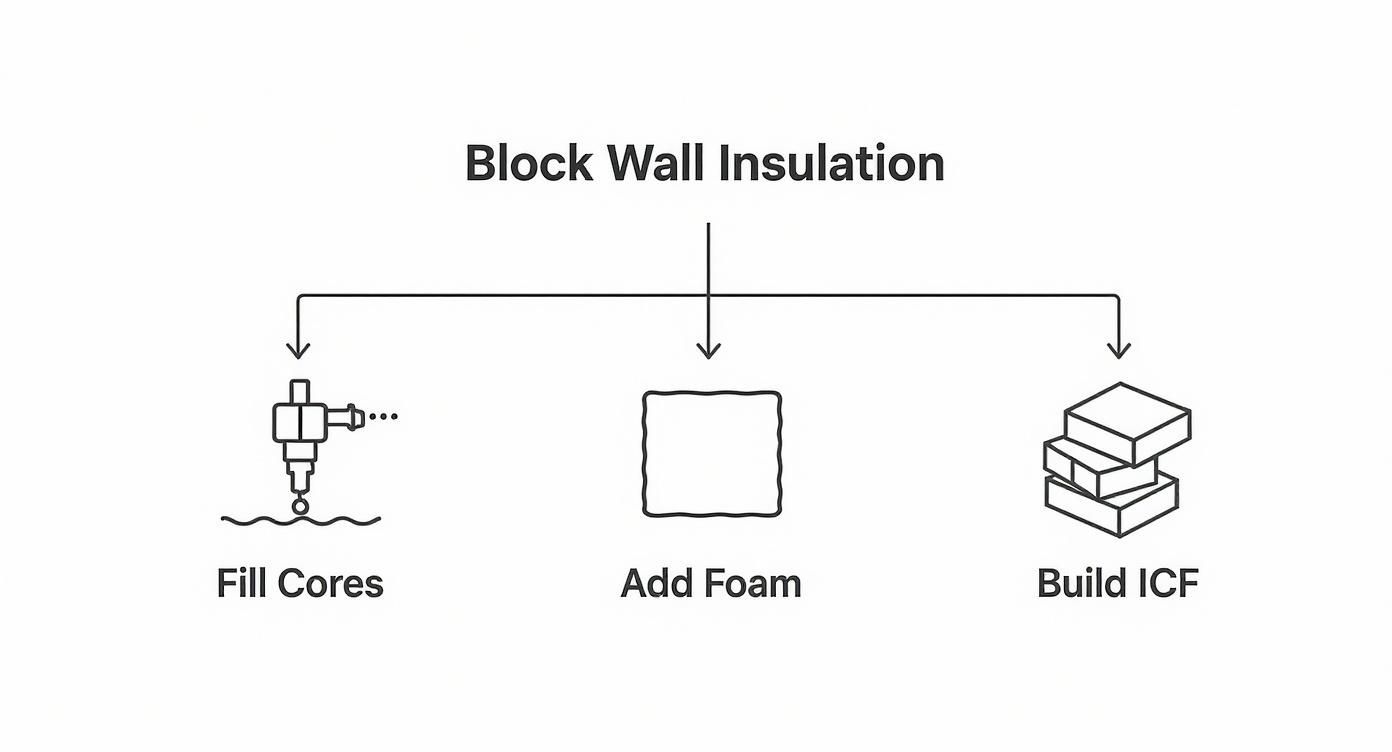

Practical Ways to Insulate Concrete Block Walls

Now that we know why standard concrete block is such a terrible insulator, we can get into the good stuff: how to fix it. The goal is to turn these energy-draining walls into a high-performance thermal barrier, and there are several ways to get it done. Each strategy tackles the core weaknesses of density, air movement, and thermal bridging from a different angle.

There’s no single “best” method for every situation. The right choice really depends on whether you’re building from scratch or working on an existing home, what your budget looks like, and the performance you’re aiming for.

Let’s break down the most effective strategies out there.

Filling the Hollow Cores

The most straightforward approach is to deal with the air circulating inside the block’s hollow cores. By filling these voids, you stop that natural convection dead in its tracks. It’s a bit like pouring sand into an empty jar—it just eliminates the open space where heat-transferring movement can happen.

A few common materials are used for this:

- Granular Fills: Lightweight materials like perlite or vermiculite can be simply poured into the block cores as the walls go up. This gives you a modest boost, typically adding R-2 to R-4 to the wall’s overall performance.

- Injected Foam: For existing walls, this is the go-to solution. A specialized injection foam is pumped into the cores, where it expands to fill every single nook and cranny. It creates a solid, insulating plug that stops both air circulation and sneaky air leaks. *** This product shrinks up after 1 – 2 years and we strongly recommend against it!!!!

Adding Interior Rigid Foam

Another popular strategy, especially for retrofitting existing homes, is to apply rigid foam insulation directly to the interior surface of the block wall. This creates a continuous, unbroken layer of insulation, almost like wrapping the inside of your home in a thermal blanket.

