Blog

Vapour Barrier and Insulation for South Florida Homes

Tired of battling South Florida's oppressive humidity? Does it feel like your air conditioner is always running, yet your home is never quite comfortable? The answer isn't just turning down the thermostat—it's buried inside your walls and attic.

Understanding the relationship between your home's vapour barrier and insulation is the key to solving these problems for good. These two components are your home’s first line of defense against our relentless, moisture-heavy climate.

Winning the War Against Florida Humidity

Here in South Florida, our homes are under constant assault from moisture. Whether you're in Jupiter or down in West Palm Beach, every homeowner is fighting the same enemy—one that inflates cooling bills, wrecks air quality, and can even cause serious structural harm.

The trouble often starts where you can't see it. Traditional insulation, if it isn't properly protected, acts like a giant sponge, soaking up all that humid air. This is exactly where the powerful duo of a vapour barrier and high-performance insulation comes in to save the day.

Think of it as a one-two punch. Insulation's job is to slow down heat transfer, but the vapour barrier's specific mission is to stop moisture vapor in its tracks before it can sneak through your walls and ceilings.

The Foundation of a Healthy Home

Getting a handle on moisture isn't just about feeling more comfortable. It’s about building a genuinely healthy living space and protecting the value of your home. When humidity runs wild, it brings a whole list of problems that are all too familiar to us Floridians.

- Mold and Mildew Growth: When warm, sticky air hits a cooler surface inside your wall cavity, it condenses. That condensation is the perfect recipe for mold.

- Reduced Energy Efficiency: Once insulation gets damp, its thermal resistance (its R-value) plummets. Your AC unit has to work overtime just to keep up, sending your FPL bill through the roof.

- Structural Damage: Over time, that constant moisture leads to wood rot, corroded metal fasteners, and the slow decay of your home’s building materials.

A properly sealed home isn't just an efficient home; it's a resilient one. By managing both air and moisture leakage, you are actively preserving the structural integrity and health of your property for the long term.

A Smarter All-in-One Solution

Thankfully, modern building science has given us a much better, more integrated approach. Combining vapour barriers with spray foam insulation can slash energy costs by up to 50% here in humid climates like ours.

In towns like Wellington and Stuart, spray foam—especially the closed-cell type we specialize in at Airtight Spray Foam Insulation—does two jobs at once. It’s an incredible insulator with a high R-value, and it acts as its own built-in vapour barrier. It also seals up all the tiny air leaks that are responsible for 25-40% of a typical home's energy loss. You can dive deeper into these focused insulation market insights.

This guide will give you a clear roadmap, helping you master your home's most important protective layers to create a healthier, more efficient, and more comfortable place to live.

Understanding Your Home's Protective Layers

To really get a handle on protecting your home from the brutal Florida climate, it helps to think of your walls and roof like layers of clothing. Each piece has a specific job. When they all work together, you get a comfortable, efficient home. But getting them mixed up is a common—and very costly—mistake.

A lot of people throw around terms like "air barrier," "vapour barrier and insulation" as if they're the same thing. They absolutely are not. They are three distinct lines of defense, and getting them right is the bedrock of a healthy, long-lasting home.

Insulation: The Thermal Sweater

Let's start with the one everyone knows: insulation. Its one and only job is to slow down the transfer of heat. Plain and simple. It's your home's thermal sweater. In our sweltering summers, it keeps the heat out. On those rare cool nights, it keeps the heat you paid for inside.

We measure insulation's muscle with its R-value—the bigger the number, the better it fights back against heat flow. Common materials you'll see are fiberglass, cellulose, and of course, spray foam. A solid thermal layer is your number one weapon for energy efficiency and is key to preventing common home issues like ice dams in colder regions by stopping heat from escaping through the roof.

The Air Barrier: The Windbreaker

Next up is the air barrier. Think of this as your home’s windbreaker. Its job is to stop air from moving where it shouldn't—through all the little gaps and cracks in your walls and ceilings. Air leaks are a huge energy killer, bringing in drafts and, more importantly, massive amounts of moisture.

Get this: air leakage can push 50 to 100 times more water vapor into a wall cavity than vapour diffusion alone. That’s not a typo. For an air barrier to do its job, it has to be perfectly continuous, sealing every single penetration without exception.

