Blog

Insulate existing walls spray foam: A Homeowner’s Guide

For homeowners in humid climates like South Florida, trying to insulate existing walls can feel like a losing battle. But there’s a retrofit solution that genuinely changes the game: spray foam. It creates a powerful, seamless air seal that directly tackles the persistent issues of drafts, moisture, and sky-high energy bills that plague so many older homes.

Using spray foam insulation transforms a drafty, inefficient house into a space that’s comfortable, quiet, and far more energy-efficient.

Why Spray Foam Is the Smart Choice for Existing Walls

When you insulate existing walls with spray foam, you’re not just stuffing insulation into a cavity—you’re creating a fully integrated air barrier. Traditional fiberglass batts can sag over time, leaving gaps that let air and moisture sneak in. Spray foam, on the other hand, expands on contact, filling every single crack and crevice.

This complete seal is what makes it so incredibly effective, especially here in South Florida, where humid air can wreak havoc on a home’s structure and your indoor comfort. The result is a major boost in comfort and a noticeable drop in your cooling costs, because your HVAC system doesn’t have to fight a constant battle against incoming hot air.

Immediate and Lasting Benefits

The great thing about retrofitting with spray foam is that the advantages are both immediate and long-term. Homeowners often tell us they feel the difference right away.

- Drastic Energy Savings: The air-sealing properties of spray foam can slash heating and cooling costs by 30-50%. Your AC runs less, saving you real money month after month.

- Enhanced Indoor Comfort: Finally, you can say goodbye to those frustrating hot and cold spots. Spray foam delivers consistent temperatures throughout your home.

- Improved Air Quality: By sealing up all those little entry points, spray foam helps block dust, pollen, and other outdoor pollutants from getting inside.

- Exceptional Sound Dampening: That dense barrier also does a fantastic job of reducing outside noise, creating a quieter, more peaceful home. You can learn more about how spray foam works as a powerful insulation and sound barrier in our detailed guide.

This single upgrade solves multiple common homeowner complaints—from high FPL bills to rooms that never seem to cool down. It’s easily one of the most effective improvements you can make to an older property.

A Powerful Investment in Your Property

The global spray foam market hit USD 2.4 billion in 2023 and keeps growing as more people look for real energy solutions. The numbers don’t lie: spray foam seals air leaks up to 24 times better than its traditional counterparts. Here in Florida, we’ve seen homeowners reduce their AC runtime by up to 40% in the summer.

Beyond the energy savings, this upgrade adds tangible value to your property. It’s consistently ranked among the best home improvements for resale because it enhances both comfort and the home’s bottom line.

When choosing the right foam for a retrofit, the decision often comes down to open-cell versus closed-cell. Here’s a quick breakdown to help you decide what’s best for your South Florida home.

Open-Cell vs Closed-Cell Foam for Existing Walls

Making the right choice between open-cell and closed-cell spray foam is crucial for a successful retrofit, especially in our humid climate. Each has its own strengths, and the best option depends on your specific goals, from moisture management to structural support.

This table gives a side-by-side look at the key differences to help guide your decision.

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-3.5 to R-4 | R-6 to R-7 (Higher insulating power) |

| Moisture Permeability | Permeable. Allows water vapor to pass through, which helps prevent moisture trapping. | Impermeable. Acts as a vapor barrier, blocking moisture entirely. |

| Structural Strength | Flexible and soft; adds minimal structural rigidity. | Rigid and dense; adds significant strength to wall assemblies. |

| Sound Dampening | Excellent. Its soft, open structure is highly effective at absorbing sound waves. | Good. Offers sound reduction, but less effective than open-cell. |

| Cost | Generally less expensive per board foot. | Generally more expensive due to its density and higher R-value. |

| Best Use Case | Ideal for interior walls where sound control is key and vapor management is needed. | Perfect for exterior walls, especially in coastal areas needing structural reinforcement. |

In many South Florida retrofits, open-cell spray foam is the hero. Its structure blocks airflow but allows vapor to pass through, which is critical for preventing moisture from getting trapped inside your wall cavities.