This method is a fantastic way to combat thermal bridging. Because the foam covers the entire wall—solid parts and all—it isolates your comfortable living space from the dense concrete webs that love to conduct heat. Using materials like Expanded Polystyrene (EPS) or Extruded Polystyrene (XPS) boards can add anywhere from R-5 to R-15 or more, depending on how thick you go.

By creating an uninterrupted thermal break, interior rigid foam effectively separates your conditioned indoor air from the thermally conductive concrete, making it one of the most reliable retrofit solutions.

Installing Exterior Insulation and Finish Systems (EIFS)

If working from the inside isn’t practical, you can take the fight outside. Exterior Insulation and Finish Systems (EIFS) involve attaching rigid foam boards to the exterior of the block wall and then covering them with a tough, weather-resistant finish.

Think of this approach like putting a winter coat on the entire building. It not only provides excellent insulation but also shields the concrete itself from extreme temperature swings and moisture, making the structure even more durable. Because it stops thermal bridging right at the source, EIFS can dramatically boost a wall’s performance. For specialized applications, especially in our humid South Florida climate, understanding the nuances of different foam types is critical; our guide on spray foam insulation in Jupiter, FL, covers these differences in detail.

Building with Insulated Concrete Forms (ICFs)

For anyone building a new home, Insulated Concrete Forms (ICFs) are the ultimate all-in-one solution. ICFs are essentially hollow blocks made of rigid foam that are stacked like Legos, reinforced with rebar, and then filled with solid concrete. The foam forms aren’t removed—they become a permanent, integrated part of the wall.

This method builds high-performance insulation right into the structure from day one. You end up with a wall that has a continuous thermal barrier on both the inside and the outside, effectively eliminating thermal bridging and creating an incredibly airtight and strong building. Walls built with ICFs often achieve R-values from R-22 to R-26, which is worlds away from standard block construction. You can dig deeper into these impressive performance metrics with market research on ICF technology.

Choosing the Right Insulation for Your Budget and Goals

Upgrading the insulation value of a concrete block wall isn’t a one-size-fits-all job. The right move for you really depends on your budget, whether you’re working on an existing home or building from the ground up, and what your long-term energy goals look like. It’s all about striking that perfect balance between the initial investment and the lasting reward of a more comfortable, less expensive home to run.

At one end of the spectrum, you have simple core fills—a solid, budget-friendly option for a noticeable performance bump. At the other, there’s building with Insulated Concrete Forms (ICFs), which requires a bigger upfront investment but pays off with incredible long-term energy savings and rock-solid structural integrity.

In between those two, you’ll find interior and exterior foam board applications. These methods offer a fantastic return on investment by creating a continuous thermal blanket around your home. This barrier dramatically cuts down on heat transfer, leading to lower monthly power bills and a much more stable indoor climate year-round.

Matching the Method to Your Needs

So, how do you decide? Start by thinking about the main goal of your project. Are you looking for a quick, low-cost improvement for an existing wall? Or are you aiming to build a high-performance home that blows past modern energy standards right from the start? Your answer will point you in the right direction.

This decision tree helps simplify the options based on what kind of project you’re tackling.

As you can see, for new construction, designing with ICFs from day one is the most integrated and effective solution. For existing homes, your best bets are usually core fills or adding layers of foam insulation.

Comparing Concrete Block Insulation Methods

Let’s put these options side-by-side to get a clearer picture of the costs and benefits. This table breaks down how each method stacks up in terms of cost, performance, and where it makes the most sense to use it.

| Insulation Method | Relative Cost | Typical Added R-Value | Best For |

|---|---|---|---|

| Core Fills (Foam/Perlite) | Low | R-4 to R-8 | Modest, cost-effective upgrades to existing hollow block walls. Goes Bad and shrinks up after 1 – 2 years leaving no insulation value. |

| Interior Rigid Foam | Medium | R-5 to R-15+ | Retrofits where you’re already planning to redo the interior drywall. |

| Exterior Foam (EIFS) | High | R-5 to R-15+ | Major retrofits that also need an exterior facelift and a new weather barrier. |

| ICF Construction | Highest | R-22+ (Total Wall) | New construction where maximum energy efficiency and durability are the top priorities. |

No matter which path you take, investing in better insulation is a smart move that pays dividends for years to come. In a demanding climate like South Florida’s, properly sealing the building envelope is everything. The professional installation of spray foam insulation in West Palm Beach, FL creates a powerful air and moisture barrier, which is a critical piece of any high-performance wall system.

It’s also worth noting that building codes are getting stricter. Codes like the International Energy Conservation Code (IECC) now require continuous exterior insulation in many climate zones to combat thermal bridging. This trend makes options like ICFs increasingly attractive, as they inherently wrap the concrete core in insulation, solving the problem in a single, elegant step.

Avoiding Common Mistakes in Block Wall Insulation Projects

When it comes to getting the most out of a concrete block wall, it’s all about the details. You can pick the best insulation material on the market, but one small mistake during installation can completely undermine its performance. That means poor energy efficiency, potential moisture damage, and a whole lot of wasted money.

Focusing on a few key areas from the start ensures your investment actually pays off for years to come.