An air barrier stops air movement. That’s it. But in doing so, it becomes your single most powerful tool for controlling air-transported moisture—the biggest enemy of most building assemblies.

The Vapour Barrier: The Raincoat

Last, we have the vapour barrier, which is more accurately called a "vapour retarder." This layer is your home's raincoat. Its function is to slow down the movement of water vapor on a molecular level, a process we call diffusion.

It's designed to stop moisture in its gas form before it can travel through your walls and condense into liquid water on a cooler surface inside. We classify materials by their permeability, and something like a plastic sheet is a classic example of a top-tier (Class I) vapour retarder. Here in Florida's hot, humid climate, where and how you install a vapour barrier is absolutely critical to avoid trapping moisture inside your walls—a recipe for disaster.

Understanding what each layer does on its own is the first step. To make it even clearer, I've broken down the key differences below.

Air Barrier vs Vapour Barrier vs Insulation At a Glance

This table simplifies the distinct role each component plays in protecting your home's building envelope.

| Component | Primary Function | What It Stops | Common Materials |

|---|---|---|---|

| Insulation | Slows heat transfer | Thermal energy (heat) | Fiberglass, Cellulose, Spray Foam |

| Air Barrier | Stops air leakage | Uncontrolled airflow and the moisture it carries | House wrap, Sealed Sheathing, Spray Foam |

| Vapour Barrier | Slows vapor diffusion | Water vapor (gas) on a molecular level | Polyethylene sheeting, Foil facings, Spray Foam |

This clear separation of duties is what makes certain modern materials so powerful. A product like closed-cell spray foam is unique because it can do all three jobs in a single, seamless application. It insulates against heat, it expands to form a perfect air seal, and its dense structure stops vapor diffusion in its tracks.

This all-in-one capability is precisely why it’s such a game-changer for structures like concrete block walls, which have their own set of thermal and moisture control challenges. For a deeper dive on that, check out our guide to understanding the true insulation value of concrete block construction: https://airtightsprayfoaminsulation.com/insulation-value-concrete-block/

How Spray Foam Does It All: Vapour Control and Insulation

Think of spray foam insulation as the ultimate multi-tool for your home's protection. It's not just one thing; it's an all-in-one solution that handles three critical jobs in a single, seamless application. Traditional insulation methods often mean layering different products—one for air sealing, another for vapour control, and a third for thermal resistance. Spray foam simplifies everything by creating one monolithic barrier that masters all three functions at once.

When our technicians apply it, the liquid expands aggressively, filling every single crack, gap, and odd-shaped cavity. This creates a perfect, airtight seal. That seal is your first and most important line of defense against moisture, because air leaks can carry up to 100 times more moisture into a wall than vapour diffusion ever could. By shutting down that airflow, spray foam effectively chokes off the main highway for humidity.

The Power of Closed-Cell Foam

While all spray foam is a fantastic air barrier, closed-cell spray foam takes this protection to a whole new level. Its structure is the key. Imagine millions of tiny, rigid bubbles, each one completely sealed off from its neighbors and filled with an insulating gas. This dense, closed-off composition makes it incredibly resistant to water vapour trying to pass through.

Because of this unique structure, closed-cell foam has a very low permeance rating, easily qualifying it as a Class II vapour retarder. What does that mean for you? It means it acts as both a vapour barrier and insulation without needing that separate layer of plastic sheeting you see in older construction. This streamlines the building process, reduces labor costs, and cuts out a major source of installation error. It just flat-out stops moisture diffusion.

Open-Cell vs. Closed-Cell: What’s the Right Call?

Choosing the right foam is critical, especially here in South Florida's relentless humidity. Both types are great insulators and air sealers, but their different structures make them suited for very different jobs.

-

Open-Cell Spray Foam: This foam is the softer, lighter, more flexible option. Think of it like a dense sponge. It’s brilliant for dampening sound and sealing air leaks. But because its cells are interconnected, it can absorb water if it gets wet, meaning it is not a vapour barrier on its own.

-

Closed-Cell Spray Foam: This is the heavy-hitter. It’s dense, rigid, and completely waterproof. Not only does it provide a superior R-value of around R-6.5 per inch, but its closed structure makes it a powerful, built-in air and vapour barrier. As a bonus, its rigidity actually adds structural strength to whatever it’s applied to.