On the other hand, closed-cell foam brings something else to the table: it adds significant structural rigidity to your walls. This can be a huge benefit for strengthening your home against high winds—a vital consideration for anyone living in coastal areas from Jupiter to West Palm Beach.

The Pro Retrofit Process: What to Expect

Ever wonder what really happens when a pro crew shows up to insulate your existing walls with spray foam? It’s a lot more than just pointing a hose and spraying. A true professional job is a precise, surgical process designed for maximum performance with minimal disruption. The goal is to leave your home perfectly sealed and comfortable, looking like we were never there.

It all kicks off with a detailed assessment. An experienced technician isn’t just taking measurements; they’re playing detective. We’re on the hunt for hidden air leaks, signs of moisture, and the unique quirks of your home’s construction. This initial diagnostic is critical—it tells us exactly how to approach the job for a flawless installation.

Getting Into the Wall Cavities

Once we have a game plan, we need to get access to the empty space between your studs. There are a couple of ways to do this, and the right method depends on your home’s siding and your own preferences.

- The Drill-and-Fill Method: This is our go-to for a reason—it’s incredibly effective and the least invasive option. We drill small, carefully placed holes (about the size of a quarter) through the exterior siding or interior drywall. These holes are just big enough for the spray foam nozzle to do its work.

- Removing Trim or Siding: Sometimes, particularly with vinyl siding, it makes more sense to gently remove a single strip of siding or an interior baseboard. This gives us a wider opening to work with, guaranteeing total coverage inside the wall. Afterward, everything is reinstalled so perfectly you’d never know it was moved.

No matter the method, we treat your home like our own. Our crews lay down protective coverings and use dust containment systems to keep everything clean and tidy.

Injection, Expansion, and the Perfect Fill

This is where the real work begins. The technician inserts the nozzle into each access point and injects the two-part liquid foam. The moment those components mix, a chemical reaction triggers a rapid expansion—the foam can grow up to 100 times its original liquid volume, filling every single crack, gap, and odd-shaped corner in the wall cavity.

This expansion isn’t random; it’s a controlled science. A seasoned installer knows the precise amount of foam to inject to get a perfect fill without over-pressurizing the wall and damaging your drywall. The foam flows seamlessly around pipes, wiring, and outlets, creating a solid, airtight barrier that you simply can’t get with fiberglass batts. To see how this works in different wall types, check out our guide on the insulation value of concrete block walls.

The hallmark of a professional job is consistency. Our technicians work methodically from one stud bay to the next, ensuring each one is completely and uniformly filled. This painstaking approach guarantees there are no thermal weak spots or cold patches left behind.