Here in South Florida, one of the most critical steps is installing a proper air and vapor barrier. Concrete is naturally porous, meaning it can absorb moisture right out of our humid air, which absolutely kills its insulating ability. A correctly installed barrier stops this water vapor from getting into your wall system, protecting your home from mold, mildew, and structural rot.

Think of it like this: your insulation is a high-performance winter coat, but the air and vapor barrier is the waterproof shell you wear over it. Without that shell, the coat gets soaked in the first rainstorm and becomes completely useless.

Why Professional Installation Is Non-Negotiable

Some insulation systems are simply not weekend warrior projects. This is especially true for spray foam and Exterior Insulation and Finish Systems (EIFS). These are complex applications that demand specialized equipment, extensive training, and a deep understanding of building science to get right.

For instance, an improper spray foam application can result in off-ratio mixing, which leads to terrible performance and can even leave behind chemical odors. With EIFS, a bad installation can trap water behind the finish, causing catastrophic damage to the wall structure itself. This is exactly why you need to trust experienced professionals. To see what that dedication looks like, you can learn more about our company’s commitment to excellence.

Meeting and Exceeding Energy Codes

Modern building codes are constantly getting stricter about energy efficiency. Regulations like the International Energy Conservation Code (IECC) now have firm requirements for wall R-values and controlling air leakage. Properly insulating your concrete block walls isn’t just a smart way to save money anymore—it’s often a legal requirement.

These codes are in place for a good reason: they ensure buildings are safe, durable, and energy-efficient. This isn’t just a local trend; North America is leading the charge with tough codes, and other regions are catching up fast to reduce building energy consumption. You can discover more insights about these global energy trends to see how construction is changing worldwide.

By investing in a high-quality insulation system, you’re not just making your project compliant for today. You’re future-proofing it for the energy standards of tomorrow.

Common Questions About Insulating Concrete Block Walls

When you start looking into upgrading the insulation value of a concrete block wall, a lot of questions come up. Getting clear, practical answers is the best way to move forward with confidence. Let’s tackle some of the ones we hear most often.

What Is the Best Way to Insulate an Existing Block House?

For a home that’s already built, your decision really boils down to insulating from the inside or the outside.

If you’re already planning an interior renovation, adding rigid foam boards directly to the inside face of the block walls is a fantastic option. It gives you a continuous thermal break and is incredibly effective, though it does mean sacrificing a little bit of interior floor space.

The other route is adding insulation to the exterior, like with an EIFS (Exterior Insulation and Finish System). This is a great choice if you’re also looking to update your home’s curb appeal. It essentially wraps the entire house in a protective, insulating blanket, which stops thermal bridging cold without any disruption to your life inside.

Can I Just Stuff Fiberglass Insulation in the Block Cores?

That’s a common thought, but the answer is a hard no. We see people ask this all the time, but standard fiberglass batts are just not made for that environment. In a humid climate like ours, they act like a sponge inside the porous concrete block.

Once that fiberglass gets damp, it loses all its insulating power and quickly turns into a hidden breeding ground for mold and mildew. You absolutely need to use materials specifically designed for filling block cores, like injected foam insulation or loose-fill products like perlite that won’t hold moisture.

Stuffing the wrong material into a block wall is one of those mistakes that can cause more harm than good. You’re essentially creating a hidden moisture trap that can compromise your home’s air quality and even its structural integrity over time.

How Does Adding Insulation Affect Moisture and Mold Risk?

When it’s done right, adding insulation dramatically reduces the risk of moisture and mold. An uninsulated block wall gets cold, and when warm, humid indoor air hits that cold surface, condensation forms. That moisture is exactly what mold needs to thrive.

By adding a continuous layer of insulation, you keep the interior surface of the wall warm, stopping that condensation cycle before it can even start. A good vapor barrier is your second line of defense, preventing moisture from moving through the wall assembly in the first place.

With energy costs on the rise, boosting the insulation value of concrete block is also a smart financial move. It’s a major reason why green building standards are pushing for better insulation systems across North America. You can learn more about these energy conservation initiatives and how they’re shaping modern construction.

Is It Worth It to Insulate a Concrete Block Garage?

Absolutely. People often think of garage insulation as just a step toward creating a finished workshop or gym, but the benefits go way beyond that.

- Protect Your Stuff: Florida’s extreme heat can wreak havoc on tools, cars, and anything else you store in the garage. Insulation keeps temperatures stable and protects your investments.

- Boost Whole-Home Comfort: If your garage is attached to the house, that uninsulated wall is a massive heat sink, bleeding heat into your living spaces and making your AC work overtime.

- Create a Thermal Buffer: A well-insulated garage acts as a buffer zone, making the rooms that share a wall with it much more comfortable and easier to cool.

At the end of the day, insulating your garage improves your home’s overall energy efficiency and makes the space far more useful.

At Airtight Spray Foam Insulation, we live and breathe the challenges of insulating concrete block homes in South Florida. Our team uses high-performance spray foam to create that seamless air and moisture barrier your home needs, delivering real comfort and lower energy bills. Ready to see the difference? Request your free quote today!

Residents of Wellington can count on our team for high-quality spray foam insulation designed to perform in Florida’s climate.