For almost every job in South Florida—especially attics, crawl spaces, and exterior walls where moisture is the enemy—closed-cell spray foam is the clear winner. It delivers a complete thermal, air, and vapour control layer in one shot.

Real-World Applications in South Florida Homes

Knowing where to use each foam can be the difference between a high-performance home and a moisture nightmare. And if you're weighing your options, it's worth taking a look at a detailed breakdown of spray foam vs. blown-in insulation to see just how far ahead modern solutions are.

Attics and Roof Decks

In our climate, the gold standard is applying closed-cell spray foam directly to the underside of the roof deck. This move insulates the entire attic, transforming it from a scorching, humid space into a semi-conditioned area that’s protected from solar-driven moisture.

Exterior Walls

Applying closed-cell foam in wall cavities gives you that high R-value and the crucial vapour barrier, all in the right place—on the "warm side" of the wall. This stops humid outdoor air from working its way in and condensing against your cool, air-conditioned drywall.

Metal Buildings

We see it all the time: metal buildings "sweating" with condensation. They are notoriously tough to insulate correctly. Closed-cell spray foam is the perfect fix. It bonds directly to the metal panels, creating a seamless thermal and vapour barrier that completely stops condensation, preventing rust and water damage for good.

The results speak for themselves. The spray foam insulation market is on track to more than double, growing from USD 2,181.5 million in 2025 to a projected USD 4,452.1 million by 2035. This isn't just hype; it's driven by its proven ability to slash air leakage by up to 75%. Stricter energy codes have already fueled a 40% increase in its use in new homes since 2020, as builders and homeowners demand better performance. You can explore more about these market trends and insights at Future Market Insights.

Where to Put the Vapour Barrier in Hot, Humid Climates

Getting the placement of your vapour barrier and insulation system right is arguably the single most important rule in Florida construction—and it’s the one we see misunderstood most often. The science behind it is simple but unforgiving: a vapour barrier must always be placed on the warm, humid side of the insulation.

In a cold northern climate, that warm, humid side is the heated interior of the house. But here in South Florida, we have to flip the script. Our warm, humid side is the exterior. This means the vapour barrier belongs on the outside of your insulation, where it can stop that sticky, humid air before it sneaks into your wall or roof assembly and condenses against your cool, air-conditioned drywall.

Getting this wrong isn't just a minor slip-up; it's a catastrophic failure waiting to happen. An incorrectly placed vapour barrier on the interior side will actively trap moisture inside your building envelope. This creates a perfect storm for structural rot, rampant mold growth, and the complete collapse of your insulation system.

The Physics of Florida Moisture Drive

To really get why this matters so much, you have to think about how moisture moves. Water vapor naturally flows from areas of high concentration to low concentration, and from warm to cold. On a typical South Florida summer day, the air outside is hot and absolutely saturated with moisture, while the air inside your home is cool and relatively dry. This creates a powerful, relentless pressure difference that drives moisture from the outside in.

An exterior-side vapour barrier acts like a dam, blocking this inward moisture drive right where it starts. It keeps your insulation dry and allows the entire wall assembly to dry toward the interior if it ever gets wet. An interior-side barrier, on the other hand, does the exact opposite. It lets all that moisture in but gives it no way to escape, basically turning your walls into a terrarium for mold.

Placing a vapour barrier on the interior side of a wall in a hot, humid climate is like wearing a raincoat underneath your sweater during a downpour. All it does is trap the water right against you, ensuring you stay wet and miserable.

Why Spray Foam Is the Ideal Solution

This is where spray foam insulation—specifically closed-cell foam—becomes the perfect tool for our climate. When we apply it directly to the underside of a roof deck or the inside of an exterior wall's sheathing, it’s positioned perfectly to act as that critical exterior-side barrier.

It bonds directly to the outermost structural layer of your home's envelope, creating a seamless, monolithic layer that is your insulation and your vapour retarder in one single application. It stops that inward-driven vapour cold, exactly where building science says it should.