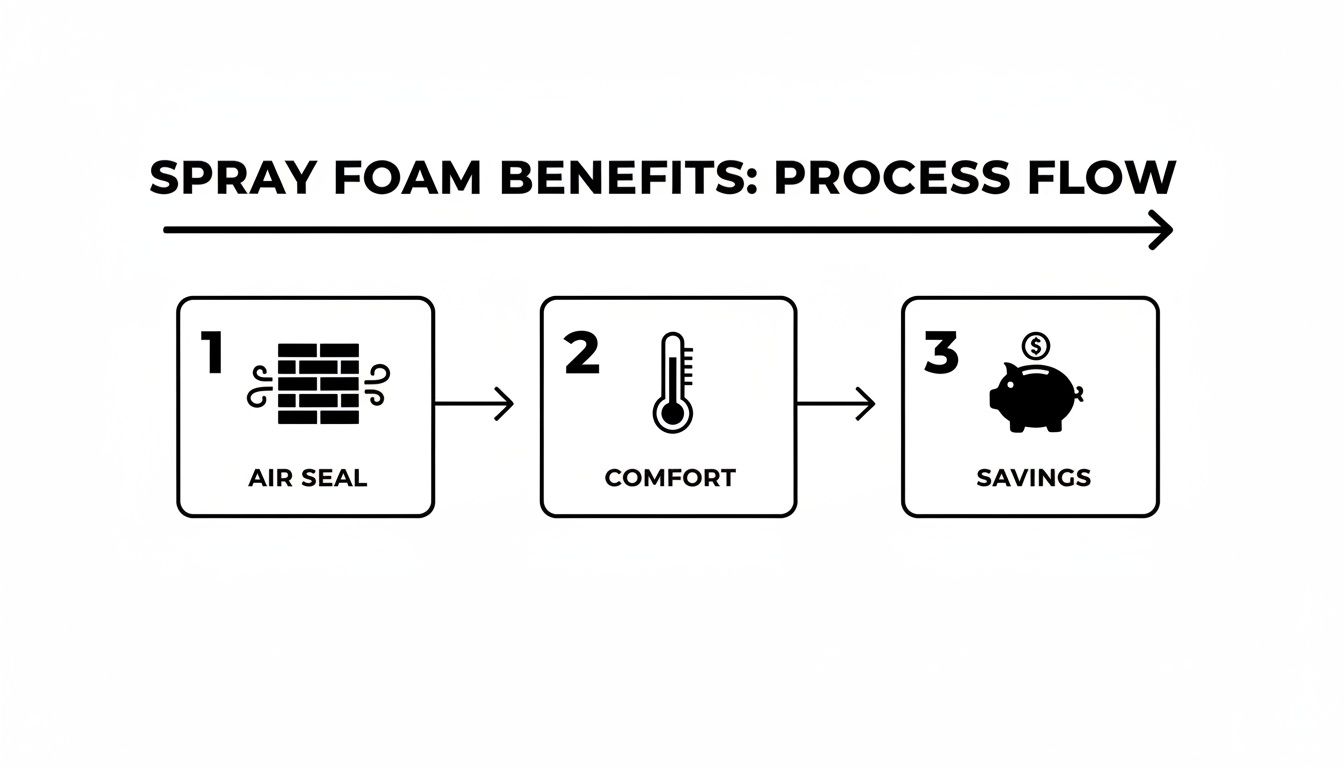

This meticulous process is what creates the airtight seal, which in turn delivers superior comfort and real energy savings.

As this shows, it all starts with the air seal. Get that right, and comfort and savings naturally follow.

Finishing Up and Final Inspection

The job isn’t finished until your home looks exactly how we found it. The final stage is all about seamless restoration.

- Plugging and Patching: We plug and patch every access hole. If we drilled through exterior brick, we even mix mortar on-site to match the existing color and texture perfectly.

- Reinstallation: Any siding, trim, or baseboards that were removed are carefully put back in their original place for a clean, tight fit.

- Total Cleanup: The crew does a full sweep of the work area, inside and out. We remove all protective coverings and make sure there isn’t a speck of dust or debris left behind.

The decision to insulate existing walls with spray foam is a major home performance upgrade. Here in the U.S., residential projects drive 53% of the demand, with wall insulation alone making up a 39% share. Why? Because older homes can leak 30% or more of their energy through unsealed walls. Studies have shown that professionally installed spray foam can cut that air leakage by 75%, leading directly to 20-40% lower utility bills and a payback period of just two to five years.

Before we leave, we do a final walkthrough with you to ensure every detail meets your expectations. When it’s all said and done, the only evidence we were ever there will be the immediate boost in your home’s comfort and the welcome drop in your next energy bill.

Managing Moisture and Humidity in Your Walls

In a climate like ours, insulation that traps moisture isn’t just a minor issue—it’s a guaranteed recipe for mold, mildew, and structural rot. When you’re looking to insulate existing walls with spray foam here in South Florida, getting moisture control right isn’t just part of the job; it’s the most critical part.

The science behind this is all about vapor control. Your home is constantly dealing with water vapor moving from warm, humid areas to cooler, drier ones. The wrong insulation can trap this moisture inside your wall cavities, leading to serious damage that stays completely hidden until it’s far too late.

Understanding How Your Walls Breathe

Spray foam gives us two completely different ways to handle moisture, and picking the right one is absolutely vital. The decision really comes down to whether you need your walls to “breathe” or if you need to create an impenetrable barrier.