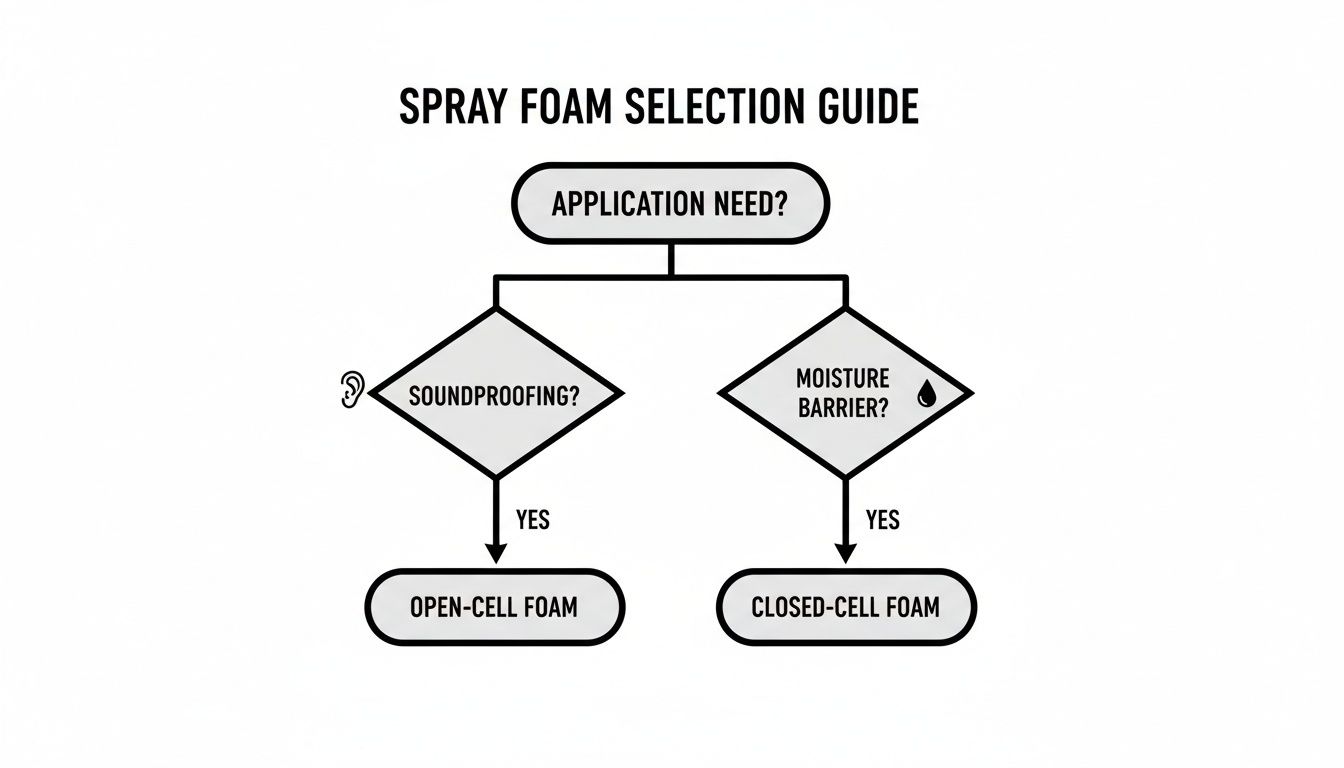

This flowchart helps simplify the choice between foam types for different jobs.

As you can see, the decision tree is clear: when creating a moisture barrier is the main goal, closed-cell spray foam is the only way to go because of its impermeable structure.

Common Scenarios and Best Practices

Understanding how this principle applies to different parts of your house is the key to building a home that lasts.

-

Vented Attics with Traditional Insulation: If you have fiberglass or cellulose on your attic floor, you should never install a traditional vapour barrier (like plastic sheeting) on top of the ceiling drywall. Doing so would trap moisture rising from your living space, with disastrous results. This type of system relies on ventilation to dry out.

-

Unvented (Sealed) Attics with Spray Foam: Applying closed-cell spray foam directly to the underside of the roof deck is the gold standard here. The foam becomes your air barrier, thermal barrier, and vapour barrier, all located on the "exterior" side of the attic space, right where it needs to be.

-

Frame Walls: In a standard wall assembly, applying closed-cell spray foam directly against the exterior sheathing (from the inside) puts the vapour retarder in the correct location. This protects the entire wall cavity from moisture being driven inward by the Florida sun and rain.

By correctly positioning your vapour barrier and insulation, you’re not just protecting your home from moisture damage. You’re also making sure your insulation performs at its peak R-value, which keeps your energy bills low and your home comfortable for decades.