Open-cell spray foam is what we call vapor-permeable. A good way to think of it is like a high-tech athletic shirt—it stops the wind (air leakage) but lets water vapor (sweat) pass right through. This is a huge advantage in our humid climate because it allows any moisture that gets into the wall cavity to dry out instead of getting trapped.

On the other hand, closed-cell spray foam is a true vapor barrier. Its dense, rigid structure is impermeable to both air and moisture. This makes it a fantastic choice for areas where you have to completely block moisture from getting in, like in flood-prone zones or on concrete block walls that can wick moisture up from the ground.

For the vast majority of wood-framed homes in our area, open-cell foam is the clear winner for wall retrofits. It gives you the air seal you need while letting the wall assembly dry out if it ever gets wet—a core principle of building durable, healthy homes in Florida.

Choosing the Right Foam for Your Wall Type

How your home was built is the single biggest factor in figuring out the right moisture strategy. What works for a concrete block house in Jupiter might be a terrible idea for a wood-framed house in Wellington.

Here’s a quick look at how we approach different wall types based on years of experience:

- Concrete Block (CMU) Walls: These walls are everywhere in South Florida and act like sponges for moisture. Closed-cell spray foam is almost always the answer here. It bonds directly to the block, creating a seamless air and vapor barrier that stops moisture dead in its tracks before it can reach your interior drywall.

- Wood-Framed Walls: For standard wood-stud walls, we lean toward open-cell foam. It perfectly fills the cavity to create an air seal, but its vapor-permeable nature protects the wood framing by allowing it to breathe and dry. The last thing you want is to trap moisture against wood with an impermeable barrier, which can seriously accelerate rot.

- Walls with Existing Vapor Barriers: This is a tricky one. If your home already has a vapor barrier (like a sheet of plastic behind the drywall), adding closed-cell foam creates a “double vapor barrier.” This is a dangerous setup that traps any moisture between the two layers with no way to escape.

Practical Scenarios From the Field

Let’s talk about a real-world example. We worked on a 1970s home in West Palm Beach with wood siding a while back. The owner was complaining about musty smells and constant high humidity. When we took a look, we found the old, sagging fiberglass insulation was soaking up moisture and holding it right against the exterior sheathing.

For this project, we prescribed a “drill and fill” retrofit using open-cell spray foam. By allowing the wall assembly to breathe and dry toward the inside, we completely solved the moisture issue while also creating a top-notch air seal. The result? A much healthier home and a noticeable drop in their FPL bill. Picking the right foam was the key to a successful, lasting fix.

Budgeting for Your Spray Foam Insulation Project

Let’s talk numbers. Figuring out the investment needed to insulate existing walls with spray foam is the first step toward making a confident decision for your home. While every project has its own unique quirks, a few key factors consistently shape the final cost.

The biggest driver is always the total square footage of the exterior walls you’re insulating. Simply put, a larger home needs more material and more labor. The type of foam you choose also plays a big role—dense, high-R-value closed-cell foam typically costs more per board foot than the lighter, more expansive open-cell foam.

Key Factors Influencing Your Project Cost

Beyond the basics, the complexity of the job itself can really move the needle on your budget. A single-story home with easy-to-remove vinyl siding is a pretty straightforward job. On the other hand, a two-story home with delicate brick or wood siding demands more time, specialized techniques, and meticulous restoration work, and that’s going to be reflected in the price.

- Home Size and Layout: The total area of your exterior walls is the biggest variable, hands down.

- Siding Type: Vinyl is often the simplest to work with. Brick or stucco? That requires more labor-intensive drilling and careful patching.

- Accessibility: Tough-to-reach areas, dense landscaping, or other obstacles can add to the project timeline and cost.

- Foam Selection: Closed-cell foam delivers a higher R-value but comes at a premium compared to open-cell.

It’s worth noting that retrofitting walls with spray foam is a booming trend. The U.S. market holds a 42% share of global demand, and wall applications now make up 39% of all residential projects. Here in South Florida, this is especially critical for sealing the tiny cracks and gaps that cause 25-40% of a home’s energy waste.

While the EPA reports average savings of 10-15% from standard insulation retrofits, spray foam can push those savings to an impressive 30-50%.