Common Mistakes That Can Sabotage Your Vapour Barrier and Insulation

Getting a vapour barrier and insulation system right isn't just about picking out the best materials—it's all about the execution. A single mistake during installation can undo all the benefits, leaving you with moisture damage, shocking energy bills, and a headache you didn’t ask for. Knowing what can go wrong is the first step to making sure your investment pays off.

One of the most damaging mistakes we see is putting a traditional vapour barrier on the wrong side of the wall. Here in South Florida, where humidity is a constant battle, the barrier has to go on the exterior side of the insulation. If you put it on the interior, you’re literally trapping moisture inside your walls. That’s an open invitation for mold and rot to move in.

Another all-too-common blunder is choosing the wrong spray foam for the climate. Open-cell foam is great for deadening sound, but it lets water vapour pass right through it. If you use it on a roof deck or in a crawlspace without a separate vapour barrier, you're setting yourself up for failure. It simply can’t stop the inward-driven humidity that defines life in our part of the country.

Skimping on Foam Thickness

Even when you use the right product, like closed-cell spray foam, how much you apply is everything. For closed-cell foam to act as a proper vapour retarder (what’s known as a Class II rating), it needs to be sprayed at least 1.5 to 2 inches thick. Anything less just won’t cut it, and your home will still be vulnerable to moisture sneaking through.

When the foam layer is too thin, you get a double whammy:

- You lose R-Value: The insulation won't deliver the thermal performance you paid for, which means your energy savings go out the window.

- You lose Vapour Control: The foam isn’t dense enough to properly block moisture, defeating one of its primary purposes.

This corner-cutting often happens with inexperienced crews trying to save a buck, but it completely undermines the reason you chose a high-performance, all-in-one insulation in the first place.

A professional installation is so much more than just spraying foam. It’s a calculated science. From meticulously prepping the surface to calibrating the equipment and checking the depth with gauges, every single step is there to guarantee you get a seamless, monolithic seal that actually works.

How the Airtight Process Prevents These Errors

At Airtight Spray Foam Insulation, our entire process is built to sidestep these common but costly mistakes. It all starts with a detailed consultation where we actually look at your property, understand its unique challenges, and engineer a real solution—not just spitball a price.

Our installation protocol is strict for a reason:

- Substrate Prep: We make sure every surface is clean, dry, and ready. If there's anything that could mess with the foam's bond, we handle it.

- Precision Application: Our certified technicians use specialized equipment to apply the foam to the exact depth required, creating a consistent, airtight layer.

- Final Walkthrough: We don’t just pack up and leave. We do a detailed inspection with you, confirm you’re happy with the coverage, and answer all your questions. The job isn’t done until it’s done right.

This disciplined approach is what makes a professional job worth it. It’s how you turn potential energy savings into a reality. We're talking about the kind of performance that can cut heating and cooling costs by 40%. That’s the power of integrating vapour barriers correctly with top-tier spray foam insulation.

This level of effectiveness is why the market is booming, with projections jumping from USD 2.97 billion in 2024 to USD 4.12 billion by 2031. Here in the U.S., spray foam’s ability to slash energy loss by 30% is a perfect fit for the push to make older homes more efficient. You can read more about the market's growth and spray foam insights on WCOnline.

Building an Airtight and Healthy Home Environment

Creating a truly comfortable and efficient home here in South Florida isn’t about just fixing one problem at a time—it's about building a complete, unified system. We've talked about the separate jobs of insulation, air barriers, and vapour barriers. Now, let's put all those pieces together into a strategy that actually works.

The goal is to create a seamless building envelope that controls heat, air, and moisture all at once. This isn't just about slapping a few products into your walls; it's about designing a performance system where every component works in perfect harmony with the others.

Your Airtight Comfort System

Think of this integrated approach as your home's total defense system. When you combine a thermal barrier, an air barrier, and the right vapour control strategy into one professionally installed system, it completely transforms your property. This is where closed-cell spray foam really shines, because it handles all three jobs in a single, monolithic application—making it a perfect fit for our humid climate.

A system like this delivers real benefits you can feel and measure every single day:

- Lower Utility Bills: When you finally seal all those air leaks and add superior thermal resistance, your HVAC system doesn't have to work nearly as hard. That means real savings.