Maximizing Your Return on Investment

Just looking at this project as an expense really misses the bigger picture. Professional spray foam installation is an investment that starts paying you back from day one through lower energy bills. For many homeowners, the upgrade pays for itself within just a few years.

Plus, significant financial incentives are available to soften the upfront cost. The federal government is currently offering a 30% tax credit for energy-efficient home improvements, including insulation, which is available through 2032. This makes the project more accessible than ever before.

An investment in high-performance insulation is more than just an energy upgrade; it’s a direct contribution to your home’s long-term market value and a powerful step toward a more comfortable, resilient property.

Thinking of your spray foam insulation as a long-term asset really highlights its benefits. For a broader look at how home improvements contribute to your home’s worth, you can explore various cost-effective strategies to increase property value.

To give you a clearer idea of the financials, we’ve broken down the typical costs and potential ROI for a standard South Florida home retrofit.

Estimated Cost and ROI for Spray Foam Wall Retrofits

| Project Aspect | Cost/Savings Estimate | Key Details |

|---|---|---|

| Material Cost | $2.50 – $4.50 per sq. ft. | Varies based on foam type (open-cell vs. closed-cell) and wall cavity depth. |

| Labor & Installation | $2,000 – $5,000+ per project | Influenced by home size, siding complexity, and accessibility. Includes prep, drilling, filling, and cleanup. |

| Total Project Estimate | $6,000 – $15,000+ | Based on a typical 1,800 sq. ft. home. Your actual cost will depend on the specific factors of your property. |

| Annual Energy Savings | $400 – $900+ | Potential savings of 30-50% on cooling costs, a significant factor in South Florida’s climate. |

| Federal Tax Credit (30%) | $1,800 – $4,500+ in savings | A direct credit on your taxes, reducing the net cost of the project significantly (available through 2032). |

| Payback Period | 5-10 years | The time it takes for energy savings to cover the initial investment, not factoring in increased home value. |

This table provides a solid baseline, but a custom quote is the only way to get precise numbers for your home. The long-term energy savings and improved comfort often make it one of the smartest upgrades a homeowner can make.

Understanding the Project Timeline

One of the best parts of a professional retrofit is just how quickly it gets done. While the initial consultation and quoting process takes a bit of time, the actual on-site work is remarkably efficient. For an average-sized home, we can often complete the entire installation in a single day—usually 3 to 5 hours of work.

A professional crew operates like a well-oiled machine. One technician might be drilling the access holes, another follows right behind with the injection hose, and a third is already managing cleanup and restoration. This streamlined process means minimal disruption to your life. From the free estimate to the final walkthrough, the entire project is built for efficiency and quality, ensuring everything is done right and complies with all local building codes.

Should You DIY or Hire a Professional Installer?

It’s tempting to look at a DIY spray foam kit and think about the money you could save. We get it. But when it comes to injecting foam into existing walls, this is one of those jobs where a seemingly simple shortcut can lead to a world of headaches.

This isn’t like painting a room or even laying down some fiberglass batts. Professional spray foam installation is a precise chemical process. Our crews use high-pressure, high-temperature equipment to ensure the two chemical components mix at a perfect 1:1 ratio. That precision is what makes the foam cure correctly, expand properly, and deliver the R-value you’re paying for.

The Risks of a DIY Approach

Those DIY kits, often called “froth paks,” are low-pressure systems that have almost no room for error. A small change in temperature or a slightly uneven mix can throw the foam “off-ratio”—and that’s when things get ugly.

Off-ratio foam might not stick right, can shrink away from the studs later on, or even fail to cure completely, leaving a nasty chemical smell inside your home.

Then there’s the application itself. Pumping foam into a wall cavity you can’t see is a skill learned through experience. It’s incredibly easy for a first-timer to make a mess.

- Under-filling Cavities: Not using enough foam leaves you with gaps and cold spots. This completely defeats the purpose of creating an air-tight seal in the first place.

- Over-pressurizing Walls: Too much foam can expand with enough force to bulge your drywall, pop trim off the wall, and even throw window and door frames out of whack. A pro knows the sound and feel of a properly filled cavity.