- Cleaner Indoor Air: A properly sealed envelope stops dust, pollen, and other pollutants from getting inside, which makes a huge difference in your home's air quality.

- Reduced Outside Noise: The dense, gap-free nature of spray foam is an incredible sound dampener. It makes for a much quieter, more peaceful home.

- Long-Term Structural Protection: By truly mastering moisture control, you're protecting your home’s wood framing from the rot and decay that humidity can cause, preserving its value for years.

Achieving this level of performance means you have to move beyond the old-school, piecemeal solutions. It takes a holistic view where air, thermal, and vapour control are treated as one interconnected system designed specifically for the challenges we face in South Florida.

Your Next Steps for a Better Home

For homeowners and builders from Jupiter to West Palm Beach, the path to a healthier, more efficient space is clear. The first step is always a professional assessment to figure out what your property actually needs, whether it's an existing home, a new build, or a renovation. If you're planning a project, a good guide on building a home addition can also help you understand the structural and energy efficiency details involved.

At Airtight Spray Foam Insulation, this is exactly what we do. We specialize in designing and installing these high-performance systems, turning building science into practical solutions that solve the real-world heat and humidity problems we all deal with.

Ready to see what a difference it can make? Learn more about how the https://airtightsprayfoaminsulation.com/airtight-comfort-system/ can deliver a quieter, healthier, and more cost-effective home for your family or your project. It's time to take the next step toward total home performance.

Your Questions, Answered

When you're dealing with something as important as your home's performance, you're bound to have questions. We get it. Let’s walk through some of the most common ones we hear from homeowners and builders in South Florida about vapour barriers and insulation, so you can feel confident about your project.

Do I Really Need a Vapour Barrier in Florida?

Not the kind you're probably thinking of. Here in our hot, humid climate, the absolute last thing you want is a traditional plastic sheet vapour barrier on the inside of your walls. That's a textbook mistake that traps moisture right where you don't want it, leading to a nightmare of mold and rot.

The real goal is to stop moisture from getting in from the outside. This is exactly where closed-cell spray foam is the hero. It's both your insulation and your vapour retarder, applied in one seamless layer. For nearly every home in Florida, a separate, dedicated vapour barrier is simply the wrong tool for the job.

Is Open-Cell Spray Foam Okay for My Attic?

It can be, but you have to know its limitations. Open-cell foam is a fantastic air barrier and does a great job of muffling sound. But it's also "vapor-permeable," which is a technical way of saying moisture can pass right through it. In a traditional vented attic, this isn't necessarily a dealbreaker because the airflow helps everything dry out.

However, if you're creating a sealed, unvented attic, putting open-cell foam on the underside of your roof deck is a risky bet. If you ever get a small roof leak, the foam can act like a sponge. For the best possible protection in an unvented attic, closed-cell spray foam is the superior choice. It's waterproof and blocks moisture from ever getting in.

Building science teaches us that you have to manage moisture by letting things dry. But in a climate like ours, an even better strategy is preventing the moisture from getting in from the start. Closed-cell foam does just that.

How Thick Does the Spray Foam Need to Be?

Thickness is everything when it comes to performance. For closed-cell spray foam to do its job as a proper Class II vapour retarder, it needs to be applied at a thickness of 1.5 to 2 inches. At that depth, its dense structure becomes impermeable enough to stop moisture in its tracks.

Anything less than that might give you some insulation value, but it won't provide the robust vapour control your home needs to stay dry and healthy. A true professional will always measure and ensure the correct depth is hit everywhere, creating a complete seal.

What's the Difference Between an Air Barrier and a Vapour Barrier?

This is a big point of confusion, but the difference is critical.

- An air barrier physically stops air from moving. This is your number one defense, because moving air can carry 50 to 100 times more moisture than the slow process of diffusion. Think of it as stopping a flood.

- A vapour barrier (or more accurately, a vapour retarder) slows down the movement of water vapour molecules through a material. This is more like stopping a slow leak.

Closed-cell spray foam is the gold standard because it does both jobs perfectly in one application. It creates a seamless, airtight seal and its material makeup is naturally resistant to vapour, giving you a complete solution for both vapour barrier and insulation needs.

Ready to build a healthier, more comfortable, and more efficient home? The team at Airtight Spray Foam Insulation has the hands-on expertise to design and install the perfect spray foam system for your South Florida property. Request your free, no-obligation quote today!