- Safety Hazards: There’s a reason our guys wear full hazmat gear. The chemical vapors released during application are seriously hazardous to breathe. Going at it without the right personal protective equipment (PPE) is a major health risk you shouldn’t take.

A DIY project gone wrong can cost far more to fix than hiring a professional from the start. We’ve seen homeowners spend thousands on repairs, from replacing damaged drywall to hiring a remediation company to remove improperly cured foam.

The Value of a Professional Installer

When you bring in a certified team, you’re buying expertise, safety, and peace of mind. A pro brings several critical advantages to the table that a DIY kit just can’t compete with.

1. Guaranteed Performance and Warranty

A reputable company stands behind its work. You get a guarantee that the job is done right, the foam performs as promised, and your home is left clean and undamaged. This warranty protects you from any material defects or installation mistakes.

2. Efficiency and Expertise

A professional crew can often insulate the entire exterior of a home in a single day. They have the process down to a science—drilling, injecting, patching, and cleaning up—all with minimal disruption. They’ve also seen it all and know how to handle unexpected finds, like old wiring or hidden pipes in the walls.

3. Proper Equipment and Materials

Professionals use commercial-grade rigs that keep the temperature and pressure perfectly dialed in, guaranteeing a perfect mix every time. We also have access to higher-quality foam products not sold to the public. While spray foam is a fantastic choice, it helps to know your options; our comparison of spray foam vs. blown-in insulation breaks down the differences in other materials.

At the end of the day, while saving a buck is always appealing, insulating existing walls with spray foam is one job best left to the experts. The risks of damaging your home, ending up with a poor-performing product, and the serious health hazards of a DIY attempt just aren’t worth the potential savings.

Common Questions About Retrofit Spray Foam Insulation

Even with all its benefits, making the jump to spray foam in an existing home brings up a lot of good questions. It’s a big investment in your property, and it’s smart to get all the facts straight first. We’ve put together answers to the most common questions we hear from homeowners across South Florida to help you make a confident decision.

Will Spray Foam Damage My Walls?

This is probably the number one concern we hear, and it’s a valid one. You’re imagining foam expanding like crazy inside a wall you can’t see, and that sounds risky.

But when it’s done by an experienced professional, the risk of damage is virtually zero. Certified installers are experts at controlling the application. They know the precise amount of foam needed to fill a cavity completely without over-pressurizing it and causing drywall to bulge or crack. This is the biggest reason to steer clear of DIY kits—improper application is almost always the cause of wall damage.

How Long Does Spray Foam Insulation Last?

One of the best things about spray foam is that you only have to do it once. Unlike traditional insulation like fiberglass that can sag, settle, and lose its R-value over time, spray foam is a permanent fix. Once it cures, it’s an inert plastic that simply doesn’t degrade.

Professionally installed spray foam will last for the entire life of your home. It holds its shape, its R-value, and its air-sealing power for decades, making it a true one-and-done investment.

Is There an Odor After Installation?

During the actual spraying, yes, there is a distinct odor as the chemical components mix and cure. That’s why professionals use powerful ventilation systems and require homeowners to be out of the house for a short period—typically 24 hours.

This gives the foam plenty of time to fully cure and “off-gas.” Once that process is complete, the foam is totally inert and odorless. You can come back to a home that’s not just more comfortable, but actually has better indoor air quality than before.

Can I Insulate Just One Wall?

Technically, you can, but we almost never recommend it if you’re looking for real energy savings. To create a complete air barrier and get the full benefit, you really need to insulate all of the exterior walls.

Insulating just one wall is like patching a single hole in a leaky bucket—it helps a little, but you’re still losing all that expensive conditioned air through the other uninsulated spots. For the best performance and return on your investment, a comprehensive approach is always the way to go.

Ready to feel the difference a truly airtight home can make? The team at Airtight Spray Foam Insulation has the experience to deliver a flawless installation that improves your comfort and lowers your energy bills for decades. Request your free, no-obligation quote today!

Homeowners in Jupiter, FL can learn more about our spray foam insulation services designed to improve comfort, control moisture, and increase energy efficiency in South Florida homes.